Tol Stack Analysis_fundamentals

Transcript of Tol Stack Analysis_fundamentals

TOLERANCE STACK UP ANALYSIS

What is stack up analysis?The study of accumulation of tolerance of individual parts in an assembly is termed as toleranceStack up analysis.

How useful is this stack up analysis?Manufacturers spend millions of dollars every year on product quality issues such as –1) Parts not fitting together properly.2) Engineering Changes3) Time consumtion4) Increase in expense

Basically we group the tolerance analysis into:

Analysis Method Analysis

Type

Tolerance

Type

Level

2D Analysis Manual calculation

Tolerance charts

Worst case only Geometric &

Dimensional

Part &

Assembly

3D Analysis Software with

Inbuilt codes

Worst case &

Statistical

Geometric &

Dimensional

Part &

Assembly

1. Approach for 2D stacks (Plus/minus dimensions)

a. To establish performance requirements b. Draw Loop Diagrams c. Calculate mean value for performance requirement d. Determine method of analysis e. Stack Table f. Re-sizing factor*

2. Usage of geometric tolerance in 2D stacks3. Examples on 2D stacks4. Note about different software’s used in 3D stacks

STEPS INVOLVED IN 2D STACK UP ANALYSIS

1. To establish performance requirements 2. Draw Loop Diagrams 3. Calculate mean value for performance requirement 4. Determine method of analysis 5. Stack Table 6. Re-sizing factor*

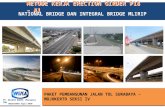

1. TO ESTABLISH PERFORMANCE REQUIREMENTS

Performance requirements :

1. “GAP” or “SPACE” – In 2D analysis GAP is the only analysis that is being made. If the GAP value equals to 0, then it’s a contact between the mating faces

2. Requirement at the GAP3. Related “DIMENSIONS” for the requirement

1.GAP

5+/-0.2

12+/-0.3

7.5+/-0.2 3. DIMENSIONS

HOUSING COVER

10+/-0.1

ALL UNITS IN MM

2. REQUIREMENT = 0.5+/-0.2 (0.3 – 0.7)

2. LOOP DIAGRAMS

LOOP DIAGRAM is a graphical representation of each DIMENSIONS. Each “GAP” needs a separate loop diagram. Loops are usually horizontal or vertical. Example, Horizontal Loop diagrams will graphically represent the dimensional contributors for horizontal “gaps”.

GAP

CB

A

A = 12+/-0.3 B = 5+/-0.2 C = 7.5+/-0.2

ALL UNITS IN MM

GAP

+ C+ B

- A

A = 12+/-0.3 B = 5+/-0.2 C = 7.5+/-0.2

ALL UNITS IN MM

For horizontal loops, start at the surface on the left side of the gap. Follow a complete dimension loop, to the surface on the right. Create a “closed” loop diagram from the starting surface to the ending surface. For horizontal dimensions:

Use a + sign for dimensions followed from left to right Use a - sign for dimensions followed from right to left

3. CALCULATE MEAN VALUE FOR THE GAP

The mean value at the gap is given by, GAP = ai di , i = 1 to n

Where,

GAP = Mean value at the gap. aI = Factor which defines direction for ith dimension (usually +1 or –1)

dI = Mean value of ith dimension

n = Number of dimensions in stack up.

In this case:GAP = a1d1 + a1d2 + a3d3GAP = [(-1)*12] + [(+1)*5] + [(+1)*7.5]

Mean GAP = 0.5 mm

4. METHOD OF ANALYSIS

2D Analysis use only Worst case condition.

Twc = | af tf| + | av tv|

Twc = Tolerance in Worst Case condition

af = Factor for ith fixed component. (+1 or –1)

tf = Tolerance for ith fixed component – fixed components are those parts which we are

not supposed to change the tolerance av = Factor for jth variable component

tv = Tolerance for jth variable component

In this case, Twc = [ 0 ] + [ (0.3) + (0.2) + (0.2)]

Twc = 0.7 mm

Minimum gap = Mean GAP – Twc = 0.5 – 0.7 = - 0.2 mmMaximum gap = Mean GAP + Twc = 0.5 + 0.7 = + 1.2 mm

Requirement at the GAP is 0.3 to 0.7 mm, where as the obtained dimension at the GAP = -0.2 mm & +1.2mm

5. STACK TABLE

Typically Stack-up table looks like as shown below:

Sensitivity: In case of 2D Analysis, Sensitivity corresponds to the flow direction of the loop, meaning the dimensions associated with the loop from left to right has sensitivity is +1 & vise versa.

All upper limit dimensions with positive sensitivity comes under Max. Value column & all upper limit dimension with negative sensitivity comes under Min. Value.

Part Number Description

Of parts

Variable

Used for dim.

Sensitivity Max. Value Min. Value Tolerance

xxxx xxxx A/B +1/-1 xxxx xxxx xxxx

STACK TABLE

SI NO

VARIABLE MEAN DIMENSION

MAX MIN TOL

1 - A - 12 -11.7 -12.3 0.6

2 + B + 5 +5.2 +4.8 0.4

3 + C + 7.5 +7.7 +7.3 0.4

TOTAL +0.5 +1.2 - 0.2 1.4

Stack-up table is used to just represent the values from earlier calculations in a table format

Requirement is, maximum gap has to be 0.7 & minimum gap has to be 0.3, where asObtained result is, maximum gap is 1.2 & minimum gap is - 0.2

6. RE-SIZING FACTOR*

Resizing is a method of allocating tolerances. The resize factor (Fwc), scales the tolerances down

to achieve the desired assembly performances. The scaling factor only applies to variable tolerances.Resize factor for the worst case model is given by, GAP – gm - | af tf|

FR = ----------------------------- gm = minimum requirement at the (assembly) gap

| av tv|

FR = [0.5 – 0.3 – ( 0 ) ] / 0.7

FR = 0.285

SI NO

VARIABLE MEAN DIMENSION

MAX MIN TOL

1 - A - 12 -11.7 -12.3 0.6

2 + B + 5 +5.2 +4.8 0.4

3 + C + 7.5 +7.7 +7.3 0.4

TOTAL + 0.5 + 1.2 - 0.2 1.4

RE-SIZED

0.171

0.114

0.114

0.4

Now, from the Re-sized tolerance we have 0.5+/-0.2, satisfying our requirement

STACKS USING FORM TOLERANCEForm tolerance states how far an actual surface of feature is permitted to vary from desired form implied in the drawing. Expressions of these tolerance refers to flatness, straightness, parallelism, perpendicularity, angularity, roundness, cylindricity, profile of line & profile of surface

1. FLATNESS:Flatness applied to a part feature is not used in about 90% of the stacks. This is because, when a stack uses the dimension associated with a surface & the surface has a flatness control, the flatness refines the form of a surface within the limits of the dimension.

10.3 – 10.0

At MMC – Max envelope 0.05, Flatness zone

STACKS USING GEOMETRIC TOLERANCE

RULES FOR USING FLATNESS TOLERANCE IN STACK UP

TO OR THRU RULE:

1. If a stack goes to a surface, the form of the surface must be accounted for in the stack2. If a stack goes thru a surface, the form of the surface is automatically included in the

limits of the dimension

1

2

There are mainly 2 conditions associated with flatness:

1. Adjacent condition – connected to rule 1, I.e, if astack path exists in the portion of the part which istouching the mating part, the stack condition is adjacent

2. Offset condition – connected to rule 2, I.e, if a stack path exists in the portion of the part which is nottouching the mating part, the stack condition is offset.

*Same thing holds good for Orientation tolerance also (Parallelism, Perpendicularity, & Angularity)

EXAMPLE FOR FLATNESS TOLERANCE

RULES FOR USING PROFILE TOLERANCE

0.4 X 0.4 X

If the profile tolerance is BILATERAL• Enter HALF the tolerance value in the minimum column• Enter HALF the tolerance value in the maximum column

If the profile tolerance is UNILATERAL1. Enter the FULL tolerance value in one of the column depending on the direction of the LOOP

diagram

2. PROFILE TOLERANCE:

EXAMPLE FOR SURFACE PROFILE

RULES FOR USING PERPENDICULARITY TOLERANCE W.R.T AXIS

3. PERPENDICULARITY:

The perpendicularity tolerance effects are combined with the feature of size dimension.

1. We need to enter virtual condition (extreme boundary condition) of the dimension in one stack column (Max value/Min value column).

2. LMC of the dimension in another stack column.

Virtual condition: Is the collective effect of size & geometric tolerances that must be considered for The calculation of fit or clearance between mating parts.For calculation Virtual condition:External features = MMC + tolerance of Orientation Internal features = MMC – tolerance of Orientation

10.6+/-0.2

ø0.1(M) A

Virtual condition: 10.8+0.1 = 10.9 mmLMC: 10.4 mm

EXAMPLE FOR PERPENDICULARITY

RULES FOR USING RUNOUT & CONCENTRICITY

A

0.3 A

4. RUNOUT:

When calculating a stack that includes a runout tolerance:

1. Note down HALF the runout tolerance value in minimum column2. And note down HALF the runout tolerance value in maximum column

Same holds good for Total Runout, & Concentricity also

EXAMPLE FOR RUNOUT

RULES FOR USING POSITION TOLERANCE IN STACK UP

Ø 0.2 (M) A (M)

A10+/-0.4

16+/-0.4

5. POSITION TOLERANCE: A position tolerance might also have other tolerance which include bonus& shift depending upon the modifiers used for tolerance & datum’s respectivelyBonus: In the above example, Ø 0.2 is the tolerance at MMC (dia 16.4), as the diameter tends to decrease(LMC), a bonus tolerance is generated.Diameter Tolerance Bonus tolerance 16.4 (MMC) 0.2 0 16.3 0.3 0.1 16.2 0.4 0.2 16.1 0.5 0.3 16.0 0.6 0.4 15.9 0.7 0.5 15.8 0.8 0.6 15.7 0.9 0.7 15.6 (LMC) 1.0 0.8 0.8 is the Maximum Bonus tolerance

Bonus tolerance: Bonus tolerance is used when there is a modifier (MMC or LMC)for the position tolerance.

For Dia. 16.4 (MMC), we have a toleranceZone of dia. 0.2

For Dia. 15.6 (LMC), we have a Tolerance zone of dia 1.0

Dia.0.2

Bonus tol. 0.4 radially

Shift tolerance: Shift tolerance is used when a modifier (MMC or LMC) is specified on the Datum Reference

DIFFERENT SOFTWARE’S USED FOR 3D STACKUP ANALYSIS

Most of the CAD software’s have inbuilt module for stack analysis, most commonly heardis the CE Tol of Pro/E.Similarly we have other software’s such as – 2D DCS & 3D DCS (Dimensional Control Systems)Vis VSA – Variation Simulation Analysis

Unlike worst case analysis done in 2D analysis, 3D analysis use an inbuilt program which gives thesolution which almost matches the real time situation for calculating the stackup analysis. Most commonly used program is Monte-Carlo Simulation. Validity of the predictions depends on the accuracy of the input variations, simulation sample size and the fit of a statistical distribution to the resultant assembly data.

1.GAP

7.5+/-0.2

HOUSING COVER

10+/-0.1

5+/-0.2

12+/-0.3