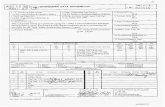

To: €01 no.: TWRS Equipment Engineering ICFKH TWRS ...

Transcript of To: €01 no.: TWRS Equipment Engineering ICFKH TWRS ...

2. To: (Receiving Orpniret im)

TWRS Equipment Engineer ing I74F101

P o r t a b l e 500 CFM Exhauster 5. Proj ./Prog./Dcpt./Div. :

I 16. KFV

3. F m : (Oripimting Oramint ion) 4. Related €01 no.:

ICFKH TWRS FACILITIES NfA TECHNICAL SUPPORT

Owen D. Nelson N/A 7. Purchase O r d u Yo.: 6. Cog. Enor.:

8. Dripinntor R r r k s :

This document i s t o acceptance t e s t t h e new 500 CFH p o r t a b l e exhauster i n support o f S a l t Well Pumping o f Tank A-101.

11. Receiver Rerrrrks:

9. E w i p . / C m t no.:

VTP- 10. SystrlBldg./Facility:

12. *.lor Aau. DW. YO.:

HVAC

H-14-100764, H-14- 100765, H-14-100766, H- 14-100737, H-14-100790

13. P e n i t l P e n i t I p p l i c a t i m No.:

NfA 14. R.quirmi Rapmne Date:

June 20, 1996

WHC-SD-WM-ATP-176, Rev. 0

ATP for 500 CFM Portable Exhauster

O.D. Nelson ICF KAISER HANFORD CO., Richland, WA 99352 U. S. Department of Energy Contract DE-AC06-87RL10930

Org Code: 74F10 Charge Code: N2243 B I R Code: 35EW31207 Tota l Pages: 83

Key Words:

Abst ract : t h a t the Exhauster meets the spec i f i ed func t i ona l requirements, sa fe ty requirements, operat ing requirements, and prov ide a record o f t he func t i ona l t e s t resu l t s . The systemlfunct ions t h a t w i l l be tes ted are l i s t e d i n the scope sec t i on o f the Acceptance Test Procedure.

EDT/ECN: EDT-612907 UC: 2030

Flamnable, Watch L i s t , Tanks, V e n t i l a t i o n System

This Acceptance Test Procedure (ATP) w i l l t e s t and v e r i f y

TRMIUUIK D I s c u I E R . Reference herein to my epecific coll.rsim1 pr&t, prosas or smrvice by trade - tr-rk Irufrturer, or otheruiu, don not m..+.rily c m t i t u t e ;r inply i t s endor-i, r d t i m , or fawr ing by the United States Oovcrrrnt or y w e m y thereof or i t s emtractors or h m t r r t o r s .

Printed i n the U n l t d S t m t n of OocUnt Cmtro l Services, P.O. Fax (509) 376-4W.

h e r i u . Box 1970.

To cbtein c o p i n of th ia docuart, c m t r t : Mallstop H6-00, R i c h l d YI 99352, Phm (509) 372-2420;

WC/BCS

Approved for Public Release

A-66W-073 (10/95) GEF321

INTERIM STABILIZATION

Release Date

ATP FOR 500 CFM PORTABLE EXHAUSTER

D O C U Y n t No. RevlWcd POW

WHC-SD-WM-ATP-176 0 1 of 82

TEST EXECUTION SHEET

Docmnt N h r : WHC-SD-WM-ATP-176 REV. 0 EXHAUSTER Unit N u h e r :

Docurnt No. RCvfMad

WHC-SD-WM-ATP-176 0

II TEST PERSONNEL

Page

2

PRINT NAME

PROJECT ENGINEER: Owen Ne1 son TEST DIRECTOR: Te r ry Kaiser

ALT TEST DIRECTOR: Chuck Monasmith

TEST EXECUTION

Test D i r e c t o r Date

TEST APPROVAL AM ACCEPTANCE

Westinghouse Hanford Company

Without With With - Exception - Exception/Resolved __ Exception/Outstanding

Test D i r e c t o r Date Qual i t y Assurance Date

Date P ro jec t Engineer Date

TABLE OF CONTENTS

DQcurnt NO . WHC-SD-WM-ATP-176

PAGE

Revfund Page

0 3

. . . . . . . . . . . . . . . . . 2

. . . . . . . . . . . . . . . . . 4 . . . . . . . . . . . . . . . 5

. . . . . . . . . . . . . . . 5

TEST EXECUTION SHEET . . . . 1.0 PURPOSE . . . . . . 2 . 0 INFORMATION . . . . . . . .

2 . 1 SCOPE . . . . . . . . . . 2.2 TERMS AND DEFINITIONS . . 2 .3 RESPONSIB IL IT IES . . . . . . . 2 . 4 REFERENCES . . . . . . . . . . 2.5 SAFETY . . . . . . . . . . . . . . 2 .6 QUALITY ASSURANCE . . . . . . . . . . 2 .7 GENERAL INFORMATION . . . . . . .

3.0 RECORDS . . . . . . . . . . 4.0 PREREQUISITES . . . . . . . . . 5.0 PROCEDURE . . . . . . . . . . . . . . . . .

5.1 POWER SYSTEM CHECK . . . . . . . . . . . . 5 . 2 PRESSURE DECAY TEST . . . . . . . . . . . . . 5.3 EXHAUSTER FAN CHECK . . . . . . . . . . . . . 5.4 HEAT TRACE CHECK . . . . . . . . . . . . . . . . . 5.5 INTERLOCK/ALARM CHECK . . . . . . . . . . . . . . 5.6 GLYCOL HEATER CHECK . . . . . . . . . . . . . . . . .

DATA SHEET 1 - LEAKAGE RATE CALCULATION . . . . . . . . . . . . . . DATA SHEET 2 - LEAKAGE RATE CALCULATION . . . . . . . . . . . . ATP EXCEPTION LOG . . . . . . . . . . . . . . . . . . . . . ATP EXCEPTION RECORD . . . . . . . . . . . . . . .

. . . . . . . . . . . . . 6

. . . . . . . . . 6 . . . . . . . . . . . 9

. . . . . . . . . 10

. . . . . . . . . . . 10

. . . 10

. . . 11 . . . . . . . 1 2

. . . . . . . . . 16

. . . . . . . 1 6

. . . . . . . 2 7

. . . . . 3 3

. . . 39

. . . . . 4 1

. . . 70

. . . 7 9

. . . 80

. . . 81

. . . 82

1.0 PURPOSE

Doctment NO.

WHC-SD-WM-ATP-176

1 . 1 There i s a concern t h a t flammable gases may exceed t h e Lower F lammabi l i ty L i m i t du r ing i n t e r i m s t a b i l i z a t i o n o f i d e n t i f i e d waste storage tanks. reduce p o t e n t i a l flammable gases t h a t may e x i s t w i t h i n the dome vapor space o f t he tank.

This Acceptance Test Procedure (ATP) w i l l t e s t and v e r i f y t h a t the Exhauster meets the spec i f i ed Functional Requirements, Safety requirements, Operations Requirements, and, prov ide a record o f t he func t i ona l t e s t r e s u l t s . The systemsl funct ions t h a t w i l l be tes ted are l i s t e d i n the Scope sec t i on t h a t f o l l ows .

The Por tab le Exhauster System w i l l be u t i l i z e d t o

1 . 2

RevlWod POPC

0 4

2.0 INFORMATION

D o c u r n t Yo. RevfWod

WHC-SD-WM-ATP-176 0

2.1 SCOPE

2 . 1 . 1

page

5

2 . 1 . 2

2 . 1 . 3

2 .1 .4

2.1.5

2 .1 .6

POWER SYSTER CHECK

This check w i l l v e r i f y t h a t t he re i s proper e l e c t r i c a l power t o a l l t he Exhauster systems.

PRESSURE DECAY TEST

This w i l l check i n t e g r i t y o f t he Exhauster t r a i n assembly a i r boundary, i nc lud ing the Seal Pot. The t e s t i s designed t o address the requirements s p e c i f i e d i n ASME N510-1989, Testing o f Nuclear A i r Treatment System, Sect ion 6.5.3, “Pressure Decay Method”.

EXHAUSTER FAN CHECK

This check w i l l v e r i f y t h a t t he Exhauster Fan operates f r e e l y and r o t a t e s i n the c o r r e c t d i r e c t i o n .

HEAT TRACE CHECK

Th is check w i l l v e r i f y t h a t t he Heat Trace func t i ons proper ly .

INTERLOCK ALARM CHECK

This check w i l l v e r i f y t h a t i n t e r l o c k s per form as requ i red t o s p e c i f i c alarm condi t ions.

GLYCOL HEATER CHECK

Th is check w i l l v e r i f y t h a t t h e Heater and Glycol C i r c u l a t i o n Pump func t i on proper ly .

TANK FARM ACCEPTANCE TEST PROCEDURE

nocurnt no.

WHC-SD-WM-ATP-176

2.2 TERMS AND DEFINITIONS

RWfRod POOC

0 6

2.2.1 ATP - Acceptance I e s t Procedure

2.2.2 DMM - D i g i t a l M u l t i meter

2.2.3 DPT - D i f f e r e n t i a l Pressure I r a n s m i t t e r

2.2.4 DS - Disconnect Swi tch

2.2.5

2.2.6 MPZ - M in i Power Lone

2.2.7

2.2.8 NO - Normally Open

2.2.9 SLC - Small Logic C o n t r o l l e r

2.2.10 QC - Q u a l i t y Contro l

2.2.11 IN W.C.- inches Water Column

HEPA - High E f f i c i e n c y P a r t i c u l a t e A i r

MSDS - Mate r ia l Safety Data Sheet

2.3 RESPONSIBILITIES

2.3.1 The Maintenance c r a f t personnel are responsib le f o r :

Schedule the t e s t as requi red.

Provide the t e s t suppl ies found i n s tep 4.1.

Provide assistance dur ing the t e s t .

TANK FARM ACCEPTANCE TEST PROCEDURE

Docment NO.

WHC-SD-WM-ATP- 1 76

2.3 RESPONSIBILITIES (Continued)

R N I M o d

0

2.3.2 Project Engineer is responsible for:

Designate a Test Director.

0 Coordinate testing with facility management.

Distribute the approved testing schedule as soon as possible, but at least two days prior to testing.

Ensure field testing and inspection has been completed.

Schedule a pre-ATP meeting with test participants prior to start of testing.

Sign Test Execution Sheet when ATP is approved and accepted.

Take necessary action to clear exceptions to the ATP.

Sign Exception Sheet when exception has been resolved.

Provide a distribution list for the approved and accepted ATP.

TANK FARM ACCEPTANCE TEST PROCEDURE I 2.3 RESPONSIBILITIES (Continued)

2 . 3 . 3 Test D i r e c t o r i s responsib le f o r :

.

. .

. I

Coordinate a l l acceptance t e s t i n g .

N o t i f y a l l concerned p a r t i e s when a change i s made i n the t e s t i n g schedule.

Conduct pre- job sa fe ty meeting.

Conduct pre-job system wal kdown.

Confirm t h a t f i e l d t e s t i n g and inspec t i on o f t he system o r p o r t i o n o f the system t o be tes ted has been completed.

Obtain from the P ro jec t Engineer, any i n fo rma t ion o r changes necessary t o c l e a r o r reso lve object ions.

Stop any t e s t which may cause damage t o the system u n t i l t he t e s t procedure has been rev ised.

Observe t e s t s , record t e s t data and ma in ta in t e s t l o g .

Evaluate recorded data, discrepancies, and exceptions.

Approve and record author ized f i e l d changes t o the ATP us ing the red l i n e method.

Sign and date every procedure sec t i on on the working copy as i t i s completed.

Sign Test Execution Sheet when ATP has been performed.

Sign Test Exception Sheet when r e t e s t has been executed and accepted.

Record exceptions and t e s t steps t h a t are n o t performed on the ATP EXCEPTION RECORD. Add a d d i t i o n a l ATP EXCEPTION RECORD sheets as needed.

Transfer t he f i n a l t e s t r e s u l t s w i t h Q u a l i t y Con t ro l ' s s ignatures and dates f o r each sec t i on t o the master i n i n k o r type. master i n the f i e l d p r o j e c t f i l e s .

Reta in the working copy and a copy o f t he

TANK FARM ACCEPTANCE TEST PROCEDURE

D o c u m t No. nev/*od

WHC-SD-WM-ATP-176 0

2.3 RESPONSIBILITIES (Continued)

P W C

9

2.3.4 Q u a l i t y Control (QC) i s responsib le f o r :

Ver i fy ing/wi tness ing r e s u l t s o f t e s t i n g t o establ ished c r i t e r i a .

Signing Test Exception Sheet(s).

* Signing and v e r i f i n g Data Sheet.

Signing Test Exception Sheet(s) when r e t e s t has been executed and accepted.

2.4 REFERENCES

2.4.1 The f o l l o w i n g documents were used t o w r i t e o r are referenced i n t h i s procedure:

WHC-CM-CM-1-10, SAFETY MANUAL, "WKS-6, PRE-JOB SAFETY PLANNING", "WKS-15, ELECTRICAL WORK SAFETY".

WHC-CM-6-1 EP 4.2., STANDARD ENGINEERING PRACTICE, "TESTING REQUIREMENTS"

WHC-IP-1026 APPX M, ENGINEERING PRACTICE GUIDELINES "ACCEPTANCE TEST PROCEDURES AND REPORTS;"

H-14-100737, 500 CFM PORTABLE EXHAUSTER Mechanical

H-14-100764, ELECTRICAL EXHAUSTER SKID DIAGRAM drawings

H-14-100765, ELECTRICAL EXHAUSTER SKID PLANS and

H-14-100766, ELECTRICAL EXHAUSTER SKID DETAILS drawings

* ASME, 1989a, Nuclear Power P lan t A i r -Cleaning U n i t s and

drawings

ELEVATIONS drawings

Components, ASME N509-1989, American Society o f Mechanical Engineers (ASCE), New York.

ASME N510-1989, ASCE, New York. * ASME, 1989b, Test ing o f Nuclear A i r Treatment Systems,

VENDOR INFORMATION

2.5

2.6

2.7

SAFETY

Warning - Energized c i r c u i t s and leads are conta ined i n s i d e the cabinets . Observe appropr ia te e l e c t r i c a l precautions. Comply w i t h WHC-CM-1-10, WKS-15, ELECTRICAL WORK SAFETY.

Caution - Do no t apply Megger vo l tage t o the Var iab le Frequency Dr i ve VTP-VFD-2212A.

2.5.1 The fo l l ow ing admin i s t ra t i ve procedures c o n t r o l work performed i n t h i s procedure:

I n d u s t r i a l Hygiene Manual, WHC-CM-4-40 Safety Manual, WHC-CM-1-10

277W B o i l e r Shop Emergency Preparedness Plan

QUALITY ASSURANCE

The QC Inspector s h a l l v e r i f y t h a t t he ATP has been performed c o r r e c t l y , v e r i f i n g Data Sheets, and s ign and date the Test Execution Sheet(s) and Data Sheets.

GENERAL INFORMATION

2.7.1 Complete each procedure s tep i n the g iven order, unless otherwise noted o r as d i r e c t e d by the Test D i r e c t o r .

A l l e n t r i e s recorded i n t h i s procedure s h a l l be made i n b lack i n k except f o r those noted us ing the r e d l i n e method.

E d i t o r i a l changes requ i red t o t h i s ATP may be made per the red l i n e method by the Test D i r e c t o r as l ong as they do n o t impact operat ional f a c i l i t y sa fe ty func t i on o r performance, and w i l l no t compromise o r i n f l uence the t e s t data. Any changes a f f e c t i n g the above s ta ted c r i t e r i a s h a l l be made i n accordance w i t h WHC-CM-6-1, Standard Engineering Pract ices, EP-2.2, Engineering Document Change Contro l Requirements.

Any non-conformance o f t he inst rumentat ion, unexpected r e s u l t s o r exceptions dur ing t e s t i n g s h a l l be sequen t ia l l y numbered and recorded i n the ATP EXCEPTION LOG. Thus, case-by-case reso lu t i on , recording, approval, and d i s t r i b u t i o n o f each exception w i l l be achieved.

Do no t perform any p a r t o f t h i s procedure on f a u l t y equipment. I f f a u l t y equipment i s discovered, STOP the execution o f t h i s procedure and resolve the problem ( i .e . r e p a i r equipment o r w r i t e up f a u l t y equipment as an exception and continue).

2.7.2

2.7.3

2.7.4

2.7.5

TANK FARM ACCEPTANCE TEST PROCEDURE

D O c v r n r YO. RCvfWod

WHC-SD-WM-ATP-176 0

2.7.6

2 .7 .7

PWC

11

2.7.8

2 . 7 . 9

This procedure DOES conta in separate data sheets. V e r i f i c a t i o n o f procedural steps and v a l i d i t y o f t he data i s incorporated i n t o each s p e c i f i c sec t i on as requi red.

A t t h e completion o f d a i l y ATP t e s t i n g o r i f t e s t i n g i s suspended f o r any reason, ensure t h a t t he 241-A-101 500 CFM Portab le Exhauster i s shutdown and i n a safe de-energized s ta te .

The i n t e n t o f t h i s ATP i s t o prov ide a method f o r documenting the cond i t i on and c a p a b i l i t i e s o f t he a s - b u i l t Exhauster u n i t . The attached ATP Exception Log and Exception Record provides the means o f documenting Acceptance Test ing r e s u l t s and equipment condi t ions. Add i t i ona l sheets are t o be used as necessary t o de l i nea te the progress o f t he ATP.

The performance o f t h i s t e s t may take several days. A t t he end o f each t e s t day the power t o a l l c i r c u i t s must be turned o f f . The Test D i r e c t o r w i l l use Drawings and Engineering judgement t o ensure proper power i s res to red as needed.

3.0 RECORDS

3.1 The completed working copy o f t h i s procedure and a l l except ion logs and except ion records generated by t h i s procedure w i l l be kept as permanent records.

TANK FARM ACCEPTANCE TEST PROCEDURE

DOcInent YO.

WHC-SD-WM-ATP-176

4.0 PREREQUISITES

Revlncd Page

0 12

4.1 The fo l l ow ing suppl ies sha l l be ava i l ab le a t t he workplace:

Pressure Source: minimum range 0 - 15 I N W.C.

Ca l i b ra t i on No. Exp i ra t i on Date

D i g i t a l M u l t i meter: Portable, 0-600 v o l t s ac, k 2% accuracy.

Cal i b r a t i on No. Exp i ra t i on Date

Type J Thermocouple Simulator and connection w i r e

Ca l i b ra t i on No. Exp i ra t i on Date

Water conta iner t h a t measures 17 t o 18 inches i n depth.

Propylene Glycol (An amount t h a t w i l l f i l l system t o an appropr ia te l e v e l )

Pressure measurement device, accurate t o 0.01 i n . wg, approximate range o f 0 t o 12 i n . wg.

Cal i b r a t i on No. Exp i ra t i on Date

Barometer, accurate t o 0.01 i n . Hg, o r use Hanford weather s t a t i o n data

Ca l i b ra t i on No. Exp i ra t i on Date

Temperature i nd i ca to r , accurate t o 0.5 "F

C a l i b r a t i o n No. Exp i ra t i on Date

V ib ra t i on Instrument, SKF CMVAlO

Ca l i b ra t i on No. Exp i ra t i on Date

Compressed a i r source ( o r blower), pressure reducer (o r damper), i s o l a t i o n valve, and sa fe ty r e l i e f mechanism

Vacuum source (Capable o f producing -12.0 I N W.C.)

Desktop/Laptop computer t o i n t e r f a c e w i t h the Exhauster SLC 500 program

480V 3 phase power source

l O O O V and 500V megohmmeter

One #14 insu la ted connection wire, f o u r f e e t l ong

4.0 PREREQUISITES (Continued)

4.2 The f o l l o w i n g documents are requ i red t o perform t h i s procedure:

Engineering drawings and appropr ia te vendor i n fo rma t ion l i s t e d i n sec t i on 2.4.

Propylene Glycol MSDS (# 01552)

The f o l l o w i n g cond i t i ons must be met be fo re t h i s t e s t may commence: 4.3

4.3.1

4.3.2

4.3.3

4.3.4

4.3.5

A pre- job sa fe ty meeting has been he ld i n accordance w i t h IS3, PREJOB SAFETY PLANNING, ICF KH ENVIRONMENTAL, SAFETY, AND HEALTH PROGRAM MANUAL.

0 V e r i f y t h a t t he Exhauster i s ready f o r t e s t i n g by walking down the t e s t area t o i d e n t i f y and c l e a r ,111 hazardous condi t ions.

0

0 Ensure a l l Exhauster valves i nc lud ing DPT valves are closed, except f o r the s tack p i t o t valves.

Ensure a l l c i r c u i t breakers are OFF p r i o r t o s t a r t i n g t e s t

0 0

V e r i f y t he Exhauster has been grounded.

4.3.6 V e r i f y a l l f i l t e r s are i n place.

4.3.7 V e r i f y the I n l e t t e s t sec t i on i s i n place.

0 0

4.4 Test D i r e c t o r SHALL VERIFY t h a t sec t i on 4.3 i s COMPLETE by SIGNING be l ow.

Test D i r e c t o r Signature -

Date

4.0 PREREQUISITES (Continued)

DOCUIM~ no. Rev/Mad

WHC-SD-WM-ATP-176 0

4.5 Test Director shall VERIFY the current calibration and, RECORD the calibration date on the table below.

Page

14

TANK FARM ACCEPTANCE TEST PROCEDURE

Docmen1 No. RW/Wod

WHC-SD-WM-ATP- 1 76 0

4.0 PREREQUISITES (Continued)

PaPC

15

4 .6 Test Director shall VERIFY the current calibration and, RECORD the calibration date on the table below.

4 . 7 Test Director SHALL VERIFY that section 4.0 is COMPLETE by SIGNING bel ow.

Test Director Signature -

Date

TANK FARM ACCEPTANCE TEST PROCEDURE 1

Docurn1 Yo. RevlWod

WHC-SD-WM-ATP- 1 76 0

5.0 PROCEDURE

5.1 POWER SYSTEM CHECK

Paoe

16

5.1.1

5.1.2

5.1.3

5.1.4

5.1.5

5.1.6

5.1.7

INSPECT t he Exhauster system AND VERIFY t h a t a l l equipment i s p roper l y CONNECTED.

0 VERIFY Main 480V Disconnect Switch VTP-CKT-22OlA i s i n the OFF p o s i t i o n . n

U

VERIFY Exhauster Fan Motor 480V Disconnect Switch VTP-DS-2212A i s i n the OFF p o s i t i o n .

0

0

0

VERIFY Glycol Heater 480V Disconnect Switch VTP-DS-2213A i s i n the OFF p o s i t i o n .

VERIFY t h a t M in i Power Zone 480V "primary" C i r c u i t Breaker VTP-CKT-22lOA ( located a t M in i Power Zone Cabinet VTP-PNL-2204A) i s OFF.

VERIFY t h a t Mini Power Zone 120'5 "secondary" C i r c u i t Breaker VTP-CKT-2211A ( l oca ted a t MPZ Cabinet) i s OFF.

VERIFY the f o l l o w i n g 12OV c i r c u i t breakers ( l oca ted a t MPZ Cabinet) are OFF:

5.1.7.1 C i r c u i t Breaker # 1 (Enclosure Heaters and Fans tl 5.1.7.2 C i r c u i t Breaker # 2 (Flammable Gas Moni tor )

0

0

0

5.1.7.3 C i r c u i t Breaker # 3 (PLC power)

5.1.7.4 C i r c u i t Breaker # 4 (Heat Trace)

5.1.7.5 C i r c u i t Breaker # 5 (Convenience Receptacle)

5.1 POWER SYSTEM CHECK (Continued)

rl0clllCnr NO.

WHC-SD-WM-ATP- 1 7 6

5.1.7.6 C i r c u i t Breaker # 6 (PLC c o n t r o l c i r c u i t , Module 8)

0 5.1.7.7 C i r c u i t Breaker # 7 (PLC c o n t r o l c i r c u i t , Module

9)

RevlMod Page

0 17

- I

5.1.7.8 C i r c u i t Breaker # 8 (spare)

0 0

5.1.8

5.1.9

5.1.10

5.1.11

5.1.12

5.1.13

VERIFY Fan Contro l Selector Switch VTP-HS-2212A ( l oca ted on door o f Exhauster Control Cabinet VTP-PNL-2205A) i s i n OFF pos i t i on .

0

0

0

0

n

VERIFY Glycol Pump Control Switch VTP-HS-2213A ( l oca ted on door o f Contro l Cabinet VTP-PNL-2205A) i s i n OFF p o s i t i o n

VERIFY Seal Pot Pump Contro l Se lec to r Switch VTP-HS-22llA ( located on door o f Exhauster Contro l Cabinet VTP-PNL-2205A) i s i n AUTO pos i t i on .

VERIFY CAB HEAT/COOL Selector Switch ( l oca ted on door o f Control Cabinet) i s i n OFF p o s i t i o n .

VERIFY CAB HEAT/COOL Selector Switch ( l oca ted on door o f I n t r i n s i c Barr ier /Heat Trace Cabinet) i s i n OFF p o s i t i o n .

U

DISCONNECT Exhauster f an motor c i r c u i t from t h e Var iab le Frequency Dr i ve te rm ina ls T1, T2 and T3.

5.1 POWER SYSTEM CHECK (Continued)

CAUTION Do n o t apply Megger vo l tage t o the Var iab le Frequency Dr i ve VTP-VFD-22 12A.

5.1.14

5.1.15

5.1.16

5.1.17

5.1.18

5.1.19

5.1.20

5.1.21

5.1.22

USING a lOOOV Megger, megger t e s t from each T1, T2 and T3 lead t o ground and between the leads T1, ‘r2 and T3, ENSURE t he re i s NOT a shor t between Exhauster fan motor o r Exhauster fan motor housing.

0

0 RECONNECT Exhauster f an motor c i r c u i t t o the Var iab le Frequency Dr i ve terminals T1, T2 and T3.

USING a l O O O V Megger, megger t e s t a t t he Heater Contactor VTP-CON-2213A load s ide ( l oca ted a t Contro l Cabinet VTP-PNL-2205A), ENSURE t he re i s NOT a sho r t between Heater c i r c u i t s o r Heater housing.

USING a 500V Megger and DMM, VERIFY t h a t Heat Trace heat ing leads i n s u l a t i o n res i s tance i s g rea te r than 100 Mohms and heat ing leads c o n t i n u i t y i s l ess than 1000 Ohm.

0

0

0

CONNECT t he Exhauster t o a 480V 3 phase power source fused no g rea te r than 30A.

POSITION Main 480V Disconnect Switch VTP-CKT-2201A t o ON p o s i t i o n .

PRESS red EMERGENCY STOP but ton ( l oca ted an door o f Main 480V Disconnect Switch VTP-CKT-2201A).

VERIFY the Main 480V Disconnect Switch C i r c u i t Breaker VTP-CKT-2201A has t r i pped .

0 RESET the Main 480V Disconnect Switch C i r c u i t Breaker VTP-CKT-ZZOlA t o ON p o s i t i o n .

TANK FARM ACCEPTANCE TEST PROCEDURE

D 0 C U T " t no. n e v f w

WHC-SD-WM-ATP-176 0

5.1 POWER SYSTEM CHECK (Continued)

Page

19

5.1.23

5.1.24

5.1.25

5.1.26

5.1.27

5.1.28

5.1.29

5.1.30

5.1.31

5.1.32

VERIFY Green FAN OFF l i g h t ( l oca ted on door o f Exhauster Control Cabinet) i s NOT ILLUNINATED.

0

0

0

0

0

VERIFY Red FAN RUNNING l i g h t ( l oca ted on (door o f Exhauster Contro l Cabinet) i s NOT ILLUMINATED.

VERIFY Glycol Heater i s OFF by OBSERVING t h a t t he Glycol Heater Contactor VTP-CON-2213A con tac to r ( l oca ted i n Control Cabinet VTP-PNL-2205A)is OPEN.

VERIFY t he Glycol C i r c u l a t i o n Pump i s OFF by LISTENING t o and/or FEELING t he Pump.

VERIFY t h a t "HEAT TRACE ON" I n d i c a t i n g L i g h t ( l oca ted on door o f I n t r i n s i c Barr ier /Heat Trace cabinet VTP-PNL-2206A) i s NOT ILLUMINATED.

VERIFY Exhauster Contro l Cabinet Heater VTP-HTR-2205A i s OFF.

VERIFY Exhauster Contro l Cabinet Fan VTP-F-2205A i s OFF.

0 VERIFY Cabinet Heater VTP-HTR-2216A i n 1n t . r i ns i c B a r r i e r / Heat Trace Cabinet i s OFF.

0 VERIFY Cabinet Fan VTP-F-2216A i n I n t r i n s i c B a r r i e r / Heat Trace Cabinet i s OFF.

0 0

VERIFY Alarm Cabinet Heater VTP-HTR-2207A i s OFF.

5.1.33 VERIFY Alarm Cabinet Fan VTP-F-2207A i s OFF.

I TANK FARM ACCEPTANCE TEST PROCEDURE

D O c m m t No. RevfWod

WHC-SD-WM-ATP-176 0

5.1 POWER SYSTEM CHECK (Continued)

Energized c i r c u i t s an Observe appropr ia te e WKS-15 ELECTRICAL WO

Page

20

5.1.34

5.1.35

5.1.36

CLOSE Min i Power Zone 480V “primary” C i r c u i t Breaker VTP-CKT-22lOA ( l oca ted a t M in i Power Zone Cabinet VTP-PNL-2204A). n CLOSE Min i Power Zone 12OV “secondary” C i r c u i t Breaker VTP-CKT-221lA ( located a t MPZ Cabinet).

0

0 POSITION the f o l l o w i n g 12OV c i r c u i t breakers ( l oca ted a t MPZ Cabinet) t o ON:

5.1.36.1 C i r c u i t Breaker # 1 (Enclosure Heaters and Fans b 5.1.36.2 C i r c u i t Breaker # 2 (Flammable Gas Mon i to r ) n 5.1.36.3 C i r c u i t Breaker # 3 (PLC power)

5.1.36.4 C i r c u i t Breaker # 4 (Heat Trace:)

n U

5.1.36.5 C i r c u i t Breaker # 5 (Convenience Receptacle) n 5.1.36.6 C i r c u i t Breaker # 6 (PLC control l c i r c u i t , Module

8)

5.1.36.7 C i r c u i t Breaker # 7 (PLC con t ro l c i r c u i t , Module 9)

5.1.36.8 C i r c u i t Breaker # 8 (spare)

0 0

5.1 POWER SYSTEM CHECK (Continued)

D O C U r n t YO.

WHC-SD-WM-ATP-176

WARNING Energized c i r c u i t s and leads are contained i n s i d e the cabinet . Observe appropr ia te e l e c t r i c a l precautions. Comply w i t h WHC-CM-1-10, WKS-15, ELECTRICAL WORK SAFETY.

RWlWod Page

0 21

5 . 1 . 3 7 USING a DMM, VERIFY 12OV a t the f o l l o w i n g c i r c u i t breakers ( located a t MPZ Cabinet):

0 5 . 1 . 3 7 . 1 C i r c u i t Breaker # 1 (Enclosure Heaters and Fans b 5.1 .37 .2 C i r c u i t Breaker # 2 (Flammable (Gas Moni tor )

0

0 0

0

5 . 1 . 3 7 . 3 C i r c u i t Breaker # 3 (PLC power)

5 . 1 . 3 7 . 4 C i r c u i t Breaker # 4 (Heat Trace)

5 . 1 . 3 7 . 5 C i r c u i t Breaker # 5 (Convenience Receptacle)

5 . 1 . 3 7 . 6 C i r c u i t Breaker # 6 (PLC contro'l c i r c u i t , Module

5 . 1 . 3 7 . 7 C i r c u i t Breaker # 7 (PLC c o n t r o l c i r c u i t , Module

0 9)

5 . 1 . 3 7 . 8 C i r c u i t Breaker # 8 (spare)

5 . 1 . 3 8 PRESSING Ground Fau l t C i r c u i t I n t e r r u p t e r bu t ton a t C i r c u i t Breaker #5 ( located a t MPZ Cabinet).

0 5 . 1 . 3 9 VERIFY c i r c u i t Breaker #5 has t r i pped .

0

I TANK FARM ACCEPTANCE TEST PROCEDURE 1

Doc-t No. RevlWoi

WHC-SD-WM-ATP-176 0

5.1 POWER SYSTEM CHECK (Continued)

Pope

22

5.1.40

5.1.41

5.1.42

RESET c i r c u i t Breaker #5.

PRESSING t he bu t ton o f Ground F a u l t P ro tec t i on f o r Equipment ( loca ted a t MPZ Cabinet C i r c u i t Breaker #4).

0 VERIFY c i r c u i t Breaker #4 ( loca ted a t MPZ Cabinet) has t r i pped . n

5.1.43 RESET c i r c u i t Breaker #4.

NOTE - Fol lowing steps v e r i f y proper opera t ion o f t he Cabinet Cooling Fans and Cabinet Heaters.

0

5.1.44 SET the Alarm Cabinet Heater VTP-HTR-2207A thermostat temperature t o above the ambient temperature.

0

0

0

5.1.45 SET the Control Cabinet Heater VTP-HTR-2205A thermostat temperature t o above the ambient temperature.

5.1.46 POSITION t he CAB HEAT/COOL Se lec tor Switch ( loca ted on door o f Control cab ine t ) t o "SUMMER".

5.1.47 VERIFY t he fo l low ing :

5.1.47.1 Control Cabinet Cool i n g Fan VTP-F-2205A i s r o t a t i n g .

0

0

0

5.1.47.2 Control Cabinet Cool ing Fan VTP-F-2205A a i r f l ow i s f l ow ing from the ou ts ide t o the i ns ide o f t he cabinet.

5.1.47.3 Alarm Cabinet Cool ing Fan VTP-F-2207A i s r o t a t i n g .

TANK FARM ACCEPTANCE TEST PROCEDURE 1

Docurnt Yo. Revlllod

WHC-SD-WM-ATP- 7 76 0

5.1 POWER SYSTEM CHECK (Continued)

Page

23

5.1.48

5.1.49

5.1.50

5.1.51

5.1.52

5.1.53

5.1.47.4 Alarm Cabinet Cooling Fan VTP-F-2207A a i r f l o w i s f lowing from the ou ts ide t o the i n s i d e o f t h e cabinet .

0

0

0

0

5.1.47.5 Control Cabinet Heater VTP-HTR-2205A i s OFF.

5.1.47.6 Alarm Cabinet Heater VTP-HTR-2207A i s OFF.

POSITION the CAB HEAT/COOL Selector Switch ( l oca ted on door o f Control cabinet ) t o "WINTER".

VERIFY t he fo l l ow ing :

5.1.49.1 Control Cabinet Cooling Fan VTP-F-2205A i s OFF.

0

0

0

0

0

0

0

0

5.1.49.2 Alarm Cabinet Cooling Fan VTP-F-2207A i s OFF.

5.1.49.3 Contro l Cabinet Heater VTP-HTR-2205A i s ON.

5.1.49.4 Alarm Cabinet Heater VTP-HTR-2205A i s ON.

SET the Control Cabinet Heater VTP-HTR-2205A thermostat temperature t o bel ow the ambient temperature.

VERIFY Control Cabinet Heater VTP-HTR-2205A i s OFF.

SET the A1 arm Cabinet Heater VTP-HTR-2207A thermostat temperature t o below the ambient temperature.

VERIFY Alarm Cabinet Heater VTP-HTR-2207A i s OFF.

5.1 POWER SYSTEM CHECK (Continued)

Docmnt NO.

WHC-SD-WM-ATP-176

5.1.54

5.1.55

5.1.56

5.1 .57

5.1.58

5.1.59

5.1.60

5.1.61

5.1.62

5.1.63

Revfllad Page

0 24

SET the I n t r i n s i c Barr ier /Heat Trace Cabinet Heater VTP-HTR-2206A thermostat temperature t o above t h e ambient temperature.

0 POSITION t he CAB HEAT/COOL Selector Switch ( l oca ted on door o f I n t r i n s i c Barr ier /Heat Trace cabinet ) t o "SUMMER.

VERIFY the I n t r i n s i c Barr ier /Heat Trace Cabinet Cooling Fan VTP-F-2206A i s r o t a t i n g .

VERIFY t he I n t r i n s i c Barr ier /Heat Trace C,abinet Cooling Fan a i r f l ow i s f lowing from the outs ide t o the i n s i d e o f the cabinet .

0

0

VERIFY I n t r i n s i c Barr ier /Heat Trace Heater VTP-HTR-2Z06A i s OFF.

POSITION t he CAB HEAT/COOL Selector Switch ( l oca ted on door o f I n t r i n s i c Barr ier /Heat Trace) t o "WINTER.

VERIFY the I n t r i n s i c Barr ier /Heat Trace Cabinet Cooling Fan VTP-F-2206A i s OFF.

VERIFY t he I n t r i n s i c Barr ier /Heat Trace Cabinet Heater VTP-HTR-2206A i s ON.

0 SET the I n t r i n s i c Barr ier /Heat Trace Cabinet Heater VTP-HTR-2206A thermostat temperature t o below the ambient temperature.

0 VERIFY I n t r i n s i c Barr ier /Heat Trace Cabinet Heater VTP-HTR-2206A i s OFF.

0

TANK FARM ACCEPTANCE TEST PROCEDURE 1

DQCl l lCl t NO. RevfMod

WHC-SD-WM-ATP-176 0

5.1 POWER SYSTEM CHECK (Continued)

PW.2

25

WARNING Energized c i r c u i t s and leads are contained i n s i d e the cabinet . Observe appropr ia te e l e c t r i c a l precautions. Comply w i t h WHC-CM-1-10, WKS-15, ELECTRICAL WORK SAFETY.

5.1.64

5.1.65

5.1.66

5.1.67

MOTE - 5.1.68

USING a DMM, VERIFY 120V a t t he M in i Power Zone Cabinet (VTP-PNL-2204A) Receptacle.

0

0

0 0

VERIFY p o l a r i t y o f t h e Mini Power Zone Cabinet Receptacle.

USING a DMM, VERIFY 120V a t t he Alarm Cabinet (VTP-PNL-2207A) Receptacle.

Wilkerson i n d i c a t o r s f o r DPTs should be i n d i c a t i n g zero.

VERIFY the Wilkerson i n d i c a t o r s are i n d i c a t i n g c o r r e c t l y by f ill i n g the f o l l o w i n g tab le .

0

VERIFY p o l a r i t y o f t he Alarm Cabinet Receptacle.

TANK FARM ACCEPTANCE TEST PROCEDURE 1

oocumr no. RevfMad

WHC-SD-WM-ATP-17 6 0

5.1 POWER SYSTEM CHECK (Continued)

Page

26

5.1.69

5.1.70

5.1.71

VERIFY t he f o l l o w i n g i n d i c a t i n g l i g h t s ( l oca ted on door o f Exhauster Control Cabinet VTP-PNL-2205A) are ILLUMINATED:

5.1.69.1 Green FAN OFF l i g h t .

0

0

5.1.69.2 D i g i t a l readouts on a l l seven DPTs.

5.1.69.3 Message View Disp lay VTP-PUI-2207A and VTP-UI-2208A ( l oca ted a t Alarm Cabinet VTP-PNL-2207A Swing Out Panel).

POSITION t h e f o l l o w i n g 12OV c i r c u i t breakers ( l oca ted a t MPZ Cabinet) t o OFF:

5.1.70.1 C i r c u i t Breaker # 2 (Flammable Gas Moni tor )

0 5.1.70.2 C i r c u i t Breaker # 8 (spare)

Test D i r e c t o r SHALL VERIFY t h a t sec t i on 5.1 i s COMPLETE by SIGNING below.

Test D i r e c t o r Signature -- Date

5.2 PRESSURE DECAY TEST

5.2.1 PERFORN t he f o l l o w i n g inspect ions:

5.2.1.1 VERIFY F i l t e r T ra in ductwork, housings, f i l t e r s , connections, gaskets, and seals DO NOT have signs o f damage, component misal’ignment, improper i n s t a l l a t i o n , o r o the r func t i ona l problems.

n 5.2.1.2 REMOVE f i l t e r housing doors.

U

5.2.1.3 INSPECT the HEPA f i l t e r s , f i l t e r housing, and the f i l t e r housing doors and t h e i r seals f o r obvious s igns o f damage.

0 5.2.1.4 ENSURE t h a t t he HEPA f i l t e r s have been p roper l y

locked against i t s sea l i ng frame and t h a t the f i l t e r housing doors ( p r e f i l t e r and HEPA f i l t e r s ) are secured.

0

0

0

5.2.1.5 REPAIR components as noted on the Exception Resolut ion .

5.2.1.6 TIGHTEN f i l t e r housing door l a t ches i n a gradual, equal sequence t o ensure an even door gasket seal.

5.2.2 CLOSE F i l t e r t r a i n I n l e t va lve VTP-V-2250A.

5.2.3 CLOSE F i l t e r t r a i n O u t l e t va lve VTP-V-2251A.

5 . 2 . 4 VERIFY Seal Pot VTP-SP-221OA i s empty. 0

5 . 2 . 5 VERIFY Seal Pot F i l l Valve VTP-V-2258A i s CLOSED.

0

TANK FARM ACCEPTANCE TEST PROCEDURE

D o c m t Yo. RevfMcd

WHC-SD-WM-ATP-176 0

5.2 PRESSURE DECAY TEST (Continued)

Page

28

5.2.6

5.2.7

5.2.8

5.2.9

5.2.10

5.2.11

5.2.12

5.2.13

NOTE -

5.2.14

5.2.15

VERIFY Seal Pot CLOSED.

VERIFY Seal Pot

Overf low Dra in L ine Valve VTP-V-2260A i s

0

0 Drain Valve VTP-V-2259A i:j CLOSED.

VERIFY Fan Dra in L ine Valve VTP-V-2257A i!; CLOSED.

0 UNSCREW cap on t h e f i r s t stage HEPA F i l t e r Aerosol I n j e c t i o n Por t VTP-FTP-2201A on the t e s t sec t i on next t o P r e f i l t e r .

INSTALL AND SEAL the pressure measuring dev ice i n t o the f i r s t stage HEPA F i l t e r Aerosol I n j e c t i o n Por t VTP-FTP-22OlA.

0 INSTALL t he a i r supply l i n e (w i th sa fe ty r e l i e f mechanism, i s o l a t i o n valve, and pressure reducer) i n t o t h e second stage HEPA F i l t e r Aerosol I n j e c t i o n Aerosol Test Po r t VTP-FTP-2204A.

0

0

UNSCRM cap on the f i r s t Stage HEPA F i l t e r Thermocouple (VTP-TE-2222A) Por t on top o f f i l t e r t r a i n housing, P re f i 1 t e r .

next t o

INSTALL and SEAL t he temperature measuring instrument i n t o t h e Thermocouple VTP-TE-2222A p o r t .

Next s tep s t a r t s checking p o s i t i v e pressure decay.

PRESSURIZE t e s t housing/duct assembly t o +11.5 2 0.5 i n w b LOCATE (using a s u i t a b l e bubble s o l u t i o n ) and SEAL a l l leaks as p r a c t i c a l .

0

TANK FARM ACCEPTANCE TEST PROCEDURE 1

Docurnt No.

WHC-SD-WM-ATP-176

5.2 PRESSURE DECAY TEST (Continued)

RW/Wod Pope

0 29

5.2.16 MAINTAIN constant pressure u n t i l temperature remains constant w i t h i n f. 0.5 "F f o r a minimum o f 10 minutes.

0 5.2.

5.2.

7 ISOLATE t he a i r supply from the f i l t e r housing w h i l e STARTING t he c lock.

8 RECORD the i n i t i a l t ime, barometric pressure, pressure, and temperature on Data Sheet 1.

0 5.2.19 RECORD pressure and temperature readings a minimum o f once a

minute, UNTIL pressure decays t o 75% o f t he recorded s t a r t i n g pressure (previous s tep) o r f o r a maximum o f 15 minutes, which ever comes f i r s t on the f o l l o w i n g tab le .

0

5.2.20 RECORD f i n a l time, barometric pressure, and temperature on Data Sheet 1.

0 5.2.21 PERFORM t he l eak r a t e ca l cu la t i ons per Data Sheet 1.

0 5.2.22 ENSURE t he l eak r a t e c a l c u l a t i o n s are v e r i f i e d independently

0

El

by QC.

5.2.23 I F Q < L then RECORD "PASS" on Data Sheet 1. Otherwise, RECORD l'kETEST'' an Data Sheet 1.

5.2 PRESSURE DECAY TEST (Continued)

ooclllCnr NO. Revlnod

WHC-SD-WM-ATP-176 0

5.2.24

Page

30

5.2.25

5.2.26

5.2.27

NOTE -

5.2.28

IF a retest is needed, then PERFORM the following:

5.2.24.1 DETERMINE the leak path(s) and REPAIR leaks as noted on the Exception Resolution.

0 5.2.24.2 REPEAT steps 5.2.14 through 5.2.24 using new data

sheets.

0

0 DISCONNECT the air supply.

SLOWLY RELIEVE pressure from Filter Train housing.

CONNECT a vacuum source to the Pressure Test Assembly at Aerosol Injection Port VTP-FTP-2204A.

Next step starts checking negative pressure decay.

DECREASE Filter Train housing internal pressure to -11.5 - t 0.5 IN W.C. as INDICATED by the Pressure measuring device.

0 5.2.29 MAINTAIN constant pressure until temperature remains

constant within 5 0.5 'F for a minimum of 10 minutes.

0

0 5.2.30 ISOLATE the vacuum source from the filter housing while

starting the clock.

5.2.31 RECORD the initial time, barometric pressure, pressure, and temperature on Data Sheet 2.

TANK FARM ACCEPTANCE TEST PROCEDURE

5.2 PRESSURE DECAY TEST (Continued)

5.2.32 RECORD pressure and temperature readings a minimum of once a minute, UNTIL pressure decays to 75% o f the recorded starting pressure (previous step) or for a maximum of 15 minutes, which ever comes first on the following table.

5.2.33 RECORD final time, barometric pressure andl temperature on Data Sheet 2.

0 5.2.34 PERFORM the leak rate calculations per Data Sheet 2.

0 5.2.35 ENSURE the leak rate calculations are verified independently

n by PC.

U

5.2.36 I F Q < L, then RECORD "PASS" on Data Sheet 2 AND 60 TO step 5.2.38. Otherwise, RECORD "RETEST" on Data Sheet 2.

5.2.37 I F a retest is needed, then PERFORM the following: 0

5.2.37.1 DETERMINE the leak path(s) and REPAIR leaks as noted on the Exception Resolution.

0 5.2.37.2 REPEAT steps 5.2.28 through 5.2.37 using new data

sheets.

5.2.38 DISCONNECT the test equipment. 0

TANK FARM ACCEPTANCE TEST PROCEDURE

DocLLnt No. RevlWd

WHC-SD-WM-ATP-176 0

5.2 PRESSURE DECAY TEST (Continued)

Page

32

5.2.39 SLOWLY equalize Filter Train housing pressure to atmospheric.

5.2.40 REINSTALL the test port plugs.

5.2.41 OPEN Filter Train Inlet valve VTP-V-2250A.

0

0

0 5.2.42 OPEN Filter Train outlet valve VTP-V-225114.

0

0 5.2.43 OPEN Fan Drain Line valve VTP-V-2257A.

5.2.44 Test Director SHALL VERIFY that section 5.2 is COMPLETE by SIGNING bel ow.

-L

Test Director Signature Date

QC Inspector SHALL VERIFY that section !I.? is COMPLETE by SIGNING below.

5.2.45

QC Inspector Signature -- Date

5.3 EXHAUSTER FAN CHECK

D o c u m t Yo.

WHC-SD-WM-ATP- 1 76

5.3.1

Revfllod

0

5.3.2

5.3.3

5.3.4

5.3.5

5.3.6

5.3.7

5.3.8

5.3.9

POSITION the Exhauster Fan Motor Disconnec:t Switch VTP-DS-2212A t o ON.

VERIFY Fan does NOT s t a r t automat ica l ly .

VERIFY Green FAN OFF l i g h t ( l oca ted on door o f Exhauster Control Cabinet VTP-PNL-2205A) i s ILLUMINATED.

0

0 VERIFY Red FAN RUNNING l i g h t ( l oca ted on door o f Exhauster Contro l Cabinet VTP-PNL-2205A) i s NOT ILLUMINATED.

0

0

0

17

POSITION Fan Control Switch (SSFC) VTP-HS-2212A t o "ENABLE" p o s i t i o n ( l oca ted on door o f Exhauster Contro l Cabinet VTP-PNL-2205A).

PRESS Fan S t a r t Button (PBSTRT) VTP-PB-2212M AND THEN QUICKLY PRESS Fan Stop Button (PBSTP) VTP-PB-2212H (i .e. bump the fan) located on door o f Exhauster Contro l Cabinet

VERIFY t h a t d i r e c t i o n o f r o t a t i o n o f t he Exhauster fan i s i n t h e DIRECTION o f the arrow on the fan housing o r motor shroud.

I F Exhauster Fan r o t a t i o n d i r e c t i o n i s co r rec t , GO TO step 5.3.10.

0 I F d i r e c t i o n o f r o t a t i o n o f t he Exhauster Fan i s i nco r rec t , then PERFORM the fo l l ow ing :

5.3.9.1 00 NOT EXECUTE any f u r t h e r p a r t o f 5.3 i n t h i s ATP UNTIL next s tep through 5.3.9.5 are CORPLETED . n

U

5.3.9.2 POSITION Fan Motor Disconnect Switch VTP-DS-2212A t o OFF.

0

5.3 EXHAUSTER FAN CHECK (Continued)

D O C m t NO. Rev/Mod

WHC-SD-WM-ATP-176 0

Energized c i r c u i t s and leads are contained i n s i d e t h e cabinet . r i c a l precautions. Comply w i t h WHC-CM-1-10,

Page

34

5.3.9.3 CORRECT the Exhauster Fan r o t a t i o n d i r e c t i o n by CORRECTING the leads a t t he Fan Motor Disconnect Switch VTP-CKT-2212A.

0 5.3.9.4 POSITION Fan Motor Disconnect Switch

VTP-CKT-2212A t o ON.

5.3.9.5 REPEAT steps 5.3.6 through 5.3.9.

0

0 5.3.10 OPEN the High and Low valves AND CLOSE Equal iz ing va lve on

each th ree va lve mani fo ld f o r t he f o l l o w i n g DPTs:

DPT 1 !!EN 1 !:EN 1 CLOSE Equal

VTP-PT-2213A

VTP-PDT-2214A

VTP-PDT-2215A

VTP-PDT-2218A

5.3.11 POSITION Fan Motor Disconnect Switch VTP-CKT-2212A t o OFF. n U

5.3.12 REMOVE Fan s h a f t / b e l t guards as requ i red t o a l l ow access t o sha f t bearings.

0

5.3 EXHAUSTER FAN CHECK (Continued)

Docurnt no.

WHC-SD-WM-ATP-176

5.3.13 POSITION Fan Motor Disconnect Switch VTP-CKT-2212A t o ON.

0

0

5.3.14 PRESS Fan S t a r t Button VTP-PB-2212M (PBSTRT) ( l oca ted on door o f Exhauster Contro l Cabinet VTP-PNL-2205A) t o t u r n ON Exhauster Fan AND NOTE t ime a t same t ime.

Rwtnod Page

0 35

5.3.15 VERIFY Fan Ramp Up Time i s approximately 10 sec, o r as programmed i n Var iab le Frequency Dr i ve VTP-VFD-2212A i s programmed.

0

0 5.3.16 VERIFY Green FAN OFF l i g h t ( l oca ted on door o f Exhauster

Contro l Cabinet VTP-PNL-2205A) i s NOT ILLUMINATED.

5.3.17 VERIFY Red FAN RUNNING l i g h t ( l oca ted on door o f Exhauster Control Cabinet VTP-PNL-2205A) i s ILLUMINATED.

0

0 5.3.18 ENSURE Exhauster Fan i s operat ing normal ly w i t h no unusual

noise.

NOTE - Next s tep s t a r t s the Exhauster Fan v ibrat i ion t e s t . The t e s t i n g i s based on ASME N509 requirements f o r 3450 RPM.

5.3.19 USING t he v i b r a t i o n instrument, RECORD t he measured data i n the t a b l e a t next step. I F t he bear ing i s n o t access ib le ENTER "N/A" .

0

5.3 EXHAUSTER FAN CHECK (Continued)

P1 ane

Sheave End Fan Shaf t Bearing Displacement ( M i 1 s) V e l o c i t y ( I N / S E C )

Fan End Fan Shaf t bear ing Displacement (M i l s ) V e l o c i t y (IN/SEC)

5.3.20 VERIFY t h a t t he F i l t e r e d Bearing V i b r a t i o n Levels on the fan sha f t bearings should meet the f o l l o w i n g c r i t e r i a :

Axi a1 OK Hor izonta l (Ol: V e r t i c a l 1 (;; I (4

Displacement <.6 M I L S (PK-TO-PK) a t one t imes the fan, speed

OR

V e l o c i t y < .ll IN/SEC (PK)at one t imes t h e fan speed.

Docurnt Yo. Revfllod

WHC-SD-WM-ATP-176 0 Page

36

5.3.21 USING the v i b r a t i o n instrument, RECORD t he measured data i n the t a b l e a t next s tep OR, I F t he bear ing i s no t accessible ENTER "N/A" .

TANK FARM ACCEPTANCE TEST PROCEDURE

P1 ane

Sheave End Fan Shaf t Bearing Displacement (M i l s ) V e l o c i t y (IN/SEC)

Fan End Fan Shaf t bear ing Displacement (M i l s ) V e l o c i t y (IN/SEC)

5.3 EXHAUSTER FAN CHECK (Continued)

Ax ia l OK Hor izonta l OK ( J ) (4

5.3.22 VERIFY t h a t t he Overa l l ( u n f i l t e r e d ) Bearing V ib ra t i on Levels on the fan shaft bearings meet the f o l l o w i n g c r i t e r i a :

OR

D i sp l acement tl .7 MILS (PK-TO-PK) Overa l l ,

Ve loc i t y < .31 IN/SEC (PK) Overa l l .

5.3.23

5.3.24

5.3.25

5.3.26

5.3.27

5.3.28

tF Exhauster Fan i s operat ing normally, GO TO step 5.3.29

0

0

0

0

0

I F the Exhauster Fan i s no t operat ing normal ly then SHUTDOWN the fan by PRESSING Fan Stop But ton VTP-PR-2212H (PBSTP)(located a t door o f Exhauster Contro l Cabinet).

P o s i t i o n Exhauster Fan Motor Disconnect Switch VTP-DS-2212A t o OFF.

REPAIR equipment as noted on the Exception Resolut ion.

POSITION EXHAUSTER FAN MOTOR DISCONNECT SWITCH VTP-DS-2212A t o ON.

REPEAT steps 5.3.15 t o 5.3.24.

5.3 EXHAUSTER FAN CHECK (Continued)

O o c m t NO. nev/uad

WHC-SD-WM-ATP-176 0

5.3.29

PaPC

38

5.3.30

5.3.31

5.3.32

5.3.33

5.3.34

5.3.35

PRESS Fan Stop Button VTP-PB-2212H (PBSTP) ( l oca ted on door o f Exhauster Control Cabinet VTP-PNL-2205A) t o t u r n OFF Exhauster Fan AND NOTE t ime a t same t ime.

0

0

0 0

0

VERIFY Fan Ramp Down Time i s approximately 10 sec, as VTP-VFD-2212A programmed.

VERIFY Exhauster f an has SHUTDOWN.

POSITION Fan Motor Disconnect Switch VTP-lCKT-2212A t o OFF.

REPLACE Fan s h a f t / b e l t guards.

POSITION Fan Motor Disconnect Switch VTP-CKT-2212A t o ON.

Test D i r e c t o r SHALL VERIFY t h a t sec t i on 5.3 i s COMPLETE by SIGNING below.

Test D i r e c t o r Signature -- Date

5.4 HEAT TRACE CHECK

DocU.Mt Yo. Rev/wad

WHC-SD-WM-ATP-176 0

5.4.1

Page

39

POSITION Heat Trace 12OV c i r c u i t breaker %4 ( l oca ted a t MPZ Cabinet VTP-DP-2204A) t o OFF.

n U

5.4.2 DISCONNECT Heat Trace Thermostat VTP-TS-2224 ( l oca ted on sk id framing a t Exhauster Contro l Cabinet VTP-PNL-2205A) from connector.

0

0 5.4.3 DE-TERM OR INSULATE t he Heat Trace Thermostat leads t h a t are

disconnected from the thermostat.

5.4.4 USING DMM, VERIFY t he re i s NO c o n t i n u i t y between the 'Thermostat NO and COM contacts .

n U

5.4.5 PLACE Heat Trace Thermostat i n a f reeze r 1.0 SIMULATE low temperature.

0 5.4.6

5.4.7

5.4.8

5.4.9

5.4.10

CONNECT a w i re jumper t o terminals TBlHTC-1 and TBlHTC-2 ( l oca ted a t I n t r i n s i c B a r r i e r / Heat Trace Cabinet).

0

0

0

POSITION Heat Trace 12OV c i r c u i t breaker #4 ( l oca ted a t MPZ Cabinet VTP-DP-2204A) t o ON.

USING a DMM, VERIFY 12OV a t t e rm ina ls TBlHTC-2 and TBZHTC-2 ( located a t I n t r i n s i c B a r r i e r / Heat Trace Cabinet VTP-PNL-2206A).

VERIFY Heat Trace ON amber l i g h t ( l oca ted a t door o f Trace Cabinet VTP-PNL-2206A) i s I n t r i n s i c B a r r i e r / Heat

ILLUMINATED.

POSITION Heat Trace 12OV Cabinet VTP-DP-2204A) t o

c i r c u i t breaker #4 ( l oca ted a t MPZ OFF.

0

TANK FARM ACCEPTANCE TEST PROCEDURE

5.4 HEAT TRACE CHECK (Continued)

5.4.11

5.4.12

5.4.13

5.4.14

5.4.15

DISCONNECT wi re jumper from te rmina ls TB:lHTC-1 and TBlHTC-2 ( loca ted a t I n t r i n s i c B a r r i e r / Heat Trace Cabinet VTP-PNL-2206A).

0 WHEN 30 minutes has elapsed, REMOVE Heat Trace Thermostat from f reezer .

0

0

n

USING DMM, VERIFY there i s c o n t i n u i t y between the Thermostat NO and COM contacts.

RECONNECT Heat Trace Thermostat VTP-TS-2224A t o the connector ( loca ted on s k i d f raming a t Exhauster Control Cabinet VTP-PNL-2205A).

U

Test D i rec to r SHALL VERIFY t h a t sec t ion 5.4 i s COMPLETE by SIGNING bel ow.

-- Test D i rec to r Signature Date

TANK FARM ACCEPTANCE TEST PROCEDURE

5.5 INTERLOCK/ALARM CHECK

NOTE -

5.5.1

5.5.2

5.5.3

5.5.4

5.5.5

5.5.6

5.5.7

5.5.8

5.5.9

5.5.10

Next s tep s t a r t s check on F i l t e r #1 DPT.

CLOSE valves l abe led h igh and low on the th ree va lve mani fo ld a t HEPA FILTER #1 Transmi t ter VTP-PDT-2216A ( l oca ted on top o f F i l t e r T ra in ) . n

U REMOVE p lug from c a l i b r a t i o n p o r t on the t r a n s m i t t e r VTP-PDT-2216A th ree va lve mani fo ld .

0 CONNECT a pressure source t o c a l i b r a t i o n p o r t on the t r a n s m i t t e r VTP-PDT-2216A th ree va lve mani fo ld .

0

0

0

0

0

OPEN Equal iz ing Valve on the t r a n s m i t t e r VTP-PDT-2216A three va lve mani fo ld .

SET pressure source pressure t o approximately 3.0 I N W.C..

VERIFY Wilkerson i n d i c a t o r VTP-PDI-Z216A(located on door o f Exhauster Control Cabinet VTP-PNL-2205A) i s READING w i t h i n a range o f 2.85 I N W.C. and 3.15 IN W.C..

PRESS Fan S t a r t Button VTP-PB-2212M ( loca ted on door o f Exhauster Control Cabinet VTP-PNL-2205A).

WAIT f o r t he Exhauster fan t o come up t o speed.

INCREASE pressure source pressure t o approximately 4.5 I N W.C..

VERIFY the fo l l ow ing :

0

5.5.10.1 Rotat ing Beacon i s ILLUMINATED.

0 5.5.10.2 Red FAN RUNNING l i g h t i s ILLUMINATED.

TANK FARM ACCEPTANCE TEST PROCEDURE

D o c m t Ya.

WHC-SD-WM-ATP-176

5.5 INTERLOCKlALARM CHECK (Continued)

Rev/Mod

0

5.5.10.3

5.5.10.4

5.5.10.5

5.5.10.6

Green FAN OFF l i g h t i s NOT ILLUHINATED.

W i l kerson i n d i c a t o r VTP-PDI-2216A ( l oca ted on door o f Exhauster Contro l Cabinet VTP-PNL-2205A), corresponding t o t r a n s m i t t e r VTP-PDT-2216A, i s READING w i t h i n a range o f 4.28 I N W.C. and 4.73 IN W.C..

0

0

Message View Disp lays VTP-UI-2207A and VTP-UI-2208A(located a t Alarm Cabinet Swing Out Panel) DISPLAY “FILTER 1 DP H I ” .

DPT readout DISPLAYS a value approximately equal t o 4.5 IN W.C.. n

5.5.11

5.5.12

5.5.13

5.5.14

5.5.15

U

ACKNOWLEDGE t he alarm by PRESSING the “1” but ton, then PRESSING the “-” but ton th ree t imes on the Message View Disp lay (1 ocated a t A1 arm Cabinet VTP-PNL-2207A Swing Out Panel ) .

0

0

VERIFY Rotat ing Beacon i s NOT ILLUMINATED.

Message View Disp lay VTP-VI-2208A ( l oca ted a t Alarm Cabinet Swing Out Panel) STILL DISPLAYS “FILTER 1 DP H I ” .

INCREASE pressure source pressure t o apprciximately 5.4 IN W.C..

VERIFY the fo l l ow ing :

0

5.5.15.1 Exhauster Fan has SHUTDOWN. 0

0 5.5.15.2 Red FAN RUNNING l i g h t i s NOT ILLUHIHATED.

5.5 INTERLOCKlALARM CHECK (Continued)

DacLnnt No.

WHC-SD-WM-ATP-176

5.5.15.3

5.5.15.4

5.5.15.5

5.5.15.6

5.5.15.7

RevfMod Page

0 43

Green FAN OFF l i g h t i s ILLUHINATED. n U

Rota t ing Beacon ( l oca ted on s tack suppor t ing framing) i s ILLURINATED. n

U

Wilkerson i n d i c a t o r VTP-PDI-2216A ( l oca ted on door o f Exhauster Contro l Cabinet VTP-PNL-2205A), corresponding t o t r a n s m i t t e r VTP-PDT-2216A, i s READING w i t h i n a range o f 5.13 I N W.C. and 5.67 I N W.C..

0

0

0

Message View Disp lay VTP-UI-2207 ( l oca ted a t Alarm Cabinet Swing Out Panel) DISPLAYS “FILTER 1 DP HIHI“ and “FAN SHUTDOWN”.

DPT readout DISPLAYS a va lue approximately equal t o 5.4 IN W.C..

5.5.16

5.5.17

5.5.18

5.5.19

5.5.20

5.5.21

ACKNOWLEDGE t he alarm by PRESSING t he “1” button, then bu t ton on the Message View Disp lay ( l oca ted a t Alarm Cabinet VTP-PNL-2207A Swing Out Panel).

0

0

0

VERIFY Rotat ing Beacon i s NOT ILLURINATED.

Message View Disp lay VTP-UI-2208A ( l oca ted a t Alarm Cabinet Swing Out Panel) STILL DISPLAYS “FILTER 1 DP HIHI” and “FAN SHUTDOWN”.

DECREASE pressure source pressure t o approximately 3.0 IN W.C..

0

0 0

PRESS Fan S t a r t Button VTP-PB-2212M ( loca ted on door o f Exhauster Control Cabinet VTP-PNL-2205A).

WAIT f o r t he Exhauster f an t o come up t o speed.

5.5 INTERLOCK/ALARM CHECK (Continued)

5 . 5 . 2 2 DECREASE pressure source pressure W.C..

5.5.23 VERIFY t he fo l l ow ing :

t o approximately 0.05 IN

0

5.5.23.1 Exhauster Fan has SHUTDOWN.

5.5.23.2 Red FAN RUNNING l i g h t i s NOT ILLUMINATED.

5.5.23.3 Green FAN OFF l i g h t i s ILLUMINATED.

0

0 n U

5.5.23.4 Rotat ing Beacon ( l oca ted on s tack suppor t ing framing) i s ILLUMINATED.

0 5.5.23.5 Wilkerson i n d i c a t o r VTP-PDI-2216A ( l oca ted on

door o f Exhauster Contro l Cabinet VTP-PNL-2205A), corresponding t o t r a n s m i t t e r VTP-PDT-2216A, i s READING w i t h i n a range o f 0.047 I N W.C. and 0.053 I N W.C..

0 5.5.23.6 Message View Disp lay VTP-UI-2207A and

VTP-UI-220BA ( l oca ted a t Alarm Cabinet Swing Out Panel) DISPLAYS “FILTER 1 DP LO” and “FAN SHUTDOWN”.

0 5.5.23.7 DPT readout DISPLAYS a va lue approximately equal

t o 0.05 IN W.C..

5.5.24 ACKNOWLEDGE t he alarm by PRESSING t h e “1” button, then PRESSING the ‘‘e” but ton th ree t imes on the Message View Disp lay ( located a t Alarm Cabinet VTP-PNL-2207A Swing Out Panel ) .

0 5.5.25 VERIFY Rotat ing Beacon i s NOT ILLUMINATED.

0

TANK FARM ACCEPTANCE TEST PROCEDURE I

nocurnt NO.

WHC-SD-WM-ATP-176

5.5 INTERLOCK/ALARM CHECK (Continued)

R W l M o d

0

5.5.26 Message View Disp lay VTP-UI-2208A ( l oca ted a t Alarm Cabinet Swing Out Panel) STILL DISPLAYS "FILTER 1 DP Lo" and "FAN SHUTDOWN".

5.5.27 DISCONNECT pressure source from t h e t r a n s m i t t e r p o r t .

5.5.28 CLOSE Equal iz ing Valve a t t he t r a n s m i t t e r t h ree manifold.

0

0 c a l i b r a t i o n

va lve

5.5.29 REPLACE p lug t o c a l i b r a t i o n p o r t on the t r a n s m i t t e r VTP-PDT-2216A th ree va lve manifold.

0 5.5.30 OPEN valves l abe led h igh and low on th ree va lve mani fo ld a t

t r a n s m i t t e r VTP-PDT-2216A ( l oca ted on top o f F i l t e r T ra in b

TANK FARM ACCEPTANCE TEST PROCEDURE

Docurnt Yo.

WHC-SD-WM-ATP-176

5.5 INTERLOCKlALARM CHECK (Continued)

Revlllod

0

NOTE - 5.5.31

5.5.32

5.5.33

5.5.34

5.5.35

5.5.36

5.5.37

5.5.38

5.5.39

5.5.40

Next step starts check on Filter #2 DPT.

CLOSE valves labeled high and low on the three valve manifold at HEPA FILTER #2 Transmitter VTP-PDT-2217A (located on top of Filter Train).

REMOVE plug from calibration port on the transmitter VTP-PDT-2217A three valve manifold.

CI

0 CONNECT a pressure source to calibration port on the transmitter VTP-PDT-2217A three valve manlfold.

0

0

0

OPEN Equalizing Valve on the transmitter VTP-PDT-2217A three valve manifold.

SET pressure source pressure to approximately 3.0 IN W.C..

VERIFY Wilkerson indicator VTP-PDI-2217A (located on door of Exhauster Control Cabinet VTP-PNL-2205A) is READING within a range of 2.85 IN W.C. and 3.15 IN W.C..

PRESS Fan Start Button VTP-PB-2212M (located on door of Exhauster Control Cabinet VTP-PNL-2205A).

0

HAIT for the Exhauster fan to come up to speed.

0 INCREASE pressure source pressure to approximately 3.2 IN W.C.. n

U

VERIFY the following:

5.5.40.1 Rotating Beacon i s ILLUMINATED.

0 0

5.5.40.2 Red FAN RUNNING light is ILLUMINATED.

5.5 INTERLOCK/ALARM CHECK (Continued)

D o c u m t Yo.

WHC-SD-WM-ATP- 1 7 6

5.5.40.3

5.5.40.4

5.5.40.5

5.5.40.6

RevIWod

0

Green FAN OFF l i g h t i s NOT ILLUMINATED.

0 W i l kerson i n d i c a t o r VTP-PDI-2217A ( l oca ted on door o f Exhauster Contro l Cabinet VTP-PNL-2205A), corresponding t o t r a n s m i t t e r VlP-PDT-2217A, i s READING w i t h i n a range o f 3.04 I N W.C. and 3.36 IN W.C..

0

0

Message View Disp lays VTP-VI-2207A and VTP-UI-2208A ( located a t Alarm Cabinet Swing Out Panel) DISPLAY “FILTER 2 DP H I ” .

DPT readout DISPLAYS a va lue approximately equal t o 3.2 I N W.C.. n

5.5.41

5.5.42

5.5.43

5.5.44

5.5.45

U

ACKNOWLEDGE t he alarm by PRESSING t he “1” but ton, then P R E S S I l t he ‘‘e” bu t ton th ree t imes on the Message View Disp lay ( located a t Alarm Cabinet VTP-PNL-2207A Swing Out Panel ) .

0

0

0

VERIFY Rotat ing Beacon i s NOT ILLUMINATED.

Message View Disp lay VTP-UI-2208A ( l oca ted a t Alarm Cabinet Swing Out Panel) STILL DISPLAYS “FILTER 2 DP HI ” .

INCREASE pressure source pressure t o approximately 3.7 IN W.C..

VERIFY the fo l l ow ing :

5.5.45.1 Exhauster Fan has SHUTDOWN.

0

0 5.5.45.2 Red FAN RUNNING l i g h t i s NOT ILLUMINATED.

5.5 INTERLOCKlALARM CHECK (Continued)

Docurn1 Yo.

WHC-SD-WM-ATP-176

5.5.46

ReVtWod Page

0 48

5.5.47

5.5.48

5.5.49

5.5.45.3

5.5.45.4

5.5.45.5

5.5.45.6

5.5.45.7

Green FAN OFF l i g h t i s ILLUMINATED.

0 Rotat ing Beacon ( l oca ted on s tack suppor t ing framing) i s ILLUMINATED.

Wilkerson i n d i c a t o r VTP-PDI-2217A ( l oca ted on door o f Exhauster Contro l Cabinet VTP-PNL-2205A), corresponding t o t r a n s m i t t e r VTP-PDT-2217A, i s READING w i t h i n a range o f 3.52 IN W.C. and 3.88 I N W.C..

0

0

Message View Disp lay VTP-UI-2207A ( l oca ted a t Alarm Cabinet Swing Out Panel) DISPLAYS “FILTER 2 DP HIHI” and “FAN SHUTDOWN”.

DPT readout DISPLAYS a value approximately equal t o 3.7 IN W.C.. n

U

ACKNOWLEDGE t he alarm by PRESSING t he “1” but ton, then PRESSING t he “-” but ton th ree t imes on the Message View Disp lay ( l oca ted a t Alarm Cabinet VTP-PNL-2207A Swing Out Panel ) .

0

0

0

VERIFY Rotat ing Beacon i s NOT ILLUMINATED.

Message View Disp lay VTP-UI-2208A ( l oca ted a t Alarm Cabinet Swing Out Panel) STILL DISPLAYS “FILTER 2 DP HIHI“ and “FAN SHUTDOWN”.

DECREASE pressure source pressure t o approximately 3.0 IN W.C..

0 5.5.50 PRESS Fan S t a r t Button VTP-PB-2212M ( loca ted on door o f

Exhauster Control Cabinet VTP-PNL-2205A).

0

5.5 INTERLOCK/ALARM CHECK (Continued)

5.5.51 WAIT f o r t he Exhauster fan t o come up t o speed.

0 5.5.52 DECREASE pressure source pressure t o approximately 0.05 IN

W.C..

0 5.5.53 VERIFY the fo l l ow ing :

5.5.53.1

5.5.53.2

5.5.53.3

5.5.53.4

5.5.53.5

5.5.53.6

5.5.53.7

Exhauster Fan has SHUTDOWN. n U

Red FAN RUNNING l i g h t i s NOT ILLUMINATED.

0

Green FAN OFF l i g h t i s ILLUMINATED.

Rotat ing Beacon ( l oca ted on s tack suppor t ing framing) i s ILLUMINATED.

W i l kerson i n d i c a t o r VTP-PDI-2217A ( l oca ted on door o f Exhauster Contro l Cabinet VTP-PNL-2205A), corresponding t o t r a n s m i t t e r VTP-PDT-2217A, i s READING w i t h i n a range o f 0.048 I N W.C. and 0.052 I N W.C..

0 Message View Disp lay VTP-UI-2207A and VTP-UI-2208A ( l oca ted a t Alarm (Cabinet Swing Out Panel) DISPLAYS “FILTER 1 DP LO’ and “FAN SHUTDOWN”.

0

0 DPT readout DISPLAYS a value approximately equal t o 0.05 IN W.C..

5.5.54 ACKNOWLEDGE the alarm by PRESSING t he “1” Ibutton, then PRESSING t he “+“ bu t ton th ree t imes on t h e Message View Disp lay ( located a t Alarm Cabinet VTP-PNL-2207A Swing Out Panel ) .

5.5 INTERLOCK/ALARM CHECK (Continued)

5.5.55 VERIFY Rota t ing Beacon i s NOT ILLUMINATED.

17 5.5.56 Message View Disp lay VTP-UI-2208A ( loca ted a t Alarm Cabinet

Swing Out Panel) STILL DISPLAYS “FILTER 2 DP LO” and “FAN SHUTDOWN”.

0 5.5.57 DISCONNECT pressure source from the t r a n s m i t t e r c a l i b r a t i o n

po r t .

0 5.5.58 CLOSE Equa l iz ing Valve a t t he t r a n s m i t t e r t h ree va lve

manifold.

0 5.5.59 REPLACE p lug t o c a l i b r a t i o n p o r t on the t r a n s m i t t e r

VTP-PDT-2217A th ree valve manifold.

‘0 5.5.60 OPEN valves labe led h igh and low on th ree va lve man i fo ld a t

t ransmi t te r VTP-POT-2217A ( loca ted on top o f F i l t e r T ra in b

5.5 INTERLOCKlALARM CHECK (Continued)

NOTE -

5.5.61

5.5.62

5.5.63

5.5.64

5.5.65

5.5.66

5.5.67

5.5.68

5.5.69

5.5.70

Next step s t a r t s check on F i l t e r #1/2 DPT

CLOSE valves l abe led h igh and low on the th ree va lve mani fo ld a t HEPA FILTER #1/2 Transmi t ter VTP-PDT-2218A ( l oca ted on top o f F i l t e r Tra in) .

0

0

0

0

0

0 n

REMOVE p lug from c a l i b r a t i o n p o r t on the t r a n s m i t t e r VTP-POT-2218A th ree va lve mani fo ld .

CONNECT a pressure source t o c a l i b r a t i o n p o r t on the t r a n s m i t t e r VTP-PDT-2218A th ree va lve mani fo ld .

OPEN Equal iz ing Valve on the t r a n s m i t t e r U'TP-PDT-2218A th ree va lve manifold.

SET pressure source pressure t o approximately 3.0 I N W.C..

VERIFY Wilkerson i n d i c a t o r VTP-PDI-2218A ( l oca ted on door o f Exhauster Control Cabinet VTP-PNL-2205A) i s READING w i t h i n a range o f 2.85 I N W.C. and 3.15 I N W.C..

PRESS Fan S t a r t But ton VTP-PB-2212M ( loca ted on door o f Exhauster Contro l Cabinet VTP-PNL-2205A).

U

HAIT f o r t he Exhauster fan t o come up t o speed. n U

INCREASE pressure source pressure t o approximately 4.5 I N W.C..

VERIFY the fo l l ow ing :

0

5.5.70.1 Rotat ing Beacon i s ILLUMINATED.

0 n 5.5.70.2 Red FAN RUNNING l i g h t i s ILLUMINATED. U

5.5 INTERLOCKlALARM CHECK (Continued)

D a c m t Yo.

WHC-SD-WM-ATP- 1 76

5.5.71

5.5.72

5.5.73

5.5.74

5.5.75

Revlwod

0

5.5.70.3

5.5.70.4

5.5.70.5

5.5.70.6

Green FAN OFF l i g h t i s NOT ILLUMINATED.

0 Wilkerson i n d i c a t o r VTP-PDI-2218A ( l oca ted on door o f Exhauster Contro l Cabinet VTP-PNL-2205A), corresponding t o t r a n s m i t t e r VTP-PDT-2218A, i s READING w i t h i n a range o f 4.28 I N W.C. and 4.73 IN W.C..

0

0

Message View Disp lays VTP-UI-2207A and VTP-UI-2208A ( l oca ted a t Alarm Cabinet Swing Out Panel) DISPLAY “FILTER 1&2 DP HI”.

DPT readout DISPLAYS a va lue approximately equal t o 4.5 IN W.C.. n

U

ACKNOWLEDGE the alarm by PRESSING t he “1” ibutton, then PRESSING t he ‘+J’ bu t ton th ree t imes on the Message View Disp lay ( located a t Alarm Cabinet VTP-PNL-2207A Swing Out Panel ) .

0 0

VERIFY Rotat ing Beacon i s NOT ILLUMINATED.

Message View Disp lay VTP-VI-2208A ( l oca ted a t Alarm Cabinet Swing Out Panel) STILL DISPLAYS “FILTER 1&2 DP H I ” . n

U

INCREASE pressure source pressure t o appralximately 5.4 IN W.C.. n

U

VERIFY the fo l l ow ing :

5.5.75.1 Exhauster Fan has SHUTDOWN. n U

5.5.75.2 Red FAN RUNNING l i g h t i s NOT ILLUHINATED.

0

TANK FARM ACCEPTANCE TEST PROCEDURE

5.5 INTERLOCKlALARM CHECK (Continued)

5.5.76

5.5.77

5.5.78

5.5.79

5.5.80

5.5.75.3

5.5.75.4

5.5.75.5

5.5.75.6

5.5.75.7

Green FAN OFF l i g h t i s ILLUMINATED. n U

Rotat ing Beacon ( l oca ted on s tack suppor t ing framing) i s ILLUMINATED.

0 W i l kerson i n d i c a t o r VTP-PDI-2218A ( l oca ted on door o f Exhauster Contro l Cabinet VTP-PNL-2205A), corresponding t o t r a n s m i t t e r VTP-PDT-2218A, i s READING w i t h i n a range o f 5.13 I N W.C. and 5.67 IN W.C..

0 Message View Disp lay VTP-UI-2207A and VTP-UI-2208A ( l oca ted a t Alarm Cabinet Swing Out Panel) DISPLAY “FILTER 1&2 DP H I H I ” and “FAN SHUTDOWN“.

0 DPT readout DISPLAYS a va lue approximately equal t o 5.4 IN W.C..

0 ACKNOWLEDGE t he alarm by PRESSING t he “1” but ton, then PRESSING t he “+-” but ton th ree t imes on the Message View Disp lay ( l oca ted a t Alarm Cabinet VTP-PNL-2207A Swing Out Panel ) .

0 VERIFY Rotat ing Beacon i s NOT ILLUMINATED. n

U

Message View Disp lay VTP-UI-2208A ( l oca ted a t Alarm Cabinet Swing Out Panel) STILL DISPLAYS “FILTER 1&2 DP HIHI” and “FAN SHUTDOWN”.

0 DECREASE pressure source pressure t o approximately 3.0 IN W.C..

PRESS Fan S t a r t But ton VTP-PB-2212M ( loca ted on door o f Exhauster Control Cabinet VTP-PNL-2205A).

0

0

5.5 INTERLOCKlALARM CHECK (Continued)

5.5.81 WAIT f o r the Exhauster f an t o come up t o speed.

0

0 5.5.82 DECREASE pressure source pressure t o approximately 0.05 IN

W.C..

5.5.83 VERIFY t he fo l l ow ing :

5.5.83.1

5.5.83.2

5.5.83.3

5.5.83.4

5.5.83.5

5.5.83.6

5.5.83.7

Exhauster Fan has SHUTDOWN.

Red FAN RUNNING l i g h t i s NOT ILLUMINATED.

o n U

Green FAN OFF l i g h t i s ILLUMINATED.

0

0 Rotat ing Beacon ( l oca ted on s tack suppor t ing framing) i s ILLUMINATED.

Wilkerson i n d i c a t o r VTP-PDI-2218A ( l oca ted on door o f Exhauster Contro l Cabinet VTP-PNL-2205A), corresponding t o t r a n s m i t t e r VTP-PDT-2218A, i s READING w i t h i n a range o f 0.048 IN W.C. and 0.052 I N W.C..

0 Message View Disp lay VTP-UI-2207A and VTP-VI-2208A ( l oca ted a t Alarm Cabinet Swing Out Panel) DISPLAYS "FILTER 1&2 DP LO" and "FAN SHUTDOWN".

0 DPT readout DISPLAYS a va lue approximately equal t o 0.05 IN W.C..

0 5.5.84 ACKNOWLEDGE t he alarm by PRESSING t he "1" but ton, then

PRESSING t he "-" but ton th ree t imes on t h e Message View Disp lay ( located a t Alarm Cabinet VTP-PNL-2207A Swing Out Panel ) .

0

TANK FARM ACCEPTANCE TEST PROCEDURE -1

D O E U M t no.

WHC-SD-WM-ATP-176

5.5 INTERLOCK/ALARM CHECK (Continued)

RcvfUod

0

5.5.85

5.5.86

5.5.87

5.5.88

5.5.89

5.5.90

VERIFY Rota t ing Beacon i s NOT ILLUMINATED.

0 Message View Disp lay VTP-UI-2208A ( loca ted a t Alarm Cabinet Swing Out Panel) STILL DISPLAYS "FILTER 1&2 DP LO" and "FAN SHUTDOWN".

0 DISCONNECT pressure source from the t r a n s m i t t e r c a l i b r a t i o n p o r t .

0 CLOSE Equa l iz ing Valve a t t he t r a n s m i t t e r t h ree valve manifold.

0 REPLACE p lug t o c a l i b r a t i o n p o r t on the t r a n s m i t t e r VTP-PDT-2218A th ree valve manifold.

OPEN valves labe led h igh and low on th ree va lve man i fo ld a t t ransmi t te r VTP-PDT-2218A ( loca ted on t op o f F i l t e r T ra in b

5.5 INTERLOCKlALARM CHECK (Continued)

NOTE -

5.5.91

5.5.92

5.5.93

5.5.94

5.5.95

5.5.96

5.5.97

5.5.98

5.5.99

5.5.100

Next step starts check on Plenum Pressure DPT interlock.

CLOSE valves labeled high and low on the three valve manifold at Plenum Pressure DPT VTP-PI-2213A (located on top of Filter Train).

0 REMOVE plug from calibration port on the transmitter VTP-PI-2213A three valve manifold.

CONNECT a pressure source to calibration port on the transmitter VTP-PI-2213A three valve manifold.

0 OPEN Equalizing Valve on the transmitter VTP-PI-2213A three valve manifold.

0

0 SET pressure source pressure to 3.0 IN W.C..

VERIFY Wilkerson indicator VTP-PDI-2216A (located on door of Exhauster Control Cabinet VTP-PNL-2205A) is READING within a range of 2.85 IN W.C. and 3.15 IN W.C..

0

0 PRESS Fan Start Button VTP-PB-2212M (located on door of Exhauster Control Cabinet VTP-PNL-2205A).

WAIT for the Exhauster fan to come up to speed.

INCREASE pressure source pressure to 7.0 IN W.C..

VERIFY the following:

5.5.100.1 Exhauster Fan has SHUTDOWN.

0

0

5.5 INTERLOCKlALARM CHECK (Continued)

5.5.100.2 Red FAN RUNNING l i g h t i s NOT ILLUMINATED.

0

0 5.5.100.3 Green FAN OFF l i g h t i s ILLUMINATED.

5.5.100.4 Rotat ing Beacon ( l oca ted on s tack suppor t ing framing) i s ILLUMINATED.

0 5.5.100.5 Wilkerson i n d i c a t o r VTP-PDI-2216A ( l oca ted on

door o f Exhauster Contro l Cabinet VTP-PNL-2205A), corresponding t o t r a n s m i t t e r VTP-PI-2213A, i s READING w i t h i n a range o f 6.65 IN W.C. and 7.35 IN W.C..

5.5.100.6 Message View Disp lay VTP-UI-2207A ( l oca ted a t Alarm Cabinet Swing Out Panel) DISPLAYS "PLENUM PRESSURE H I " and "FAN SHUTDOWN".

0 5.5.100.7 DPT readout DISPLAYS a va lue approximately equal

t o 7.0 I N W.C.. n U

5.5.101

5.5.102

5.5.103

5.5.104

5.5.105

ACKNOWLEDQE t he alarm by PRESSING t h e "1" but ton, then PRESSING t he "e" but ton th ree t imes on the Message View Disp lay ( located a t Alarm Cabinet VTP-PNL-2207A Swing Out Panel ) .

0 VERIFY Rotat ing Beacon i s NOT ILLUMINATED.

0 Message View Disp lay VTP-UI-2208A ( l oca ted a t Alarm Cabinet Swing Out Panel) STILL DISPLAYS "PLENUM PRIISSURE H I " and "FAN SHUTDOWN".

DECREASE pressure source pressure t o approximately 1.0 IN W.C..

PRESS Fan S t a r t But ton PB-2212M ( loca ted on door o f Exhauster Contro l Cabinet VTP-PNL-2205A).

0

TANK FARM ACCEPTANCE TEST PROCEDURE I

D0C-t NO.

WHC-SD-WM-ATP-176

5.5 INTERLOCK/ALARM CHECK (Continued)

RcVIWod

0

5.5.106 WAIT f o r t he Exhauster fan t o come up t o speed.

5.5.107 DECREASE pressure source pressure t o 1.0 I[N W.C..

5.5.108

5.5.109

5.5.

5.5.

10

11

VERIFY the fo l l ow ing :

0

0

5.5.108.1 Rotat ing Beacon ( l oca ted on s tack suppor t ing framing) i s ILLUMINATED.

17 5.5.108.2 Wilkerson i n d i c a t o r VTP-PDI-2216 A(1ocated on

door o f Exhauster Contro l Cabinet VTP-PNL-2205A), corresponding t o t r a n s m i t t e r VTP-PI-2213A, i s READING w i t h i n a range o f 0.95 I N W.C. and 1.05 I N W.C..

0

0

5.5.108.3 Message View Disp lay VTP-UI-2207A and VTP-VI-2208A ( located a t Alarm (Cabinet Swing Out Panel) DISPLAY “PLENUM PRESSURE Lo”.

5.5.108.4 DPT readout DISPLAYS a va lue approximately equal t o 1.0 IN W.C..

ACKNOWLEDGE the alarm by PRESSING t h e “1” but ton, then PRESSING the “c” but ton th ree t imes on the Message View Disp lay ( l oca ted a t Alarm Cabinet VTP-PNL-2207A Swing Out Panel ) .

VERIFY Rotat ing Beacon i s NOT ILLUMINATED. 0

Message View Disp lay VTP-UI-220BA ( l oca ted a t Alarm Cabinet Swing Out Panel) STILL DISPLAYS “PLENUM PRESSURE LO.

0

5.5 INTERLOCKlALARM CHECK' (Continued)

5.5.112 DISCONNECT pressure source from the transmitter calibration port.

0

0

0

0

5.5.113 CLOSE Equalizing Valve at the transmitter three valve manifold.

5.5.114 REPLACE plug to calibration port on the transmitter VTP-PI-2213A three valve manifold.

5.5.115 OPEN valves labeled high and low on three valve manifold at transmitter VTP-PI-2213A (located on top of Filter Train)

00e-t wo.

WHC-SD-WM-ATP-176 Renfllod

0

5.5 INTERLOCK/ALARM CHECK (Continued)

D Q C U T ~ ~ No.

WHC-SD-WM-ATP-176

NOTE -

5.5.116

5.5.117

5.5.118

5.5.119

5.5.120

5.5.121

5.5.122

5.5.123

5.5.124

5.5.125

nev/*od

0

Next s tep s t a r t s check on P r e f i l t e r DPT alarm.

CLOSE valves l abe led h igh and low on t h e th ree va lve mani fo ld a t P r e f i l t e r DPT VTP-PDT-2215A ( l oca ted on top o f F i l t e r T ra in ) .

0 REMOVE p lug from c a l i b r a t i o n p o r t on t h e t r a n s m i t t e r VTP-PDT-2215A th ree va lve mani fo ld .

0 CONNECT a pressure source t o c a l i b r a t i o n p o r t on the t r a n s m i t t e r VTP-PDT-2215A th ree va lve mani fo ld .

0

0 OPEN Equal iz ing Valve on the t r a n s m i t t e r VTP-PDT-2215A th ree va lve mani fo ld .

SET pressure source pressure t o 0.5 IN W.C..

0

CI

VERIFY Wilkerson i n d i c a t o r VTP-PDI-2215A ( l oca ted on door o f Exhauster Control Cabinet VTP-PNL-2205A) i s READING w i t h i n a range o f 0.48 IN W.C. and 0.53 IN W.C..

PRESS Fan S t a r t Button VTP-PB-2212M ( loca ted on door o f Exhauster Control Cabinet VTP-PNL-2205A).

0

0

0

WAIT f o r the Exhauster fan t o come up t o speed.

INCREASE pressure source pressure t o 2.0 I N W.C..

VERIFY t he fo l l ow ing :

5.5.125.1 Rotat ing Beacon i s ILLUMINATED.

0

5.5 INTERLOCKlALARM CHECK (Continued)

5.5.125.2 Red FAN RUNNING l i g h t i s ILLUMINATED.

0 5.5.125.3 Green FAN OFF l i g h t i s NOT ILLUMINATED.

0 5.5.125.4 W i l kerson i n d i c a t o r VTP-PDI-2215A ( l oca ted on

door o f Exhauster Contro l Cabinet VTP-PNL-2205A), corresponding t o t r a n s m i t t e r VTP-PDT-2215A, i s READING w i t h i n a range o f 1.90 I N W.C. and 2.10 IN W.C..

0

0

5.5.125.5 Message View Disp lay VTP-UI-2207A ( l oca ted a t Alarm Cabinet Swing Out Panel) IDISPLAYS “PREFILTER DP H I ” .

5.5.125.6 DPT readout DISPLAYS a va lue approximately equal t o 2.0 I N W.C.. n

5.5.126

5.5.127

5.5.128

5.5.129

5.5.130

5.5.131

U

ACKNOWLEDGE the alarm by PRESSING t he “1” but ton, then PRESSING the “c” but ton th ree t imes on the Message View Disp lay ( located a t Alarm Cabinet VTP-PNL-2207A Swing Out Panel ) .

0

0 VERIFY Rotat ing Beacon i s NOT ILLUMINATED.

Message View Disp lay VTP-VI-2208A ( l oca ted a t Alarm Cabinet Swing Out Panel) STILL DISPLAYS “PLENUM PRIESSURE LO. n

Y

DISCONNECT pressure source from the t r a n s m i t t e r c a l i b r a t i o n p o r t .

0 CLOSE Equal iz ing Valve a t the t r a n s m i t t e r t h ree va lve manifold. n

Y

REPLACE p lug t o c a l i b r a t i o n p o r t on the t r a n s m i t t e r VTP-PDT-2215 th ree va lve mani fo ld .

0

5.5 INTERLOCK/ALARM CHECK (Continued)

5.5.132 OPEN valves l abe led h igh and low on th ree va l ve man i fo ld a t t r a n s m i t t e r VTP-PDT-2215A ( l oca ted on top o f F i l t e r T ra in b

5.5 INTERLOCK/ALARM CHECK (Continued)

D o c m a t No.

WHC-SD-WM-ATP-176

NOTE -

5.5.133

Revfnod

0

5.5.134

5.5.135

5.5.136

5.5.137

5.5.138

5.5.139

5.5.140

Next s tep s t a r t s t e s t i n g o f s tack f l o w DPT.

CLOSE valves l abe led h igh and low on the t h r e e va lve mani fo ld a t Stack Flow DPT VTP-FT-2221A ( l oca ted next t o Stack).

REMOVE p lug from c a l i b r a t i o n p o r t on the t r a n s m i t t e r VTP-FT-2221A th ree va lve manifold.

CONNECT a pressure source t o c a l i b r a t i o n p o r t on the t r a n s m i t t e r VTP-FT-2221A th ree va lve mani fo ld .

0

0

0

0

OPEN Equal iz ing Valve on the t r a n s m i t t e r VTP-FT-2221A th ree va lve manifold.

SET pressure source pressure t o 0.32 I N W.C. ( t h i s corresponds t o a f l o w o f 450 CFM).

VERIFY W i l kerson i n d i c a t o r VTP-PDI-ZZZlA(located on door o f Exhauster Control Cabinet VTP-PNL-2205A) i s READING w i t h i n a range o f 430 CFM and 470 CFM.

n U

INCREASE pressure source pressure t o 0.41 IN W.C. ( t h i s corresponds t o a f l o w o f 510 CFM).

0 VERIFY t he fo l l ow ing :

5.5.140.1 Rotat ing Beacon ( l oca ted on s tack suppor t ing framing) i s ILLUMINATED.

0 5.5.140.2 W i l kerson i n d i c a t o r (VTP-PDI-2ZZlA) ( l oca ted on

door o f Exhauster Contro l Cabinet VTP-PNL-2205A), corresponding t o t r a n s m i t t e r FT-2221, i s READING a f l o w r a t e w i t h i n a range o f 485 CFM and 535 CFM.

0

5.5 INTERLOCK/ALARM CHECK (Continued)

5.5.141

5.5.142

5.5.143

5.5.144

5.5.140.3 Message View Disp lay VTP-UI-2207A and VTP-UI-2208A ( l oca ted a t Alarm Cabinet Swing Out Panel) DISPLAY “STACK FLOW H I ”

0 ACKNOWLEDGE the alarm by PRESSING the “1” but ton, then PRESSING the “-” but ton th ree t imes on the Message View Disp lay ( located a t Alarm Cabinet VTP-PNL-2207A Swing Out Panel ) .

0 0

0

VERIFY Rotat ion Beacon i s NOT ILLUMINATED.

Message View Disp lay VTP-UI-2207A ( l oca ted a t Alarm Cabinet Swing Out Panel) CLEARS alarm message.

DECREASE pressure source pressure t o 0.19 I N W.C. ( t h i s corresponds t o a f l o w o f 350 CFM).

0 5.5.145 VERIFY the fo l l ow ing :

5.5.145.1 W i l kerson i n d i c a t o r VTP-PDI-2221A(located on door o f Exhauster Control Cabinet VTP-PNL-2205A), corresponding t o t r a n s m i t t e r VTP-FT-2221A, i s READING a f l o w r a t e w i t h i n a range o f 335 CFM and 365 CFM.

0

Y-1-10, a 5.5.146 USING a DMM, VERIFY NO c o n t i n u i t y between 7 and 8 contacts

o f t he Act ion Pak A (AP1690) F i e l d Configuirable L i m i t Alarm ( l oca ted a t cabinet VTP-PNL-2206A).

0

TANK FARM ACCEPTANCE TEST PROCEDURE -1

DOCL.L~C No.

WHC-SD-WM-ATP-176

5.5 INTERLOCKlALARM CHECK (Continued)

U N l U m

0

WARNING Energized c i r c u i t s and leads are contained i n s i d e the cabinet . Observe appropr ia te e l e c t r i c a l precautions. Comply w i t h WHC-CM-1-10, WKS-15, ELECTRICAL WORK SAFETY.