TQM Unit 7, VTU Syallabus

-

date post

12-Sep-2014 -

Category

Education

-

view

1.587 -

download

0

description

Transcript of TQM Unit 7, VTU Syallabus

Quality Management System

Quality Management SystemProf. Raghavendran.VQMSThe International Organization for Standards (ISO) was founded in 1946 in Geneva, Switzerland. Its mandate is to promote the development of international standards to facilitate the exchange of goods & services worldwide. ISO is composed of 90+ countries, and US representative is American National Standards institute (ANSI)QMSISO technical committee published international standards in the year 1987. The standards are adopted in almost all countriesBenefits of ISO registrationThere are various reasons for implementing a quality that conforms to an ISO standard. The primary reason is that customers demand for compliance to a quality system. Other reasons are needed improvement in processes or systems and desire for global deployment of product & servicesSignificant improvement neededInternal quality is measured by %of scrap, rework & nonconformance at final inspection.Production reliability as measured by the number of breakdowns/month, time dedicated to emergencies and % of downtime/shift.External quality is measured by the customers of acceptanceISO 9000 series of standardsIt is generic in scope. By design, the series can be tailored to fit any organizations needs, whether it is large or small, a manufacturer or a service organization. It can be applied to construction, engineering, health care, legal and other professional services as well as the manufacturing of any form.ISO The three standards of the series are described briefly below,

ISO 9000:2000, QMS Fundamentals & Vocabulary: Establishes a starting point for understanding the standards and defines the fundamental terms and definition used in the ISO 9000 FamilyISOISO 9001:2000, QMS Requirement: ISO 9001, ISO 9002 and ISO 9003 in the old standards were integrated in ISO 9001:2000. The ISO 9000:2000 standard is used to assess a firms ability to meet customer and applicable regulatory requirement and thereby address customer satisfaction.ISOISO 9004:2000, Quality management systems guidelines for performance improvements: The standard provides guidance for continual improvement of a firms quality management system to benefit all parties through sustained customer satisfaction. ISOISO 9000 system is designed as a simple system that could be used by any industry, but specific industry have been developed quality systems and currently three quality systems are:

AS9100ISO/TS 16949TL 9000

10AS9100This systems is introduced for aerospace industry officially by the Society of Automotive Engineers in May 1997.

This development was an attempt to unify the requirement of NASA, DOD, and FAA.In march 2001, the International Aerospace Quality Group (IAQG) aligned with ISO9001:2000.ISO/TL 16949This standard is entitled Quality Systems Automotive Suppliers-Particular Requirements for the application of ISO 9001. It harmonizes the supplier quality requirements of US auto makers and approved by Asian automakers.TL 9000It will consolidate the various quality system requirements within telecommunications industry, it has 5layers and they areISO 9000 requirementsTL 9000 requirements(hardware, software & services)TL 9000 measurementsISO 9001 RequirementsThe standard has 8 clauses and they areScopeNormative referencesDefinitionQuality management systemsManagement responsibilityResource managementProduct/service realizationMeasurement analysis & Improvement

This is for the information onlyRequirements that organizations must meet

ISO 9001Scope: The purpose of the standard is for the organization to demonstrate its ability to provide a product that meet customer & regulatory requirements and achieves customer satisfaction.Normative reference: QMS that provides concepts & definitions.Terms & Conditions: Every parameters are explained. ISO 9001Quality Management System (QMS)4.1 General requirement4.2 Documentation4.2.1 General4.2.2 Quality manual4.2.3 Control of documents4.2.4 Control of records

ISO5 Management Responsibility5.1 Management Commitment5.2 Customers Focus5.3 Quality Policy5.4 Planning5.5 Responsibility, Authority & Communication5.5.1 Responsibility & Authority5.5.2 Management representative5.5.3 Internal communicationISO6 Resource Management6.1 Provision of resources6.2 Human resources6.3 Infrastructure6.4 Work environmentISO7 Product realization7.1 Planning of product7.2 Customer related process7.3 Design & Development7.4 Purchasing7.5 Production and service provision7.6 Control of monitoring & measuring devicesISO8 Measurement, Analysis & Improvement8.1 General8.2 Monitoring & measurement8.3 Control of nonconforming product8.4 Analysis of data8.5 Improvement

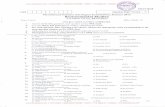

Implementation Top management commitmentAppoint the management representativeAwarenessAppoint an ImplementationTrainingTime scheduleSelect Element ownersReview the present SystemWrite the documentsInstall the new systemInternal AuditManagement reviewPre assessmentRegistrationDocumentationPolicyProcedureWork instructionsRecordsDocument development

Assignment Time: to be submitted by 16th Sept11Write briefly about Internal Auditing?Explain the procedure of Registration of Quality system?Elaborate the ISO14000 complete series?List the benefits of EMS?