Timber Cavity Batten Technical Specification · 6.3 Drainage joint 7 6.4 Internal corner joint 7...

Transcript of Timber Cavity Batten Technical Specification · 6.3 Drainage joint 7 6.4 Internal corner joint 7...

DECEMBER 2014 I NEW ZEALAND

Timber Cavity BattenTechnical Specification

James Hardie Stria® Cladding Technical Specification December 2014 New Zealand 3

5 STRIACLADDINGINSTALLATION 65.1 General 65.2 Fastener durability 75.3 Fastener – size and layout 7

6 JOINTS 86.1 Vertical joint 76.2 Horizontal joint 76.3 Drainage joint 76.4 Internal corner joint 76.5 External corner joint 7

7 FINISHES 77.1 Painting 77.2 Flexible sealant 8

8 STORAGEANDHANDLING 8

9 MAINTENANCE 8

10 PRODUCTINFORMATION 810.1 Manufacturing and classification 810.2 Product mass 810.3 Durability 8

11 SAFEWORKINGPRACTICES 9

12 PRODUCTANDACCESSORIES 10

13 DETAILS 12

PRODUCTWARRANTY 35

1 APPLICATIONANDSCOPE 31.1 Application 31.2 Scope 31.3 Details 3 1.4 Specific design 3

2 DESIGN 32.1 Compliance 32.2 Responsibility 32.3 Site and foundation 32.4 Clearances 32.5 Moisture management 42.6 Structure 42.7 Fire rated walls 42.8 Structural bracing 42.9 Energy efficiency 4

3 FRAMING 53.1 General 53.2 Timber framing 53.3 Steel framing 53.4 Special framing requirements 53.5 Tolerances 5

4 PREPARATION 54.1 Building underlay / HomeRAB Pre-Cladding 54.2 Rab board 64.3 Cavity closure / vent strip 64.4 Cavity battens 64.5 Intermediate support 64.6 Flashings 64.7 Junctions and penetrations 6

Contents

WEVALUEYOURFEEDBACKTocontinuewiththedevelopmentofourproductsandsystems,wevalueyourinput.Pleasesendanysuggestions,includingyourname,contactdetails,andrelevantsketchesto:

Ask James HardieTM [email protected]

James Hardie Stria® Cladding Technical Specification December 2014 New Zealand 3

1.1 APPLICATIONStria®Claddinginstalledasperthisspecificationgivesapanelisedplasteredmasonryappearanceonbuildingfacades.StriaCladdingcanbefixedtoeithertimberorlightweightsteel-framedexternalwalls.Awiderangeofcolourscanbeusedvaryingfromlighttodark.StriaCladdingisavailablein405mmwidex4200mmlengthsandis14mmthick.

If you are a specifierOrotherresponsiblepartyforaprojectensurethattheinformationinthisdocumentisappropriatefortheapplicationyouareplanningandthatyouundertakespecificdesignanddetailingforareaswhichfalloutsidethescopeofthesespecifications.

If you are an installerEnsurethatyoufollowthedesign,moisturemanagementprinciples,associatedfiguresandmaterialselectionprovidedbythedesignerandthisJamesHardieTechnicalSpecification.Allthedetailsprovidedinthisdocumentmustbereadinconjunctionwiththeprojectspecification.

Make sure your information is up to dateWhenspecifyingorinstallingJamesHardieproducts,ensurethatyouhavethecurrentmanual.Additionalinstallationinformation,warrantiesandwarningsareavailableatwww.jameshardie.co.nzorAskJamesHardie™on0800808868.

1.2 SCOPEThisspecificationcoverstheinstallationofStriaCladdingfixedovertimbercavitybattensonbuildingsthatfallwithinthescopelimitationofNZS3604andE2/AS1oftheNewZealandBuildingCode(NZBC).

ThisspecificationalsocoverstheinstallationofStriaCladdingonprojects,whicharesubjecttospecificengineeringdesign(SED)uptoawindpressureof2.5kPa(ULS).

Note: Refer to Stria Cladding CLD Structural Cavity Batten technical specification when fixing to CLD Structural Cavity Battens.

1.3 DETAILSVarioustypicalStriaCladdingconstructiondetailsareprovidedintheDetailssectionofthisdocument.ThesedetailsareavailableinCAD,ArchiCAD,MODandpdffileformatandcanbedownloadedfromourwebsiteatwww.jameshardie.co.nz.

Alldimensionsshownareinmillimetresunlessnotedotherwise.

1.4 SPECIFIC DESIGNForuseoftheStriaCladdingonspecificdesignprojects,thedesigner,architectorengineermustensurethatallclausesofNZBChavebeenconsideredandaspecificdesignhasbeenundertakenfortheareaswhichfalloutsidethescopeofthisliterature.

2 Design1 Application and scope

2.1 COMPLIANCEStriaCladdinginstalledinaccordancewiththisspecificationhasbeentestedasperE2/VM1andcomplieswithExternalMoisture-E2ClauseofNZBC.ThecladdinghasalsobeentestedandcomplieswiththerequirementsofStructure-B1,Durability-B2,EnergyEfficiency-H1andHazardousBuildingMaterial-F2ClausesofNZBC.

2.2 RESPONSIBILITYThespecifierorotherpartyresponsiblefortheprojectmustensurethattheinformationanddetailsinthisspecificationareappropriatefortheintendedapplicationandthatadditionaldetailingisperformedforspecificdesignoranyareasthatfalloutsidethescopeofthistechnicalspecification.Forapplicationsoutsidethescopeofthisliteratureanddetails,whicharenotprovidedherein,thearchitect,designerorengineermustundertakespecificdesignanditshouldbeensuredthattheintentoftheirdesignmeetstherequirementsoftheNZBC.

AllNewZealandStandardsreferencedinthismanualarecurrenteditionsandmustbecompliedwith.

JamesHardieconductsstringentqualitycheckstoensurethatanyproductmanufacturedfallswithinourqualityspectrum.Itistheresponsibilityofthebuildertoensurethattheproductmeetsaestheticrequirementsbeforeinstallation.JamesHardiewillnotberesponsibleforrectifyingobviousaestheticsurfacevariationsfollowinginstallation.

2.3 SITE AND FOUNDATIONThesiteonwhichthebuildingissituatedmustcomplywithE1/AS1SurfaceWaterClauseofNZBC.

Foundationsdesignmustcomplywithrelevantregulations,standardsandmeettherequirementsofNZBC.

Thegradeofadjacentfinishedgroundmustslopeawayfromthebuildingtoavoidanypossibilityofwateraccumulation.

2.4 CLEARANCESTheclearancebetweenthebottomedgeandpaved/unpavedgroundofcladdingmustcomplywithsection9.1.3ofE2/AS1.Thefinishedfloormustalsocomplywiththeserequirements.Theseclearancesmustbemaintainedthroughoutthelifeofthebuilding.

Stria Cladding must overhang the bottom plate by a minimum of 50mm as required by E2/AS1.

Stria Cladding must maintain a minimum clearance of 100mm from paved ground, and 175mm from unpaved ground. On the roofs and decks, the minimum clearance must be 50mm.

Do not install external cladding such that it may remain in contact with water or ground. Refer Figures 4 and 5.

4 James Hardie Stria® Cladding Technical Specification December 2014 New Zealand James Hardie Stria® Cladding Technical Specification December 2014 New Zealand 5

2.5 MOISTURE MANAGEMENTIt is the responsibility of the specifier to identify moisture related risks associated with any particular building design.

Wall construction design must effectively manage moisture, considering both interior and exterior environments of the building, particularly in buildings that have a higher risk of wind driven rain penetration. The buildings should also be ventilated sufficiently to control moisture accumulation due to condensation especially in artificially cooled/heated buildings.

Walls shall include those provisions as required by External Moisture Clause E2/AS1 of NZBC. In addition, all wall openings, penetrations, junctions, connections, window sills, heads and jambs must incorporate appropriate flashings for waterproofing. The other materials, components and installation methods used to manage moisture in external walls, must comply with the requirements of relevant standards and the NZBC. For further guidance on designing for weather tightness, refer to BRANZ Ltd. and the Department of Building and Housing updates on the following websites respectively, www.branz.co.nz and www.dbh.govt.nz.

In addition, the following issues must also be considered:

• Sealant must be installed where detailed in this literature.

• Where the walls are higher than two storeys, it is necessary to provide a horizontal flashing at the second floor level to drain the cavity.

• The installation of smoke chimneys, pipe penetrations and other fixtures etc. must not track moisture into the wall or restrict the drainage of moisture to the exterior.

2.6 STRUCTURE2.6.1 Timber FramingTimber-framed buildings must either be in accordance with NZS 3604 (Timber Framed Buildings) or designed as per specific engineering design. For a building requiring a specific engineering design, the framing stiffness must be equivalent to or more than the stiffness requirements of NZS 3604.

For specific design projects, the timber framing must be designed in accordance with the requirements of NZS 3603 and AS/NZS 1170.

For timber frame walls longer than 12m, it is best practice to allow for construction joints to accommodate movements generated due to timber shrinkage or deflections etc.

2.6.2 Steel FramingSteel-framed buildings must comply with the requirements of AS/NZS 3404 ‘Steel Structures Standard’ or specific engineering design requirements. Also refer to NASH 3405 steel framed buildings guidance document published by ‘National Association of Steel Housing’ (NASH).

2.6.3 Wind PressuresStria Cladding is suitable for use in all wind zones in New Zealand up to and including EH as defined in NZS 3604.

Stria Cladding is also suitable in specific design projects up to wind pressures of 2.5kPa uls.

2.7 FIRE RATED WALLSStria Cladding when fixed over timber cavity battens to external walls can achieve fire ratings up to 60/60/60 to comply with Clause C/AS1 of the NZBC when the walls are constructed in accordance with the current James Hardie ‘Fire and Acoustic’ Design Manual.

Stria Cladding is classified as a 'non-combustible' material suitable for use on walls close to a boundary.

2.8 STRUCTURAL BRACINGStriaCladdinginstalledasperthisspecificationhasnotbeentestedandthereforecannotbeusedtoachieveanystructuralbracing.However,bracingcanbeachievedbyusingJamesHardierigidairbarrierinstalleddirecttoframinginsteadofabuildingunderlayorbyusingVillaboard®Liningbracingsystemontheinternalface.

2.9 ENERGY EFFICIENCYExternalwallsconstructedusingStriaCladdingandbulkinsulation,wheretheareaofglazingis30%orlessofthetotalwallarea,constructedasperthistechnicalspecificationcomplieswiththeinsulationrequirementsforwallsinNZBCAcceptableSolutionH1/AS1(EnergyEfficiencyClauseH1),ReplacementTable1.Tomeetthermalinsulationrequirementsfortheconstruction,thebulkinsulationasspecifiedinTable1mustbeused.ThisinsulationmaybesubstitutedwithinsulationshavinghigherR-values.Thethermalinsulationofawallchangeswhenthesizeorspacingoftimberframingisincreasedordecreased.ThecalculationusedinTable1isbasedonatimberframingsize90x45mmandusinganinternalliningmaterialsuchasJamesHardieVillaboardLiningora10mmplasterboard.

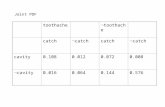

Table1Insulation capability

Climate Zone*

R-Value Requirement*

Cavity Insulation Infill Requirement

1and2 1.9m2ºC/W #R2.0

3 2.0m2ºC/W #R2.2

TotalconstructionR-Valuedependsontheinsulationmaterialusedandtheframingratio.TheinsulationmaterialR-Valuesspecifiedinthistableareforstudsspacedat600mmc/candnogsspacedat800mmc/c.

#ToachievehigherR-ValuesofconstructionthewallinsulationmaterialmustbereplacedwithaninsulationmaterialhavinghigherR-Valuestosuittherequirements.

Forfurtherguidanceoninsulationrequirementrefertothecurrenteditionof‘HouseInsulationGuide’publishedbyBRANZ.

4 James Hardie Stria® Cladding Technical Specification December 2014 New Zealand James Hardie Stria® Cladding Technical Specification December 2014 New Zealand 5

3.3 STEEL FRAMING3.3.1 Dimensions and GaugeA38mmminimumwidestudcanbeusedtoinstallStriaCladding.Thethicknessofsteelframemustbeintherange0.55to1.6mmBMT(BaseMetalThickness).Consideringtheeaseofinstallation,therecommendedminimumBMTis0.75mm.

3.3.2 DurabilityThesteelframingmusthavetheappropriatelevelofcoatingtocomplywithdurabilityrequirementsofNZBC.

3.3.3 Frame ConstructionSteelframingmustcomplywithNASHhandbook/guidelines.Studandbattenspacingmustnotbemorethanwhathasbeenspecifiedinthisspecification.Refertoframingmanufacturer’sspecificationsorNASH3405forfurtherguidanceonsteelframe.

3.4 SPECIAL FRAMING REQUIREMENTSThefollowingarespecialframingrequirementsforbothtimberandsteelframing:

• Double studs are required at internal corners, refer Figure 15.

• Extra packers maybe required at external corners.

3.5 TOLERANCESInordertoachievetherequiredperformanceandanacceptablewallfinish,itisimperativethatframingisstraightandtrue.FramingtolerancesshallcomplywithTable2.1ofNZS3604andthemanufacturer’sspecifications.Allframingshallbemadeflush.

4 Preparation

4.1 BUILDING UNDERLAY / HOMERAB PRE-CLADDING

Buildingunderlay/HomeRAB®Pre-CladdingmustbeprovidedaspertherequirementsofExternalMoistureClauseE2ofNZBC.ThebuildingunderlayselectedforusemustcomplywithTable23ofE2/AS1.

Thebuildingunderlaymustbefixedinaccordancewithsection9.1.7E2/AS1andunderlaymanufacturer’srecommendations.

Wallswhicharenotlinedontheinsidefacee.g.garagewallsorgableendsmustincludearigidsheathingoranairbarrierbehindthecladdingwhichcomplieswithTable23ofE2/AS1.JamesHardieHomeRABPre-Claddingcomplieswiththeserequirementsandissuitableforuseinthissituation.ItmustbeinstalledinaccordancewithJamesHardieRigidAirBarriersinstallationmanual.

3 Framing

3.1 GENERALStriaCladdingcanbefixedeithertoatimber-frameorsteel-frame.

ForfixingintosteelframeAskJamesHardieon0800808868forspecificrequirements.

•Studsmustbeprovidedat600mmcentrsmaximum.•Nogsmustbeprovidedat800mmcentresmaximum.

Note: For fixing Stria Cladding, fastener spacing is provided in Section 5.

3.2 TIMBER FRAMING3.2.1 DimensionsA45x90mmminimumframingsizeisrequired.

Aminimum70mmwidestudisrequiredatverticaljointflashingjoints.

3.2.2 Structural GradeTimbergradeusedmustbeinaccordancewithtimbergradesspecifiedinNZS3604.

3.2.3 DurabilityTheexternalframingtimbermustbetreatedtoaminimumH1.2treatment.Highertreatmentlevelsmaybeusedbutcheckforthecompatibilityoftreatmentchemicalswithothermaterials.RefertoNZBCAcceptableSolutionB2/AS1Durabilityforfurtherinformationaboutthedurabilityrequirements.

FortimbertreatmentandallowablemoisturecontentinformationrefertoNZS3602(TimberandWood-BasedProductsforuseinBuildings)andNZS3640(ChemicalPreservationofRoundSawnTimber)forminimumtimbertreatmentselectionandtreatmentrequirements.

Alsorefertoframingmanufacturer’sliteratureforfurtherguidanceontimberselection.Framingmustbeprotectedfrommoistureatsitesinaccordancewiththeframingmanufacturerrecommendations.

Note: Refer to NZS 3602 for information about the allowable moisture content in timber framing.

3.2.4 Frame ConstructionUseoftimberframingmustbeinaccordancewithNZS3604andtheframingmanufacturer’sspecifications.Theframingmustberigidandnotrelyonthecladdingforstability.Timberframingsizesanditsset-outmustcomplywithNZS3604andasspecifiedinthistechnicalspecification.

Thefollowingframingisrequired:

• Studs must be provided at 600mm centres maximum.

• Nogs must be provided at 800mm centres maximum.

• When studs are spaced at 400mm centres then the nogs / dwangs may be provided at 1200mm centres

• An extra stud is required in internal corners

• For specific design projects exposed to wind speeds higher than 50m/sec, the stud spacing must be closed to 400mm c/c.

6 James Hardie Stria® Cladding Technical Specification December 2014 New Zealand James Hardie Stria® Cladding Technical Specification December 2014 New Zealand 7

4.2 RAB BOARDGeneralbuildingunderlayorHomeRABPre-Claddingissuitableforuseuptoveryhighwindspeedzone(50m/sec).

WhenanEHwindzoneorforspecificdesignprojectswherethewindpressureishigherthan1.5kPa,JamesHardieRABBoardmustbeusedinsteadofbuildingunderlay.

ToachievethetemporaryweathertightnessusingJamesHardierigidairbarriers,windows/doorsneedtobetemporarilyinstalled.RefertoJamesHardieRigidAirBarriersinstallationmanualforinformationregardingitsinstallation.

4.3 CAVITY CLOSURE / VENT STRIPTheJamesHardieStriaAluminiumCavityClosureoruPVCcavityventstripmustbeinstalledatthebottomofallwallsandaboveallopeningsconstructedusingthedrainedandventilatedcavityconstructionmethod.Itisimportantthattheopeningsinthecavityclosure/ventstriparekeptclearandunobstructedtoallowfreedrainageandventilationofcavities.JamesHardiecavityclosure/ventstriphasanopeningareaof1000mm2/mlength.

4.4 CAVITY BATTENSStria Cladding to be installed on a cavity. The battens provide ventilation and drainage between the frame and the panel and are considered a “packer” only in this specification.

The timber cavity battens must be minimum H3.1 treated in accordance with NZS 3640 (Chemical preservation of rough and sawn timber) to comply with the durability requirements of B2/AS1.

Cavity battens must comply with E2/AS1 and:

• be minimum 18mm thick

• be as wide as the width of studs

• fixed vertically to studs

• be fixed by the cladding fixings to the main framing over the building underlay. Therefore until claddings are fixed the battens only need to be tacked to framing by 40 x 2.8mm or longer nails at 800mm c/c.

4.5 INTERMEDIATE SUPPORTWhere studs are at 600mm centres an intermediate means of restraining the building underlay and insulation from bulging into the cavity shall be installed. An acceptable method to achieve this is using one of the following options:

• intermediate cavity batten between the studs

• 75mm galvanised mesh

• polypropylene tape at 300mm centres fixed horizontally and drawn taut

No intermediate supports are required:

• when studs are spaced at 400mm centres

• when rigid air barriers instead of building underlays are used.

4.6 FLASHINGSAllwallopenings,penetrations,intersections,connections,windowsills,headsandjambsmustbeflashedpriortoStriaCladdinginstallation.RefertomoisturemanagementrequirementsinClause2.5.Thebuildingunderlay/rigidairbarriermustbeappropriatelyincorporatedwithpenetrationandjunctionflashingsusingflashingtapes.Materialsmustbelappedinsuchawaythatwatertracksdowntotheexterioronthefaceofbuildingunderlayorrigidairbarrier.JamesHardiewillassumenoresponsibilityforwaterinfiltrationwithinthewallduetopoorinstallationofflashingsorbuildingunderlay.

TheselectedflashingmaterialsmustcomplywiththedurabilityrequirementsofNZBC.ForinformationrefertoTable20ofE2/AS1.

WhenusingJamesHardierigidairbarrierstheentireframingaroundopeningsmustbesealedwithaflashingtape.Thetapemustbefinishedoverthefaceoftherigidairbarrier.RefertoJamesHardieRigidAirBarriersinstallationmanualforfurtherinformation.

4.7 JUNCTIONS AND PENETRATIONSRefertoClause2.5ofthisspecificationformoisturemanagementrequirements.Allwindowsanddoorsmustbedetailedaspertherequirementsofthisspecification.JamesHardiehasdevelopedthewindowdetailsforStriaCladdingwhichmeettherequirementsofE2ExternalMoisture,anapproveddocumentoftheNZBC.RefertoFigures17to19.

5 Stria Cladding installation

5.1 GENERALStriaCladdingmustbekeptundercoverwhilstinstorageoratsitesandtheymustbedryatthetimeoftheirinstallation.AllsitecutpaneledgesmustbesealedwithDuluxAcraprime501/1,DuluxPrimacryl,ReseneQuickDryorsimilarsealercompatiblewiththefinishcoatbeforeinstallation.

StriaCladdingmustbefullysupportedandfixedintotimbercavitybattens.Ensurethatcladdingishardagainstthebattenstoavoiddrumminess.

Toachievebestastheticresultsitisrecommendedtopositionverticaljointerbythecornerofopeningsorcoincidingwiththecentrelineofopenings.RefertoFigure3

ThistechnicalspecificationonlycoversthehorizontalinstallationofStriaCladding.

AskJamesHardieon0800808868forverticalinstallationtechnicalsupplementofStriaCladding.

6 James Hardie Stria® Cladding Technical Specification December 2014 New Zealand James Hardie Stria® Cladding Technical Specification December 2014 New Zealand 7

5.2 FASTENER DURABILITYFasteners must meet the minimum durability requirements of the NZBC. NZS 3604 specifies the requirements for fixing material to be used in relation to exposure conditions and are summarised in Table 2.

Table2Exposure conditions and nail selection prescribed by NZS 3604

NAIL MATERIAL

Zone D Zone C outside sea spay zone and Zone B and geothermal hot spots

Bracing - all zones

Grade 316 Stainless

Hot-dipped galvanised or 316 Stainless

Grade 316 Stainless

* (Zone C areas where local knowledge dictates that increased durability is required, appropriate selection shall be made). Microclimate conditions as detailed in NZS 3604, Paragraph 4.2.4 require SED.

Also refer to the NZBC Acceptable Solution E2/AS1’ Table 20 and 21 for information regarding the selection of suitable fixing materials and their compatibility with other materials.

5.3 FASTENER – SIZE AND LAYOUTStria Cladding must be fixed to framing using the fixings as specified in Table 3 below and follow the edge distance required for nails as shown in the details. Refer to Figure 7.

When using rigid air barrier like HomeRAB Pre-Cladding or RAB Board, the cladding fixing nails must be increased in length equal to the thickness of the rigid air barrier.

Table3Panel fixing

cavity construction

65x2.87mm D head or 60x2.87mm RounDrive nails

Fix nails at 100mm from top edge and 100mm from bottom edge/per board/per stud. Refer to Figure 12

For other fixing options Ask James Hardie on 0800 808 868.

• When fixing the panels using nail guns, refer to the nail gun manufacturer for information about nails and the type of nail gun to be used.

• Stud width of 70mm min required when using a vertical joint flashing. Refer Figure 9.

• D head nails - finish nails 2mm below panel surface.

• RounDrive nails - finish nails flush with panel surface.

6 Joints

6.1 VERTICAL JOINTStria Cladding can be jointed using vertical joint flashing, trimline joint flashing or a butt joint. Refer to Figures 7 to 11.

Asinglestudisrequiredwhenusingtrimlinejointflashing.RefertoFigure7.Doublestudsarerequiredwhenusingverticaljointflashing.ReferFigure9.

6.2 HORIZONTAL JOINTStriaCladdingpanelsarelappedovereachotherasperFigure12.Thereisaminimum25mmlapbetweenthetwopanels.EnsurethatStriaCladdingpanelsaresecurelyinterlockedbeforenailing.StriaCladdingcanruncontinuousoverfloorjoistswithoutanyhorizontaljointwhenLVLtimberfloorjoistsareused.RefertoFigure28.

WhenanengineeredjoistorLVLjoistisnotused,ahorizontaljointoramovementjointmustbeformedatfloorjoist,refertoFigures25and26.

6.3 DRAINAGE JOINTAftereverytwofloorsahorizontaldrainagejointflashingisrequired,refertoFigure26.

6.4 EXTERNAL CORNER JOINTAnexternalboxcornerflashingisusedtofixtheexternalcorners,refertoFigure13and14.

6.5 INTERNAL CORNER JOINTAn internal corner flashing is to be used to form an internal corner joint, refer to Figure 15. Alternatively an internal mitre corner, refer to Figure 16.

An extra stud is required in internal corners.Note: All joint mouldings to be fixed at 400mm centres both sides.

7 Finishes7.1 PREPARATIONTheDheadnailheadsmustbefinished2mmbelowthepanelsurface.Thenailholesmustbefilledwithanexteriorgradetwopartbuildersfill,ie.CRCBuildersFillorsimilartwopartexternalgradefiller.TheRounDrivenailheadsmustfinishflushwithpanelsurface.

7.2 PAINTINGStriaCladdingispre-primedandissuitableforsiteappliedacrylicpaints.

Inordertosealcutedgesorsandedpatches,DuluxPrimacryl,Acroprime501/1ReseneQuickDryorasimilarproductshouldbeapplied.Theprimershouldbecompatiblewiththepainttobeused.

PaintingofStriaCladdingismandatorytomeetthedurabilityrequirementsofNZBCand15yearJamesHardieproductwarranty.StriaCladdingmustbedryandfreeofanydustorgrimebeforepainting.Thepanelsmustbepaintedwithin90daysoftheirinstallation.ThereisnorestrictionontheLRVofpainttobeappliedontheStriaCladding.

8 James Hardie Stria® Cladding Technical Specification December 2014 New Zealand James Hardie Stria® Cladding Technical Specification December 2014 New Zealand 9

10 Product information

10.1 MANUFACTURING AND CLASSIFICATION

StriaCladdingisanadvancedlightweightcementcompositecladdingmanufacturedusingJamesHardieformulation.BasiccompositionisPortlandcement,groundsand,cellulosefibreandwater.

StriaCladdingismanufacturedtoAustralian/NewZealandStandardAS/NZS2908.2‘Cellulose-CementProducts’(ISO8336‘Fibre-CementFlatSheet’).

StriaCladdingisclassifiedTypeA,Category2inaccordancewithAS/NZS2908.2“Cellulose-CementProducts”.

ForSafetyDataSheets(SDS)visitwww.jameshardie.co.nzorAskJamesHardieon0800808868.

10.2 PRODUCT MASSStriaCladdingismanufacturedin14.0mmthicknessandhasamassof13.8kg/m2atEMC.

StriaCladdingisdefinedasaLightWeightWallCladding(notexceeding30kg/m2)asperNZS3604.

10.3 DURABILITYStriaCladdingandJamesHardierigidairbarrierinstalledandmaintainedasperthistechnicalspecificationwillmeetthedurabilityrequirementforcladdingasperDurabilityB2clauseofNZBC.

10.3.1 Resistance to Moisture/Rotting StriaCladdinghastestedtocheckitsresistancetopermanentmoistureinduceddeterioration(rotting)bypassingthefollowingtestsinaccordancewithAS/NZS2908.2:

• Water Permeability (Clause 8.2.2)

• Warm Water (Clause 8.2.4)

• Heat Rain (Clause 6.5)

• Soak Dry (Clause 8.2.5)

10.3.2 Resistance to fireStria Cladding is classified as ‘Non-Combustible Material’ which is suitable for use as external wall cladding and complies with Performance C3.7 of the NZBC Clause C3 Fire Affecting Areas Beyond the Fire Source.

11.3.3 Alpine RegionsInregionssubjecttofreeze/thawconditions,StriaCladdingandJamesHardierigidairbarriermustnotbeindirectcontactwithsnoworicebuildupforextendedperiods,e.g.externalwallsinalpineregionsmustbeprotectedwheresnowdriftsoverwinterisexpected.

TheseproductshavebeentestedinaccordancewithAS/NZS2908.2Clause8.2.3.

JamesHardierecommendsaminimumoftwocoatsofexteriorgradeacrylicpaint.Followthepaintmanufacturer’srecommendationstopreparethesurfaceandtoadequatelycoverandconcealthepanelfixings.

7.3 FLEXIBLE SEALANT SealantusedmustcomplywiththerelevantrequirementsoftheNZBC.Theirapplicationandusagemustbeinaccordancewiththemanufacturer’sinstructions.Checkwiththesealantmanufacturerpriortocoatingoversealant.Somesealantmanufacturersdonotrecommendcoatingovertheirproduct.

8 Storage and handling

StriaCladdingmustbelaidflatonasmoothlevelsurface.Edgesandcornersmustbeprotectedfromchipping.

Toensureoptimumperformance,storepanelsundercoverandkeepdrypriortofixing.Ifthepanelsbecomewet,allowthemtodrythoroughlybeforefixing.

Donotcarrypanelsontheflat,carryintheverticalpositiontoavoidexcessivebending.

9 MaintenanceItistheresponsibilityofthespecifiertodeterminenormalmaintenancerequirementstomaintaintheeffectivenessofthecladding.Theextentandnatureofmaintenancerequiredwilldependonthegeographicallocationandexposureofthebuilding.

Asaguide,itisrecommendedthatthebasicnormalmaintenancetasksshallinclude,butnotbelimitedto:

• Washing down exterior surfaces every 6-12 months*

• Re-coating exterior protective finishes**

• Regular inspection and repair if necessary of the cladding, sealants, etc.

• Cleaning out gutters, down pipes and overflow pipes as required.

• Pruning back vegetation which is close to or touching the building as well as ensuring the NZBC ground clearance requirements are maintained especially where gardens are concerned.

• The clearance between the bottom edge of the Stria Cladding and the finished/unfinished ground must always be maintained.

*Do not use a water blaster to wash down the cladding.*In extreme coastal conditions or sea spray zones, wash every 3-4 months.** Refer to your paint manufacturer for washing down and

recoating requirements related to paint performance.

8 James Hardie Stria® Cladding Technical Specification December 2014 New Zealand James Hardie Stria® Cladding Technical Specification December 2014 New Zealand 9

Working Instructions• Refer to Recommended Safe Working

Practices before starting any cutting or machining of product.

HardieBlade™ Saw BladeTheHardieBlade™SawBladeusedwithadust-reducingsawisidealforfast,cleancuttingofJamesHardiefibrecementproducts.Adust-reducingsawusesadustdeflectororadustcollectorconnectedtoavacuumsystem.Whensawing,clampastraight-edgetothesheetasaguideandrunthesawbaseplatealongthestraightedgewhenmakingthecut.

Hole-FormingFor smooth clean cut circular holes:

• Mark the centre of the hole on the sheet.

• Pre-drill a ‘pilot’ hole.

• Using the pilot hole as a guide, cut the hole to the appropriate diameter with a hole saw fitted to a heavy duty electric drill.

For irregular holes:

• Small rectangular or circular holes can be cut by drilling a series of small holes around the perimeter of the hole then tapping out the waste piece from the sheet face.

• Tap carefully to avoid damage to sheets, ensuring that the sheet edges are properly supported.

Handling and StorageAllmaterialsshouldbestoredtoavoiddamage,withedgesandcornersoftheStriaCladdingprotectedfromchipping.

StriaCladdingmustbeprotectedfromrainduringtransportandstorage.StriaCladdingmustbelaidflatundercoveronasmoothlevelsurfaceclearofthegroundtoavoidexposuretowaterormoistureetc.StriaCladdingandJamesHardierigidairbarrierisresistanttopermanentwaterdamagewheninstalledasdirected,andmustonlybeinstalledinadrystate.

WhenhandlingStriaCladding,carrypanelsontheedgetakingcarenottochipedgesandcorners.

RefertothecurrentinstallationmanualforrecommendedSafeWorkingPractices.

QualityJamesHardieconductsstringentqualitycheckstoensurethatanyproductmanufacturedfallswithinourqualityspectrum.Itistheresponsibilityofthebuildertoensurethattheproductmeetsaestheticrequirementsbeforeinstallation.JamesHardiewillnotberesponsibleforrectifyingobviousaestheticsurfacevariationsfollowinginstallation.

11 Safe working practices

DO NOT BREATHE DUST AND CUT ONLY IN WELL VENTILATED AREAJamesHardieproductscontainrespirablecrystallinesilicawhichisconsideredbysomeinternationalauthoritiestobeacauseofcancerfromsomeoccupationalsources.Breathingexcessiveamountsofrespirablesilicadustcanalsocauseadisablingandpotentiallyfatallungdiseasecalledsilicosis,andhasbeenlinkedwithotherdiseases.Somestudiessuggestsmokingmayincreasetheserisks.Duringinstallationorhandling:(1)workinoutdoorareaswithampleventilation;(2)minimisedustwhencuttingbyusingeither'ScoreandSnap'knife,fibrecementshearsor,wherenotfeasible,useaHardieBlade™SawBladeanddust-reducingcircularsawattachedtoaHEPAvacuum;(3)warnothersintheimmediateareatoavoidbreathingdust;(4)wearaproperly-fitted,approveddustmaskorrespirator(e.g.P1orP2)inaccordancewithapplicablegovernmentregulationsandmanufacturerinstructionstofurtherlimitrespirablesilicaexposures.Duringclean-up,useHEPAvacuumsorwetcleanupmethods-neverdrysweep.Forfurtherinformation,refertoourinstallationinstructionsandSafetyDataSheetsavailableatwww.jameshardie.co.nz.

FAILURE TO ADHERE TO OUR WARNINGS, SAFETY DATA SHEETS, AND INSTALLATION INSTRUCTIONS MAY LEAD TO SERIOUS PERSONAL INJURY OR DEATH.

James Hardie recommended safe working practices

CUTTING OUTDOORS

1. Position cutting station so wind will blow dust away from the user or others in working area.

2. Use one of the following methods based on the required cutting rate:

BEST

• Dust reducing circular saw equipped with HardieBlade™ Saw Blade and HEPA vacuum extraction.

GOOD

• Dust reducing circular saw with HardieBlade™ Saw Blade.

SANDING/REBATING/DRILLING/OTHER MACHINING

When sanding, rebating, drilling or machining you should always wear a P1 or P2 dust mask and warn others in the immediate area.

IMPORTANT NOTES

1. For maximum protection (lowest respirable dust production), James Hardie recommends always using “Best” — level cutting methods where feasible.

2. NEVER use a power saw indoors.3. NEVER use a circular saw blade that does not carry

the HardieBlade™ logo.4. NEVER dry sweep — Use wet suppression or HEPA vacuum.5. NEVER use grinders.6. ALWAYS follow tool manufacturers’ safety recommendations.

P1 or P2 respirators should be used in conjunction with above cutting practices to further reduce dust exposures. Additional exposure information is available at www.jameshardie.co.nz to help you determine the most appropriate cutting method for your job requirements. If concern still exists about exposure levels or you do not comply with the above practices, you should always consult a qualified industrial hygienist or contact James Hardie for further information.

10 James Hardie Stria® Cladding Technical Specification December 2014 New Zealand James Hardie Stria® Cladding Technical Specification December 2014 New Zealand 11

Stria Cladding information

Product Description Size (mm)Code

Thickness Length Width

Stria CladdingA14mmprofiledpanelforexpressedjointedresidentialfacades.Factorysealedonallsixsides.Eachpanelhasamanilawhitecolourprimerappliedonitsface,whichacceptsawiderangeofpaintfinishes.

14 4200 405 404263

James Hardie rigid air barrier Usedasarigidairbarrier.Ithasgreencoloursealerappliedoveroneface.Installedwithgreensidefacingout.

6 2450 1200 402980

6 3000 1200 402981

HomeRAB Pre-CladdingUsedasarigidairbarrier.Ithasgreencoloursealerappliedoveroneface.Installedwithgreensidefacingout.

4.5 2450 1200 404766

4.5 2750 1200 404768

Accessories/tools supplied by James Hardie

Accessories Description Size/Quantity Code

Vertical Joint FlashingAluminiumextrusionusedbehindcladdingatverticaljoints. 3000mmlong 305507

Stria Trimline Joint FlashingAluminiumextrusionusedbehindcladdingatverticaljoints. 3000mmlong 305827

Internal Corner FlashingAnodisedaluminiumextrusionusedtocreateinternalcorners. 3000mmlong 304871

Stria External Box CornerAnodisedaluminiumextrusionusedtocreateexternalcorners.

2700mmlong4000mmlong

305824 305823

Aluminium Window Jamb FlashingAluminiummouldingusedbesidewindowopeningtoendbutttheStriaCladding.

3000mmlong 305430

Stria Aluminium Cavity ClosureAluminiummouldingusedasverminproofing. 3000mmlong 305431

JH 9mm Panel Aluminium External Box CornerAboxcornermouldtoformtheexternaljoints.9mmetchprimed.

2450mmlong2750mmlong3000mmlong4000mmlong

304509 304510305150 305808

uPVC Vent Strip PVCmouldingusedasverminproofing. 3000mmlong 302490

Tools

HardieBlade™ Saw Blade Diamondtip184mmdiameterfibrecementcircularsawblade.Spacersnotincluded.

Each 300660

HardieFlex™ Stainless Steel 316 Nails For fixing panels through cavity battens. 60 x 3.15mm Jar 302782

HardieFlex™ Hot Dip Galv. Nails For fixing panels through cavity battens. 60 x 3.15mm Jar 302784

12 Product and accessories

Note:Alldimensionsandmassesprovidedareapproximateonlyandsubjecttomanufacturingtolerances.

10 James Hardie Stria® Cladding Technical Specification December 2014 New Zealand James Hardie Stria® Cladding Technical Specification December 2014 New Zealand 11

Accessories/tools not supplied by James HardieJamesHardierecommendsthefollowingproductsforuseinconjunctionwithStriaCladdingandJamesHardierigidairbarrier.JamesHardiedoesnotsupplytheseproductsanddoesnotprovideawarrantyfortheiruse.Pleasecontactcomponentmanufacturerforinformationontheirwarrantiesandfurtherinformationontheirproducts.

Product Description

Building underlayMustcomplywithTable23ofE2/AS1.

Flexible Window Opening Flashing Tape Aflexibleself-adhesivetapeusedinpreparationofawindow.Refertothewindowinstallationsectioninthismanualformoreinformation.

e.g.ProtectoorSuperStickbyProtectoWrapor3M™AllWeatherFlashingTape8067by3M™Protecto:080077697273M™0800474787

James Hardie rigid air barrier Vertical Joint Sealing TapeThetapetobeusedtosealJamesHardierigidairbarrierverticaljoints.

SuperStickbyProtectoWrapor3M™AllWeatherFlashingTape8067by3M™Protecto:080077697273M™0800474787

Flexible SealantRequiredtosealtheverticaljoints.BostikSealNFlex-1,SikaflexATFacade,SikaflexMSorsimilar.

65x2.87mm'D'headnailor60x2.87RounDrivenail(hotdippedgalvanised/stainlesssteel)ForfixingStriaCladding.

40x2.8mmorlongerHardieFlex™nail.Forfixingtimbercavitybattensandaluminiumflashings.

Meter BoxReferElectricalSuppliers.

Head flashing Required over window heads to be supplied by window installer. Material must comply with Table 20 and 21 of E2/AS1.

Timber cavity batten H3.1 minimum treated Timber cavity batten the cladding is fixed over.

Exterior grade filler CRC Builders Fill or similar two part filler to fill over nail holes

Sealant

12 James Hardie Stria® Cladding Technical Specification December 2014 New Zealand James Hardie Stria® Cladding Technical Specification December 2014 New Zealand 13

13 Details

Thefollowinggenericdetailshavebeenprovidedinthisdocumentforcavityconstructionmethods.

Table5Details

DescriptionCavity Construction

Figure No. Page No.

Framing set out Figure 1 13

Batten fixing set out Figure 2 14

Stria Cladding layout Figure 3 15

Foundation detail – option 1 Figure 4 15

Foundation detail – option 2 Figure 5 16

Soffit detail Figure 6 16

Vertical trimline joint flashing option Figure 7 17

Vertical trimline joint flashing option Figure 8 18

Vertical joint flashing option Figure 9 19

Vertical joint flashing option Figure 10 20

Vertical butt joint option Figure 11 21

Fixing detail Figure 12 22

External aluminium box corner Figure 13 23

External aluminium box corner (Alternative) Figure 14 23

Internal aluminium corner Figure 15 24

Internal mitred corner Figure 16 24

Window sill Figure 17 25

Window jamb Figure 18 25

Window head Figure 19 26

Stria cutting around sill Figure 20 27

Stria cutting around head Figure 21 27

Window head Figure 22 28

Window head to Stria Cladding cut board Figure 23 28

Window head Figure 24 29

Trimline Horizontal joint at floor joist Figure 25 30

Drained flashing joint at floor level Figure 26 31

Drained flashing joint at floor joist Figure 27 32

Engineered floor joist Figure 28 33

Apron flashing detail Figure 29 33

Parapet flashing Figure 30 34

Roof to wall junction detail Figure 31 34

Meter box at sill Figure 32 35

Meter box at jamb Figure 33 35

Meter box at head Figure 34 36

Enclosed deck Figure 35 36

WIN

DO

WD

OO

R

Th

e cl

addi

ng v

ertic

al jo

int m

ust b

e fo

rmed

on

the

batte

n fix

ed o

ver t

he d

oubl

e st

ud.

If

stud

s ar

e pl

aced

at 4

00m

m c

entre

s no

inte

rmed

iate

sup

port

is re

quire

d.

Ext

erna

l cor

ner,

batte

nla

yout

to s

uit t

hecl

addi

ng e

xter

nal c

orne

r

Tim

ber c

avity

bat

tens

Bat

tens

sho

wn

shad

ed, f

ixed

over

bui

ldin

g un

derla

y an

dfra

me

Inte

rnal

cor

ner

Nyl

on s

trap

inte

rmed

iate

sup

port

to h

old

insu

latio

n in

pla

ce a

t 300

mm

cen

tres

Bat

ten

fixin

g - 4

0 x

2.8m

m H

ardi

eFle

xTM n

ails

Ref

erto

Sec

tion

5 fo

r inf

orm

atio

n

Sof

fitS

tria®

Cla

ddin

g jo

int

Floo

rO

n st

ud c

ladd

ing

join

t

Dra

ined

flas

hing

join

t

www.jameshardie.co.nz

Stria® Cladding On Timber Cavity Battena smarter wayTM

®

FRAMING SETOUT

December 2014

Scale 1:25

stimfig_01.dwg

FIGURE 1

12 James Hardie Stria® Cladding Technical Specification December 2014 New Zealand James Hardie Stria® Cladding Technical Specification December 2014 New Zealand 13

Figure1:Framingsetout

Max

imum

nog

spa

cing

maximum stud centres maximum stud centres

Timber cavity battens at 600mmcentres maximum Horizontal battens between

verticals

Batten fixing points

Nylon strap intermediate supportto hold insulation in place Stria® Cavity Closure with opening

area of 1000mm² per m length

800m

m80

0mm

600mm 600mm 600mm

800m

m

45m

mty

pica

l

600mm

www.jameshardie.co.nz

Stria® Cladding On Timber Cavity Battena smarter wayTM

®

BATTEN FIXING SETOUT

December 2014

Scale 1:20

stimfig_02.dwg

FIGURE 2

14 James Hardie Stria® Cladding Technical Specification December 2014 New Zealand James Hardie Stria® Cladding Technical Specification December 2014 New Zealand 15

Figure2:Battenfixingsetout

14 James Hardie Stria® Cladding Technical Specification December 2014 New Zealand James Hardie Stria® Cladding Technical Specification December 2014 New Zealand 15

Figure4:Foundationdetail–option1

Figure3:StriaCladdinglayout

4200mm mm max

Opening

Opening

Typical Storey Layout

Heavy linerepresents joints

Stria® Trimlinehorizontal joint

Opening

Corner

Opening Opening

Drainedflashingjoint

www.jameshardie.co.nz

Stria® Cladding On Timber Cavity Battena smarter wayTM

®

STRIA CLADDING LAYOUT

December 2014

Scale 1:100

stimfig_03.dwg

FIGURE 3

50m

m o

verh

ang

5mm

G.L.

Timber cavity battens

Building underlay / James Hardie rigidair barrier

Bottom plate

Nail for batten fixing

DPC

Concrete slab or blockwork

Stria® Cavity Closure with1000mm² of opening per linealmetre. Keep clear of debris.

Machined Stria® Cladding bottom edge

Stria® Cladding

Selected coating

150mm min to permanentpaving or 225mm min tounpaved ground toclause 9.1.3 of E2/AS1

Nail at 600mm centres

65 x 2.87mm D head gun nail,finish 2mm below surface and fillover with 2 part exterior grade filleror 60 x 2.87mm RounDrive nailfinish flush with surface

www.jameshardie.co.nz

Stria® Cladding On Timber Cavity Battena smarter wayTM

®

FOUNDATION DETAIL OPTION 1

December 2014

Scale 1:2

stimfig_04.dwg

FIGURE 4

16 James Hardie Stria® Cladding Technical Specification December 2014 New Zealand James Hardie Stria® Cladding Technical Specification December 2014 New Zealand 17

Figure6:Soffitdetail

Selected coating

Stria® Cladding

Nail for batten fixing

Site cut edge to be sealed

Flexible sealant

Soffit

8mm minimum gap

Offset nog to blockairflow into roof spacefrom cladding cavity

Nog

Stud

Timber cavity batten

Building underlay /JamesHardie rigid air barrier

65 x 2.87mm D head gunnail, finish 2mm belowsurface and fill over with 2part exterior grade filler or60 x 2.87mm RounDrivenail finish flush withsurface

www.jameshardie.co.nz

Stria® Cladding On Timber Cavity Battena smarter wayTM

®

SOFFIT DETAIL

December 2014

Scale 1:2

stimfig_05.dwg

FIGURE 6

Figure5:Foundationdetail–option2

50m

m o

verh

ang

75m

m

5mm

G.L.

Timber cavity battens

Building underlay / James Hardie rigid airbarrier

Bottom plate

Nail for batten fixing

DPC

Stria® Cladding

Selected coating

150mm min to permanentpaving or 225mm min tounpaved ground to clause9.1.3 of E2/AS1

Concrete slab or blockwork

James Hardie vent strip with 1000mm² of opening per linealmetre. Keep clear of debris.

Site cut bottom edge of Stria® Cladding to bewell sealed

Nail at 600mm centres

65 x 2.87mm D head gunnail, finish 2mm belowsurface and fill over with 2part exterior grade filler or60 x 2.87mm RounDrivenail finish flush withsurface

www.jameshardie.co.nz

Stria® Cladding On Timber Cavity Battena smarter wayTM

®

FOUNDATION DETAIL OPTION 2

December 2014

Scale 1:2

stimfig_04.dwg

FIGURE 5

16 James Hardie Stria® Cladding Technical Specification December 2014 New Zealand James Hardie Stria® Cladding Technical Specification December 2014 New Zealand 17

Figure7:Verticaltrimlinejointflashingoption

3mm gap maximum12mm

12mm

Note: All site cut edges to be sealed

Framing

65 x 2.87mm D head gun nail, finish2mm below surface and fill over with 2part exterior grade filler or 60 x2.87mm RounDrive nail finish flushwith surface

Nail for batten fixing

Building underlay / JamesHardie rigid air barrier

Timber cavity battens

Stria® Cladding4mm continuous bead of flexiblesealant to end of Stria® Cladding priorto butting to trimline joint

Stria® trimline jointflashing

www.jameshardie.co.nz

Stria® Cladding On Timber Cavity Battena smarter wayTM

®

VERTICAL TRIMLINE JOINT OPTION

December 2014

Scale 1:2

stimfig_08.dwg

FIGURE 7

18 James Hardie Stria® Cladding Technical Specification December 2014 New Zealand James Hardie Stria® Cladding Technical Specification December 2014 New Zealand 19

Figure8:Verticaltrimlinejointflashingoption

Note: All site cut edges to be sealed

FramingBuilding underlay / James Hardie rigidair barrier

Timber cavity battens

Stria® Cladding

4mm continuous bead of flexible sealantto end of Stria® Cladding prior to buttingto trimline joint

Stria® trimline joint flashing

www.jameshardie.co.nz

Stria® Cladding On Timber Cavity Battena smarter wayTM

®

VERTICAL TRIMLINE JOINT OPTION

December 2014

Scale 1:5

stimfig_08.dwg

FIGURE 8

18 James Hardie Stria® Cladding Technical Specification December 2014 New Zealand James Hardie Stria® Cladding Technical Specification December 2014 New Zealand 19

Figure9:Verticaljointflashingoption

12mm

Double stud behind vertical joint

65 x 2.87mm D head gunnail, finish 2mm belowsurface and fill over with 2part exterior grade filler or60 x 2.87mm RounDrivenail finish flush with surface

Stria® vertical joint flashing

Nail for batten fixing

Building underlay / JamesHardie rigid air barrier

Timber cavity battens

Apply continuous bead of flexible sealant inthe corner

Note: All site cut edges to be sealed

www.jameshardie.co.nz

Stria® Cladding On Timber Cavity Battena smarter wayTM

®

VERTICAL JOINT FLASHING OPTION

December 2014

Scale 1:2

stimfig_09.dwg

FIGURE 9

20 James Hardie Stria® Cladding Technical Specification December 2014 New Zealand James Hardie Stria® Cladding Technical Specification December 2014 New Zealand 21

Figure10:Verticaljointflashingoption

Enlarged Detail XNote: All site cut edges to be sealed

Intermediate stud

Building underlay / JamesHardie rigid air barrier

Joint stud

Timber cavity battens

Stria® joint flashing

Fit next board prior to fixingtop of board below

Datum line, bottom of boards

Detail X

Position first board with bottom on datum line i.e.50mm overhang from bottom plate and fix in place

Stria® Cavity Closure

Ensure boards are locked infirmly and are level byknocking down with a softblock placed on the grooveledge.

Timber cavity battens

Apply sealant to the lap edge

Fix remaining boards usingthe same method

Apply sealant to the lap edge

Remove face of cavityclosure only behind Striajoint flashing

www.jameshardie.co.nz

Stria® Cladding On Timber Cavity Battena smarter wayTM

®

VERTICAL JOINT FLASHING OPTION

December 2014

Scale 1:10

stimfig_07.dwg

FIGURE 10

20 James Hardie Stria® Cladding Technical Specification December 2014 New Zealand James Hardie Stria® Cladding Technical Specification December 2014 New Zealand 21

Figure11:Verticalbuttjointoption

3mm gap maximum12mm

12mm

Note: All site cut edges to be sealed

Framing

65 x 2.87mm D head gun nail, finish2mm below surface and fill over with 2part exterior grade filler or 60 x2.87mm RounDrive nail finish flushwith surface

Nail for batten fixing

Building underlay / JamesHardie rigid air barrier

Timber cavity battens

Stria® Cladding

Close butt joint sealed withcontinuous 4mm thick bead of flexiblesealant on one end before butting theboards. Cut off the excess flexiblesealant on surface when it's dry. Thisjoint formed in line on same batten

50mm wide x 1.5mmthick Inseal® 3259

www.jameshardie.co.nz

Stria® Cladding On Timber Cavity Battena smarter wayTM

®

VERTICAL BUTT JOINTING OPTION

December 2014

Scale 1:2

stimfig_08.dwg

FIGURE 11

22 James Hardie Stria® Cladding Technical Specification December 2014 New Zealand James Hardie Stria® Cladding Technical Specification December 2014 New Zealand 23

Figure12:Fixingdetail

100m

m

380m

m c

over

100m

m15

mm

405m

m

Stria Cladding

Selected coating

Building underlay /James Hardie rigid air barrier

Timber cavity battens

65 x 2.87mm D head gun nail,finish 2mm below surface andfill over with 2 part exteriorgrade filler or 60 x 2.87mmRounDrive nail finish flush withsurface

Stud

www.jameshardie.co.nz

Stria® Cladding On Timber Cavity Battena smarter wayTM

®

FIXING DETAIL

December 2014

Scale 1:2

stimfig_10.dwg

FIGURE 12

22 James Hardie Stria® Cladding Technical Specification December 2014 New Zealand James Hardie Stria® Cladding Technical Specification December 2014 New Zealand 23

Figure13:Externalaluminiumboxcorner

Note: All site cut edges to be sealed

Studs

Building underlay / JamesHardie rigid air barrier

Timber cavity battens

Nail for batten fixing

Stria® Cladding

Selected coating

65 x 2.87mm D head gun nail,finish 2mm below surface andfill over with 2 part exteriorgrade filler or 60 x 2.87mmRounDrive nail finish flush withsurface

Maximum 2mm gap typical

Stria Aluminium External BoxCorner

Seal end of board

50mm

50m

m

www.jameshardie.co.nz

Stria® Cladding On Timber Cavity Battena smarter wayTM

®

EXTERNAL ALUMINIUM BOX CORNER

December 2014

Scale 1:2

stimfig_11.dwg

FIGURE 13

Figure14:Externalaluminiumboxcorner(Alternative)

Note: All site cut edges to be sealed

Studs

Building underlay / JamesHardie rigid air barrier

Timber cavity battens

Nail for batten fixing

Stria® Cladding

Selected coating

65 x 2.87mm D head gun nail,finish 2mm below surface andfill over with 2 part exteriorgrade filler or 60 x 2.87mmRounDrive nail finish flush withsurface

Maximum 2mm gap typical

JH 9mm PanelAluminium ExternalBox Corner

Seal end of board50mm

50m

m

www.jameshardie.co.nz

Stria® Cladding On Timber Cavity Battena smarter wayTM

®

EXTERNAL ALUMINIUM BOX CORNER (ALTERNATIVE)

December 2014

Scale 1:2

stimfig_13.dwg

FIGURE 14

24 James Hardie Stria® Cladding Technical Specification December 2014 New Zealand James Hardie Stria® Cladding Technical Specification December 2014 New Zealand 25

Figure15:Internalaluminiumcorner

Figure16:Internalmitredcorner

Note: All site cut edges to be sealed

35m

m

35mm

Building underlay /James Hardie rigid air barrier

65 x 2.87mm D head gun nail,finish 2mm below surface and fillover with 2 part exterior gradefiller or 60 x 2.87mm RounDrivenail finish flush with surfaceStria® Aluminium Internal Corner mould

Apply adhesive sealant to StriaCladding in internal corner

Stria® Cladding

Selected coating

Timber cavity battens

Studs

Nail for batten fixing

Blocking asrequired

Fix internal corner over with 40 x 2.8mmHardieFlexTM nails at 300mm centres bothsides.

Nail for batten fixing

www.jameshardie.co.nz

Stria® Cladding On Timber Cavity Battena smarter wayTM

®

INTERNAL ALUMINIUM CORNER

December 2014

Scale 1:2

stimfig_14.dwg

FIGURE 15

Mitre cut end of boards, prime endsand join with Bostik Seal n Flex -1 orSika Sikaflex 11FC adhesivesealant. Push tightly together andonce cured cut off excess sealant.

12m

m

12mm

Polypropylene or a flashing tapeapplied to protect building underlay100mm wide each side.

65 x 2.87mm D head gun nail, finish2mm below surface and fill over with2 part exterior grade filler or 60 x2.87mm RounDrive nail finish flushwith surface

Stria® Cladding

Selected coating

Timber cavity battens

Building underlay / JamesHardie rigid air barrier

Nail for batten fixing

Studs

James Hardie corner underflashing

www.jameshardie.co.nz

Stria® Cladding On Timber Cavity Battena smarter wayTM

®

INTERNAL MITRED CORNER

December 2014

Scale 1:2

stimfig_15.dwg

FIGURE 16

24 James Hardie Stria® Cladding Technical Specification December 2014 New Zealand James Hardie Stria® Cladding Technical Specification December 2014 New Zealand 25

Figure17:Windowsill

10m

m m

in

8mm

gap

nom

inal

General notes for materials selection1. Flashing materials must be selected based on environmental exposure, refer to NZS 3604 and Table 20 of NZBC

E2/AS1.2. Building underlay must comply with acceptable solution E2/AS1 and NZS 3604.3. Flashing tape must have proven compatibility with the selected building underlay and other materials with which it comes

into contact as per Table 21 of E2/AS1.4. When James Hardie rigid air barriers are used flashing tape to be applied to the entire opening.

Waterproof airseal toperimeter of trim cavitywith expandable foam orsealant as per section9.1.6 of E2/AS1

Selected interior lining

Building underlay / JamesHardie rigid air barrierNail for batten fixing

Window liner

Flexible flashing tape wrapped overwindow sill

Window frame (refer towindow manufacturer formethod of support and fixing)

Window support as suppliedby window manufacturerEdge of cladding and verticalsection under window flange to besealed before window is installed.

65 x 2.87mm D head gunnail, finish 2mm belowsurface and fill over with 2part exterior grade filler or60 x 2.87mm RounDrive nailfinish flush with surface

Timber cavity battens

Stria® Cladding

Selected coating

Refer to the manufacturer or supplier for technical information for these materials.

5mm gap

www.jameshardie.co.nz

Stria® Cladding On Timber Cavity Battena smarter wayTM

®

WINDOW SILL

December 2014

Scale 1:2

stimfig_17.dwg

FIGURE 17

Figure18:Windowjamb

8mm

gap

nom

inal

past

win

dow

to e

nd o

ffla

shin

g

Note: When James Hardie rigid air barriers are used flashing tape to beapplied to the entire window opening

Building underlay / JamesHardie rigid air barrier

Timber cavity battens

Stria® Cladding

Selected coating

Stria® Cladding cut edges tobe sealed before window isinstalled

Inseal min 19mm thickx 10mm wide 3109

Window frame (refer towindow manufacturer formethod of support and fixing)

Line of head flashing over

Aluminium window jamb flashing tomatch length of jamb. Apply continuousbead of Bostik Seal n Flex -1 or SikaSikaflex 11FC adhesive sealant. Insertinto profile gaps flexible sealant tomake window edge weathertight.

Selected interiorlining

Window liner

Waterproof airseal

65 x 2.87mm D head gun nail,finish 2mm below surface and fillover with 2 part exterior grade filleror 60 x 2.87mm RounDrive nailfinish flush with surface

Nail for batten fixing

Flashing tape 100mm upstand on jamb

20mm min10mm min

5

Continuous protectivesealant

www.jameshardie.co.nz

Stria® Cladding On Timber Cavity Battena smarter wayTM

®

WINDOW JAMB

December 2014

Scale 1:2

stimfig_18.dwg

FIGURE 18

26 James Hardie Stria® Cladding Technical Specification December 2014 New Zealand James Hardie Stria® Cladding Technical Specification December 2014 New Zealand 27

Figure19:Windowhead

35m

m m

in

5mm

50m

m

Note: When James Hardie rigid air barriers are used flashing tape to beapplied to the entire window opening

Stop end to head flashingbehind the cladding or buttthe ends againsttimber cavity battens andseal the joint

5mm

gap

25m

m

8mm

gap

nom

inal

To a

llow

for h

ead

defle

ctio

n an

d ai

rsea

l

50m

mLintel

Nail for batten fixing

Selected interior lining

Window linerWaterproof airseal

Building underlay / JamesHardie rigid air barrier

Timber cavity battens

Proprietary tape or alternativelyadditional layer of buildingunderlay over head flashing

Stria® Cladding

Selected coating

65 x 2.87mm D head gunnail, finish 2mm belowsurface and fill over with 2part exterior grade filler or60 x 2.87mm RounDrivenail finish flush withsurface

Stria cavity closure

One piece head flashing

Site cut edge to be sealed

Flashing tape overbuilding underlayrequired in corners onlyWindow frame (refer towindow manufacturer formethod of support and fixing)

This dimension must bechecked on site with joinerymanufacturer

5mm gap

Stria® Cladding

Flashing

www.jameshardie.co.nz

Stria® Cladding On Timber Cavity Battena smarter wayTM

®

WINDOW HEAD

December 2014

Scale 1:2

stimfig_23.dwg

FIGURE 19

26 James Hardie Stria® Cladding Technical Specification December 2014 New Zealand James Hardie Stria® Cladding Technical Specification December 2014 New Zealand 27

Figure20:Striacuttingaroundsill

Window frame omitted for clarity

100m

mm

inim

um

Note: All site cut edges to be sealed

Trimmer studs

Building underlay / James Hardie rigid air barrier

Timber cavity battens

Aluminium window jamb flashingApply continuous bead of flexible sealant beforebutting in panel. Insert into profile gaps flexiblesealant to make window edge weathertight

Flashing tape

Window sill plate

Stria® Cladding

www.jameshardie.co.nz

Stria® Cladding On Timber Cavity Battena smarter wayTM

®

CUTTING AROUND SILL

December 2014

Scale 1:8

stimfig_20.dwg

FIGURE 20

Figure21:Striacuttingaroundhead

Window frame omitted for clarity

100m

mm

inim

um

Note: All site cut edges to be sealed

Apply continuous bead of flexiblesealant.before butting into panel. Insertinto profile gaps flexible sealant to makewindow edge weathertight

100m

mm

inim

um

Flashing tape

James Hardie uPVCvent stripWindow head flashing

Lintel

Flashing tape

Aluminium window jamb flashing

Trimmer studs

Building underlay /James Hardie rigid airbarrier

Timber cavity battens

Check window headflashing into Stria®

Cladding

Window head flashingmust extend 20mmpast edge of aluminiumwindow joinery.

Stop end to head flashingbehind the cladding or buttthe ends against timbercavity battens and seal thejoint

Stria® Cladding, horizontaljoint must not coincidewith window head flashing

www.jameshardie.co.nz

Stria® Cladding On Timber Cavity Battena smarter wayTM

®

CUTTING AROUND HEAD

December 2014

Scale 1:8

stimfig_21.dwg

FIGURE 21

28 James Hardie Stria® Cladding Technical Specification December 2014 New Zealand James Hardie Stria® Cladding Technical Specification December 2014 New Zealand 29

Figure22:Windowhead

Figure23:WindowheadtoStriaCladdingcutboard

35m

m m

in

15m

m50

mm

Note: When James Hardie rigid air barriers are used flashing tape to beapplied to the entire window opening

Stop end to head flashingbehind the cladding or buttthe ends againstTimber cavity battens andseal the joint

5mm

gap

25m

m

8mm

gap

nom

inal

To a

llow

for h

ead

defle

ctio

n an

d ai

rsea

l

50m

m

Lintel

Nail for batten fixing

Selected interior lining

Window linerWaterproof airseal

Building underlay / JamesHardie rigid air barrier

Timber cavity battens

Proprietary tape or alternativelyadditional layer of buildingunderlay over head flashing

Stria® Cladding

Selected coating

65 x 2.87mm D head gunnail, finish 2mm belowsurface and fill over with 2part exterior grade filler or60 x 2.87mm RounDrivenail finish flush withsurfaceJames HardieuPVC vent strip

One piece head flashing

Site cut edge to be sealed

Flashing tape overbuilding underlayrequired in corners onlyWindow frame (refer towindow manufacturer formethod of support and fixing)

This dimension must bechecked on site with joinerymanufacturer

50mm strip of sealant at bothends of flashing

www.jameshardie.co.nz

Stria® Cladding On Timber Cavity Battena smarter wayTM

®

WINDOW HEAD

December 2014

Scale 1:2

stimfig_19.dwg

FIGURE 22

Window frame omitted for clarity

100m

mm

inim

um

Note: All site cut edges to be sealed

Apply continuous bead of flexiblesealant before butting in panel.Insert into profile gaps flexible sealantto make window edge weathertight

100m

mm

inim

um

Flashing tape

James Hardie uPVCvent stripWindow head flashing

Lintel

Flashing tape

Aluminium window jamb flashing

Trimmer studs

Building underlay /James Hardie rigid airbarrier

Timber cavity battens

Check window headflashing into Stria®

Cladding

Window head flashingmust extend 20mmpast edge of aluminiumwindow joinery.

Stop end to head flashingbehind the cladding or buttthe ends against CLD®

Structural Cavity Battenand seal the joint

Stria® Cladding, horizontaljoint must not coincidewith window head flashing

6mm continuous bead ofBostik Seal n Flex - 1 orSika Sikaflex 11FCadhesive sealant to batten.

Stria® Vertical Trimlinejoint or Vertical JointFlashing

Timber cavity battens

www.jameshardie.co.nz

Stria® Cladding On Timber Cavity Battena smarter wayTM

®

WINDOW HEAD TO STRIA CLADDING CUT BOARD

December 2014

Scale 1:8

stfig_23.dwg

FIGURE 23

28 James Hardie Stria® Cladding Technical Specification December 2014 New Zealand James Hardie Stria® Cladding Technical Specification December 2014 New Zealand 29

Figure24:Windowhead

Note: All site cut edges to be sealed

Stud

Timber cavity battens aboveand below head flashing

Seal Timber cavity battens andhead flashing junction with abead of Seal n Flex - 1 orSikaflex 11FC adhesivesealant

Head flashing to extend min20mm past window joinery

Seal end of head flashing toTimber cavity battens

10mm minimum windowjoinery lap over Stria® Cladding

Blocking as required to support timbercavity battens

Building underlay / JamesHardie rigid air barrier

Proprietary tape or alternativelyadditional layer of buildingunderlay over head flashing

Lintel

Head flashing with 15° min slope

Stria® Cladding to terminate 5mmabove head flashing

James Hardie uPVCvent strip

www.jameshardie.co.nz

Stria® Cladding On Timber Cavity Battena smarter wayTM

®

WINDOW HEAD

December 2014

Scale 1:7

stimfig_22.dwg

FIGURE 24

30 James Hardie Stria® Cladding Technical Specification December 2014 New Zealand James Hardie Stria® Cladding Technical Specification December 2014 New Zealand 31

Figure25:Trimlinehorizontaljointatfloorjoists

15m

m m

in g

ap

Nail for batten fixing65 x 2.87mm D head gunnail, finish 2mm belowsurface and fill over with 2part exterior grade filler or60 x 2.87mm RounDrive nailfinish flush with surface

Panel edge to be sealedprior to flashing installation

Stria® Cladding

STEP 1 Check architects plans for the type of flashing to be used.

STEP 2 Check fixing centres and edge distances.

STEP 3 When 50 year durability is required refer Table 20 E2/AS1.

STEP 4 The flashing to be placed in the centre of the floor joists. Do not fix timber cavity battens or cladding

into floor joists.

65 x 2.87mm D head gunnail, finish 2mm belowsurface and fill over with 2part exterior grade filler or60 x 2.87mm RounDrive nailfinish flush with surface

Notes: Stria aluminium trimline joint, take care to ensure continuous seal is formed between panel and the

trimline joint. A purpose made 100mm long x 16mm deep x 0.7mm thick 'L' shaped flashing will be required over

the butt joint of the Stria aluminium trimline joint.

Apply two 6mm thick linesof adhesive sealant on thebottom portion of the Striaaluminium trimline joint toseal.

www.jameshardie.co.nz

Stria® Cladding On Timber Cavity Battena smarter wayTM

®

TRIMLINE HORIZONTAL JOINT AT FLOOR LEVEL

December 2014

Scale 1:2

stimfig_24.dwg

FIGURE 25

30 James Hardie Stria® Cladding Technical Specification December 2014 New Zealand James Hardie Stria® Cladding Technical Specification December 2014 New Zealand 31

Figure26:Drainedflashingjointatfloorlevel

15m

m m

in g

ap

5mm

Nail for batten fixing

Proprietary tape over flashingor alternatively additionallayer of building underlay

65 x 2.87mm D head gunnail, finish 2mm belowsurface and fill over with 2part exterior grade filler or60 x 2.87mm RounDrive nailfinish flush with surface

Stria® Cavity Closure with1000mm² of opening perlineal metre.

Panel to be sealed prior toflashing installation

Stria® Cladding

STEP 1 Check architects plans for the type of flashing to be used.

STEP 2 Check fixing centres and edge distances. If top fixings are to be hidden by the Z flashing they will need to be fixed and sealed before the Z

flashing is installed.

STEP 3 When 50 year durability is required refer Table 20 E2/AS1.

STEP 4 The flashing to be placed in the centre of the floor joists. Do not fix timber cavity battens or cladding

into floor joists.

65 x 2.87mm D head gunnail, finish 2mm belowsurface and fill over with 2part exterior grade filler or60 x 2.87mm RounDrive nailfinish flush with surface

Note: This detail is required to limit cavities to a maximum of 2 stories or 7 metres. Refer toE2/AS1 clause 9.1.9.4

www.jameshardie.co.nz

Stria® Cladding On Timber Cavity Battena smarter wayTM

®

DRAINED FLASHING JOINT AT FLOOR LEVEL

December 2014

Scale 1:2

stimfig_24.dwg

FIGURE 26

32 James Hardie Stria® Cladding Technical Specification December 2014 New Zealand James Hardie Stria® Cladding Technical Specification December 2014 New Zealand 33

Figure27:Drainedflashingjointatfloorjoist

Note: All site cut edges to be sealed This detail is required to limit cavities to a maximum of 2 stories or 7 metres.

Refer to E2/AS1 clause 9.1.9.4

Framing

Stria® Cladding

Timber cavity battens

Building underlay/ James Hardierigid air barrier

Stria® Cavity Closure

'Z' flashing (Architectto design)

www.jameshardie.co.nz

Stria® Cladding On Timber Cavity Battena smarter wayTM

®

DRAINED FLASHING JOINT AT FLOOR JOIST

December 2014

Scale 1:3

stimfig_25.dwg

FIGURE 27

32 James Hardie Stria® Cladding Technical Specification December 2014 New Zealand James Hardie Stria® Cladding Technical Specification December 2014 New Zealand 33

Figure29:Apronflashingdetail

Figure28:Engineeredfloorjoist

When 50 year durability forflashing is required referTable 20 NZBC E2/AS1document.

*

50m

m

Note: All site cut edges tobe sealed

Timber cavity battens

Stria® CladdingSelected coating

65 x 2.87mm D head gunnail, finish 2mm belowsurface and fill over with 2part exterior grade filler or60 x 2.87mm RounDrivenail finish flush with surface

James Hardie uPVC ventstrip with 1000mm² ofopening per lineal metrefitted between battens

Selected roofing with stopend

Flashing edge of flashingdressed down or notched

Roof framing

Proprietary tape oralternatively additional layerof building underlay overapron flashing

Nail for batten fixing

Nog as required

Building underlay / JamesHardie rigid air barrier overroof underlay

Roof underlay continued upbehind flashing Refer Figure 7 and Table 7

of E2/AS1 document

50mm min clear gap

75mm min. flashing legabove bottom of sheet

www.jameshardie.co.nz

Stria® Cladding On Timber Cavity Battena smarter wayTM

®

APRON FLASHING DETAIL

December 2014

Scale 1:3

stimfig_26.dwg

FIGURE 29

Stria® Cladding

Glulam orengineeredjoist

Floor

Top plate

Stud

10m

m m

ax.

65 x 2.87mm D head gunnail, finish 2mm belowsurface and fill over with 2part exterior grade filler or60 x 2.87mm RounDrive nailfinish flush with surface

www.jameshardie.co.nz

Stria® Cladding On Timber Cavity Battena smarter wayTM

®

OVER JOIST AT FLOOR LEVEL

December 2014

Scale 1:2

stfig_25.dwg

FIGURE 28

34 James Hardie Stria® Cladding Technical Specification December 2014 New Zealand James Hardie Stria® Cladding Technical Specification December 2014 New Zealand 35

Figure30:Parapetflashing

See

Tab

le 7

E2/

AS

15° slope minimum

for b

oth

side

s

Metal capping flashingmust be fixed to sidesonly

Underlay to provideisolation of metal flashingto timber

Timber cavity battens

Stria® Cladding

Selected coating

H3.1 treated timberpacker to form slope

65 x 2.87mm D headgun nail, finish 2mmbelow surface and fillover with 2 part exteriorgrade filler or 60 x2.87mm RounDrive nailfinish flush with surface

Nail for batten fixing

Building underlay / James Hardie rigidair barrier

www.jameshardie.co.nz

Stria® Cladding On Timber Cavity Battena smarter wayTM

®

PARAPET FLASHING

December 2014

Scale 1:2

stimfig_30.dwg

FIGURE 30

Figure31:Rooftowalljunctiondetail

* When 50 year durability for flashing isrequired refer Table 20 NZBC E2/AS1document.

Fall

Note: All cut edges tobe sealed

Timber cavity battensBuilding underlay / JamesHardie rigid air barrier

Stria® Cladding

James Hardie uPVC vent stripfitted between battens

Flashing tape or extra layer ofbuilding underlay over flashing

Flashing upstand behindbuilding underlay

* Apron flashing with taperedstopend. Cladding to becarefully cut over stopend andsealed.

Apply flexible sealant to sealStria® Cladding to fascia board

End of spouting must be10mm min clear of finishedStria® Cladding

Selected roofingSoffit

Fascia board

Selected spouting

www.jameshardie.co.nz

Stria® Cladding On Timber Cavity Battena smarter wayTM

®

ROOF TO WALL JUNCTION DETAIL

December 2014

Scale 1:10

stimfig_28.dwg

FIGURE 31

34 James Hardie Stria® Cladding Technical Specification December 2014 New Zealand James Hardie Stria® Cladding Technical Specification December 2014 New Zealand 35

Figure32:Meterboxatsill

10m

m

5mm

gap

10m

mm

in

min

cov

er

Alternative; Fit Electra meterbox, follow manufacturersinstructions.

Note: When James Hardie rigid air barriers are used flashing tape tobe applied to the entire window opening

Metal meter box Metal angle to be continuous aroundmeter box. Seal and rivet in place.

Seal the claddingagainst the metal angle

Selected coating

Stria® Cladding

Timber cavity battens

65 x 2.87mm D head gun nail,finish 2mm below surface andfill over with 2 part exteriorgrade filler or 60 x 2.87mmRounDrive nail finish flush withsurface

Panel edge to be sealed prior toapplying sealant over bond breaker tape

Airseal around allsides of meter box

Flexible flashing tapeat corners overbuilding underlay

Nail for batten fixing

Building underlay / James Hardie rigidair barrier

www.jameshardie.co.nz

Stria® Cladding On Timber Cavity Battena smarter wayTM

®

METER BOX AT SILL

December 2014

Scale 1:2

stimfig_29.dwg

FIGURE 32

Figure33:Meterboxatjamb

10m

m

5mm

10m

m

Panel edge to be sealed prior to applyingsealant over bond breaker tape

min

imum

cove

r

min

imum

gap

Alternative; Fit Electra meter box,follow manufacturers instructions.

Note: When James Hardie rigid air barriers are usedflashing tape to be applied to the entire window opening

Selected coating

Stria® Cladding

Timber cavity battens

65 x 2.87mm D head gun nail,finish 2mm below surface andfill over with 2 part exteriorgrade filler or 60 x 2.87mmRounDrive nail finish flushwith surface

Airseal around all sidesof meter box

Metal angle to becontinuous around meterbox. Seal and rivet inplace.

Metal meter box

Seal the claddingagainst the metalangle

Nail for batten fixing

Flexible flashing tape atcorners over building underlay

Building underlay / JamesHardie rigid air barrier

www.jameshardie.co.nz

Stria® Cladding On Timber Cavity Battena smarter wayTM

®

METER BOX AT JAMB

December 2014

Scale 1:2

stimfig_30.dwg

FIGURE 33

36 James Hardie Stria® Cladding Technical Specification December 2014 New Zealand James Hardie Stria® Cladding Technical Specification December 2014 New Zealand 3736 James Hardie Stria® Cladding Technical Specification December 2014 New Zealand James Hardie Stria® Cladding Technical Specification December 2014 New Zealand 37

Figure34:Meterboxathead

35m

m m

in

15m

m

Alternative; FitElectra meter box,followmanufacturersinstructions.

Note: When JamesHardie rigid airbarriers are usedflashing tape to beapplied to the entirewindow opening

Note: Do not run claddingpast flashing

~Nog as required~Note: All site cutedges to be sealed

Selected coating

Stria® Cladding

Timber cavity battens65 x 2.87mm D head gun nail,finish 2mm below surface and fillover with 2 part exterior gradefiller or 60 x 2.87mm RounDrivenail finish flush with surfaceJames Hardie uPVC vent stripwith 1000mm² of opening perlineal metre

Flashing 15° min slope, rivet tometal angle, required at headonly

5mm min gap - do not block

Metal angle to be continuousaround meter box. Seal andrivet in place.

Nail for batten fixing

Building underlay / JamesHardie rigid air barrier

Additional building underlay orflashing tape over flashing

Flexible flashing tape at cornersover building underlay

Airseal around all sidesof meter box

Metal meter box

10mm min. cover

www.jameshardie.co.nz

Stria® Cladding On Timber Cavity Battena smarter wayTM

®

METER BOX AT HEAD

December 2014

Scale 1:2

stimfig_31.dwg

FIGURE 34

Figure35:Encloseddeck

150m

m m

in m

embr

ane

upst

and

5mm 50m

m

Enclosed deck structure

100m

m m

inim

um

50m

m m

inim

um

Floor structure

Selected coating

Stria® Cladding

Timber cavity battens

65 x 2.87mm D head gun nail,finish 2mm below surface and fillover with 2 part exterior gradefiller or 60 x 2.87mm RounDrivenail finish flush with surface

Deck waterproof membrane carryup behind building underlay pastwall framing bottom plate.

Building underlay / JamesHardie rigid air barrier

Nail for batten fixing

Bottom plate

D.P.C.

Corner fillet

Stria® Cavity Closure with1000mm² of opening per linealmetre

www.jameshardie.co.nz

Stria® Cladding On Timber Cavity Battena smarter wayTM

®

ENCLOSED DECK

December 2014

Scale 1:2

stimfig_32.dwg

FIGURE 35

Notes

36 James Hardie Stria® Cladding Technical Specification December 2014 New Zealand James Hardie Stria® Cladding Technical Specification December 2014 New Zealand 3736 James Hardie Stria® Cladding Technical Specification December 2014 New Zealand James Hardie Stria® Cladding Technical Specification December 2014 New Zealand 37

Notes

38 James Hardie Stria® Cladding Technical Specification December 2014 New Zealand James Hardie Stria® Cladding Technical Specification December 2014 New Zealand 39

Product Warranty

38 James Hardie Stria® Cladding Technical Specification December 2014 New Zealand James Hardie Stria® Cladding Technical Specification December 2014 New Zealand 39

February 2015JamesHardieNewZealand(“JamesHardie”)warrantsforaperiodof15yearsfromthedateofpurchasethattheStria®Cladding(the“Product”),willbefreefromdefectsduetodefectivefactoryworkmanshipormaterialsand,subjecttocompliancewiththeconditionsbelow,willberesistanttocracking,rotting,fireanddamagefromtermiteattackstotheextentsetoutinJamesHardie’srelevantpublishedliteraturecurrentatthetimeofinstallation.JamesHardiewarrantsforaperiodof15yearsfromthedateofpurchasethattheaccessoriessuppliedbyJamesHardiewillbefreefromdefectsduetodefectivefactoryworkmanshipormaterials.