TPO Material PDF - Western · PDF fileT P O R E P O R T WESTERN ROOFING – MAY/JUNE 2010...

Transcript of TPO Material PDF - Western · PDF fileT P O R E P O R T WESTERN ROOFING – MAY/JUNE 2010...

TP

OR

EP

OR

T

WESTERN ROOFING – MAY/JUNE 2010 55

Seven-Year TPO ReportAn Update on Western Sates Roofing Contractors Association’sTPO Weathering Farm ProjectThe following update describes highlights from some of the latest findings from WSRCA’s TPO Research and TestingProject, which WSRCA is conducting on four different TPO roofing membranes with the participation of three U. S.TPO roofing manufacturers.by: Chuck Chapman, WSRCA President; KC Barnhardt, WSRCA Low-Slope Committee Member; Jim Carlson, WSRCA Techni-cal Advisor; Ana H. Delgado and Ralph M. Paroli, National Research Council of Canada; Randy Ober, Carlisle; DwayneWacenske, Firestone; Steve Moskowitz, Dow Roofing Systems (Formerly Stevens); Michael Ludwig and Stephen Elliott, BuildingEnvelope Technology & Research’s Technical Research Associates and Jim Carlson, Building Envelope Technology & Research’sTechnical Director and WSRCA’s Technical Advisor.Brief Background:In a concerted effort to learn moreabout the weathering characteristicsof TPO (thermoplastic polyolefin) sin-gle ply roof membranes, WSRCAbegan an in situ testing program dur-ing the year 2000. The program con-sisted of what may be referred to asweathering farms utilizing four testroofs, each incorporating the samefour different TPO roofing mem-branes in order to study the effects ofreal-world weathering on TPO mem-branes in different Western UnitedStates climate regions. The mem-branes were installed in 2001/2002and have been periodically inspectedand tested. The most recent round ofinspections occurred in 2009 in whatis considered to be the seventh-year ofaging of these membranes. Note thatthe roofs were not all installed on the

same date and some have aged slight-ly longer (i.e., months) than others.

The Western States Roofing Con-tractors Association TPO Roof Mem-brane In-Situ Testing and ResearchProgram Protocol, created in 2000,states that the Project Purpose is to:

“Examine weathering characteris-tics of Thermoplastic Polyolefin(TPO) roof membranes by exposingthem to various weather conditionsof four distinctly different climaticregions in the Western UnitedStates.”

Test Roof Locations Represent theFour Different Climatic Areas of theWestern U.S.:

The test site locations were chosenbecause they represent four of themore diverse climatic regions of theWestern United States.

General Highlights:This TPO roofing research project

is now in its 8th (and in the case ofSeattle 9th) year of weathering (i.e., allroofs have aged for over seven years).Based on the visual field inspections,all of the roofs are generally perform-ing well, even in the rather harshexposure extremes at the differentsites. Each site presents uniqueweathering conditions. For example,the Anchorage, Alaska roof has expe-rienced low temperatures below -30°F, and weeks of being coveredwith snow and ice, to highs in the+80°F with sun; but not as much sunas the Las Vegas, Nevada site thatnormally has about 210 very intensesunny days per year and experiencesroof-top temperatures in excess of130°F. Seattle, although the climate isgenerally mild, experiences rain, somesnow, little hail, but numerous days

(Continued on Page 56)

TPO WEATHERING TEST ROOF IN LAS VEGAS, NEVADA.

TP

OR

EP

OR

T

WESTERN ROOFING – MAY/JUNE 201056

Seven-Year TPO Reportand nights during fall, winter andspring where temperature fluctua-tions result in freeze-thaw conditions,and summer temperatures into the90°s F. The San Antonio, Texas roof,in addition to many very sunny, hotdays has been subject to relativelysevere hail storms.

In general, all seams are perform-ing well. Contractors accompaniedthe task group during the inspec-

tions. Those seams that wereobserved to have unbonded wereeither re-welded during the inspec-tion or were scheduled to be repairedwithin the following week. Perfor-mance of these repairs and the weld-ing of the patches for the test cutsshow that after seven years of aging,these membranes can be effectivelywelded to. All roofs are presently

leak-free and these 60 mil, white TPOmembranes are so far showing goodin-service performance.

Generally, the project is progress-ing well, with cooperation from all,including:

The participating contractors:Snyder Roofing, Kyle King and

(Continued on Page 58)

(Continued from Page 55)

Figure 1. Test roof locations.The locales and climates are: Las Vegas, Nevada, generally Hot and Dry;San Antonio, Texas, generally Hot and Humid;Anchorage, Alaska, generally Cold and Damp;Seattle, Washington, generally Moderate with Wet and Dry periods.

Lighter. Stronger. Better.

UDL

UDL Plus™

BERGER BUILDING PRODUCTS, INC.

(800) 523-8852

TM

UD

Lig Stron.ghter Better.nger .r

BERGER BUILDING PRO

(800) 523-8852

ODUCTS, INC.

TM

TP

OR

EP

OR

T

WESTERN ROOFING – MAY/JUNE 201058

Seven-Year TPO ReportTim Gardner of Snohomish, Washington;RainProof Roofing, Curt Miller and Misty Stoddard ofAnchorage, Alaska;American Roofing, Eddie Spalten and Richard Higgs ofSan Antonio, Texas; andCommercial Roofers, Inc., Dennis Conway of LasVegas, Nevada

The participating manufacturers (in alphabetical order):Carlisle Syntec Inc., with project representative, RandyOber;Dow Roofing Systems, represented by Steve MoskowitzFirestone Building Products, represented by DwayneWacenske;GenFlex Roofing Systems, whom withdrew during2007; and

WSRCA’s TPO Task Group:KC Barnhardt, WSRCA Former PresidentChuck Chapman, WSRCA PresidentDon Fry, Associate, WSRCA Vice PresidentChristian Madsen, WSRCA Senior Vice PresidentMichael Ludwig and Stephen Elliott, Research Associ-ates and

Jim Carlson, WSRCA’s Technical AdvisorAlong with the skilled research personnel from theNational Research Council of Canada (Institute forResearch in Construction):Ana H. Delgado, Research Council Officer, BuildingEnvelope and Structure; andDr. Ralph M. Paroli, Director, Building Envelope andStructure.

Required Cooperation:The joint TPO Task Group continues to work together,

complementing each other by filling the voids in each oth-er’s knowledge and experience base. In this way the pro-ject has been kept on track in an unbiased manner. It isbelieved that this is the largest joint in-situ roof researchand testing project ever taken on publicly by the roofingcontractor sector of the industry, with approximately 470squares of roofing weathering in view of the entire NorthAmerican roofing industry.

This project is now entering the middle phase of thegenerally expected service life of a low-slope membraneroof system1, and the following is a brief recap of thefindings from the field and the laboratory.

Some Findings from the Field:Seam Integrity:

In general, all of the TPO membranes examined in thefield to date have proven to maintain their seam quality.

(Continued from Page 56)

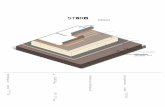

Figure 2. Roof Layout.On-Roof Weathering and Testing is Unbiased,All Materials Are Blind-labeled:The TPO membranes were blind labeled, andlaid out similarly in each of the four test roofs.

Photo 1. Depicts a void in the weld at T-seam covers. T-seam covers suchas this on Roof Area 1 of the San Antonio, Texas roof, are hand-welded, notrobotic welded.

Photo 2. Closer view of an open weld at T-seam covershown in previous photo.

TP

OR

EP

OR

T

WESTERN ROOFING – MAY/JUNE 2010 59

All hot-air welded seams, which are randomly probedduring the inspections, are proving to have great weldintegrity. A few isolated, small voids were found duringthe most recent round of inspections. (See Photos No. 1through 8.) A void was found in the weld at a T-seamcover on Roof Area 1, at the San Antonio, Texas site. Inaddition, a small void was observed at a field seam onSan Antonio Roof Area 3, at the transition point betweena hand-weld to a robotic weld, and at a hand-welded T-seam cover on that same Roof Area. A small void wasalso observed at a field seam on Seattle Roof Area 1 and ata penetration flashing boot on that same roof area.

These types of issues after 7 years appear to be relative-ly normal occurrences for single-ply roof membraneswhere there are hand-welded seams, and appear to beattributable to minor cold weld locations during applica-tion. A few other seam voids were observed, but weregenerally smaller than those depicted here. All roboticwelds probed thus far on all four of the test roofs werefound to be intact, except a few at the intersection where ahand-weld joined the start of a robotic weld.Membranes Continue to Tighten:

As observed during previous years’ field inspectionsand data collection, some tightening of the sheets, visibleat a few locations as slight bridging at roof-to-wall inter-sections and some roof-to-area divider transitions appearto have gradually increased. (See Photos No. 9 and 10.)The tightening observed has been similar to what theNorth American roofing industry has experienced overthe years with mechanically-attached single-ply roof

membranes, which can tighten as they age.Initially, and up through the first year of weathering,

some of the TPO membranes were somewhat loose orbaggy with some apparent wrinkling. The San Antonioroof, which was installed a bit differently than the others(by first welding adjacent sheets then installing themechanical fasteners), did not exhibit the fullness orlooseness that the other three roofs presented during theirfirst two or three years of service. It was noted that all ofthe roofs at their third-and fourth-year inspections, had

(Continued on Page 60)

Photo 3. Depicts a small void in a seam at the transitionpoint between the robotic welded field seam and the hand-

welded portion close to the area divider curb. This locationis on Roof Area 3 at the San Antonio site.

TP

OR

EP

OR

T

tightened and were then generallyquite smooth. The areas of minorbridging observed had been identi-fied and marked, and they were mon-itored as this research and testingproject progressed through its fifthyear. The site visit, which was con-ducted for the fourth year roof surveyat the San Antonio site, revealed thatno additional tightening appeared tohave occurred. However, the sev-enth-year inspection revealed slight,further tightening at a couple loca-tions. Photos 9 and 10 depict an areaof bridging membrane on San Anto-nio Roof Area 1, with marks appliedduring the most recent and two pre-vious inspections.

Walk Pads:The San Antonio test roof has a

significant amount of on-roof equip-ment where manufacturer suppliedwalk pads were installed to protectthe roof membrane from maintenancetraffic. As observed on Roof Areas 1and 2 of the San Antonio roof, walk

pads have degraded significantlysince the 2007 inspection. (See Pho-tos 11 through 14.) Walk pads onRoof Areas 3 and 4 appear to be inrelatively serviceable condition. (SeePhotos 15 through 18) However,instances of apparent walk padshrinkage were observed on RoofArea 3. (See Photos 16 and 17.) Theshrinkage is evidenced by the diago-nal wrinkles in the underlying roofmembrane on both sides of the walkpad caused by the walk pad pullingon the membrane. Some of the walkpad material on Roof Area 3 isinstalled in fairly long runs and it isthose longer sections where the

shrinkage is noticeable. Note that theSan Antonio roof is the only onewhere all four manufacturers’ walkpads are well represented. It shouldbe noted that new generation of walkpads by these manufacturers aremuch improved and are expected toprovide longer service than thosedepicted here.

Potential Effects ofHard Creases in Membrane:

A small surface crack through theupper portion (i.e., top coating) of themembrane was observed during theseventh-year inspection of Roof Area2 at the San Antonio, Texas roof. Thecrack occurred at a location where themembrane had originally been

Seven-Year TPO Report(Continued from Page 59)

Photo 5. Depicts asmall void in a

termination coverat Roof Area 3 ofthe San Antonio

site.

Photo 4. Close-up of small voidin seam shown in previous photo.

TP

OR

EP

OR

T

creased during installation. (See Pho-tos 19 and 20.) The red pointer in thephotos indicates the crack location.Red arrows added to the photo indi-cate the crease. Note that the crackwas repaired during the inspection.Note that at the time/era of thisinstallation, it was common for theapplicators to fold back the mem-brane and to crease it or to placeweight on the fold to hold the mem-brane back. Manufacturers recog-nized that this may cause problemswith TPO membranes and now dis-courage this practice.

Chalking:Roof membranes were checked

for chalking using the “black rag

test.” Dust, rain, and debris can addto roof surface composition, howev-er, this rag test showed minimalchalking or pickup on the cloth. Ithad been approximately three dayssince any significant rainfall. Veryslight chalking was detected at mostlocations tested. Slight chalking isan indication that some weatheringhas occurred, but the amountobserved appears minimal and to beexpected in TPO roof membranes ofthis age. Note that precipitation hadoccurred on April 16th, 17th and18th, with 0.11 inches falling on the16th, 0.76 inches on the 17th and 0.60inches on the 18th. A trace of precip-itation was recorded on the 19th andthe 20th and 21st were dry and sun-

ny, as was the day the test was per-formed.

Sealing of Cut Edges:On the Seattle, Washington Roof inRoof Area 1, sealant applied at cutedges of some patches and flashingsappears to be reaching the end of itsuseful service life and in a few loca-tions it has separated and failed. Thesealant appeared to be a type not rec-ommended for use as cut-edgesealant that was applied at a repairlocation. (See Photo 24.) The type offailure observed appears to be similarto typical urethane-based sealantaging. Urethanes tend to lose theirflexibility and elongation properties

(Continued on Page 62)

Photo 8. Close-up of void in weld at flashingcollar shown in previous photo.

Photo 7. Depicts a small void in the weldof a flashing collar flange at Roof Area 1 ofthe Seattle, Washington site.Note that flashingcollars arehand-welded.

Photo 6. Close-up of voidshown in previous photo.

Visit us in Booth “G” atWestern Roofing Expo 2010

TP

OR

EP

OR

T

WESTERN ROOFING – MAY/JUNE 201062

over time when exposed to naturalultraviolet radiation from the sun. Ithas been observed that these types ofsealants can begin to craze and sepa-rate after seven to ten years of serviceand require replacement. Failure ofthe sealant at cut edges may makethe exposed scrim at the edge suscep-tible to water absorption, whichcould lead to wicking and/or mem-brane damage. All purpose sealantsare not recommended for sealing cutedges. For this reason, it is recom-mended that the manufacturer’s cutedge sealant be used to seal all cutedges of the membrane that areexposed.

It should be noted that sealants onall roofing systems should be regu-larly inspected, maintained, andreplaced as needed.

If an alternate sealant choice orselection is desired when sealing cutedges, ensure it is approved for thisuse by the roof membrane manufac-turer.

Surface Characteristicsand Color or Hue:

A uniqueness that was previouslyobserved where the surface conditionof some of the TPO roof membranesheets appeared dirtier than others,apparently accumulating dust and airborne particulate differently thantheir neighboring sheets, appears tohave eased somewhat in the seventh-year, as the membrane surfaces nowappear to be generally cleaner thanthey were. This may be attributed toa change in the static charge of these

assemblies over time and/or achange in the physical surface condi-tions due to weathering. It was alsoconsidered that weather conditionsthat existed just prior to the inspec-tion, such as rain events could havehad a cleaning effect as well. There

are also basic differences in color andtexture of the membrane surfacesbetween the different manufacturer’ssheets that can account for variations

Seven-Year TPO Report

(Continued on Page 64)

(Continued from Page 61)

Photo 9. Depicts a roof-to-curb intersection at the edge of RoofArea 1 on the San Antonio test roof. This location has been observedin 2003, 2007, and again in 2009 during the seventh year inspection.Bridging of the membrane across the 90-degree roof-to-curb inter-section that was observed in 2003, had increased slightly by 2007and a bit more by 2009.

Photo 10. Closer view of locationdepicted in previous photo.

Photo 11. Depicts walkway paddegradation at Roof Area 1 of theSan Antonio, Texas roof. Thesurface of the pad is cracked atnumerous locations, likely due toultraviolet degradation from sunlight.

Photo 12. Close-up of crazecracks in walk pad shown inprevious photo.

Photo 15. Depicts walk pad on Roof Area 4 of theSan Antonio roof with Roof Area 3 in background.Roof Area 4 walk pads appeared to be in serviceablecondition at the seventh year of weathering.

Photo 16. Depicts walk pad on Roof Area 3 ofthe San Antonio roof that has shrunk and pulledon the underlying membrane as evidenced by thediagonal wrinkles on either side of the pad.

Photo 14. Close-up of splitsin walk pad shown inprevious photo.

Photo 13. Depicts walk pad at Roof Area 2 ofthe San Antonio roof. The walk pad material hascracked and split through at numerous locations.

TP

OR

EP

OR

T

WESTERN ROOFING – MAY/JUNE 201064

in dust and dirt accumulation as wellas slight, basic color differences, evenon clean membrane surfaces.

Photo No. 25 is from the Seattleroof during the fifth-year inspection.Photo 26 is from a nearby location onthe same roof during the seventh-year inspection. Both photos showRoof Area 1 on the left and Roof Area2 on the right. Note that in the 30days prior to the date of the fifth yearinspection; there was approximately3.16 inches total precipitation in theSeattle area, which was similar to pre-vious years. That rainfall was rela-tively evenly distributed over thattime period with the most rain in anyone day measured at 0.22 inches.Similar conditions existed prior to theseventh year inspection, with 3.53inches of precipitation in the 30 dayspreceding the inspection and thatwas also relatively evenly distributed

over that time period with the mostrain in any one day measured at 0.18inches.

Photo No. 27 is a close-up ofunexposed membrane samples forRoof Areas 1 and 2, compared sideby side, with Area 1 membrane onthe left and Area 2 membrane on theright. Area 2 membrane appearsrougher and of a slightly darkershade. Photos 28 and 29 show com-parisons between unexposed Area 1membrane and unexposed Areas 3and 4 membranes respectively. Eachunexposed membrane sample has itsown uniqueness in color as well assurface texture. Note that the unex-posed samples were taken from newrolls during original installation ofthe membranes and have beenstored at Building Envelope Tech-nology & Research’s office. Similarsamples are also stored at the offices

of Ralph Paroli and Ana Delgado atNRC and used for their comparisontests.

Solar Reflectivity:Reflectivity measurements were

obtained on the roofs during thethird- and fifth-year inspections.Solar reflectivity measurements wereconducted on both the uncleaned andcleaned weathered areas. (See Pho-tos No. 30 and 31.) A comparison oftwo common cleaning methods weretested: Areas were wetted, scrubbedwith stiff-bristle push brooms orlong-handled brushes using a milddetergent and water solution, thenrinsed, along with a side-by-sidecomparison of pressure rins-ing/“washing.” In nearly all cases,the carefully scrubbed areas pro-duced a visually cleaner and a slight-ly more reflective surface.

However, even before cleaning, allof the TPO roofs far surpassed thereflectivity standard that has been setfor three year old roof membranes byENERGY STAR®. At all of the testroof areas, solar reflectivity improvedafter cleaning, but not as much as onewould have thought by looking atthe cleaned areas next to weatheredareas of the membrane. This is dueto the fact that 58% of the reflectivitycomponent occurs in the non-visibleportion of the solar spectrum.

This suggests that a roofing con-

Seven-Year TPO Report(Continued from Page 62)

Photo 17. Depicts anotherwalk pad on Roof Area 3

that has shrunk.

Photo 18. Close-up of thesurface of a Roof Area 3 walkpad reveals the material to bein serviceable condition other

than the shrinkage issue.

Photo 21. Depicts the black, cotton cloth/ragand the test area for the black rag test on Roof

Area 4 of the San Antonio Roof. Photo taken onApril 22, 2009.

Photo 22. Close-up of clothafter test showing whitish dustwhere it was rubbed on thesurface of the membrane.

Photo 19. Depicts location on Roof Area 2 at theSan Antonio, Texas roof where a surface crack wasobserved at previously creased portion of themembrane.

Photo 20. Close-up of location shown inprevious photo depicting the small crack through

the top coating of the membrane and thecrease that continues on either side

of the crack.

Photo 23. Depicts typicalcut-edge sealant installed onRoof Area 3 of the Seattle,Washington roof.

Photo 24. Depicts missing sealant previouslyinstalled at the cut-edge of a patch on Roof Area 1of the Seattle roof. This sealant does not appear tobe the manufacturer’s cut-edge sealant. An all pur-pose polyurethane sealant may have been used atthis location.

TP

OR

EP

OR

T

WESTERN ROOFING – MAY/JUNE 2010 65

tractor can install a TPO roof in areasof the country that have a standardfor reflectivity, and he/she can beassured that under normal exposureconditions it will continue to meet the

current reflectivity standard after atleast three years of weathering(depending on local conditions).

Reflectivity was not examined dur-ing the seventh-year inspections,however, it was noted that the mem-

brane surfaces appeared generallycleaner and lighter than they had atprevious inspections and we suspectthat reflectivity continues to meet orexceed the three year ENERGYSTAR® standard, although there iscurrently no standard or requirementfor reflectivity beyond the three-yearmark.

Some Highlights of theLaboratory Testing Results:

Each of these four TPO mem-branes is quite different, visually notwo are alike, not only in their surfacetexture and reinforcement profiletelegraphing through the surface, butperhaps even their chemical make-upand compounding. However, follow-ing are some of the more interestinglaboratory results.

Overall Thickness:One of the tests performed is a

measurement of the overall thicknessof the membrane. All membraneswere approximately 0.060 inches or“60 mils” nominal thickness wheninitially installed. To monitor poten-tial changes, we measured samples ofthe test cuts in the laboratory. So far,the overall mil thickness of the sheetshas varied a bit, as they continue toweather in the diverse climates. Mea-surements have been recordedgreater than 0.060 inches, and othersless than the specified as-new thick-ness. Thickness measurements areillustrated in Figure 4.

The variations in thickness mea-

surements are thought to be due tovariations in the manufacturingprocess and the sampling procedures.However, these variations are withinthe tolerances for overall thickness asspecified in ASTM 6878, Standard

(Continued on Page 66)

Photo 25. Depicts Roof Areas 1 and 2 of theSeattle, Washington test roof. Photo taken onFebruary 9, 2005 during the third year inspection.Note the beige color of the Roof Area 2 membraneon the right side of the photo, due to airborne dirtand dust accumulation.

Photo 26. Another view of Roof Areas 1 and 2 ofthe Seattle roof taken on March 17th, 2008, duringthe seventh year inspection. Roof membranesappear generally cleaner in this photo, with theexception of what appearsto be some algae growthalong the roof-to-curbintersection of RoofArea 1, on the leftside of the areadivider curb shownin the center ofthe photo.

Photo 27. Depicts unexposed TPO membranesamples from the new membrane rolls in 2001that were installed on the Seattle, Washington testroof. The sample on the left is from the materialinstalled on Roof Area 1 and the sample on theright if from the material that was installed on RoofArea 2.

Photo 28. Depicts an unexposed sample fromthe material that was installed on Roof Area 3 onthe right side of the photo compared to the RoofArea 1 unexposed sample on the left.

Photo 29. Depicts an unexposed sample fromthe material that was installed on Roof Area 4 onthe right side of the photo compared to the RoofArea 1 unexposed sample on the left.

TP

OR

EP

OR

T

WESTERN ROOFING – MAY/JUNE 201066

Specification for Thermoplastic Poly-olefin Based Sheet Roofing. Thisstandard provides minimum valuesand tolerances for new TPO roofingmembranes.Thickness of the TPO Membrane/Coating Over the ScrimReinforcing:

The thickness of the coating overthe scrim reinforcing of the samples

measured during the seventh-yearinspections do not show a definitivetrend toward loss of material. Over-all thicknesses changed only slightlyor remained the same since the lasttests were run in 2007 for the fifth-year inspections. Two notablechanges in thickness over the scrimwere observed, one in the sampletaken from Roof Area 3 of the Seattlesite and one from Roof Area 1 of the

San Antonio site.Microscopic examination of the

Seattle sample in Building EnvelopeTechnology & Research’s laboratoryfound that at this particular locationthe membrane had a thicker bottomlayer than that observed in previoussamples. (See microscopy imagecomparison in Photo 32.) The layerabove the scrim was indeed thinnerthan measured on previous samples,but with the fact that the under layeris thicker came the thought that thethinness above the scrim may be ananomaly created during the manufac-ture of the membrane rather thandefinitive indication of a loss of mate-rial due to weathering.

Examination of the San Antoniosamples shows the thickness overscrim to be slightly less on the sev-

enth-year weathered sample than onthe unexposed sample. However, inthe portion of the sample observed,the scrim appeared to be somewhathigh within the weathering layer,

and again the measurement may beindicating a variation in how thesheet was manufactured rather thanevidence of thickness loss due toweathering. In all the comparativemicroscopic review, only the SeattleRoof Area 3 measurement fell belowthe ASTM standard of 12 mils overthe scrim after 7 years of weathering.It should be noted that test cuts are

Seven-Year TPO Report(Continued from Page 65)

Photo 30. Depicts one of thesolar reflectivity test locations onthe Las Vegas test roof,Roof Area 4, which are identifiedby steel washers with a small pieceof construction tape attached,positioned randomly, thatwas also pressure washedfor the re-testing of solar reflectivityafter pressure washing.

Photo 31. Depicts the solar reflectivity test areaon the Las Vegas test roof, Roof Area 4 that wasre-tested for solar reflectivity after hand scrubbing.

TP

OR

EP

OR

T

WESTERN ROOFING – MAY/JUNE 2010 67

taken from different areas of the testroofs, and the initial sheet thicknesscan vary from one location to anoth-er, which can affect the reported mea-surements/readings. This particular

finding may represent a manufactur-ing anomaly limited to just the por-tion of the membrane.

Photo 32 was taken in BET&R’slaboratory with a digital camera

through a Leica microscope andshows a comparison betweenexposed and unexposed membranefor Roof Area 3 in Seattle. The

(Continued on Page 68)

Figure 3. Solar reflectivity, through year 3.

TP

OR

EP

OR

T

WESTERN ROOFING – MAY/JUNE 201068

exposed membrane is on top and theunexposed is on the bottom. Notethe difference in thickness of thedark material below the scrim. Theunexposed membrane shows thedark and light material approxi-mately the same thickness, whereasthe exposed membrane shows avery thick layer of the dark materialand a quite thin layer of the white(i.e., weathering grade) material,which is the top, weathering surfaceof the membrane. The microscope’sreticule appeared out of focus andhas been drawn over in this photoand shows a rule marked in mil-

limeters. Both mem-brane samples measurea little less than 1.5 mil-limeters thick (approxi-mately 58 mils).

It may be important tonote that even thoughthicknesses have differedfrom some of the mem-brane test cuts, the mea-surements, with the oneexception, fall within theASTM standard, D6878-03. 2 (See Figure 5).However, note that this standard is notspecific to thicker TPOs such as the 60

mil products. This WSRCA TPO TaskGroup and WSRCA’s Low-Slope Com-mittee recommend that the ASTM con-sider changing this standard to pro-vide different classifications for eachproduct thickness category.

The charts in Figure 6 show a com-parison between overall thicknessand thickness over scrim with arrowsadded to indicate Roof Area 3’s sev-enth year data at the Seattle site.

Linear DimensionalStability Changes:

The membrane samples were mea-sured for linear dimensional stability

Seven-Year TPO Report(Continued from Page 67)

Figure 4. Overall Thickness

Photo 32. Photo taken through microscope. The microscope was set at15X magnification. However, the actual scale changes depending on thesize of the printed image. Therefore the scale can be determined by themillimeter reticule scale used in the image.

TP

OR

EP

OR

T

WESTERN ROOFING – MAY/JUNE 2010 69

changes in the first, third, fifth andthe seventh year. After small changeswere observed in the first year, thelinear dimensional stability in boththe machine direction and the crossdirection appears generally unch-anged.

Water Absorption:Another test that is being run with

each of the membrane test cuts is thewater absorption test. Research car-ried out on a separate project indi-cated a correlation between thelongevity of some roofing mem-branes and their degradation withage and tendency to absorb morewater overtime. A working theory isthat the higher the water absorption,the potentially more likely it is that

the membrane is yielding to theeffects of weathering and the surfaceis degrading.

The results of the latest round oftesting for water absorption indicatethat the weather surface of the sam-ples remains resistant to waterabsorption after seven years expo-sure.

Breaking Strength:The breaking strength was tested

on the membrane samples taken dur-ing the seventh year’s inspections. Ingeneral, there was no significant dif-ference between the unexposed mem-brane and that from the seven yearsof service in the field. It appears thatso far, exposure has not affected thebreaking strength of the membrane at

the locations tested. Test results forbreaking strength are illustrated inFigures 7 and 8.

ASTM D6878 specifies the GrabMethod for measuring the breakingstrength and elongation of TPO roof-ing membranes. However, due to thelimited size of the samples that werecollected for this project, the GrabMethod could not be used. In itsplace, a Strip Method was used. Thevalues from the Strip Method shouldnot be correlated to the Grab Method.

Elongation at Break:Membrane samples were tested

for elongation at break both at thefifth-year and the seventh-yearinvestigation. Elongation at break of

(Continued on Page 70)

Figure 6. Comparison of thickness overall and thickness over scrim.

Figure 5: Thickness, coating over scrim.

TP

OR

EP

OR

T

WESTERN ROOFING – MAY/JUNE 201070

0

200

400

600

800

1000

1200

LV1 LV2 LV3 LV4

Bre

akin

gS

tren

gth

(N)

0

50

100

150

200

250

Bre

akin

gS

tren

gth

(lb

f)

MD

Ex

po

sed

7− −Y

rs

Ex

po

sed

1− −Y

r

Ex

po

sed

5− −Y

rsE

xp

ose

d3

− −Yrs

Un

exp

ose

d

800

1000

1200

)N(

htg

MD200

250

)fbl(

ht

dd

0

200

400

600

800gn

ertS

gni

ka

erB

deU

so

pxe

nUU

ddde

p

d11

p

LVVL 1 LVVL 2 LVVL 3

deeesssooo

pppE

xE

xE

x777

s−−

ssrrrYYY

ddeessoo

pp

d

Ex

Ex

−Yr

−Yr

eso

pE

5d−−Y

Y rsdee5

e dssss dooo

pppE

xE

xE

x33

Ex

3s

−s

−srrr

YYYY

LVVL 4

0

50

100

150

tg

nert

Sg

nik

aer

B

XD

0

200

400

600

800

1000

1200

LV1 LV2 LV3 LV4

Bre

ak

ing

Str

en

gth

(N)

0

50

100

150

200

250

Bre

ak

ing

Str

en

gth

(lb

f)

Ex

po

sed

7−− Y

rs

Ex

po

sed

1−−Y

r

Ex

po

sed

5− −Y

rsE

xp

ose

d3

− −Yrs

Un

exp

ose

d

800

1000

1200

th(N

) XD200

250

en

gth

(lb

f)

dd dd

p

1d

0

200

400

600

800

LV1

Bre

ak

ing

Str

en

gt

deso

pE

x−−Y

r

E5

Ydeeeessss

oooopppp

Ex

Ex

Ex

Ex

3333sss

−srrrr

YYYY

eso

pxe

nU

dddp

1 LV2 LV3

deeesssooo

pppE

xE

xE

x777

s−

ssrrrYYY

pes

op

Ex

5−−Y

rs

LV4

0

50

100

150

Bre

ak

ing

Str

e

0

200

400

600

800

1000

1200

AK1 AK2 AK3 AK4

Bre

akin

gS

tren

gth

(N)

0

50

100

150

200

250

Bre

akin

gS

tren

gth

(lb

f)

MD

Ex

po

sed

7− −Y

rs

Ex

po

sed

1− −Y

r

Ex

po

sed

5− −Y

rsE

xp

ose

d3

− −Yrs

Un

exp

ose

d

1200MD

250

d

0

200

400

600

800

1000)N(

htg

nert

Sg

nik

aer

B

eso

pxe

nU

ppd 1 d

pd

p

pdes

opp

Ex

7−−

srY

p

deso

pE

x−−Y

r

eso

pE

x5

−−Yrs

pes

op

Ex

3−−

srY

eso

pxe

nU

0

50

100

150

200

)fbl(

htg

nert

Sg

nik

aer

B

0

AK1 AK22K AK33K AK44K

0 0

200

400

600

800

1000

1200

AK1 AK2 AK3 AK4

Bre

ak

ing

Str

en

gth

(N)

0

50

100

150

200

250

Bre

ak

ing

Str

en

gth

(lb

f)XD

Ex

po

sed

7− −Y

rs

Ex

po

sed

1− −Y

r

Ex

po

sed

5− −Y

rsE

xp

ose

d3

− −Yrs

Un

exp

ose

d

1200XD

250

f)

dd 1

d dd

0

200

400

600

800

1000

Bre

ak

ing

Str

en

gth

(N)

deso

pE

x−−Y

r

E5

Ydeeesss

oooppp

Ex

Ex

Ex

333−

ss−

srrrYYY

eU

so

pxe

nU

pd

pdes

opp

7−−

srY

pes

op

Ex

Ex

5−−Y

rs

0

50

100

150

200

Bre

ak

ing

Str

en

gth

(lb

f

0

AK11 AK2 AK3 AK4

0

all seventh-year samples wasbetween 22% and 35% in both direc-tions using the Strip Method. Slightchanges have been detected but it

should be noted that these are mini-mal, are considered insignificant anddo not affect membrane perfor-mance.

Glass Transition Temperature:The unexposed membrane sam-

ples were tested in the lab as well asfield-exposed samples from the third-, fifth-, and seventh-year inspectionsfor all four regions and all four roofareas of each region for their glass

Seven-Year TPO Report(Continued from Page 69)

Figure 7. Breaking strength for 0-7-years for AK and LV samples – MD and XD.

Figure 8. Breaking strength between 0- and 7-years for SEA and TX samples – MD and XD.

TP

OR

EP

OR

T

WESTERN ROOFING – MAY/JUNE 2010 71

transition temperature. Note that theunexposed samples were taken fromnew rolls in 2001/2002 at the time ofinstallation and have been stored inthe lab to be used for comparisonstudies. The glass transition tempera-ture is the temperature at which thepolymers in the membrane can nolonger move relative to each otherand this creates a condition resultingin brittleness and breakage if themembrane is bent.

In general, the tests show the glasstransition temperature rising, but byonly 1 or 2 degrees Celsius from thatwhich the membranes had whencompared to the initial data; and ingeneral, this change had occurred bythe first year’s inspection and hasremained relatively steady since. Thetest has a tolerance of +/- 2 degrees

Celsius and so these minor changesappear to be insignificant. Glass tran-sition temperature will continue to betested and monitored in future at theten-year inspection. Results of theseventh-year glass transition testingare summarized in Figure 9.

Other Items of Note:A tactile examination reveals a

detectable difference in the seventh-year samples from San Antonio and

Las Vegas Roof Areas 1 and 2 as com-pared to the unexposed samples, pre-vious years’ samples and even ascompared to the seventh-year sam-ples from Seattle and Anchorage RoofAreas 1 and 2. The samples from San

Antonio and Las Vegas feel some-what harder and stiffer, likely indi-cating there are slight changes occur-ring due to the warmer climates’temperature, sun and heat loading. Itmay be that changes are occurring toall of the membranes but they arenoticeable on Roof Areas 1 and 2 inthe hotter climate regions. However,the changes seem slight and do notappear to represent any sort of fail-ure.

Hailstone Impact:When the inspection team arrived

in San Antonio for the seventh-yearroof survey, there had reportedlybeen relatively recent hail storms inthe area. Once on the roof, evidenceof hail having impacted the roof wasobserved. Don Frye, a WSRCAboard member and Texas roofingcontractor, who accompanied theinspection team, reported that manyroofs in the area had been badlydamaged by hail, and was surprisedto see this TPO roof undamaged.For instance, light-colored spotsapproximately 1/4 to 3/4 inch indiameter were observed throughoutthe membrane’s surface and closerexamination revealed the light spotsto be areas where there was less dirtand dust accumulation. (See Photos34 and 35.) The theory is that hail-stone impact had “blasted” away thecoating of dirt and dust in thesespots. Other evidence of hail wasalso observed as dented cooling fansat on-roof HVAC units. (See Photo36.) Note: Historically, for hail

impacts on low-slope roofing mem-branes, the size of the marks left athail impact sites are generally small-er than the hail stone itself, thereforeit can be assumed that hailstoneslarger than 3/4 inch in diameterwere among those that impacted thisroof.

Membrane test cut samples includ-ing some of the white spots wereremoved from the roof and sent fortesting to NRC-CNRC. In the labora-tory the samples were observed andphotographed through a scanningelectron microscope. Then the sam-ples were cleaned and observed, andphotographed through the micro-scope again. The surface of the mem-brane within the white spot areaappeared somewhat smoother thanthat outside the white spotted areasindicating hail impact may haveslightly compressed the materialupon the hail’s impact.

Micro cracks were observed insome of the images but the crackswere reported by laboratory person-nel to be very minute, ranging from 2to 4 micrometers (µm). For a per-spective on how small this is, notethat the average width of a humanhair is reported to be approximately80 µm. Photo 37 is a scanning elec-tron microscopy image copied fromNRC-CNRC’s draft report depictingan area within one of the white spotson a membrane sample from SanAntonio Roof Area 3 after cleaning.Note the scale at the lower right ofthe image marks off 10 µm.

(Continued on Page 72)

Figure 9. Changes in glass transition temperature (DTg) of TPO samples.

Photo 33. Depicts white spots caused by hailimpact displacing dust and dirt on the surface ofthe TPO membrane at Roof Area 1 of the San Anto-nio test roof.

Photo 34. Depicts one of the spots viewedthrough a magnifying lens.

TP

OR

EP

OR

T

WESTERN ROOFING – MAY/JUNE 201072

Seven-Year TPO ReportIt appears that the membrane was

undamaged by the hail impacts.

Recommendations:Bridging/Tightening:

The WSRCA TPO Task Group hasdecided to continue to monitor thisitem.

Walk Pads:The failed walk pads are no longer

properly protecting the underlyingmembrane and should be replaced.Unfortunately replacement willrequire cutting and patching the

underlying roof membrane. Pleasenote: The participating manufactur-ers have made changes to their walkpad composition and design sincethis study was started. Reportedly,longer service life and stability can beexpected from the newer walk pads.

The roof walkway pads installedon Roof Area 3, which have clearlyshrunk and impinged strain onto theunderlying membrane, should also bereplaced, and again this must includecutting and patching the underlyingmembrane. It was observed that thiswalk pad material is darker than theroofing membrane and this may be

contributing to the problem by allow-ing the walk pads to gain higher on-roof temperatures. The problemseems to be exacerbated where it isinstalled in long runs. However, awalk pad needs to be able to performwell, regardless of the length of walk-way that is required.

Cut-Edge Sealant:Sealant installed at cut-edges

should be repaired where it hasdegraded, eroded, is missing or hasfailed as observed on Roof Area 1 ofthe Seattle, Washington test roof.Sealant should be replaced with themanufacturer’s supplied cut-edgesealant.

Conclusion:The WSRCA TPO Roof Research

and Test Project results have beenpresented in great detail over theyears, in written form, and duringthree different WSRCA annual Con-ventions/Expositions. The facts havebeen provided as the Task Group haslearned more about these four exam-

(Continued on Page 74)

(Continued from Page 71)

Photo 36. Scanning electronmicroscopy of TPO membraneat one of the white spot locations.

Photo 35. Depicts roof-top equipment at RoofArea 1 of the San Antonio roof exhibiting hail dam-age in the form of dented cooling fins.

CCAALLIIFFOORRNNIIAA CCOONNTTRRAACCTTOORRSSDDiidd yyoouu kknnooww tthhaatt yyoouu ccaann ssaavvee uupp ttoo 66%% ooffff tthhee ccoosstt ooff wwoorrkkeerrss’’ ccoommppeennssaattiioonn

iinnssuurraannccee tthhrroouugghh RRCCAACC’’ss ggrroouupp ddiissccoouunntt pprrooggrraamm aatt SSttaattee FFuunndd??Qualifying members of the Roofing Contractors Association ofCalifornia (RCAC) are eligible for direct savings on workers’comp insurance. In addition to a 6% premium discount,individual and group dividends are often awarded. You caneven use your own broker! For more information on RCACmembership or insurance savings with State Fund Group #639, call RCAC at 916-456-4790.CCuurrrreenntt GGrroouupp 663399 mmeemmbbeerrss –– ddoonn’’tt ffoorrggeett,,

AApprriill rreenneewwaallss aarree rriigghhtt aarroouunndd tthhee ccoorrnneerr.. EEnnssuurree yyoouurr ggrroouupp ssaavviinnggss bbyy rreenneewwiinngg yyoouurr ppoolliiccyy iinn GGrroouupp 663399!!

RRooooffiinngg CCoonnttrraaccttoorrss AAssssoocciiaattiioonn ooff CCaalliiffoorrnniiaawwwwww..rrccaaccaall..ccoomm ((991166)) 445566--44779900

6% OFFWorkers

Comp!

TP

O R

EP

OR

T

WESTERN ROOFING – MAY/JUNE 201074

Seven-Year TPO Reportple 60 mil white TPO roof mem-branes. All physical properties andvisual observations will continue tobe observed by the WSRCA TPOTask Group. WSRCA believes theseitems and others are important to bemonitored.

WSRCA’s Low-Slope Committee,the assigned TPO Task Group, andWSRCA in general intend to continuemonitoring the findings from thefield and the laboratory testing —through the next round of test cutsand testing, which will be done afterthe 10th year of the project.

After seven years of service, themembranes at all Roof Areas appearto be weathering quite well on thefour WSRCA TPO Weathering Farmtest sites. This suggests that whenTPO roofing is considered for a pro-ject, that white, 60 mil TPO mem-branes are a reasonable alternative toother single-ply roof membrane sys-tems. WSRCA will continue to moni-tor and inspect these roofs and report

the findings with another round ofinspections scheduled for 2011, afterthe 10th year of weathering.

One of the problematic issues,brought to light during this study,has been the lack of ASTM standardsfor single-ply roofing membranesrelating to the varying thicknesses ofthe roofing membranes available onthe market. WSRCA’s Low-SlopeCommittee recommends that theASTM standards be refined to addclassifications related to membranethicknesses [e.g., 45, 60 and 80, etc.],including standards for thicknessover scrim, and perhaps include aseries of simple physical data or per-formance values, which may relate toweathering and aging, so roofingindustry professionals can better esti-mate expected service life of roofingmembranes.

WSRCA believes that the measure-ment of thickness over scrim is criti-cal to the expected life of the mem-brane. Each gauge or thickness of

reinforced single ply membraneshould have a different standard nota single standard covering all thick-nesses such as exists today.

WSRCA welcomes others to con-duct similar full-scale roofing andwaterproofing research. It should benoted that, to the best of our knowl-edge, no other roofing material hasundergone such an independent, thor-ough, and long-term full-scale studyas WSRCA has diligently conductedhere with TPO. WSRCA continues toencourage membership in the Associ-ation, and welcomes new members, sothis and other important roofing andwaterproofing research can be funded,progress in an unbiased fashion, forthe benefit of the Western roofing andwaterproofing community as well asthe industry at large. 1 Carl G. Cash, “The Relative Durability of Low-SlopeRoofing,” Proceedings from The Fourth InternationalSymposium on Roofing Technology (1997): 1192 As noted in the original article, ASTM 6878 was notyet finalized at the time the test roofs were installed,but shortly there after it was, as ASTM 6878-03.Subsequent revisions to ASTM D6878 in 2006 and2008 did not change the specification for thickness ofthe coating over scrim or overall thickness.

(Continued from Page 72)

Acme Cone Company strives to offer the best and most comprehensive lineof accessories on the market today. We can also customize practically any dimension for your needs.

Our advantage is that our accessoriesare designed by roofers for roofers and have gone through stringent fieldtesting and revision. This gives us the field tested edge our competitorscan't match.

Toll-Free: (866) 516-4079Fax: (541) 461-0806www.acmecone.com

Email: [email protected]

YYoouurr OOnnee--SSttoopp SSoouurrccee ffoorrTTPPOO && PPVVCC

SSiinnggllee--PPllyy AAcccceessssoorriieess