Total Synthesis of Ketamine

-

Upload

hoffman-lysergic -

Category

Documents

-

view

2.725 -

download

59

Transcript of Total Synthesis of Ketamine

Total Synthesis of Ketamine

1110

Total Synthesis of Ketamine

[Type the document subtitle]

[Type the abstract of the document here. The abstract is typically a short summary of the contents of the document. Type the abstract of the document here. The abstract is typically a short summary of the contents of the document.]

Total Synthesis of Ketamine

While theres 11 steps in the synthesis, its longitude is explained by the fact that all the precursors and even some reagents are made from scratch, employing user-friendly techniques and equipment (in fact, a need for vacuum is mentioned only once, and even that is for the removal of solvent); as well as only easy-to-get reactants.

Still the synth is obviously for the skilled only; for one thing, it involves making a Grignard. There is a potential possibility to use zinc organic compounds instead (discussed in detail below) which is much cheaper and easier technically.

Also there is added an alternate preparation of o-chlorobenzonitrile Experimental sodium nitrite

Sodium nitrate is also synthesized industrially by neutralizing nitric acid with soda ash2 HNO3 + Na2CO3 2 NaNO3 + H2O + CO2

nitric acid HNO3 Molar mass 63.01 g mol1 / Density 1.5129 g cm3

soda ash Molar mass 105.9784 g/mol (anhydrous) 124.00 g/mol (monohydrate) 286.14 g/mol (decahydrate)

Density 2.54 g/cm3 (anhydrous) 2.25 g/cm3 (monohydrate) 1.51 g/cm3 (heptahydrate)1.46 g/cm3 (decahydrate)

756 GRAMS (498 ML,S) NITRIC ACID HNO3

636 GRAMS (246 ML,S) SODIUM CARBONATE (SODA ASH)

.

1. o-Chlorobenzoic acid Anthranilic acid 13,7g HCl (conc., d=1,19)

NaNO2 8g ( sodium nitrite) CuCl 10g (Copper Chlorides)13,7 grams anthranilic acid is stirred in a glass beaker in 40ml,s destiled water, 28ml,s hydrochloric acid HCl and 20 grams ice. With constant stirring and cooling there's added 8 grams sodium nitrite NaNO2 in 40ml,ss water. Thus obtained clear solution of diazonium salt is very slowly added with stirring into a soln. of 10 grams copper chloride CuCl in 25 grams hydrochloric acid HCl conc. A vigorous evolution of nitrogen is observed.

When the rxn ends, the ppt is filtered, washed with cold water and reprecipitated from aq. Sodium carbonate Na2CO3. The product represents fine crystals and melts at 140-141C.

o-Bromobenzoic acid can be obtained in an analogous manner, substituting copper chloride CuCl for CuBr.CuBr (ver)

Preparation of Copper Chlorides

I prepared cuprous chloride by mixing copper wire, CuCO3 and a excess of

commercial 20 % hydrochloric acid HCl and warming it near boiling point until all copper was dissolved. It was the deposition of a white powder (cuprous chloride). This product can't be dried because it oxydizes quickly, it was washed with water.

Normal reaction is with copper wire or powder, cupric chloride CuCl2 and hydrochloric acid HCl, but I had then CuCO3.CuCO3 (ver)

Also cupric chloride was prepared by reacting a solution of CuCO3 with an

slightly excess of hydrochloric acid HCl, then evaporating water and finally, when product starts to turn brown, air dried to give a hydrate form.copper wireCuCO320 % hydrochloric acid HCl solution--------------------------------------------------------------------------- 2. o-ChlorobenzonitrilePreparation A. (RCOO)2Zn + Pb(SCN)2 = 2 RCN + ZnS + PbS + 2 CO2The best results are obtained when a zinc salt is employed instead of free acid. This rxn is unsuitable for amino-, nitro- and oxy- acids, but can bee used for bromo- and chlorobenzoic acids.

To a hot soln of 50 grams sodium hydroxide NaOH in 400ml,s water there's added 195 grams o-chlorobenzoic acid. Carefully neutralize with ammonium hydroxide NH3 or sodium bicarbonate NaHCO3 and add with heating 105 grams (~5% excess) zinc sulphate ZnSO4 in 400 ml,s destiled water. The precipitated salt is dried for prolonged time at 200C and mixed intimately with 205 grams (Lead(II) thiocyanate) Pb(SCN)2. The mixture is coffee ground and dried at 120-140C for a prolonged time, then heated on open flame - the mixture melts and gases are evolved.

Distilled nitrile is treated with hydroxide de ammonia NH4OH, steam-distilled and salted out. Yield 137 grams (80%), mp 43-46C, bp 232C. The rxn usually takes place within 30-60 mins, but the duration of dryings makes the method quite time-consuming.

Preparation B.This one doesn't require a prolonged drying. Sulfaminic acid is dirt cheap and can be acquired without causing any suspicion...

Electrowinning processing leaches zinc from the ore concentrate by sulfuric acid:[81] ZnO + H2SO4 ZnSO4 + H2O

............................................................................................................................................. o-Bromobenzonitrile50 grams o-Bromobenzamide and 35 grams (25 grams =theory) sulfaminic (sulfamic) acid is thoroughly mixed and heated in a Wurtz flask. At 250-255C distillation begins, which is over at 285-295C (takes approx. 1.5-2 hrs). The collected product is redistilled, yield 36 grams (80% of theory). mp 53-57C, bp 251-253C

As I found recently, this can bee simplified yet more, by forming benzamides in situ from the corresponding acid and urea..but since this is a very good route to substd benzaldehydes from benzoic acids, Ill post it later separately...

ADIPIC ACID

Into a 3-litre three-necked flask, fitted with a dropping funnel, a mechanical stirrer (1) and a long reflux condenser, place 1900 ml. (2700 g.) of concentrated nitric acid, sp. gr. 1-42. Since oxides of nitrogen are evolved in the subsequent oxidation, the reaction should be carried out in a fume cupboard, or the oxides of nitrogen are led by a tube from the top of the condenser to a water trap (Fig.//, 8, l,c). Heat the nitric acid to boiling, set the stirrer in motion, add a few drops of ciclohexanol and make certain that these are acted upon by the acid before adding more ; an explosion may result if cyclohexanol is allowed to accumulate in the acid. Once the reaction has started, add 500 g. of cyclohexanol through the dropping funnel at such a rate that all is introduced in 4-5 hours ; if the addition of the secondary alcohol is too slow, the corks (2), which are attacked by nitrous fumes, may have to be replaced before the operation is complete. Keep the reaction mixture at the boiling point during the addition of the cyclohexanol and for a further period of about 15 minutes in order to complete the oxidation. Pour the warm reaction mixture into a beaker ; upon cooling, the adipic acid crystallises.

Filter on a large sintered glass funnel, and wash with 200 ml. of cold

water. Recrystallise the crude acid from 700 ml. of concentrated nitric

acid ; filter and wash as above. The yield of recrystallised adipic acid,

m.p. 152, is 400 g. (3).

2700 grams concentrated nitric acid

500 grams cyclohexanol

200 ml,s destiled water.

700 ml,s concentrated nitric acid

.. 3. Cyclopentanone100 grams adipic acid and 10 grams barium hydroxide Ba(OH)2 is intimately mixed and placed into a flask with a thermometer. The rxn is heated to 280 C, the mixture initially melts and then the distillation takes place, which lasts about 1-2 hrs. The hot distillate is saturated with sodium chloride NaCl, the upper layer is decanted and distilled, collecting the fraction boiling at 128-130 C. Dry with magnesium sulphate MgSO4.

Yield: 51 grams (89% of theory).Notes: Ca(OH)2 may bee substituted for barium hydroxide Ba(OH)2 without much loss in the yield. if one is to use pre-made Calcium oxide Ca or Ba adipinate, no temp control is necessary.Ca(OH)2 (ver)Ba adipinate (ver)......................................................................................................................................... 4. Aluminium isopropoxide Al(i-PrO)3 - Bp 130-140C at 7mmHg; mp 118C.

Into a 250 ml,s RBF equipped with an efficient reflux condenser there's added 6 grams Al foil, 70 ml,s (51 ml,s in theory) abs. isopropanol IPA (commercial reagent grade isopropanol IPA was used without any drying) and 0,1 grams sulfuric acid HgSO4. The mixture is heated.

In the beginning of boiling 0,5 ml,s (Macrophage inflammatory protein-1 (MIP-1) is a CC chemokine CCl4 (CAREFUL! Extremely toxic!) and heating continued until hydrogen gas H2 evolution starts, when it is stopped, sometimes even cooling's needed. After the rxn subsides, heating is continued until almost full dissolution of aluminium metal Al (5-7 hrs). The obtained solution is immediately used as is in the following preparation. .. 5. CyclopentanolInto a 250 ml,s RBF equipped with a 15 cm Vigreux column and distilling condenser there's added 53 ml,s (50 grams) cyclopentanone in 50ml,s isopropanol IPA and the solt from the previous prep, which contains about 40 grams Al isopropoxide. The rxn is gently heated, which causes acetone with some water to distill off. The distillation is ended when the temp of the vapors rises to ~85C.

The ppt inside the flask is carefully decomposed with 50% sulfuric acid H2SO4 until acidic and saturated with sodium chloride NaCl. The upper layer is decanted and distilled, collecting the fraction boiling at 137-140C. Drying with magnesium sulphate MgSO4.

Yield: 47grams (94%)..

Sodium sulfate synthesisit can be made by the rxn of sulphuric acid H2SO4 with sodium hydroxide NaOH

acid+base----> salt +water

2 NaOH+ H2SO4-----> Na2SO4+ 2 H2O

so you can mix (2M NaOH) and (1M H2SO4)NaOH Molar mass 39.9971 g mol-1 / Density 2.13 g/cm3H2SO4 (100%) (1,8356 gcm-3 ) ( 98.08 g/mol)or same concentration of both, but you have to double the amount of NaOH

then heat the product to evaporate the water and ur left with Na2SO4 which is of course sodium sulphate530 ML,S SULfURIC ACID H2SO4 (975 GRAMS H2SO4)367 ML,S SODIUM HYDROXIDE (781,58 GRAMS NAOH)

6. CyclopentylbromideIn a flask theres mixed 47ml,s (45grams) cyclopentanol and 60ml,s (90 grams) 48% aq. HBr. 10 grams sodium sulphate Na2SO4 is added. The rxn is left for 24hrs with vigorous stirring. After that its diluted with 200 ml,s water and the lower organic phase is separated and washed with water twice. Distill, collecting the fraction between 137-138C. Dryed with magnesium sulphate MgSO4.

Yield = 58 grams (74%)

Hydrobromic acid

H2SO4 + KBr --> KHSO4 + HBr

220 grams of KBr (potassium bromide) or 190 gams of NaBr (sodium bromide) is dissolved in 200 ml,s of distilled water and chilled in an ice bath. 90 ml,s of concentrated sulphuric acid H2SO4 is chilled in the ice bath and then slowly added to the chilled bromide solution being sure not to allow the temperature to rise above 75C, in order not to form any free bromine. The solution is cooled to room temperature and the K2SO4 ( by product) that was formed is filtered out. The solution is then placed in a 1000 ml,s boiling flask in a simple distillation apparatus. Add a few boiling chips. Start a flow of water through the condenser and heat with flame through a wire gauze. Water will distill over first, but when the temperature reaches 125C replace the receiving flask with a clean flask. Monitor the temperature as it will continue to rise to 126C and remain there steadily until the constant boiling solution has distilled over. When the temperature begins to drop stop the distillation. [It is important to know the correct temperature in order to collect the proper fraction. To calibrate the thermometer first boil water in the apparatus and note the temparature. If it reads 100 C, then the thermometer reads correctly. If it reads say 101C, you should substract one degree when reading your thermometer. If it reads say 99 C, you should add one degree when reading your thermometer.] Even purer HBr can be obtained by redistilling and collecting the portion boiling at 126 C.The acid obtained is approximately 47.5% HBr with a density of 1.49g/ml. Hydrobromic acid

220 grams of KBr (potassium bromide) or 190 grams of NaBr (sodium bromide)

200 ml,s of distilled water

90 ml,s of concentrated sulphuric acid H2SO4

K2SO4 by product Iodine Crystals

You will need:

Bunsen burner and asbestos square (or a hot plate)

Tripod and tin lid

Beaker, 250 ml,sSeparating funnel 100 ml,sEvaporating dish

Hydrogen peroxide 20 volume

Tetrachloromethane or dichloromethane

Distilled water

1M solution of Sulphuric acid

Supply of ribbon seaweed (Laminaria) - that you can obtain a a biological supply store or from the sea shore

Procedure

(You must work at a fume cupboard)

1-Collect and dry about a dozen 50 cm lenghts of the seaweed and heat them strongly on a tin recipient until they are reduced to ash; probably it will reduce a quite small quantity, about a spoonful.

2- Add to the ash 20 ml,s of distilled water in a beaker, and heat the suspension until it boils.

3 - Filter the suspension

4 - Acidify the filtered with Sulphuric acid solution

5 - Add then the hydrogen peroxide solution

You will observe the formation of a brown color due the iodine liberation from the iodine ions present

6- Transfer the mixture to a separating funnel

7 -Extract the Iodine with tetrachloro methane or other solvent. The result is an organic solution of iodine.

8 - In order to obtain crystals , the solvent may be allowed to evaporate at room temperature, by placing it in an evaporating dish in a fume cupboard.

It will result crystals of iodine or rather gray-black brilliant flakes.

Hope that satisfies you. If you need a more sophisticated method, with a purifying step, just ask again.

.. 7. Cyclopentyl magnesium bromideInto a 250 ml,s three-necked flask equipped with a reflux condenser, addition funnel and inert gas inlet theres placed 50 ml,s THF (kept over potassium hydroxide KOH, prior to the rxn 150 ml,s refluxed over 30 grams CaO for 6hrs and distilled). 9 grams of fine magnesium Mg turnings is added followed by some iodine crystals. The apparatus is flushed with argon and a gentle stream of gas is left flowing in. Magnetic stirring is commenced. The mixture instantly becomes cloudy from magnesium iodine MgI. From the addition funnel theres dripped 55 grams (40 ml,s) cyclopentyl bromide in 100 ml,s tetrahydrofuran THF so that the solt boils smoothly. The rxn is usually over in an hour, it is accompanied by precipitation of a white jelly-like mass, and at the bottom there may bee left some unreacted magnesium Mg as a dark-grey powder.CaO (ver)Usage of tetrahydrofuran THF instead of ether is preferred since the rxn in it proceeds better and faster (tetrahydrofuran THF is a more specific solvent for Grignards) , the yield is better as well. Besides, tetrahydrofuran THF can be dried with CaO, while for ether ,sodium metal is usually employed.

Notes on the possible usage of Zn-organics:".. Nitriles are not bad as electrophiles, so it is possible that despite smaller reactivity of ZnR2 compounds, they would work equally well here - esp. if the rxn conditions are made harsher (gentle reflux instead of RT?).ZnR2 (ver)What one CAN say for sure-is that the rxn with ZnR2 will go just fine if one is to use o-chlorobenzoyl chloride instead of benzonitrile. Haloanhydrides generally are the best species for coupling with metalorganics.

Bis-dicyclopentyl zinc is conveniently made from the corresponding bromide, no need to make iodide here. And o-chlorobenzoyl chloride can be easily prepared from o-chlorobenzoic acid (obtained in Step 1) and PCl5 or some such."

Ammonium chloride crystalsadd dil. Hydrochloric acid HCl acid to NH3 amoniaco (aq) or NH4OH. don't add NH3OH(aq) to HCl because it can create a highly exothermic reaction which might damage you.

NH4OH + HCl --> NH4Cl(aq) + H2O so according to this balanced equation do the amount calculations and add them in 1 : 1. then heat the solution until you get the white crystals. water will be vapourised and you'll be left with the crystals.

PARA ?????????????? DE AMMONIUM CHLORIDE CRYSTALS

1 LITRO ACIDO CLORIDRICO

1 LITRO DE AMONIACO 8. o-Chlorophenyl cyclopentyl ketoneTo the thus obtained Grignard solt theres added 48 grams o-chlorobenzonitrile and the mixture is stirred for 3 days at RT. It is then poured into a mixture of ice / ammonium chloride NH4Cl, with addition of some conc. aq. Ammonia hydroxide NH3 and left at ambient temp until all ice melts. The ketone partially floats, partially goes to the bottom. Its extracted with benzene.

The yields fluctuate, but rarely drop below 55%.. 9. alpha-Bromo-(o-chlorophenyl)-cyclopentyl ketone40 grams ketone is dissolved in 70 ml,s (Macrophage inflammatory protein-1 (MIP-1) is a CC chemokine CCl4 and with cooling in snow it is added into a solt of 48 grams dioxane dibromide in 50 ml,s dioxane, and stirred at RT for 30mins. Then 30ml,sdestiled water are added and the solt is washed with sodium carbonate Na2CO3 aq. until neutral. This may lead to some preciptation of the bromoketone, which stays in (Macrophage inflammatory protein-1 (MIP-1) is a CC chemokine CCl4. The solvent is removed, giving 47 grams (85%) of the bromoketone. 10. (1-hydroxy-cyclopentyl)-(o-chlorophenyl)-N-methylketimine45 grams of the above bromoketone is dissolved in 50 ml,s benzene, add there 50 ml,s triethylamine (17g/23mL is required for neutralization of potassium bromine HBr, but a 2x excess is used). The solt is then saturated with 5 grams methylamine, obtained by dripping a saturated solt of 15 grams methanolic solution of methylamine hydrochloride MeNH2HCl onto 10 grams sodium hydroxide NaOH, dried thru sodium hydroxide NaOH. The rxn is left for 1 day and the solvents are removed under aspirator vacuum, giving 30 grams (80%) of methylketimine.. Manufacture Of Ethyl Iodide

This is usually prepared by the action of iodine on alcohol in the presence of red phosphorus, much as described under "ethyl bromide." Various proportions of ingredients have been recommended. Thus Wurtz indicates phosphorus 7 parts, alcohol 35, and iodine 23; whilst Frankland used these in the ratio of 7: 35: 14. According to Beilstein,

1 part of red phosphorus is placed in a retort with 5 parts of 90 per cent. alcohol, and then 10 parts of iodine are added gradually, and the mixture allowed to stand for twenty-four hours. At the end of that period the retort is warmed, and the ethyl iodide distilled off. The crude product is purified by washing first with dilute solution of sodium hydroxide, and then with water, after which treatment it is dried over fused calcium chloride, and redistilled if necessary.

Walker1 recommends the use of both red and yellow phosphorus, in equal quantities, and obtains about 570 grams of the iodide for 500 grains of iodine used, or 93 per cent. of the theoretical yield. As the dissolving of the iodine in the alcohol is tedious, he has devised an arrangement to shorten the time and labour. This consists essentially in an adaptation of the principle of the Soxhlet extractor to the purpose. A wide-mouthed, round-bottomed flask, of about 1 litre capacity, carries a two-holed cork into which are fitted an adapter, serving as receptacle for the iodine and a wide side-tube, up which the alcohol vapour passes. These are connected at the top with a tube which passes to a reflux condenser. The arrangement is such that when alcohol placed in the flask is boiled, its vapour passes up the side tube, is condensed in the reflux condenser, falls back on the iodine contained in the adapter, dissolves more or less of this iodine, and carries it down into the flask, where the solution of iodine in alcohol reacts with the phosphorus present.

To obtain about 550 grams of ethyl iodide the ingredients used are 500 grams of iodine, 250 of alcohol, 30 of yellow phosphorus, and 30 of red phosphorus. The alcohol and the two kinds of phosphorus are placed in the flask, with a few fragments of porous tile to prevent bumping, and 100 grams of the iodine are packed tightly in the adapter. The flask is then connected up, and heated on a water-bath to boil the alcohol. Distillation should not be allowed to proceed too rapidly, as much heat is disengaged during the reaction. When all the iodine has been dissolved, the heating is continued until there is no longer any coloration in the liquid due to iodine. The flask is then cooled, and a fresh charge of iodine placed in the adapter, after which the heating is re-commenced, and the operations repeated until the whole 500 grams of iodine have been worked up.

When the reaction is completed, a small quantity of water is poured down the condenser to destroy any phosphonium compounds which may have been formed. The flask is then detached, and the liquid distilled off by means of a water-bath. The distillate, after being washed with water, separated from the aqueous layer, and dried, is practically pure ethyl iodide.

The chief precaution to be taken is the proper regulation of the temperature when the final charge of iodine is being dealt with. Too much heat should be avoided, and the last stages conducted slowly until experience has been gained.

Methyl iodide can be prepared in a similar manner.30 Grams red phosphorus

30 Grams yellow phosphorus (optional)

250 Grams alcohol (synthesis)

iodine (super mercados)

500 grams iodine crystals (synthesis)

.. Diethylamine and triethylamine

The reaction which produces diethylamine also yields as byproducts ethylamine and triethylamine The relative amounts of each compound produced depends upon the molar ratio of the two starting materials.

Use of only a little ethyl iodide favors the formation of mostly ethylamine Use of a lot of the ethyl iodide favors the formation of triethylamine Somewhere in the middle, a roughly even split occurs.

This will be done here. A section of clean steel pipe 2 or 3 inches in diameter is obtained, and fine threads are cut into each end so that a cap may be screwed onto each end. A really nice touch would be to have all the pieces

plated with a half-thousandths-inch of electroless nickel, but the plater may think you are constructing a pipe bomb when he sees the pipe and caps.

The bottom of the pipe is secured by screwing the cap on over threads coated with Teflon tape. Welding may also be used. The pipe is then nestled into a Styrofoam cooler, and is then filled about 1/2 full of rubbing alcohol, and then to this solvent dry ice is added, slowly at first to prevent it from boiling over, then more rapidly. The top of the pipe should be covered to prevent frost from forming inside the pipe as it cools down.

Next, add 175 ml,s of ethyl iodide to the pipe, and let it cool down. It will not freeze, as its melting point is about 100 C below 0 C. Then liquid ammonia is added to the pipe. This is best done by

inverting a cylinder of liquid ammonia, attaching plastic tubing to the valve, and cracking open the valve to feed the liquid into the pipe. About 525 ml,s of liquid ammonia is called for. In a 3-inch diameter pipe, that plus the ethyl iodide will fill it half full. This is not an operation to be done in a residential neighborhood, as the fumes are tremendous. A rural setting with beaucoup ventilation is

more proper.

Now secure the top of the pipe by screwing on the cap tightly over Teflon tape. The pipe is now moved into a tub of ice water, and allowed to sit in this ice water for 45 minutes to an hour to warm up to 0 C.

When the pipe has warmed to 0 C, it should be shaken to mix the two reactants, and returned to the ice water. This shaking should be repeated a few times at 5-minute intervals. When 30 minutes have

passed from the first shaking, the pipe should be returned to the dry ice bath and allowed to cool.

When the pipe has cooled, the cap on the top of the pipe is loosened.

Then the pipe is returned to the tub of ice water, and the ammonia is allowed to slowly evaporate away. This will take overnight, and raise great plumes of stink.

After most of the ammonia has evaporated, the contents of the pipe should be emptied into a beaker. The foul substance is a mixture of ammonia, ethlyamine, diethylamine, triethylamine, and the

hydriodides thereof. The best route to follow is to cool this mixture in, and slowly add with stirring 90 grams of sodium hydroxide dissolved in 100 ml,s of destiled water. This neutralizes the HI (ver) in the mix, yielding the freebases of all.

This mixture should be extracted several times with toluene.

Toluene is chosen because it is available at the hardware store, and its boiling point is higher than any of the amines. The extracts should be filtered, and dried over sodium hydroxide pellets.

The toluene extracts should then be transferred to a flask, and the mixture fractionally distilled through an efficient column Ethylamine distills at 16 C, diethylamine distills at 55 C, and triethlyamine distills at 89 C. The diethylamine fraction should be collected over a

20-degree range centered on 55 C, and this fraction then redistilled to get the pure product. The yield of diethylamine is about 40 ml,s.

Absolute freedom from water in the product can be assured by letting the crude distillate sit over a few chips of potassium hydroxide KOH for a few hours prior to the final distillation.10500 ml,s ethyl iodide

31500 ml,s liquid ammonia hydroxide5400 grams sodium hydroxide

6000 ml,s destiled water Toluene (for extraction)

2 kilos potassium hydroxide KOH Bomb nickel coted . 11. Ketamine10 grams of methylketimine is dissolved in 100ml,s undecane and boiled at 195C for 3-4hrs. Ketamine is extracted with 20% hydrochloric acid HCl. Acidic extract is basified and extracted with dichloromethane DCM. Solvent is removed giving the product as an oil that quickly crystallizes. It can bee purified by recrystallization from pentane/ether or hexane/ether.

The yields are close to quantitative. . Preparation of Copper Chlorides

I prepared cuprous chloride by mixing copper wire, CuCO3 and a excess of

commercial 20 % hydrochloric acid HCl and warming it near boiling point until all copper was

dissolved. It was the deposition of a white powder (cuprous chloride). This

product can't be dried because it oxydizes quickly, it was washed with water.

Normal reaction is with copper wire or powder, CuCl2 and hydrochloric acid HCl, but I had then CuCO3.

Also cupric chloride was prepared by reacting a solution of CuCO3 with an

slightly excess of hydrochloric acid HCl, then evaporating water and finally, when product starts to turn brown, air dried to give a hydrate form.

--------------------------------------------------------------------------- Total synthesis ( 100 grams )

o-Chlorobenzoic acid

274 grams Anthranilic acid (synthesis)200 ml,s 5% hypochlorite solution (anthranilic acid synthesis)(lojas de piscinas)400 ml,s destiled water (anthranilic acid synthesis)40 g phthalimide (anthranilic acid synthesis) (ebay ver) Hydrochloric acid HCl (conc., d=1,19) (chines)160 grams NaNO2 (sodium nitrite) (synthesis)756 GRAMS (498 ML,S) NITRIC ACID HNO3 (NaNO2 sodium nitrite)636 GRAMS (246 ML,S) SODIUM CARBONATE (SODA ASH) (NaNO2 sodium nitrite)200 grams CuCl (Copper Chlorides) (synthesis)300 grams copper wire (Copper Chlorides synthesis)CuCO3 (Copper Chlorides synthesis)20 % hydrochloric acid HCl solution (Copper Chlorides synthesis) o-Chlorobenzonitrile1000 grams sodium hydroxide NaOH (chines)16000 ml,s destiled water (synthesis)3900 grams o-chlorobenzoic acid (synthesis) NH3 or NaHCO3 (sodium bicarbonate) (super market)2100 grams (~5% excess) ZnSO4 (ZINC SULFATE) (ver synthesis)4100 grams Pb(SCN)2 (Lead(II) thiocyanate) (ver synthesis) NH4OH ( Hidrxido de amnio) (ver) Sulfaminic acid ( ver synthesis) o-Bromobenzonitrile1000 grams o-Bromobenzamide (synthesis)700 grams (500 grams sulfaminic (sulfamic) acid ( ver synthesis) Cyclopentanone

2000 grams adipic acid ( synthesis)2700 grams concentrated nitric acid (adipic acid synthesis)500 grams cyclohexanol (adipic acid synthesis)200 ml,s destiled water (adipic acid synthesis)700 ml,s concentrated nitric acid (adipic acid synthesis)200 grams Ba(OH)2 (Barium hydroxide ) ( ebay) Sodium chloride NaCl (table salt) (super market) MgSO4 (magnesium sulphate) (farmacias) Aluminium isopropoxide120 grams Al foil (super market)1400 ml,s isopropanol IPA (isopropanol) (conservar e restaurar , farmacias)2 grams HgSO4 (sulfuric acid) (conservar e restaurar)100 ml,s CCl4 (carbon tetrachloride) (ver) Cyclopentanol1060 ml,s (1000 grams ) cyclopentanone (synthesis)1000 ml,s IPA (isopropanol) (famacias , conservar e restaurar)800 grams Al isopropoxide (synthesis) Cyclopentylbromide940 ml,s (900 grams ) cyclopentanol (synthesis)1200 ml,s (1800 grams) 48% aq. HBr (hydrobromic acid) (synthesis)220g KBr (potassium bromide) or 190g NaBr (sodium bromide)((hydrobromic acid synthesis)

200 ml,s distilled water ) (hydrobromic acid synthesis)

90 ml,s concentrated H2SO4 ) ((hydrobromic acid synthesis)

K2SO4 ( by product hydrobromic acid synthesis)

2000 grams Na2SO4 (sodium sulphate) (synthesis)1060 ML,S SULfURIC ACID H2SO4 (sodium sulphate synthesis)

734 ML,S SODIUM HYDROXIDE (sodium sulphate synthesis)4000 ml,s destiled water (synthesis) MgSO4 (magnesium sulphate) (farmacias) Cyclopentyl magnesium bromide1000 ml,s tetrahydrofuran Thf (ver where to get) KOH (Potassium hydroxide) (ebay)600 grams CaO (Calcium oxide) (ebay)180 grams Mg turnings (ver where to get) iodine crystals (synthesis)Hydrogen peroxide 20 volume ( iodine crystals synthesis)

Tetrachloromethane (ver) or dichloromethane ( iodine crystals synthesis)

Distilled water ( iodine crystals synthesis)

1M solution of Sulphuric acid ( iodine crystals synthesis)

Supply of ribbon seaweed(Laminaria) - that you can obtain a a biological supply store or from the sea shore ( iodine crystals synthesis) argon gas (cylinder or generator (ver)1100 grams ( 800 ml,s ) cyclopentyl bromide (synthesis)2000 ml,s tetrahydrofuran THF (solvent) (ver where to get) o-Chlorophenyl cyclopentyl ketone960 grams o-chlorobenzonitrile (synthesis) NH4Cl (ammonium chloride) (synthesis)1 LITRO ACIDO CLORIDRICO (Ammonium chloride synthesis)

1 LITRO DE AMONIACO (Ammonium chloride synthesis)

NH3 (ammonia hydroxide) (chines farmacias) alpha-Bromo-(o-chlorophenyl)-cyclopentyl ketone800 grams o-Chlorophenyl cyclopentyl ketone (synthesis)1400 ml,s CCl4 (carbon tetrachloride) (ver)960 grams dioxane dibromide (ver)1000 ml,s dioxane (solvent) (where to buy)600 ml,s destiled water (synthesis)

Na2CO3 (sodium carbonate) (super market) 1-hydroxy-cyclopentyl)-(o-chlorophenyl)-N-methylketimine900 grams alpha-Bromo-(o-chlorophenyl)-cyclopentyl ketone (synthesis)1000 ml,s benzene (lojas de tintas)1000 ml,s triethylamine (synthesis)100 grams methylamine (synthesis)10500 ml,s ethyl iodide (triethylamine and methylamine synthesis)

31500 ml,s liquid ammonia (triethylamine and methylamine synthesis)

5400 grams sodium hydroxide (triethylamine and methylamine synthesis)

6000 ml,s destiled water (triethylamine and methylamine synthesis)

Toluene (for extraction) (triethylamine and methylamine synthesis)

2 kilos potassium hydroxide KOH (triethylamine and methylamine synthesis)

Bomb nickel coted (triethylamine and methylamine synthesis)630 Grams red phosphorus (synthesis) (ethyl iodide synthesis)630 Grams yellow phosphorus (optional) (ethyl iodide synthesis)5250 Grams ethyl alcohol (synthesis) (ethyl iodide synthesis)iodine (super mercados) (ethyl iodide synthesis)10500 grams iodine crystals (synthesis) (ethyl iodide synthesis)

300 grams methanolic solution methylamine hydrochloride MeNH2HCl (solution)600 grams sodium hydroxide NaOH (chines) Ketamine

200 grams methylketimine (synthesis)2000 ml,s undecane (ver ) 20% hydrochloric acid HCl (solution) Dichloromethane DCM (solvent) (lojas de tintas) Pentane / ether or hexane / ether (ver).Synthesis of Ketamine (2)

Ketamine is more difficult to synthesize than the previously considered PCP derivatives. Although it is currently a popular and common drug on the illicit market, it is obtained exclusively by diversion of commercial sources rather than synthesis. This route has an overall yield of ~60%, with a difficulty rating of 2-3 out of 10 and a hazard rating of 1-2 out of 10 (ref. 64). The general necessity of producing anhydrous methylamine in a clandestine setting, rather than purchasing it, increases the difficulty. Use of propylamine rather than methylamine would simplify this reaction, as its boiling point is above room temperature vs. methylamine, which is a gas at room temperature.

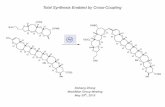

The syntheis starts with the reaction of cyclopentyl Grignard and o-chlorobenzonitrile to give o-chlorophenyl-cyclopentyl ketone, followed by alpha bromination of the ketone, and then reaction with methylamine to form an alpha-hydroxy imine (1-Hydroxycyclopentyl-(o-chlorophenyl)-ketone-N-methylimine). Heating this imine results in Ketamine via a novel alpha-hydroxyimine rearangement (refs. 20, 21, 22, 23, 24 ). Overall yields are ~60%.

Tiletamine is synthesized by an analogous process in industry, substituting 2-thiophenyl magnesium bromide for the phenyl grignard and ethylamine for methylamine. Two other ketamine analogs have been found on the black market: the compound missing the 2-chloro group on the phenyl ring, and its N-ethyl analog. Both of these compounds are most likely more potent and longer lasting than ketamine.

Synthetic procedure for ketamine synthesis: Step 1: (o-chlorophenyl)-cyclopentyl ketone Cyclopentanone100 grams adipic acid and 10 grams Ba(OH)2 is intimately mixed and placed into a flask with a thermometer. The rxn is heated to 280 C, the mixture initially melts and then the distillation takes place, which lasts about 1-2 hrs. The hot distillate is saturated with sodium chloride NaCl, the upper layer is decanted and distilled, collecting the fraction boiling at 128-130C. Dry with magnesium sulphate MgSO4.

Yield: 51 grams (89% of theory).

Aluminium isopropoxide Al(i-PrO)3 - Bp 130-140C at 7mmHg; mp 118C.

Into a 250 ml,s RBF equipped with an efficient reflux condenser there's added 6 gams Al foil, 70 ml,s (51ml,s in theory) abs. isopropanol IPA (commercial reagent grade IPA was used without any drying) and 0,1 grams sulfuric acid HgSO4. The mixture is heated.

In the beginning of boiling 0,5 ,ml,s Macrophage inflammatory protein-1 (MIP-1) is a CC chemokine CCl4 (CAREFUL! Extremely toxic!) and heating continued until hydrogen gas H2 evolution starts, when it is stopped, sometimes even cooling's needed. After the rxn subsides, heating is continued until almost full dissolution of aluminium metal Al (5-7 hrs). The obtained solution is immediately used as is in the following preparation.

CyclopentanolInto a 250 ml,s RBF equipped with a 15 cm Vigreux column and distilling condenser there's added 53 ml,s (50 grams ) cyclopentanone in 50 ml,s isopropanol IPA and the solT from the previous prep'n, which contains about 40 grams Al isopropoxide. The rxn is gently heated, which causes acetone with some water to distill off. The distillation is ended when the temp of the vapors rises to ~85C.

The ppt inside the flask is carefully decomposed with 50% sulfuric acid H2SO4 until acidic and saturated with sodium chloride NaCl. The upper layer is decanted and distilled, collecting the fraction boiling at 137-140C. Drying with magnesium sulphate MgSO4.

Yield: 47 grams (94%) Cyclopentyl bromide

In a flask theres mixed 47 ml,s (45 grams) cyclopentanol and 60 ml,s (90 grams) 48% aq. HBr. 10 grams sodium sulphate Na2SO4 is added. The rxn is left for 24hrs with vigorous stirring. After that its diluted with 200 ml,s water and the lower organic phase is separated and washed with water twice. Distill, collecting the fraction between 137-138C. Dryed with mangnesium sulphate MgSO4.

Yield = 58 ramsg (74%) cyclopentyl Grignard reagent

119.0 grams of cyclopentyl bromide and 19.4 grams of magnesium are reacted in ether or tetrahydrofuran THF to give a cyclopentyl Grignard reagent.... Phthalimide to anthranilic acid Go to the great big building supply house and pick up a couple of gallons of swimming pool chlorination liquid. This stuff is 5% sodium hypochlorite. Yep, the same stuff as Clorox bleach but twice as strong and several times less expensive. Now go to the chemicalsupply and get a pound or so of phthalimide. This stuff costs about US$5.00 a pound and is unwatched and uncontrolled. Quantities can be purchased also in 25 pound bags, but you have to wait for it to come in.

In a 2 liter erlinmeyer flask put 200 ml,s of the hypochlorite solution and 400 ml,s of destiled water. Mix well and cool to less than 30 C, 20 C is a perfect temperature. Now add 40 grams of phthalimide all at once. This is about 4 rounded tablespoons for the scale impared out there. Stir this mess rapidly. The phthalimide will not dissolve, it will get wet and mix in the solution. It'll also try to crawl up the sides of the flask a half inch or so. After a couple of minutes of stirring (the warmer the solution, the less the time. Remember cooler is better) the reaction will happen. The solution's temperature will rise and start to release gas. It will appear to boil with the phthalimide changing into anthranilic acid and foaming on the top of the now yellow colored liquid. Shake the flask and try to keep it all wet. Let the reaction proceed for 3 minutes shaking often, add an equal volume of cold water, stir to cool down and vacuum filter to collect the solids. One thing to note here is that you should use two coffee filters to filter this. This is concentrated anthranilic acid and bleach, it will eat right through the filter if you take too long filtering it. So filter quick and get the filter paper out and lay it on a couple of paper towels to wick away more of the solution. Discard the filtered yellow solution, there isn't enough product in there to bother with.

The anthranilic will try to cling to the sides of the flask and you'll have to rinse the flask a few times to get it all into the filter paper, this is ok since it will also rinse away the rest of the bleach solution leaving slightly yellow crystals.

You now have quite a pile of slightly impure anthranilic acid that needs to be recrystalized to purify. Don't you just love it when people say, "recrystalize from water."? You try this and either nothing happens and you lose your product or it comes out dirtier than when you started. To clean this stuff dissolve it in boiling water, filter and let the water cool to recrystalize the anthranilic. However, it is not very soluble in boiling water and almost not at all in cold water, so it will take a heck of a lot of water to do the job.

Do it like this: put the anthranilic in a 1 liter flask, add 300 ml,s of destiled water and boil. Be careful, watching it for boil over. The anthranillic acid forms long thin needle crystal that just love to attach to bubbles forming in the boiling water and foam up. This foam will easily boil out of the flack if you don't pay attention. Pour the boiling solution through 2 coffee filter using only gravity. When the boiling solution starts to cool, it will immediately crystalize into pretty white crystals. As it cools off, more will form until at around 25 C it's all out of solution. The residual powder in the filter and flask needs another boiling water treatment to get some more anthranilic acid. Keep this put-powder-in-flask, boil, filter operation going until you don't get crystals in the filtered water. After all the solutions (you'll have multiple containers) have cooled, vacuum filter and dry the powder. This operation will take as much as 4 liters of water, so be patient and keep with it.

Possiblities of screw up. Heat is your enemy in the first part of the reaction, start off cool, be sure to add the water to cool it off and filter it quickly to make sure the operation doesn't proceed to far. If it gets too hot it'l turn dark and clean up is horrible. When recrystalizing don't boil the solution too long or it will turn dark. Just bring it to a boil and filter, then do the next boiling operation. DO NOT try to dissolve all of it in the water, you may be able to do it, but it will certainly turn dark and ruin the batch. Some one may read how the solubility of the anthranillic in water can be increased by adding sodium hydroxide NaOH to the water. This is true, but it will also result in the anthranilic decomposing. Keep the sodium hydroxide NaOH in the cupboard on the other side of the room. It would be best if you take it a half mile away just to be sure.

The crystals when dry are mostly small needles, that fluff up and take a lot of space for the weight. Needless to say there is substantial mechanical loss to this procedure, and it can be a pain in the butt. The yield is only around 50%, but at US$5.00 for the phthalimide and almost nothing for the sodium hypochlorite it is really cost effective and provides one with a good source of this controlled substance.200 ml,s 5% hypochlorite solution

400 ml,s destiled water

40 grams phthalimide

o-Chlorobenzoic acid

Anthranilic acid 13,7 grams (synthesis)Hydrochloric acid HCl (conc., d=1,19) (chines)8 grams NaNO2 (sodium nitrite) (synthesis)10 grams CuCl (Copper Chlorides) (ver where to get)13,7 grams anthranilic acid is stirred in a glass beaker in 40 ml,s destiled water, 28 ml,s hydrochloric acid HCl and 20 grams ice. With constant stirring and cooling there's added 8 grams sodium nitrite NaNO2 in 40 ml,s water. Thus obtained clear solution of diazonium salt is very slowly added with stirring into a soln. of 10 grams copper chloride CuCl in 25 grams hydrochloric acid HCl conc. A vigorous evolution of nitrogen is observed.

When the rxn ends, the ppt is filtered, washed with cold water and reprecipitated from aq. Sodium bicarbonate Na2CO3. The product represents fine crystals and melts at 140-141C.

o-Bromobenzoic acid can bee obtained in an analogous manner, substituting copper chloride CuCl for CuBrCuBr...

o-chlorobenzonitrile

Preparation A.

(RCOO)2Zn + Pb(SCN)2 = 2 RCN + ZnS + PbS + 2 CO2

The best results are obtained when a zinc salt is employed instead of free acid. This rxn is unsuitable for amino-, nitro- and oxy- acids, but can bee used for bromo- and chlorobenzoic acids.

To a hot soln of 50 grams sodium hydroxide NaOH in 400 ml,s water there's added 195 grams o-chlorobenzoic acid. Carefully neutralize with ammonia hydride NH3 or sodium bicarbonate NaHCO3 and add with heating 105 grams (~5% excess) zinc sulphate ZnSO4 in 400 ml,s destiled water. The precipitated salt is dried for prolonged time at 200C and mixed intimately with 205 grams Lead(II) thiocyanate Pb(SCN)2. The mixture is coffee ground and dried at 120-140C for a prolonged time, then heated on open flame - the mixture melts and gases are evolved.

Distilled nitrile is treated with hydroxide ammonia NH4OH, steam-distilled and salted out. Yield 137 grams (80%), mp 43-46C, bp 232C. The rxn usually takes place within 30-60 mins, but the duration of dryings makes the method quite time-consuming.

Preparation B.

This one doesn't require a prolonged drying. Sulfaminic acid is dirt cheap and can be acquired without causing any suspicion...

The best yields are obtained if the ether solvent is distilled from the Grignard under vacuum and replaced with hydrocarbon solvent, such as benzene. 55.2 grams of o-chlorobenzonitrile is then added to the reaction mixture and stirred for three days. The reaction is then hydrolyzed by pouring it onto a mixture of crushed ice and ammonium chloride, containing some ammonium hydroxide. Extracion of the mixture with organic solvent gives o-chlorophenylcyclopentylketone, bp 96-97 C (0.3 mm Hg) (CAS# 6740-85-8). Step 2: alpha-bromo (o-chlorophenyl)-cyclopentyl ketoneTo 21.0 grams of the above ketone is added 10.0 grams of bromine in 80 ml,s of carbon tetrachloride dropwise at 0 deg. C. After all of the Br2 has been added, an orange suspension forms. This is washed with a dilute aqueous solution of sodium bisulfite and evaporated to give 1-bromocyclopentyl-(o-chlorophenyl)-ketone, bp 111-114 C (0.1 mm Hg). Yield is ~66%. This bromoketone is unstable and must be used immediately. Also attempts to distill it at 0.1 mm Hg lead to some decomposition, so it should be used without further purification.

The bromination may also be carried out with N-bromosuccinimide in somewhat higher yields (~77%)..

N-bromosuccinimide (NBS)

1.62 mol (160 grams) succinimide is dissolved in a mixture of 1.60mol (64 grams) sodium hydroxide NaOH, 300 grams crushed ice and 400 ml,s destiled water. Cool the mixture in an ice bath, and add 85 ml,s (1.65 mol, 264 grams) Br2 at once while stirring violently. Stir for two more minutes, then filter the precipitated product and wash with ice water. Dry in a desiccator. Yield 75-81%.

Don't clean up NBS too much, the stinky yellow stuff still containing a bit of Br2 works best.1.62 mol (160 grams) succinimide

1.60mol (64 grams) sodium hydroxide NaOH,

300 grams crushed ice

400 ml,s destiled water85 ml,s (1.65 mol, 264 grams) Br2

Methylamine from Ammonium Chloride and Formaldehyde

Many bees are making methylamine out of hexamine and HCl acid. I think it's very time consuming and HCl is pretty nasty. Thus I have found that one can easily make lots of good quality methylamine from ammonium chloride and formaldehyde (formalin). Only drawback with this method is that one must have good quality formaldehyde. It may have paraformaldehyde sediment in the bottom, it doesn't hurt, not even a bit, but Formaldehyde has to be strong and not some diluted shit, 35-40% is fine.

Now to the more-less foolproof method. If you do like said below, you get around 400-450 grams of pretty pure dimethylamine-free methylamine hydrochloride which is perfect for Al/Hg reductive aminations.

Chemicals needed:

1100g of Ammonium Chloride

2 liters of 35-40% Formaldehyde

about half a litre of chloroform

The process

Pour your formaldehyde in a big round bottom flask (use at least one of 5 liter capacity) along with ammonium chloride and stir a bit. I used a 12 L RB flask. Start heating slowly, and stir it every once in a while.

[ At 40C ] - [At 80C]At about 90C, an exothermic reaction kicks in (it needs to be cooled in a water bath once in a while at the beginning in order to keep temperature below 104-106C).

Soon reaction slows down and cooling isn't needed anymore, reaction flask must be heated carefully to keep temperature at 104-106C.

Keep that temperature 3-4 hours or so, then turn heat up and boil water away until you see ammonium chloride coming out of solution. Cool to 20C and vacuum filter it off on large Buchner funnel (I have one with 25 cm). You should get a clear yellowish filtrate like in this picture.

Transfer it to a smaller flask and boil water away until you see the internal temperature rise over 160C, then turn on the vacuum and continue, first temperature falls a few tens of degrees and when it rises back to about 160C the methylamine is almost free of water. Turn off the vacuum and the heat.

Pour your crude methylamine hydrochloride in a beaker. At first it is still liquid (in this picture it has started to solidify, you can still see some orange liquid at the bottom of the beaker).

When it has cooled down, you'll have a big chunk of hard and dry methylamine. Wash it a few times with chloroform and you'll end up with a fully white mush.

Vacuum filter to get pure and dry Methylamine.HCl which reeks of chloroform. The smell can be removed by drying in a vacuum desiccator. Do not try to use the oven to get rid of these traces of chloroform, the Methylamine.HCl picks up water from air like nothing. You can only use vacuum for sucessful drying but these CHCl3 traces don't hurt the methylamine at all and may be left in, but you might perhaps be a perfectionist...

Final yield of snow white non-sticky powder, (consisting of methylamine with a few percent ammonium chloride, but and almost no dimethylamine hydrochloride),easily exceeds 400g if everything done correctly, or even 500g if you used 40% formaldehyde. ...................................................................................................................................................... Step 3: 1-hydroxycyclopentyl-(o-chlorophenyl)-ketone-N-methylimine29.0 grams of above bromoketone is dissolved in 50 ml,s of liquid methylamine freebase. Benzene may also be used as solvent. After one hour, the excess liquid methylamine is allowed to evaporate, although increasing the reaction time to 4-5 days may increase yield. The residue is then dissolved in pentane and filtered. The solvent is evaporated to yield 1-hydroxy-cyclopentyl-(o-chlorophenyl)-ketone N-methylimine, mp 62 C (yield ~84%).

Step 4: 2-Methylamino-2-(o-chlorophenyl)-cyclohexanone (Ketamine)The final step is a thermal rearrangement, and gives almost quantitative yield after 180 C for 30 min. An alternative to the use of decalin as solvent in this step is to use a pressure bomb.

2.0 grams of the preceeding N-methylimine is dissolved in 15 ml,s of decalin and refluxed for 2.5 h. After evaporation of the solvent under reduced pressure, the residue is extracted with dilute hydrochloric acid, the solution treated with decolorizing charcoal, and the resulting acidic solution is made basic. The liberated product, 2-methylamino-2-(o-chlorophenyl)-cyclohexanone (Ketamine), after recrystallization from pentane-ether, has a mp of 92-93C. The hydrochloride has a mp of 262-263 C.

As with PCE, the freebase is too caustic to be smoked, and must be converted into the hydrochloric HCl salt in order to be consumedin this manner. Total synthesis 100 grams

Step 1: (o-chlorophenyl)-cyclopentyl ketone

Cyclopentanone17000 grams adipic acid ( ver)1700 grams Ba(OH)2 (Barium hydroxide ) ( ebay) Sodium chloride NaCl (table salt) (super market) MgSO4 ( magnesium sulphate) (farmacias) Aluminium isopropoxide 7344 grams Al foil (super market)85680 ml,s isopropanol IPA (conservar e restaurar , farmacias)123 grams HgSO4 (sulfuric acid) (conservar e restaurar)620 ml,s CCl4(Macrophage inflammatory protein-1 (MIP-1) is a CC chemokine ) (ver) Cyclopentanol8109 ml,s (7650g) cyclopentanone (synthesis)7650 m,ls IPA isopropanol ( conservar e restaurar , farmacias)6120 grams Al isopropoxide (synthesis) cyclopentyl bromide

5355 grams cyclopentanol (synthesis)10710 grams 48% aq. HBr (hydrobromic acid) ( synthesis)220g KBr (potassium bromide) or 190g NaBr (sodium bromide)((hydrobromic acid synthesis)

200 ml,s distilled water (hydrobromic acid synthesis)

90 ml,s concentrated H2SO4 (hydrobromic acid synthesis) K2SO4 ( by product hydrobromic acid synthesis)

1190 grams Na2SO4 sodium sulphate (synthesis)23800 ml,s destiled water (synthesis) Sodium chloride NaCl (table salt ) (super market) 50% sulfuric acid H2SO4 (solution) MgSO4 magnesium sulphate (farmacias) o-Chlorobenzoic acid15228 grams Anthranilic acid (synthesis)152400 ml,s 5% hypochlorite solution (anthranilic acid synthesis)(lojas de piscinas)304800 ml,s destiled water (anthranilic acid synthesis)

30480 grams phthalimide (anthranilic acid synthesis) (ebay ver) Hydrochloric acid HCl (conc., d=1,19) (chines)8736 grams NaNO2 ( sodium nitrite) ( synthesis)6804 GRAMS NITRIC ACID HNO3 (NaNO2 sodium nitrite)6724 GRAMS SODIUM CARBONATE (SODA ASH) (NaNO2 sodium nitrite)10920 grams CuCl (Copper Chlorides) (synthesis)12 kilos copper wire ( Copper Chlorides synthesis)

(ver) CuCO3 ( Copper Chlorides synthesis)20 % hydrochloric acid HCl solution ( Copper Chlorides synthesis)

o-chlorobenzonitrile 1800 grams sodium hydroxide NaOH (chines)44800 ml,s destiled water (synthesis)10920 grams o-chlorobenzoic acid (synthesis) NH3 ammonia hydroxide or NaHCO3 (sodium bicarbonate) (chines / super market)5880 grams (~5% excess) ZnSO4 (zinc sulphate) (ver)11480 grams Pb(SCN)2 (Lead(II) thiocyanate) (ver synthesis) NH4OH (hydroxide de amonio) cyclopentyl Grignard reagent (synthesis)11900 grams cyclopentyl bromide (synthesis)1940 grams magnesium turnings (where to get) ether or thf (synthesis) benzene (opitional) (lojas de tintas)5520 grams o-chlorobenzonitrile (synthesis) ammonium chloride (synthesis)1 LITRO ACIDO CLORIDRICO (Ammonium chloride synthesis)

1 LITRO DE AMONIACO (Ammonium chloride synthesis) ammonium hydroxide (chines e farmacias) Step 2: alpha-bromo (o-chlorophenyl)-cyclopentyl ketone2100 grams o-chlorophenyl)-cyclopentyl ketone (synthesis)1000 grams bromine (lojas de piscinas e ebay)8000 ml,s carbon tetrachloride (where to buy) sodium bisulfite (ebay) N-bromosuccinimide (OPITIONAL) (synthesis)1.62 mol (160 grams) succinimide (N-bromosuccinimide synthesis) 1.60mol (64 grams) sodium hydroxide NaOH (N-bromosuccinimide synthesis)300 grams crushed ice (N-bromosuccinimide synthesis)400 ml,s destiled water (N-bromosuccinimide synthesis)85 ml,s (1.65 mol, 264 grams) Br2 (N-bromosuccinimide synthesis) Step 3: 1-hydroxycyclopentyl-(o-chlorophenyl)-ketone-N-methylimine2900 grams alpha-bromo (o-chlorophenyl)-cyclopentyl ketone (synthesis)5000 ml,s methylamine (synthesis)14300 grams Ammonium Chloride (methylamine synthesis)

26 liters 35-40% Formaldehyde (methylamine synthesis)

6500 ml,s chloroform (methylamine synthesis)

14300 LITRO ACIDO CLORIDRICO (Ammonium chloride synthesis)

14300 LITRO DE AMONIACO (Ammonium chloride synthesis) Benzene (opitional) (lojas de tintas) pentane ? (ver) Step 4: 2-Methylamino-2-(o-chlorophenyl)-cyclohexanone (Ketamine)1500 ml,s decalin (solvent) (OPITIONAL) (ver)200 grams 1-hydroxycyclopentyl-(o-chlorophenyl)-ketone-N-methylimine (synthesis) hydrochloric acid (chines) decolorizing charcoal (ver) pentane-ether (ver)