OPERATING MANUAL FOR · OPERATING MANUAL FOR ... 4 -: , ) ...

Translation of the Original Operating Manual8 OPERATING MANUAL EDITION 07/2014 ORDER NUMBER DOC...

Transcript of Translation of the Original Operating Manual8 OPERATING MANUAL EDITION 07/2014 ORDER NUMBER DOC...

B_03154

c us

Electrostatic AirCoat Spray Gun for

Manual Operation and for Flat or

Round Jet Nozzles

Version 07/2014

Translation of the Original

Operating Manual

3

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

Contents

1 ABOUT THIS OPERATING MANUAL 6

1.1 Preface 61.2 Warnings, Notices, and Symbols in this Operating Manual 61.3 Languages 71.4 Abbreviations 7

2 CORRECT USE 8

2.1 Device Type 82.2 Correct Use 82.3 Use in an Explosion Hazard Area 82.4 Safety Parameters 82.5 Processible Products 92.6 Reasonably Foreseeable Misuse 102.7 Residual Risks 10

3 IDENTIFICATION 11

3.1 Explosion Protection Identifi cation FM 113.2 Information for safe and correct operation 113.3 Permissible Device Combinations 12

4 GENERAL SAFETY INSTRUCTIONS 13

4.1 Safety Instructions for the Operator 134.1.1 Electrical Equipment 134.1.2 Staff Qualifi cations 134.1.3 Safe Work Environment 134.2 Safety Instructions for Staff 144.2.1 Safe Handling of WAGNER Spray Devices 144.2.2 Grounding the Device 154.2.3 Material Hoses 154.2.4 Cleaning 164.2.5 Handling Hazardous Liquids, Varnishes, and Paints 174.2.6 Touching Hot Surfaces 174.3 Correct Use 174.4 Safety Information on Discharges 184.5 Use in an Explosion Hazard Area 184.6 Notes to German Regulations and Guidelines 18

5 DESCRIPTION 19

5.1 Functional Description 195.1.1 Design of the Spray Gun (Basic Version) 195.1.2 Functioning of the Spray Gun 205.2 Scope of Delivery 225.3 Technical Data 235.4 Spray Process 245.4.1 AirCoat Round Jet Spray Process 245.4.2 AirCoat Flat Jet Spray Process 245.4.3 Electrostatic Eff ect 25

4

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

Table of Contents

6 COMMISSIONING AND OPERATION 26

6.1 Training Assembly/Commissioning Staff 266.2 Storage Conditions 266.3 Installation Conditions 266.4 Installation and Connection 276.4.1 Typical Electrostatic Spraying System 276.4.2 Ventilation of the Spray Booth 286.4.3 Air Supply 296.4.4 Material Supply 296.4.5 Grounding 306.5 Preparation of Lacquer 336.5.1 Viscosity Conversion Table 336.6 Commissioning 346.6.1 General Rules for Manipulation of the Spray Gun 346.6.2 Preparation for Starting Up 34

7 OPERATION 37

7.1 Training the Operating Staff 377.2 Safety Instructions 377.3 Work 387.3.1 Filling with Working Product 387.3.2 Start-up for Spraying AirCoat 397.3.3 Flushing Out Clogged Round Jet Nozzles 407.3.4 Replacing Round Jet Nozzle's Nozzle Insert 407.3.5 Changing from AirCoat Round Jet to AirCoat Flat Jet 417.3.6 Replacing the AirCoat Flat Jet Nozzles 427.3.7 Cleaning of the Nozzle Parts 427.3.8 Eliminate Nozzle Clogging 427.3.9 Changing the Valve Housing 44

8 CLEANING AND MAINTENANCE 45

8.1 Cleaning 458.1.1 Cleaning Staff 458.1.2 Safety Instructions 458.1.3 Cleaning and Decommissioning 468.2 Maintenance 488.2.1 Maintenance Staff 488.2.2 Safety Instructions 488.3 Disassembly of the Spray Gun 498.3.1 Tools 498.3.2 Disassembly of the Spray Gun 508.4 Cleaning the Parts after Disassembly 538.5 Assembly of the Spray Gun 548.6 Function Test after Assembly of the Gun 598.6.1 Test of the High-Voltage 598.6.2 Air Test 608.6.3 Product Pressure Test 608.6.4 Test of Spray Pattern 618.7 High-Pressure Hoses 62

5

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

Table of Contents

9 INSPECTIONS 63

9.1 Periodical Inspections 63

10 TROUBLESHOOTING AND RECTIFICATION 64

11 PRODUCT DISPOSAL 65

12 ACCESSORIES 66

12.1 Round Jet Nozzles 6612.1.1 ACR 5000 Round Jet Nozzle Cap 6612.1.2 AirCoat Round Jet Nozzle Inserts 6612.2 Flat Jet Nozzles 6612.2.1 ACF 5000 Air Caps (Flat Jet) 6612.2.2 ACF5000 AirCoat Flat Jet Nozzles 6712.3 Filter 6912.4 Reduction Fittings for High-Pressure Hoses 6912.5 Hoses and Electric Cables 7012.5.1 Standard Hose Sets and Components 7012.5.2 Hose Sets for Low-resistance Products 7212.5.3 Gun Cables and Gun Cable Extensions 7412.6 Miscellaneous 74

13 SPARE PARTS 77

13.1 How Can Spare Parts Be Ordered? 7713.2 GM 5000EAC Spare Parts List 7813.2.1 GM 5000EAC - Adapter Spare Parts List 8013.2.2 GM 5000EAC - Handle Spare Parts List 8213.3 Accessories Spare Parts Lists 8413.3.1 Flat Jet Nozzles Spare Parts List 8413.3.2 ACR 5000 Round Jet Nozzle Cap Spare Parts List 85

14 WARRANTY 86

14.1 Important Notes Regarding Product Liability 8614.2 Warranty Claim 86

6

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

1 ABOUT THIS OPERATING MANUAL

1.2 WARNINGS, NOTICES, AND SYMBOLS IN THIS OPERATING MANUAL

Warning instructions in this operating manual highlight particular dangers to users and to the device and state measures for avoiding the hazard. These warning instructions fall into the following categories:

Danger - immediate risk of danger.Non-observance will result in death or serious injury.

Warning - possible imminent danger.Non-observance may result in death or serious injury.

Caution - a possibly hazardous situation.Non-observance may result in minor injury.

Notice - a possibly hazardous situation.Non-observance may result in material damage.

Note - provides information about particular characteristics and how to proceed.

This notice warns you of a hazard!Possible consequences of not observing the warning instructions.The signal word indicates the hazard level.

The following are measures which can be taken to prevent the hazard and its consequences.

DANGER

This notice warns you of a hazard!Possible consequences of not observing the warning instructions.The signal word indicates the hazard level.

The following are measures which can be taken to prevent the hazard and its consequences.

WARNING

This notice warns you of a hazard!Possible consequences of not observing the warning instructions.The signal word indicates the hazard level.

The following are measures which can be taken to prevent the hazard and its consequences.

CAUTION

This notice warns you of a hazard!Possible consequences of not observing the warning instructions. The signal word indicates the hazard level.

The following are measures which can be taken to prevent the hazard and its consequences.

NOTICE

1.1 PREFACE

The operating manual contains information about safely operating, maintaining, cleaning and repairing the device.The operating manual is part of the device and must be available to operating and service staff .Operating and service staff should be instructed according to the safety instructions.The device may only be operated in compliance with this operating manual.This equipment can be dangerous if it is not operated according to the instructions in this operating manual.Electrostatic spray guns may only be operated by trained personnel.

7

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

1.3 LANGUAGES

The operating manual is available in the following languages:German English 2344500

1.4 ABBREVIATIONS

Order No. Order numberET Spare part

Marking in the spare parts listsLow R Low-resistance

PositionNumber of piecesWidth across fl ats

8

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

2 CORRECT USE

2.1 DEVICE TYPE

Electrostatic manual spray gun for manual coating of grounded work pieces

2.2 CORRECT USE

The GM 5000EAC electrostatic hand spray gun is suitable for spraying liquid products, particularly coating products, using the AirCoat method. Coating products containing solvents of explosion class II A may be used.

2.4 SAFETY PARAMETERS

The GM 5000EAC electrostatic manual spray gun is only suitable for spraying liquid products, particularly coating products.J. Wagner AG forbids any other use!The electrostatic manual spray gun may only be operated under the following conditions:

the operating staff have previously been trained on the basis of this operating manual,the safety regulations listed in this operating manual are observed,the operating, maintenance and repair information in this operating manual is observed,and the statutory requirements and accident prevention regulations standards in the country of use are observed.

The electrostatic manual spray gun may only be operated if all parameters are set and all measurements/safety checks are carried out correctly.

2.3 USE IN AN EXPLOSION HAZARD AREA

The GM 5000EAC electrostatic manual spray gun is suitable for coating electrically conductive objects with liquid coating products and can be used in potentially explosive areas. (See Chapter 3 "Identifi cation".)

9

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

2.5 PROCESSIBLE PRODUCTS

With the GM 5000EAC gun, paints can be applied which contain solvents of explosion class II A.The spray gun basic version is suitable for processing sprayed substances with an electrical resistance of > 150 kΩ (according to the WAGNER scale).Equipped with a special product hose for low-resistance sprayed substances (available as an accessory) you can also successfully process sprayed substances with an electrical resistance > 50 kΩ (according to the WAGNER scale).The transfer effi ciency is always dependant on the composition of the product being used, e.g. pigmentation or resin.

Conversion of Paint Resistance

There are paint resistance measuring devices available on the market that do not directly measure the specifi c paint resistance.Multiplying the result of the measurement with the device-specifi c cell constant (K), we obtain the specifi c resistance value of the product.

Example:

With Wagner’s paint resistance measuring device the cell constant is K =123.Measured value according to the WAGNER scaleSpecifi c resistance (RS)

Notice

Using sprayed substances with too low an electrical resistance, the application of electrostatics does not show any eff ect, i.e. there is no "paint wrap around" on the object to be sprayed.The suitability of the sprayed product with regard to the charging ability can be read from the indicators showing the actual values for the high-voltage (kV) and for the spray current (μA) the actual values are shown either on the VM 5000 control unit or on the spray gun.high kV value, low μA value = ok.low kV value, high μA value = excessive conductivity of the paint

-> no wrap-around

In the event of application problems, please contact your local WAGNER offi ce and the paint manufacturer.

10

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

2.6 REASONABLY FORESEEABLE MISUSE

Processing inadmissible coating productsUse of defective spare partsUse for foodstuff sUse in the pharmaceutical sector

2.7 RESIDUAL RISKS

Residual risks are risks which cannot be excluded even in the event of correct use.If necessary, warning and prohibition signs at the relevant points of risk indicate residual risks.

Residual risk Source Consequences Specifi c measures Lifecycle phase

Skin contact with solvent-based paints and cleaning agents

Handling of solvent-based paints and cleaning agents

Skin irritations, Wear protective clothing,

Operation,

allergies observe safety data sheets

maintenance,

disassembly

Solvent-based paint in air outside the defi ned working area

Painting outside the defi ned working area

Inhalation of substances hazardous to health

Observe work and operation instructions

Operation,

maintenance

11

C US

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

3 IDENTIFICATION

Safety instructions

Maximum surface temperature

Maximum surface temperature: 85 °C; 185 °FMaximum permissible product temperature: 50 °C; 122 °FPermissible ambient temperature: 0 to +40 °C; +32 to +104 °F

Safe handling of WAGNER spray devices

Mechanical sparks can form if the device comes into contact with metal.In an explosive atmosphere:

Do not knock or push the unit against steel or rusty iron. Do not drop the spray gun. Only use tools that are made of a permitted material.

3.1 EXPLOSION PROTECTION IDENTIFICATION FM

For Electrostatic Finishing Applications using Class I, Group D, Spray Material

In accordance with 2316160

This device has been manufactured and tested by FM, according to the FM (Factory Mutual) standard "Class Number 7260" (Approval Standard for Electrostatic Finishing Equipment). All tested combinations of devices including accessories are given in the FM Control Document with part number 2316160.

3.2 INFORMATION FOR SAFE AND CORRECT OPERATION

Ignition temperature of the coating product

Ensure that the ignition temperature of the coating material is above the maximum surface temperature.

12

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

3.3 PERMISSIBLE DEVICE COMBINATIONS

The GM 5000EAC manual spray gun may only be connected to the control units listed below:

VM 500 control unitVM 5000 control unit

Incorrect use!

Risk of injury and equipment damage.

Connect the GM 5000EAC manual spray gun only to original Wagner control units.

WARNING

Surface spraying, electrostatics

Never spray device parts using electrostatic equipment (electrostatic spray gun!).

Medium supporting atomizing

To atomize the product, use only weakly oxidizing gases, e.g. air.

Cleaning

If there are deposits on the surfaces, the device may form electrostatic charges. Flames or sparks can form during discharge.

Remove deposits from the surfaces to maintain conductivity. Only use a damp cloth to clean the device.

13

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

4 GENERAL SAFETY INSTRUCTIONS

4.1 SAFETY INSTRUCTIONS FOR THE OPERATOR

4.1.1 ELECTRICAL EQUIPMENT

4.1.2 STAFF QUALIFICATIONS

4.1.3 SAFE WORK ENVIRONMENT

Keep this operating manual at hand near the unit at all times. Always follow local regulations concerning occupational safety and accident prevention.

Electrical devices and equipment To be provided in accordance with the local safety requirements with regard to the

operating mode and ambient infl uences. May only be maintained by skilled electricians or under their supervision. Must be operated in accordance with the safety regulations and electrotechnical regulations. Must be repaired immediately in the event of problems. Must be decommissioned if they pose a hazard. Must be de-energized before work is commenced on active parts. Inform staff about

planned work. Observe electrical safety regulations.

Ensure that the device is operated and repaired only by trained persons.

Ensure that the fl oor in the working area is static dissipative in accordance with EN 61340-4-1 (resistance must not exceed 100 Mohm).

Ensure that all persons within the working area wear static dissipative shoes. Footwear must comply with EN 20344. The measured insulation resistance must not exceed100 Mohm.

Ensure that during spraying, persons wear static dissipative gloves. The grounding takes place via the spray gun handle.

If protective clothing is worn, including gloves, it has to comply with EN 1149-5.The measured insulation resistance must not exceed 100 Mohm.

Paint mist extraction systems must be fi tted on site according to local regulations. Ensure that the following components of a safe working environment are available:

– Product/air hoses adapted to the working pressure. – Personal safety equipment (breathing and skin protection).

Ensure that there are no ignition sources such as naked fl ames, sparks, glowing wires, or hot surfaces in the vicinity. Do not smoke.

14

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

4.2 SAFETY INSTRUCTIONS FOR STAFF

Always follow the information in this manual, particularly the general safety instructions and the warning instructions.

Always follow local regulations concerning occupational safety and accident prevention.

4.2.1 SAFE HANDLING OF WAGNER SPRAY DEVICES

The spray jet is under pressure and can cause dangerous injuries.Avoid injection of paint or cleaning agents:

Never point the spray gun at people. Never reach into the spray jet. Before all work on the device, in the event of work interruptions and functional faults:

– Switch off the energy/compressed air supply. – Relieve the pressure from the spray gun and device. – Secure the spray gun against actuation. – In the event of functional faults: remedy the fault as described in the "Troubleshooting"

chapter. The liquid ejection devices are to be checked for safe working conditions by an expert

(e.g. Wagner Service Technician) as often as necessary or at least every 12 months, in accordance with the guidelines for liquid ejection devices (ZH 1/406 and BGR 500 Part 2 Chapter 2.36).

– For shut down devices, the examination can be suspended until the next commissioning. Carry out the work steps as described in the "Pressure Relief/Work Interruptions" chapter:

– if pressure relief is required. – if the spraying work is interrupted or stopped. – before the device is cleaned on the outside, checked, or serviced. – before the spray nozzle is installed or cleaned.In the event of skin injuries caused by paint or cleaning agents:

Note down the paint or cleaning agent that you have been using. Consult a doctor immediately.

Avoid danger of injury through recoil forces: Ensure that you have firm footing when operating the spray gun. Only hold the spray gun briefl y in a position.

15

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

4.2.2 GROUNDING THE DEVICE

In order to avoid electrostatic charging of the device, the device must be grounded.Friction, fl owing liquids, and air or electrostatic coating processes create charges. Flames or sparks can form during discharge.

Ensure that the device is grounded at all times. Ground the work pieces to be coated. Ensure that all persons inside the working area are grounded, e.g. that they are wearing

static dissipative shoes. Wear dissipative gloves when spraying. The grounding takes place via the spray gun handle. Grounding of the coating product supply (coating product tank, pump, etc.) is mandatory.

Ensure that the hose material is chemically resistant to the sprayed products. Ensure that the product hose is suitable for the pressure generated in the device. Ensure that the following information can be seen on the high-pressure hose:

– Manufacturer – Permissible operating overpressure – Date of manufacture

Make sure that the hoses are laid only in suitable places. In no case, should hoses be laid in the following places:

– in high-traffic areas, – on sharp edges, – on moving parts, or – on hot surfaces

Make sure that the hoses are never used to pull or move the equipment. The electrical resistance of the complete high-pressure hose must be less than 1 Mohm.

4.2.3 MATERIAL HOSES

16

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

4.2.4 CLEANING

De-energize the device electrically. Disconnect the pneumatic supply line. Relieve the pressure from the device. Ensure that the fl ash point of the cleaning agent is at least 15 K above the ambient

temperature or that cleaning is undertaken at a cleaning station with technical ventilation. To clean, use cloths and brushes moistened with solvent. Abrasive agents or objects

must not be used. Ensure that the spray gun is not damaged in any way while cleaning. Parts of the spray gun must not be sprayed with or immersed into cleaning agent. Preferably, non-combustible cleaning agents should be used. The choice of the appropriate cleaning agent depends on which parts of the spray

gun have to be cleaned and which product has to be removed. When cleaning the spray gun only use non-polar cleaning agents to prevent conductive residues on the surface of the spray gun. Should it however, be necessary to use a polar cleaning agent, all residues of this cleaning agent have to be removed by using a non-conductive and non-polar cleaning agent, once the cleaning is fi nished.

Ensure that no electrical component is cleaned with nor even immersed into solvent.

An explosive gas/air mixture forms in closed tanks.

When cleaning devices with solvents, never spray into a closed tank. Only use electrically conductive tanks for cleaning liquids. The tanks must be grounded.

17

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

4.2.5 HANDLING HAZARDOUS LIQUIDS, VARNISHES, AND PAINTS

When preparing or working with paint and when cleaning the device, follow the working instructions of the manufacturer of the paints, solvents, and cleaning agents being used.

Take the specifi ed protective measures. In particular, wear safety goggles, protective clothing and gloves, as well as skin protection cream if necessary.

Use a mask or a breathing apparatus if necessary. For suffi cient health and environmental safety: operate the device in a spray booth or

on a spraying wall with the ventilation (extraction) switched on. Wear suitable protective clothing when working with hot products.

4.2.6 TOUCHING HOT SURFACES

Only touch hot surfaces if you are wearing protective gloves. When operating the device with a coating product with a temperature of > 43 °C;

109.4 °F: - Identify the device with a warning label "Warning - hot surface".Order No.

9998910 Instruction label9998911 Protection stickerNote: Order the two stickers together.

4.3 CORRECT USE

WAGNER accepts no liability for any damage arising from incorrect use. Use the device only to work with the products recommended by WAGNER. Only operate the device as a whole. Do not deactivate safety fi xtures. Use only WAGNER original spare parts and accessories.

18

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

4.4 SAFETY INFORMATION ON DISCHARGES

The plastic parts of the spray gun are charged electrostatically by the high-voltage fi eld of the spray gun. In case of contact with plastic parts harmless discharges (brush discharges) may occur. They are completely non-hazardous for human health.When keeping a distance of 4 to 10 mm; 0.15 to 0.4 inch between spray gun and object to be sprayed, the corona discharge at the end of the electrode is visible during darkness.

4.5 USE IN AN EXPLOSION HAZARD AREA

In explosion hazard areas only use approved explosion-proof electrical devices.

4.6 NOTES TO GERMAN REGULATIONS AND GUIDELINES

Electrical devices and equipmentPart 2, Chapter 2.36 Working with Liquid Ejection DevicesPart 2, Chapter 2.29 Working with Coating ProductsExplosion protection rulesAvoiding ignition risksEquipment for cleaning work pieces with solventsGuidelines for liquid ejection devicesPainting rooms and equipmentElectrostatic coatingPlant Safety Ordinance

Note: All titles can be ordered from Heymanns Publishing House in Cologne, or they can be found on the Internet.

19

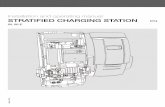

B_03558S

B_03156

7

13

14

6

5 11

1615

24

20

3

1

9

10

8

1918

17

21

22

12

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

5 DESCRIPTION

5.1 FUNCTIONAL DESCRIPTION

Description

1 Suspension hook2 Display (spray current and recipe)3 Display standby4 Operating button

(standby and recipe change)5 Protection against contact with union nut6 Air cap for fl at jet nozzle

(see accessories in Chapter 12.2.1)7 Flat jet nozzle ACF 5000

(see accessories in Chapter 12.2.2)8 Adapter9 Cover

10 Handle11 Trigger lock

Description

12 Trigger lever13 Round jet nozzle adapter

(see accessories in Chapter 12.1.1)14 Round jet nozzle insert

(see accessories in Chapter 12.1.2)15 Sealing plug16 Air adjustment17 Electric cable connection18 Atomizing air connection19 Product connection20 Filter housing with fi lter21 Type plate left22 Type plate right

Note:

The nozzle parts (pos 6; 7; 13 and 14) do not belong to the basic equipment of the spray gun. The diff erent versions can be found in Chapter 12 "Accessories".

Note:

The gun type (T) on the type plate (21) and the serial number (S) on the underside of the handle.

5.1.1 DESIGN OF THE SPRAY GUN (BASIC VERSION)

20

R1 R3R2

B_03182

2

4

3

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

5.1.2 FUNCTIONING OF THE SPRAY GUN

When the spray gun is connected to the control unit and the control unit is switched on, the pre-defi ned recipe (R1, R2 or R3) is shown on the gun display (2) as follows.Recipe 1 -> Recipe 2 -> Recipe 3 ->

Recipe change R1 -> R2 -> R3 -> R1.Press the operating button (4) and keep the button pressed of at least 2 seconds, then it is advanced by 1 recipe.

Display (2) -> = recipe values changed temporarily:The stored recipe values of the previously selected recipe number are re-loaded from memory by pressing the operating button (4) for 2 seconds.

During spraying (trigger lever pressed), the status is shown in the display (2) by LEDs.

LED display Description

LEDs 1 - 3 light up green The spray gun is working in an optimal high-voltage spray current range

one or both right-hand LEDs light up orange

spray current too high

Possible causes:

(Warning display: You can continue working without any limitations.)

Spray gun too close to the work piece

Contamination of the spray gun

Paint conductivity too high

21

12

3

4

B_03157

R1 R3R2

E

B_03262

16

4

23

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

Distance Description

1 AirCoat air opens.2 AirCoat air opened and electrostatic

(high-voltage) activated.Display (2) for "spray current" on the spray gun

to activated.3 AirCoat air opened and electrostatic

(high-voltage) activated and product valve opened.4 Overall way of trigger

An increase in the force needed to pull the trigger back will be perceived at the position where the product valve opens.For spraying without high-voltage, the high-voltage can be switched off using the operating button (4). Press the operating button (4) briefl y: High-voltage is switched off . The standby display (3) illuminates.In the event of a malfunction the spray gun switches to "standby" operating mode and the display (3) blinks.The width of the spray jet can be adjusted using the air adjustment (16) (only for fl at-jet method).

The trigger can be used to activate, one after the other, the various functions of the spray gun.

22

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

Stk Order No. Description

1 2344473 GM 5000EAC spray gunWithout control unit, product and air hose, electric cable, air cap and nozzle.

Each gun includes as standard equipment:Order No. Description

1 2309368 Assembly tool valve needle1 2325263 Assembly tool clamping screw1 2319653 Protection gloves against spray mist1 2316160 FM Control Document GM 5000E1 see Chapter 1.3 Operating manual in local language

The spray gun basic version can be set according to requirement and the desired accessories by means of the spray gun confi guration.

The delivery note shows the exact scope of delivery.

5.2 SCOPE OF DELIVERY

23

C

A

B_03155

B

C

A

B_03193

B

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

5.3 TECHNICAL DATA

GM 5000EAC Fwith fl at jet nozzle

mm inchA 280 11.02B 46 1.81C 264 10.39

GM 5000EAC Rwith round jet nozzle

mm inchA 264 10.39B 46 1.81C 264 10.39

Dimensions

Maximum air pressure 0.8 MPa; 8 bar; 116 psiMaximum product pressure 25 MPa; 250 bar; 3,626 psiFluid inlet NPSM 1/4"-18Air connection G 1/4" AInput voltage maximum 20 VppInput current maximum 1.0 A ACOutput voltage maximum 70 kV DCOutput current maximum 100 μA DCPolarity negativeWeight (without hose set) 710g

(including union nut, nozzle, air cap and edge fi lterOperating temperature range 0 °C to 40 °C

32 °F to 104 °FMaximum product temperature 50°C

122 °FSound level at 0.3 MPa; 3 bar; 43.5 psi air pressure and 11 MPa; 110 bar; 1,549 psi product pressure.

73 dB(A) *

* A-rated sound pressure level measured at 1 m distance, LpA1m, in accordance with DIN EN 14462: 2005.

24

B_00020

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

5.4 SPRAY PROCESS

AirCoat air

Multi-channel swirl nozzle

Spray jet

Nozzle nut

Spray productAirCoat air

Advantages

Large application volumeLow fogging tendencyGood fi nishHigh viscosity paints can easily be appliedHigh endurance of the nozzlesJet width adjustment

5.4.2 AIRCOAT FLAT JET SPRAY PROCESS

Shaping air

Aircap

Variable spray jet width

Atomizing air

Advantages

Large application volumeLow fogging tendencyGood fi nishHigh viscosity paints can easily be appliedHigh endurance of the AC-nozzlesJet width adjustment

In the AirCoat process, the spray product is atomized under a pressure of 3-15 MPa; 30-150 bar; 435-2,176 psi. With the help of an air pressure of 0-0.25 MPa; 0-2.5 bar; 0-36 psi, a soft, spray jet is produced. The spray jet diameter can be adjusted by turning the nozzle nut.

5.4.1 AIRCOAT ROUND JET SPRAY PROCESS

In the AirCoat process, the spray product is atomized under a pressure of 3-15 MPa; 30-150 bar; 435-2,176 psi. With the help of the AirCoat air, with a pressure of 0-0.25 MPa; 0-2.5 bar; 0-36 psi, a soft, fl at spray jet is produced which largely eliminates the problem of overlapping in the peripheral zones. With shaping air, there is the possibility of reducing the width of the spray jet.

25

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

ElectrodePaint particle

Object to be sprayedgrounded

The spray gun produces an electrostatic fi eld by means of the high-voltage electrode. As a result, the paint particles atomized by the spray gun are carried to the grounded work piece by kinetic and electrostatic energy where they adhere fi nely dispersed to the object to be sprayed.

5.4.3 ELECTROSTATIC EFFECT

Advantages

Very high application eff ectivenessLow over sprayCoating of entire circumferences due to the electrostatic eff ectSavings in working time

26

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

6 COMMISSIONING AND OPERATION

6.1 TRAINING ASSEMBLY/COMMISSIONING STAFF

Incorrect installation/operation!

Risk of injury and equipment damage.

The commissioning staff must have the technical skills to safely undertake commissioning.

When commissioning and for all work, read and follow the operating manual and safety regulations for the additionally required system components.

WARNING

6.2 STORAGE CONDITIONS

Until the point of assembly, the manual spray gun must be stored in a dry location, free from vibrations and with a minimum of dust. The manual spray gun must be stored in closed rooms.The air temperature at the storage location must be between -20 - +60 °C; -4 - +140 °F.The relative air humidity at the storage location must be between 10 and 95 % (without condensation).

6.3 INSTALLATION CONDITIONS

The air temperature at the installation site must be between 0 - 40 °C; 32 - 132 °F.The relative air humidity at the installation site must be between 10 and 95 %(without condensation).

27

EXT

100

80

60

40

20

μA

80

60

40

20

10

kV

R3

R1

R2

VM 5000

7

6

8

45

9

17

1

21615

14

21

12

11

10

B_03158

18 19

20

3

3

13

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

6.4 INSTALLATION AND CONNECTION

Description

1 GM 5000EACF spray gun2 Gun cable3 Grounding cable4 Pneumatic pump5 Trolley6 Pressure regulator + air

fi lter7 Product suction system8 Return hose9 High-pressure fi lter

10 Compressed air connection

Description

11 Stop valve12 Air pressure regulator13 VM 5000 control unit14 Protective hose15 Air hose16 Product hose17 Return valve18 Tank for return fl ow

Description

19 Paint tank20 Tank, cleaning agent21 Power cable

6.4.1 TYPICAL ELECTROSTATIC SPRAYING SYSTEM

28

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

6.4.2 VENTILATION OF THE SPRAY BOOTH

The GM 5000EAC spray gun must be used as part of a spraying system (Spraypack). The system shown in fi gure B_03158 is only one example of an electrostatic spraying system. Your WAGNER distributor would be happy to assist you in creating a spraying system solution that meets your individual needs. You must familiarize yourself with the operating instructions and the safety regulations of all additional system components before starting commissioning.

Incorrect installation/operation!

Risk of injury and equipment damage.

When commissioning and for all work, read and follow the operating manual and safety regulations for the additionally required system components.

WARNING

Toxic and/or fl ammable vapor mixtures!

Risk of poisoning and burns.

Operate the device in a spray booth approved for the working products.

-or- Operate the device on an appropriate spraying wall with the

ventilation (extraction) switched on. Observe national and local regulations for the outgoing air

speed.

WARNING

The electrostatic hand spraying equipment is for use only in spray areas which correspond with standard EN 12215.The electrostatic hand spraying equipment has to be locked to the technical ventilation so that the coating product supply and the high-voltage are not eff ective as long as the technical ventilation is not operated with the minimum exhaust air volume fl ow or a larger exhaust air volume fl ow.Ensure that the excess coating product (overspray) will be collected up safely.

29

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

6.4.4 MATERIAL SUPPLY

Impurities in the spraying system!

Spray gun blockage, products harden in the spraying system.

Flush the spray gun and paint supply with a suitable cleaning agent.

NOTICE

6.4.3 AIR SUPPLY

The use of an air fi lter with the air regulator (6) ensures that only dry, clean atomizing air gets into the spray gun. Dirt and moisture in the atomizing air worsens the spraying quality and spraying pattern.

Bursting hose, bursting threaded joints!

Danger to life from injection of product.

Ensure that the hose material is chemically resistant to the sprayed products.

Ensure that the spray gun, threaded joints, and product hose between the device and the spray gun are suitable for the pressure generated in the device.

Ensure that the following information can be seen on the high-pressure hose:

- Manufacturer - Permissible operating pressure - Date of manufacture

DANGER

Hose connections

Risk of injury and equipment damage.

Do not exchange hose connections of product hose and air hose.

WARNING

30

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

Perfect grounding of all conductive parts such as fl oors, walls, roofs is important for optimum coating and safety. Barriers, work pieces, transport devices, coating product tank, coating product supply or construction parts in the spray area with exception of the high-voltage parts during normal operation.Parts of the booth must be grounded in accordance with EN 12215.

A poorly grounded work piece causes:

very bad wrap around,uneven coating,back spraying to the spray gun, i.e. contamination.

Prerequisites for perfect grounding and coating are:

Clean work piece suspension.Grounding of spray booth, conveyor system and suspension on the building side in accordance with the operating instruction or the manufacturer's information.Grounding of all conductive parts within the working area.The grounding resistance of the work piece may not exceed 1 MΩ (Megohm).Note:

Resistance to ground measured at 500 V or 1,000 V.Connect the control unit to the system ground.

6.4.5 GROUNDING

Discharge of electrostatically charged components in atmospheres

containing solvents!

Explosion hazard from electrostatic sparks or fl ames.

Ground all device components. Ground the work pieces to be coated.

WARNING

Heavy paint mist if grounding is insuffi cient!

Danger of poisoning.Insuffi cient paint application quality.

Ground all device components. Ground the work pieces to be coated.

WARNING

31

B_03234

R max < 1 MΩ

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

Minimum cable cross-section

Control unitPumpPaint tankConveyorBoothSpraying stand

Control unit

Grounding cable

Spraying stand

Floor static dissipative

Work piece

Pump or pressure tank

Paint tank or tank for return fl ow

Grounding schema (example):

Note for the sprayer:

Safety shoes and gloves, if used, must be static dissipative.

Conveyor

Power cable

32

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

33

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

6.5 PREPARATION OF LACQUER

6.5.1 VISCOSITY CONVERSION TABLE

The viscosity of the lacquers is of great importance. The best spraying results are obtained with values between 25 and 40 DIN-s (measured in immersion fl ow cup DIN 4 mm; 0.16 inch). Processing of up to 60 DIN-s is generally possible without problem, if high coating thicknesses are required.

With the Wagner AirCoat fl at jet spraying process, the diff erent viscosities of the lacquer are optimally covered by two air cap types. These can be found in "Accessories".

In the case of application problems contact the paint producer.

10 10 0.1 5 1615 15 0.15 8 1720 20 0.2 10 1825 25 0.25 14 12 1930 30 0.3 15 14 2040 40 0.4 17 18 2250 50 0.5 19 22 2460 60 0.6 21 26 2770 70 0.7 23 28 3080 80 0.8 25 31 3490 90 0.9 28 32 37

100 100 1 30 34 41120 120 1.2 33 41 49140 140 1.4 37 45 58160 160 1.6 43 50 66180 180 1.8 46 54 74200 200 2 49 58 82220 220 2.2 52 62240 240 2.4 56 65260 260 2.6 62 68280 280 2.8 65 70300 300 3 70 74320 320 3.2340 340 3.4360 360 3.6 80380 380 3.8400 400 4 90

34

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

Observe safety instructions in Chapter 4.

The following points should be noted before commissioning

Grounding see Chapter 6.4.5. Make sure that all other conductive parts within the work area are grounded.Connect the product hose to spray gun and product pump.Check that all product-conveying connections are correctly connectedConnect air hose to spray gun and to supply of oil-free dry air, approx. 0.25 MPa; 2.5 bar; 36 psi. Compressed air quality class 3.5.2 according to ISO 8573.1.Check that all air-conveying connections are correctly connected.Connect the electric cable to the spray gun and to the VM 5000 or VM 500 control unit.Visually check the permissible pressures for all the system components.Check the level of the separating agent in the Wagner pneumatic pump and fi ll the separating agent up if necessary.

6.6 COMMISSIONING

6.6.1 GENERAL RULES FOR MANIPULATION OF THE SPRAY GUN

High-voltage fi eld!

Danger to life from malfunction of heart pacemakers.

Make sure that persons with pace makers: Do not work with the electrostatic spray gun. Stay outside the area of the electrostatic spray gun/work piece.

DANGER

Unintentional putting into operation!

Risk of injury.

Before any work on the device, in the event of work interruptions and malfunctions:

Switch off the energy/compressed air supply. Relieve the pressure from the spray gun and unit. Secure the spray gun against actuation. In the event of functional faults: remedy the fault as described

in the "Troubleshooting" chapter.

WARNING

6.6.2 PREPARATION FOR STARTING UP

35

B_03691

84

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

Attention: gun cable to control unit

Secure the cover sleeve with the warning sign by means of the screw (84) on the connector.

GM 5000E gun cable

Provide product tank, tanks for fl ushing agent and an empty tank for return.Connect the system with a secured gun to the air and power supply.A basic fl ushing of system must be carried out before commissioning. Make sure that no nozzle is inserted into the gun.

Sparks form when the plug is removed!

Explosion hazard.

When using the spray gun in explosion hazard areas: The cable connection on the gun and the connection to any

cable extensions may not be disconnected or connected in this area.

WARNING

36

B_03690

84 84

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

GM 5000E gun cableExtension cable to the control unit

Attention: guns with electric extension cable

Secure the cover sleeves with the warning sign by means of the screws (84) on the connectors.

Note:

In order to prevent power losses, keep the cable length as short as possible. The maximum power is available with the standard cable length of 10 m.An extension to a total length of up to 40 m will cause a power loss of up to 10%. The gun cable can be extended to a total length of 80 m, however, a power loss of up to 30 % will be caused.

37

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

7 OPERATION

7.1 TRAINING THE OPERATING STAFF

7.2 SAFETY INSTRUCTIONS

Incorrect operation!

Risk of injury and equipment damage.

The operating staff must be qualifi ed to operate the entire system.

Before work commences, the operating staff must receive appropriate training.

WARNING

Incorrect operation!

Risk of injury and equipment damage.

If contact with solvent-based paints or cleaning agents causes skin irritation, appropriate precautionary measures must be taken, e.g. wearing protective clothing.

The footwear worn by operating staff must comply withEN ISO 20344. The measured insulation resistance must not exceed 100 MΩ.

The protective clothing, including gloves, must comply with EN ISO 1149-5. The measured insulation resistance must not exceed 100 MΩ.

WARNING

Discharge of electrostatically charged components in atmospheres

containing solvents!

Explosion hazard from electrostatic spark-over.

Use gun only with fi tted nozzle, air cap and union nut. Tighten the union nut, especially with nozzle in the cleaning

position.

WARNING

38

EXT

100

80

60

40

20

μA

80

60

40

20

10

kV

R3

R1

R2

VM 5000

7

6

8

45

9

17

1

21615

14

21

12

11

10

B_03158

18 19

20

3

3

13

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

7.3 WORK

1. Place an empty tank (18) under the return tube (8) (see picture B_03158).2. Place suction hose (7) in the tank with working product (19).

Note:

If the pump is equipped with a rigid suction system, it should only be dipped in into the working product up to the middle of the inlet housing at the maximum!

3. Adjust the pressure regulator (12) to approx. 0.05 MPa; 0.5 bar; 7.25 psi.4. Open return valve (17).5. Slowly open the ball valve (11).6. Adjust the air pressure on the pressure regulator (12) so that the pump runs smoothly.7. Close ball valve (11) as soon as pure working product starts coming from the return

tube (8).

7.3.1 FILLING WITH WORKING PRODUCT

39

B_03192

B_03159

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

8. Close return valve (17).9. Point the gun, without nozzle, into tank (18) and open it.

10. Slowly open the ball valve (11).11. Close ball valve (11) as soon as pure working product starts coming from the gun.12. When there is no pressure remaining in the system, close the gun.13. Secure the gun.14. Dispose of the contents of the tank (18) according to the local regulations.

1. Secure gun and insert the desired nozzle into the gun.2. Set pump (4) to about 8 Mpa; 80 bar; 1,160 psi operating pressure and start up

control unit (13).3. Spraying (pull trigger).4. Adjust the spray pressure at the paint pump according to the nozzle and object

being sprayed5. Now open AirCoat air (6), approx. 0.01-0.25 MPa; 1-2.5 bar; 14,5-36 psi, and adjust for

the optimal atomization.

For round-jet method:

6. By turning the nozzle nut, the atomizing air jet can additionally be adjusted.Notes:

Do not turn the nozzle nut until it is fl ush with the nozzle body. There must be play for the atomizing air between the nozzle nut and the nozzle body.The air adjustment at the back of the gun does not aff ect the spray pattern in this process.

For fl at-jet method:

7. Change the width of the spray jet by turning the air adjustment on the back of the spray gun or by appropriate selection of the nozzle.

7.3.2 START-UP FOR SPRAYING AIRCOAT

40

1/2

1

2B_03160

B_031611

2

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

7.3.3 FLUSHING OUT CLOGGED ROUND JET NOZZLES

1. Use nozzle spanner (2) to loosen nozzle insert (1) by a half turn.

2. Remove the nozzle spanner and briefl y actuate trigger.

3. After fl ushing the nozzle, re-tighten the nozzle insert.

7.3.4 REPLACING ROUND JET NOZZLE'S NOZZLE INSERT

Exploding gas / air mixture!

Danger to life from fl ying parts and burns.

Never spray into a closed tank. Ground the tank.

DANGER

1. Remove nozzle insert (1) using nozzle spanner (2).2. Assembling new nozzle insert.

41

B_03162

1

2

34

5

67

8

109

Y

11

1

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

7.3.5 CHANGING FROM AIRCOAT ROUND JET TO AIRCOAT FLAT JET

1. Flush the spray gun (1) out thoroughly with cleaning agent.

2. Relieve the pressure of gun and device.3. Secure the spray gun (1) using the trigger lock.4. Unscrew round jet nozzle cap (2) incl. nozzle insert (3).5. Unscrew nozzle insert (3) using nozzle spanner (4).6. Unscrew nozzle nut (5) and remove nozzle screw

connection (7) and sealing fi tting (8) out off the nozzle body (6) and clean all parts thoroughly.

7. Insert desired ACF 5000 nozzle (11) into the valve housing.

8. Put the air cap (10) on the nozzle (11) and pay attention to the position of the guide surfaces.

9. Screw union nut with attached nozzle guard (9) to the gun body and make sure that the air cap horns lie in the designated recess (Y).

10. Before tightening with the air cap horns (Y), set the desired jet level and then tighten the union nut to stop by hand.

42

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

7.3.6 REPLACING THE AIRCOAT FLAT JET NOZZLES

1. Switch off control unit.2. Relieve pressure from the gun (1) and from the device!3. Secure the spray gun (1) using the trigger lock.4. Unscrew union nut (12) and remove air cap (10).5. Remove ACF5000 AirCoat nozzle (11) and treat it with cleaning agent until all traces

of paint have been removed.

The ACF5000 AirCoat nozzles (11), the nozzle inserts (3) and the nozzle screw connection (7) can be placed in a cleaning solvent recommended by the lacquer manufacturer.

All other nozzle parts may not be put into cleaning solvent.Clean these parts with a cleaning solvent recommended by the lacquer manufacturer and dry with a cloth or blow gun.

1. Switch off control unit.2. Relieve the pressure of gun and device.3. Secure the spray gun (1) using the trigger lock (14).4. Unscrew complete union nut (12) with air cap (10) and ACF5000 nozzle (11).5. Remove air cap (10).6. Push ACF 5000 nozzle (11) out of air cap (10) by hand, reverse it and put it into the air

cap (10) with the nozzle tip towards the rear.Pay attention to the position of the guide surfaces (X).

7. Insert air cap (10) with integrated ACF5000 nozzle (11) into the union nut (9).Make sure that the air cap horns (Y) lie in the recess of the nozzle guard.

Defective AirCoat nozzle!

Insuffi cient paint application quality.

Do not use sharp-edged objects to treat carbide on the AirCoat nozzle.

NOTICE

6. Insert new ACF5000 nozzle (11) into the valve housing.7. Put the air cap (10) on the nozzle (11) and pay attention to the position of the guide

surfaces.8. Screw union nut with attached nozzle guard (9) to the gun body and make sure that

the air cap horns lie in the designated recess (Y).9. Before tightening with the air cap horns (Y), set the desired jet level and then tighten

the union nut to stop by hand.

7.3.7 CLEANING OF THE NOZZLE PARTS

7.3.8 ELIMINATE NOZZLE CLOGGING

43

B_03211

10

11

X

Y

1

14

12

12

Y

9

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

8. Screw preassembled union nut (12) to gun (1) and tighten by hand.9. Switch the product pressure back on.

10. Turn the trigger lock (14) to the spraying position and briefl y pull the trigger.11. When the blockage has been fl ushed out, secure the gun with the trigger lock.12. Relieve the pressure of gun and device.13. Unscrew union nut (12).14. Remove air cap (10) and push ACF5000 nozzle (11) out of the air cap by hand.

Clean ACF5000 nozzle and insert it in the spraying position into the valve housing.15. Put the air cap (10) on the nozzle (11) and pay attention to the position of the guide

surfaces (X).16. Screw union nut with attached nozzle guard (9) to the gun body and make sure that

the air cap horns lie in the designated recess (Y).17. Before tightening with the air cap horns (Y), set the desired jet level and then tighten

the union nut to stop by hand.18. Switch the product pressure and the air pressure back on.19. Switch on the control unit.

ACF5000 nozzle in cleaning position

ACF5000 nozzle in spray position

44

B_03847

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

7.3.9 CHANGING THE VALVE HOUSING

Changing the valve housing!

Equipment damage.

Activate the spray gun trigger when changing the valve housing.

NOTICE

To prevent damage to the gun (valve seat rubs on the valve needle, valve needle may loosen), activate the spray gun trigger when changing the valve housing.

45

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

8 CLEANING AND MAINTENANCE

Cleaning work should be undertaken regularly and carefully by qualifi ed and trained staff . They should be informed of specifi c hazards during their training.

The following hazards may arise during cleaning work:Health hazard from inhaling solvent vaporsUse of unsuitable cleaning tools and aids

8.1 CLEANING

8.1.2 SAFETY INSTRUCTIONS

8.1.1 CLEANING STAFF

Explosive powder/air mixes!

Danger to life and equipment damage.

Before starting cleaning or other manual work, the high-voltage must be shut down and locked to prevent it from being switched back on!

The spray gun must be separated from the high-voltage supply before any cleaning work is started!

Use only electrically conductive tanks for cleaning liquids! Ground the tank!

Preference should be given to non-fl ammable cleaning fl uids. Only cleaning agents of explosion class IIA should be used

(maximum ignition energy 0.24 mJ). The cleaning agent's fl ash point must be at least 15 K above the

ambient temperature. Ensure that no electric component is cleaned with or immersed

into solvent.

DANGER

46

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

The spray gun and the unit must be cleaned daily. The cleaning agents used for cleaning must correspond with the working product.

Cleaning of the nozzle parts -> Chapter 7.3.7Eliminating Nozzle Clogging -> Chapter 7.3.8

8.1.3 CLEANING AND DECOMMISSIONING

Flushing agent in the air duct!

Functional faults caused by swollen seals.

Never immerse the spray gun in cleaning agent.

NOTICE

Incorrect maintenance/repair!

Risk of injury and equipment damage.

Have repairs and part replacements be carried out only by specially trained staff or a WAGNER service center.

Before all work on the device and in the event of work interruptions:

- Switch off the energy/compressed air supply. - Relieve the pressure from the spray gun and device. - Secure the spray gun against actuation.

Observe the operating instructions for any work.

WARNING

47

B_03453

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

Gun fl ushing

1. Switch off control unit.2. Ensure that the product pressure is relieved and shut off the air supply to the gun.3. Connect the cleaning agent supply.

With round jet nozzle fi tted:

4. By means of nozzle spanner, loosen nozzle insert by 1/2 turn.5. Actuate the trigger. Flush the gun thoroughly.6. Relieve the pressure from gun and unit!7. Re-tighten the nozzle insert.8. Clean the spray gun body with a cleaning agent recommended by the manufacturer

and dry with a cloth or blow gun.With fl at jet nozzle fi tted:

4. Dismount AirCoat nozzle and clean separately (see Chapter 7.3.7).5. Actuate the trigger. Flush the gun through thoroughly.6. Relieve the pressure from gun and unit!7. Clean the spray gun body with a cleaning agent recommended by the lacquer

manufacturer and dry with a cloth or blow gun.

Exploding gas / air mixture!

Danger to life from fl ying parts and burns.

Never spray into a closed tank. Ground the tank.

DANGER

NOTICEFlushing agent in the air duct!

Functional faults caused by swollen seals.Discharge current to ground -> no high-voltage

Always point the spray gun down when cleaning. Ensure that neither paint nor cleaning agent enters the air duct. When taking a break from work or when stored for a longer period, the spray gun

should be positioned with the adapter pointing downwards.

48

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

8.2 MAINTENANCE

Maintenance work should be undertaken regularly and carefully by qualifi ed and trained staff . They should be informed of specifi c hazards during their training.

The following hazards may arise during maintenance work:Health hazard from inhaling solvent vaporsUse of unsuitable tools and aids

Once the maintenance work is complete, the device must be checked by a qualifi ed person to ensure a reliable condition.

8.2.1 MAINTENANCE STAFF

8.2.2 SAFETY INSTRUCTIONS

Incorrect maintenance/repair!

Danger to life and equipment damage.

Repair or replacement of devices or parts of devices are only allowed to be performed outside the hazard area by qualifi ed personnel.

DANGER

Check hoses, pipes, and couplings every day and replace if necessary.

In accordance with the guideline for liquid ejection devices (ZH 1/406 and BGR 500 Part 2 Chapter 2.36):- The liquid ejection devices should be checked by an expert (e.g. Wagner service

technician) for their safe working conditions as required and at least every 12 months.

- If devices have been decommissioned, the examination can be suspended until the next start-up.

49

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

DANGER

8.3.1 TOOLS

For disassembling and assembling the gun the following tools are required:

Allen wrench SW 2Allen wrench SW 3Allen wrench SW 5Open-end wrench SW 5Open-end wrench SW 6Open-end wrench SW 8Open-end wrench SW 11Open-end wrench SW 12Open-end wrench SW 14Open-end wrench SW 19Open-end wrench SW 21Open-end wrench SW 22Ring spanner SW 9Torx wrench 20Torx wrench 25Assembly tool valve needle Order No. 2309368Assembly tool clamping screw Order No. 2325263

Incorrect maintenance/repair!

Danger to life and equipment damage.

Only a WAGNER service center or a suitably trained person may carry out repairs and replace parts.

Only repair and replace parts that are listed in the "Spare Parts" chapter and that are assigned to the device.

Before all work on the device and in the event of work interruptions:

- Disconnect the control unit from the mains. - Relieve the pressure from the spray gun and device. - Secure the spray gun against actuation.

Observe the operating manual and service instructions at all times when carrying out work.

8.3 DISASSEMBLY OF THE SPRAY GUN

50

B_03194

SW3

SW12SW12

B_03195

SW3

SW19

SW21

Torx 25

1

2

3

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

8.3.2 DISASSEMBLY OF THE SPRAY GUN

51

4

5

6

B_03197

SW9

B_03196

SW22

SW19

SW19

25

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

Assembly tool for needle valve.Order No. 2309368

Assembly tool for the valve housingOrder No. 2325263

Note:

Loosen AC valve tip by hand using an assembly tool.

Do not pull out on contact wire.

Carefully release the cascade without pliers.

Use assembly tool, socket or ring spanner (no wrench).

Use screw driver to lever out the ring carefully.

Note:

If the fi tting (25) is not on the dismounted product hose when it is replaced, the fi tting must be removed from the gun adapter.

52

8

9

7

B_03198

SW6

SW5

SW2

14

5

2

6 7

3

ø 3

.0

B_03199

SW14

SW9

SW5

SW8

Torx 20

2

1

2

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

1. Remove pressure spring (4).2. Loosen clamping screw compl. (1) with

assembly tool (5).3. Unscrew the complete packing (3) via

valve rod unit complete (2, 6 and 7) or pull out the valve rod unit and unscrew it using an Allen wrench SW5.

4. If the loosened packing (3) is jammed in the hole, push from the front (see illustration above).

1. Loosen the oval head screw (1).2. Pull the air valve (2) out off the

hole.

53

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

8.4 CLEANING THE PARTS AFTER DISASSEMBLY

In Chapter 13 the part numbers for gun spare parts can be found as well as for wearing parts such as seals.

Incompatibility of cleaning agent and working medium!

Risk of explosion and danger of poisoning by toxic gasses.

Examine the compatibility of the cleaning agents and working media on the basis of the safety data sheets.

WARNING

Please note:

All reusable parts (except for the parts conducting high-voltage such as cascade, adapter, plug compl. etc.) should be cleaned thoroughly using a suitable cleaning agent.

The adapter, plug compl. and the handle inside must be clean and dry after cleaning. Care should be taken that these parts remain free of solvents, grease or sweat from the hands (salt water).

Spare parts may have safety-relevant properties. Use only WAGNER original spare parts and accessories. Defective parts, O-rings and seal sets must always be re-placed.

ATTENTION

54

1

2B_03448

B_03201a

SW143 Nm

SW9 1 Nm

Torx

20 1

4

2

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

8.5 ASSEMBLY OF THE SPRAY GUN

Assembly aids:

Order No. Description

1 9992590 Loctite 2222 9992698 Vaseline white PHHV II3 9992831 Loctite 5424 9992511 Loctite 2435 9992609 Anti-seize paste

Ensure the correct insertion position!

Ensu

re th

e co

rrec

t ins

ertio

n po

sitio

n!

55

3

B_03202

0.5 Nm

SW60.4 - 0.5 Nm

SW5

2

2

2

SW5/ 0.4 - 0.5 Nm

X = 123 ±0.1

SW2

1Nm

X

14

5

4 5

B_03203

SW91.8 Nm

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

Set measure X with withdrawal nut and then fasten it with the threaded pin (SW2).

Push the valve rod unit and the complete packing together.

Screw the valve rod unit and the complete packing together.

Only as required:

Remove the valve rod unit.Tighten the complete packing.

Carefully insert the valve rod unit and mount the complete clamping screw (1) with assembly tool (5).

Slightly tighten AC valve tip by hand using an assembly tool(Order No. 2309368).

Assembly tool (Order No. 2325263)

Note:

Use assembly tool, socket or ring spanner (no wrench).

Ensure the correct insertion position.

Ensure the correct insertion position.

56

6

7

B_03205

SW3

0.8 Nm

SW21

SW19

B_03204

SW22

SW19

SW192.5 Nm

2

5

525

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

Clean and degrease the inside of the adapter and the cascade, then grease the cascade surface with Vaseline.

Note:

Before assembling the product hose, check that no fi tting (25) is in the gun adapter!Check the fi tting for damage and replace if necessary (Order No. 2338853).

57

8

B_03206

Torx 25

9

B_03207

SW30.8 Nm

SW12

SW12

2

R1 R3R2

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

Push the trigger upward into the air valve piston.

Ensure the correct insertion position!

58

10

B_03208

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

Flat jet nozzleAssembly see Chapter 13.3.1.Various nozzle sizes see Chapter 12.2

Round jet nozzleAssembly see Chapter 13.3.2.Various nozzle sizes see Chapter 12.1.

59

B_03212

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

8.6 FUNCTION TEST AFTER ASSEMBLY OF THE GUN

8.6.1 TEST OF THE HIGH-VOLTAGE

Necessary test equipment:VM 500 or VM 5000 control unit and HV200 high-voltage tester. High-voltage measurement on spraying gun.

Connect gun cable to control unit. Take the spray gun in your hand and hold into open space. Switch on control unit and actuate trigger guard.The high-voltage should be 50 to 60 kV in dry ambient air. The value can be checked with the display on the control unit (VM 5000).Notice

The gun must be clean and dry and must not have any color or cleaning agent residues. In the case of ambient air with a high air humidity, the measured value can reduce to 40 to 50 kV.

High-voltage measurement with high-voltage tester

Place the ball of the high-voltage tester on the gun electrode and turn on the high-voltage. The measured value should be 60 to 70 kV.Notes

- When measuring the high-voltage the gun and the measuring device should be held at arms length as far from the body as possible.

- There should be no chargeable objects within a radius of 1 m; 3.28 ft of the place where the measurements are taken.

- The placing of the measuring ball of the high-voltage measuring device reduces the spraying of the high-voltage electrode. As a result the high-voltage value increases compared to the spraying in the free space.

Disruptive discharge test

Check the gun against ground with the grounding rod. No sparks should be formed.Note: in the vicinity of the electrode harmless corona discharges can occur.

Grounding rodOrder No. 175519

60

B_03213

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

Connect test or air hose to the spray gun and switch on mains pressure to a maximum of 0.8 MPa; 8 bar; 116 psi.

Checking the air valve

The air valve must switch on and off correctly.Test up to approx. 0.8 MPa; 8 bar; 116 psi.

Air tightness

With the trigger unactuated, test for air tightness at the points marked in the illustration:

Connect high-pressure hose to the spray gun.Test the spray gun for tightness with solvent or spray oil (e.g. Macrol 52) and a maximum pressure of 25 MPa; 250 bar; 3,626 psi.Observe the following gun components:Product connection, nozzle body, product valve (no after-spraying).

8.6.2 AIR TEST

8.6.3 PRODUCT PRESSURE TEST

Exploding gas / air mixture!

Danger to life from fl ying parts and burns.

Never spray into a closed tank. Ground the tank.

DANGER

61

B_00071

B_03214

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

8.6.4 TEST OF SPRAY PATTERN

Start AirCoat spraying (without electrostatics)

1. Start up with product supply set to approx. 8 MPa; 80 bar; 1,160 psi operating pressure.2. Spray (release locking device and pull trigger) and at the same time, check the

atomization.3. Set the product pressure on the product supply to the point where a good product

atomization is achieved.4. Open the air pressure regulator for the atomizing air and adjust it so that an optimal

atomization is achieved. (The interrelation between spray pattern and atomizing air is shown in the fi gure below).

5. With the air adjustment on the gun, set the ratio shaping air / atomizing air so as to achieve an optimum spray pattern.

Note:

Repeat points 4 and 5 until the optimum spray pattern is reached (iterative process).

Spray pattern shapes

No atomization air Too little atomization air Correct amount of atomization air

Infl uence of the air adjustment on the spray pattern shape

The spray pattern can be adjusted to suit the object to be sprayed using the air adjustment. The illustration shows the infl uence of the shaping air regulator on the spraying pattern.Other nozzle sizes can be used to obtain larger or smaller spraying patterns.

Closed air adjustment

Completely opened air adjustment

Notice

The paint output can be changed by:changing the product pressure orusing a diff erent fl at jet nozzle (see Chapter 12.2).

62

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

8.7 HIGH-PRESSURE HOSES

The service life of the fl uid hoses is reduced due to environmental infl uences even when handled correctly.

Check hoses, pipes, and couplings every day and replace if necessary.As a precaution, fl uid hoses should be replaced after a period specifi ed by the operator.

Bursting hose, bursting threaded joints!

Danger to life from injection of product.

Ensure that the hose material is chemically resistant to the sprayed products.

Ensure that the spray gun, threaded joints, and product hose between the device and the spray gun are suitable for the pressure generated in the device.

Ensure that the following information can be seen on the high-pressure hose:

- Manufacturer - Permissible operating pressure - Date of manufacture

DANGER

63

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

9 INSPECTIONS

Observe safety instructions in Chapter 4.

9.1 PERIODICAL INSPECTIONS

For the safe operation of electrostatic manual coating systems for fl ammable liquid coating products, intervals for periodical inspections are defi ned as follows:

Inspection point Inspection interval Remarks

Gun cleaning, gun fl ushing daily Chapter 4.2.4, Chapter 8.1.3Hoses, tubes, couplings daily Chapter 8.7Grounding weekly Chapter 4.2.2, Chapter 6.4.5Inspection for damage weekly Chapters 8.1.3, 8.2, 8.3, 8.4 and 8.5Locking of the technical ventilation with the electrostatic manual coating system

annually Chapter 6.4.2

The above recommended intervals are maximum values and may be modifi ed by the operator depending on the local and operational conditions and the contamination.

Damaged devices must be decommissioned and repaired immediately.

64

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

Functional fault Cause Remedy

Insuffi cient product output Nozzle too small. Select larger nozzle(see nozzle table 12.2 und 12.3).

Product pressure too low. Increase product pressure.Gun fi lter or high pressure fi lter clogged at pump.

Clean or replace fi lter.

Nozzle is clogged. Nozzle cleaning(see Chapters 7.3.3 to 7.3.8).

Poor spray pattern Atomizing air incorrectly adjusted. Readjust the atomizing air.Nozzle is too large. Select a smaller nozzle

(see nozzle table).Product pressure too low. Increase the product pressure at

pump.The product viscosity is too high. Thin product in accordance with the

manufacturer's instructions.Valve rod leaks Seals at the valve rod are damaged. Replace the seals (see Chapter 8).

Loose packing TightenPoor wrap-around Insuffi cient grounding. Check grounding.

Inadequate electric resistance of the lacquer.

Check lacquer resistance(see Chapter 2.5).

Spraying pressure too high. Readjust spraying pressure.Back-spray No grounding Check grounding.

Distance between spray gun and work piece too large.

Reduce distance between spray gun and work piece.

Nozzle nut placed too far forward Move nozzle nut back(Decrease air distributor ring gap).

No wrap-around High-voltage switched off . Switch on the high-voltage switch.No electrostatics. Repair malfunction as laid down

in the control unit operating instructions.

10 TROUBLESHOOTING AND RECTIFICATION

65

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

11 PRODUCT DISPOSAL

Do not dispose of used electrical equipment with household

refuse!

In accordance with European Directive 2002/96/EC on the disposal of used electrical equipment and its implementation in national law, this product may not be disposed of with the household refuse, but must be recycled in an environmentally correct manner.Wagner or one of our dealers will take back your used Wagner electric or electronic equipment and will dispose of it for you in an environmentally-friendly way. Please contact one of our service points, one of our representatives or us directly to arrange this.

NOTICE

66

B_03210

B_03209

B_03454

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

12 ACCESSORIES

12.1.1 ACR 5000 ROUND JET NOZZLE CAP

Order No. Designation

2344483 ACR 5000 round jet nozzle cap(with nozzle spanner, without AC round jet nozzle insert)

Order No. Designation

2309882 ACF 5000 air cap - LV suitable for low viscosity products (marked red)

2314203 ACF 5000 air cap - HV suitable for high viscosity products (marked blue)

12.2.1 ACF 5000 AIR CAPS (FLAT JET)

Order No. Marking Jet width Recommended gun fi lter

mm; inch

132720 11 approx. 250; 10 Red132721 12 approx. 250; 10 200 meshes132722 13 approx. 250; 10132723 14 approx. 250; 10

132724 * 15 approx. 250; 10132725 16 approx. 250; 10 Yellow132726 17 approx. 250; 10 100 meshes132727 18 approx. 250; 10132728 19 approx. 250; 10132729 20 approx. 250; 10 white132730 21 approx. 250; 10 50 meshes132731 22 approx. 250; 10

* Standard versionJet width in mm; inches at a distance of 30 cm; 11.8 inches from the object and at a pressure of 10 MPa; 100 bar; 1,450 psi.

12.1.2 AIRCOAT ROUND JET NOZZLE INSERTS

The round jet nozzles are especially suited to spray pipes, profi les and complex work pieces.

12.1 ROUND JET NOZZLES

12.2 FLAT JET NOZZLES

67

B_03163

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

12.2.2 ACF5000 AIRCOAT FLAT JET NOZZLES

Ord

er

No

.

Ma

rkin

g

Bo

re

mm

;

inc

h

Sp

ray

an

gle

Application

395107 07/10 0.18; 0.007 10° Natural lacquer395207 07/20 20°395407 07/40 40°395109 09/10 0.23; 0.009 10° Clear lacquer395209 09/20 20° Oils395309 09/30 30°395409 09/40 40°395509 09/50 50°395609 09/60 60°395111 11/10 0.28; 0.011 10° Synthetic resin lacquer395211 11/20 20° PVC lacquer395311 11/30 30°395411 11/40 40°395511 11/50 50°395611 11/60 60°395811 11/80 80°395113 13/10 0.33; 0.013 10° Lacquer395213 13/20 20° Base coat395313 13/30 30° Primer395413 13/40 40° Filler395513 13/50 50°395613 13/60 60°395813 13/80 80°395115 15/10 0.38; 0.015 10° Filler395215 15/20 20° Rust proofi ng paints395315 15/30 30°395415 15/40 40°395515 15/50 50°395615 15/60 60°395815 15/80 80°395217 17/20 0.43; 0.017 20° Rust proofi ng paints395317 17/30 30° Latex paints395417 17/40 40°395517 17/50 50°395617 17/60 60°395817 17/80 80°

68

B_03163

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500O

rde

r N

o.

Ma

rkin

g

Bo

re

mm

;

inc

h

Sp

ray

an

gle

Application

395219 19/20 0.48; 0.019 20° Rust proofi ng paints395319 19/30 30° Latex paints395419 19/40 40°395519 19/50 50°395619 19/60 60°395819 19/80 80°395221 21/20 0.53; 0.021 20° Mica paints395421 21/40 40° Zinc rich paints395521 21/50 50° Rust proofi ng paints395621 21/60 60° Glue paints395821 21/80 80°395423 23/40 0.58; 0.023 40°395623 23/60 60°395823 23/80 80°395425 25/40 0.64; 0.025 40°395625 25/60 60°395825 25/80 80°395427 27/40 0.69; 0.027 40°395627 27/60 60°395827 27/80 80°395429 29/40 0.75; 0.029 40°395629 29/60 60°395829 29/80 80°395431 31/40 0.79; 0.031 40°395631 31/60 60°395831 31/80 80°395435 35/40 0.90; 0.035 40°395635 35/60 60°395835 35/80 80°

69

B_00019

B_03221

M

F

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

12.3 FILTER

Order No. Designation

3204604 Edge fi lter 60 mesh (white)3204605 Edge fi lter 100 mesh (black)9999002 Edge fi lter 200 mesh (yellow)

12.4 REDUCTION FITTINGS FOR HIGH-PRESSURE HOSES

The classifi cation of WAGNER fi ttings is consistent with the following classifi cation, each separated by high-pressure and low pressure fi ttings:

Double fi tting - male / male thread Reduction fi tting - female / male thread Adjustable screw - female / male thread: allows precise angle adjustment (swivel) 90° elbow - adjustable or male / male thread (elbow fi tting) Bulkhead fastener - male / male thread with pressure-resistant feed-through Stopper - male thread for closing (plug fi tting)

Hose fi tting with union nut and sealing cone (hose fi tting)The short description of the fi ttings are as follows:

Materials, SSt = Stainless steelNominal pressure (in bar)

1st thread, e.g. G1/4", 1/4"NPS2nd thread, e.g. G1/4", 1/4"NPS, M16x1.5

M: male (outer thread) F: female (interior thread)Short description see table above, e.g. RF = Reduction Fitting

Order No. Designation

384555 Reduction fi tting-RF-FM-M16x1,5-1/4"NPS-PN530-SSt384559 Reduction fi tting RF-FM-M16x1,5-G1/4"-PN530-SSt384556 Reduction fi tting RF-FM-M16x1,5-3/8"NPSM-PN530-SSt34041 Reduction fi tting RF-FM-1/4"NPS-M16x1,5--PN270-SSt

179732 Reduction fi tting RF-FM-1/4"NPS-3/8"NPS--PN270-SSt179247 Reduction fi tting RF-FM-1/4"NPS-G1/4"--PN270-SSt

In the large Wagner Accessories Catalogue for wet coating you will also fi nd other material fi ttings.

70

23 4

5

B_03217

1

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

12.5 HOSES AND ELECTRIC CABLES

12.5.1 STANDARD HOSE SETS AND COMPONENTS

Order No. Designation

1 1 2339171 GM 5000EAC hose set (7.5 m)Consists of:

2 1 9984573 High-pressure hose-DN4-PN270-¼"NPS-7.5 m-PA3 1 2339152 Air hose complete (8.0 m)4 1 2339157 GM 5000E gun cable (10.0 m)5 7 m 3676437 Protection hose fabric PP30 (8.0 m)

Order No. Designation

1 1 2339172 GM 5000EAC hose set (10.0 m)Consists of:

2 1 2302374 High-pressure hose-DN4-PN270-¼"NPS-10.0 m-PA3 1 2339153 Air hose complete (10.5 m)4 1 2339158 GM 5000E gun cable (15.0 m)5 10.5 m 3676437 Protection hose fabric PP30 (10.5 m)

Order No. Designation

1 1 2339173 GM 5000EAC hose set (15.0 m)Consists of:

2 1 9984573-15 High-pressure hose-DN4-PN270-¼"NPS-15.0 m-PA3 1 2339154 Air hose complete (15.5 m)4 1 2339159 GM 5000E gun cable (20.0 m)5 15.5 m 3676437 Protection hose fabric PP30 (15.5 m)

Order No. Designation

1 1 2339174 GM 5000EAC hose set (20.0 m)Consists of:

2 1 9984573-20 High-pressure hose-DN4-PN270-¼"NPS-20.0 m-PA3 1 2339155 Air hose complete (20.5 m)4 1 2339160 GM 5000E gun cable (25.0 m)5 20.5 m 3676437 Protection hose fabric PP30 (20.5 m)

Note regarding the product hose:

- Nominal pressure 25 MPa; 250 bar; 3,626 psi- Internal diameter 4 mm; 0.16 inch- Inner hose material PA

71

A****B****

B_03849

1

23

A

BC

D

E

(**)

B_03845(*)(***)

123

(****)

OPERATING MANUAL

EDITION 07/2014 ORDER NUMBER DOC 2344500

Hose colors:

Product hose yellowAir hose blue

Dimensions: