THIS WAY - NanoTerraSwarovski Crystal World in Austria is a highly visited attraction center for the...

Transcript of THIS WAY - NanoTerraSwarovski Crystal World in Austria is a highly visited attraction center for the...

GO this way

INNOVATIVE CEMENTADDITIVES FOR ROAD CONSTRUCTION

NanoTerra products are liquid polymers, made in Germany, containing nano-scaled silica which substantially improve the performance of cement.

Using NanoTerra products improve the quality and durability of roads, reduces the construction costs and time with lower machine utilization and CO2 emission.

COSTS QUALITY TIME ENVIRONMENT

YOUR BENEfITS

3

For your BeneFitNanoTerra products can be used with any types of present soil with recycled

aggregates, bitumen, organic components and pollutants. Consequently it

cuts the disposal and reduces the new material costs. Mixed with the

cement it reacts during the curing phase and improves the cement reaction

significantly. Increasing the elasticity and thermal resilience, it reduces

cracks in the stabilized layer over the lifetime.

These advantages offer an unknown flexibility in road construction. The

possibility of reducing the layer design and thickness without compromises

in quality is as unique as the NanoTerra technology.

The unique combination

of polymers together with

nano scaled components

improves the cement

reaction leading to higher

compression strength,

added elasticity and

cladding effects to prevent

elutriation.

UNCONVENTIONAL

IDEAS COSTS

· Reduction of disposal costs up to 100%

· Reduction of raw material costs up to 48%

· Reduction of diesel consumption

· Reduction of machinery costs up to 40%

· Reduction of labour costs up to 40%

QUALITY

· Increase of elasticity

· Increase of loading capacity

· Increase of thermal resilience up to 44%

· Reduction of crack formation

· Increase of lifetime

TIME

· Reduction of construction time up to 75%

· Reduction of setting process up to 50%

· Premature fit for traffic up to 50%

ENVIRONMENT

· Reduction of carbon emissions up to 75%

• Reductionofrawmaterialsand natural resources

• Increaseofrecycling capability

• Reductionofdisposal up to 100%

• Reductionofdiesel consumption up to 31%

NaNoTerra producTs coNTaiN NaNoscale aNd amorphous reacTive sio2

· Improved reactivity due to

higher surface

· Nanoscale lying effect with SiO2

· Leads to cotton wool-like structure

of CSH-matrix

NaNoTerra producTs coNTaiN aqueous polymer emulsioNs

· Acts as internal cladding

· Acts as elastic adhesive

· Preserves water for the 3rd phase

cement hydration

Polymer coating

AggregatePolymer chains

Cotton-like CSH Matrix

4 5

BASE

NT BASE is used for base layers to create hydraulically-bound subbases and can be produced on site (in-situ) or at a pre-mixing plant (in-plant). THE

EfficiEnT

WayRURAL ROAD IN LOIBERSDORf, AUSTRIA The road maintenance association Eisenwurzen in Austria is

responsible for the maintenance and preservation of roads in

60 communes.

NT BASE increases the elasticity to prevent crack formation at

the highest level, so that it is not necessary to asphalt the

road. After the road was milled to a depth of 25 cm, mixed

with cement, NT BASE and water with a Wirtgen cold recycler

AT A PrE-MixiNg PlANT (IN-PLANT) The substrate is pre-mixed in a stationary or mobile

mixing plant, which also mixes cement and NT BASE.

Subsequently, a truck will transport the respective

mix to the construction site and to the equipment

which will apply the base layer. A paver or a grader

will then create the plane prior to compaction.

Additional steps include the application of surface

layers consisting of grit, asphalt or concrete.

iN SiTu (ON-SITE) After cement has been applied to the soil in situ,

it is milled to a certain level. During this process,

the cement is introduced and mixed in the milling

chamber. Water and additive NT BASE are then also

injected into the milling chamber. The surface is

already slightly pre-compacted, but does require

additional compaction prior to the top layer

application (if desired).

fUNCTIONAL pRINCIpLE MILLINg MAChINE

water

working direction

BASE

in-situ soil

processed soil

milling and mixing

Addition of polymer-additive and water

dispersed cement

BASE

RURALROAD

and compacted, 16 mm fine gravel was rolled in.

Subsequently bitumen emulsion has been sprayed

on the surface and 10 mm fine gravel was rolled

in, as replacement of the at lower costs.

After several years all layer are still flawless as

observable in the main picture.

ROAD STRUCTURE AND COSTS

with NT BASEwithout

Cement Base Layer 25 cm / 17 €

Asphalt Top Layer 6 cm / 10 €

Asphalt Binder Course 8 cm / 14 €

Base Course 33 cm / 28 €

Cement Base Layer 30 cm / 21 €

Granular Top Layer 2,5 cm / 7 €

62% MATERIAL COSTS SAVED

CUSTOMER REQUIREMENTS

LOW COStS

AVOIDANCE OF CRACK FORMAtION

NT BASE ENABLES TO

• Specifytheelasticmoduleofthemixtureindependentlyfrom

the amount of cement used. thus you can define thicknesses

and characteristics of the construction layers. With Nt BASE you

can realize continuous or discontinuous granulometric curves

(open grade or close grade).

• Decreasethewatersensitivity.NTBASEwillextendthelifeand

the maintenance cycles of your roads and layers made with

any type of inert or recycled material.

• Stabilizeanytypeofsoiloraggregatematerialasitallowsthe

reaction of the cement in the presence of organic substances or

pollutants of chemical origin.

• Saveupto75%ofconstructiontimecomparedtoastandard

road design, in which base layer and soil stabilization are two

separate processes. Milling machines, graders, compactors are

needed for each layer. Using quicklime in the standard process

makes two separate milling and mixing processes necessary.

With Nt BASE the stabilization layer can be done in one work

process, which means that the construction of the base layer is

up to 4-times faster than without Nt BASE.

The use of NT BASE gives the user advantages in costs and quality

of the road construction and reduces the construction time and

carbon emission significantly compared to standard building

technology.

6 7

RECYCLINg CENTER IN WEINfELDEN, SWITZERLAND

The recycling center in Switzerland deposits, separates and

stores mineral and non-mineral construction materials. Due

to heavy truck traffic and wheel loader operation the access

RECYCLINGCENTER

roads had to be maintained permanently. The

target was to avoid potholes and reduce the

maintenance cost as much as possible. Therefor

the roads had to be reconstructed appropriate and

cost-efficient.

The existing road was milled and mixed with

cement, NT BASE and water and compacted.

NT BASE increases the compressive strength as

well as the elasticity. The result is a durable access

road without cracks, grooves or any need for

maintenance.

COMpRESSIVE STRENgTh

with NT BASERoad sections without

1,20 (N/mm2) 2,10 (N/mm2)

MOUNTAIN ROAD IN TERENTO, ITALY

Serpentine roads overcome steep hills or mountains in several

narrow bends. If driving through winding roads, the vehicle

driver may have to brake several times in succession, steer

hard and accelerate once more. These loads put an extreme

strain on the roads and the shearing force in the turns is

very high which causes a fast abrasion. Constructions of busy

roads put construction companies under time pressure while

still not compromising the work`s quality. Especially climate

STEEP ASCENTSROADS ANDSERPENTINES

changes strain sub-bases due to heavy rain and

storms.

NT BASE significantly improves the compression

strength and the elasticity of the road, while at

the same time allowing the reuse of the existing

material. NT BASE increased tensile strength,

prevents crack formations and keeps the road in

perfect condition of decades.

ROAD SECTIONS

Tested by Geothema srl, Italy

STABILITY AfTER fREEZE-ThAW-TEST

with NT BASERoad sections without

1,15 (Mpa)

44% INCREASED STABILITY

1,66 (Mpa)

BASE BASE

Tested by Consultest AG, Switzerland

CUSTOMER REQUIREMENTS

LOW MAINtENANCE

COMPRESSIVE StRENGtH

HIGH LIFEtIME

CUSTOMER REQUIREMENTS

HIGH StABILItY

FASt IMPLEMENtAtION

ENVIRONMENtAL FRIENDLY

with NT BASE

75% INCREASED STRENgTh

8 9

design your Places

NT TOP is used for constructing cement-based surface layers in road engineering projects. Mainly used for cycle paths, park paths, parking lots, yards and rural roads.

TOP TOP

BOBOLI gARDEN IN fLORENCE, ITALY

Boboli Garden is some of the first and most familiar parks

with a total size of 42.000 m2. The retaining style of 16th

century, including the stone elements, fountains and paths,

is the essence of the garden`s design. The existing park paths

had to be redone with improved strength for the high

amount of visitors and maintenance vehicles. Also gravel

should not longer been carry out in the meadows.

Park

Regional gravel with a low quantity cement and

NT TOP created durable and drainable park paths

in the requested design. Due to narrow work

environment and numerous steps the work

needed to be carried out with small machines and

by hand. As the surface is hygroscopic the surface

remains in perfect condition in heavy weather

conditions.

CUSTOMER REQUIREMENTS

NAtURAL LANDSCAPING

LOW MAINtENANCE

REGIONAL MAtERIALS

NT TOp ENABLES TO

• Specifytheelasticmoduleofthemixture

independently from the amount of cement used.

thus you can define thicknesses and characteristics

of the construction layers.

With Nt tOP you can realize continuous or

discontinuous granulometric curves (open grade

or close grade).

• Designyourplacesandpathwayswithcoloredand

selected aggregates.

• Builddurable,eco-friendlyandcost-effectiveroads

in sensitive environments with high resistance to

wear and deformation.

10 11

CYCLEPath

CYCLE pATh IN MALCESINE, ITALY

The cycle path of Malcesine is right at the lake Garda in Italy.

As the path might be flooded, the challenge was to create a

water-resistant, durable and environmental friendly path with

strong grip. In the original mix design gravel would have been

mixed with 200kg/m3 expensive special cement containing

glasfibers to get the necessary strength. By using NT TOP, only

100kg standard cement was needed to get the same com-

pressive strength and in addition to improve the elasticity to

avoid crack formations. As glasfiber is hazardous during

handling, NT TOP also offered the environmental friendly

solution. Saving money, improve the quality and

less impact on the en vironment made the decision

for the NanoTerra way.

The mixture was made with regional gravel,

cement and NT TOP. During the design of the

mixture the elastic module was adjusted to the

optimal results for this application. An eluat test

by Bachema AG, Switzerland was mandatory to

ensure the protection of the environment.

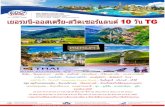

pARKINg LOT IN WATTENS, AUSTRIA

Swarovski Crystal World in Austria is a highly visited attraction

center for the crystal glass manufacturer Swarovski. The

parking lot should present the noble and natural concept.

Originally used self binding gravel layer got many potholes

and ruts by the maneuvering and parking vehicles. Rain

formed puddles making the parking lot almost impassable

despite high maintenance costs.

PARKINGLOT

The top layer with regional gravel, cement and

NT TOP is a durable hygroscopic surface, close to

the nature which stays in perfect shape und every

weather condition. The hygroscopicity can be

adjusted by the gravel size. The mixture was

prepared in a concrete plant and laid with a paver.

Since then low abrasion reduces the maintenance

costs and ensures an attractive parking and

entrance area.

TOP TOP

CUSTOMER REQUIREMENTS

NAtURAL LANDSCAPING

IMRPOVED StRENGtH

ENVIRONMENtAL SOUNDNESS

CUSTOMER REQUIREMENTS

NAtURAL LANDSCAPING

LOW MAINtENANCE

REGIONAL MAtERIALS

12 13

9

ECO-fRIENDLy CONSTRUCTION

· The efficient construction of roads with

NanoTerra products helps to minimize

the use of heavy machines and help to

reduce the carbon emission up to 75%

· The local soil and gravel can be used,

existing road layers can be recycled,

which minimizes transport needs and

saves resources.

ECO-fRIENDLy DURING LIfE TIME

· Reduction of environmental pollution

and elutriation with hazardous material

such as metals or bituminous materials

due to the cladding abilities of

NanoTerra products.

· Less maintenance needs additionally

lead to a reduction of carbon emission

during lifetime.

· Our products are demonstrably below

the limit values according to the

Ordinance on the Prevention and

Disposal of Waste in Switzerland, which

means the road material can be recycled

completely without any replacements at

the end of life time.

NANOTERRA - YOUR pARTNER fOR SUSTAINABLE ROADS

Private, public and commercial projects have different demands, expectations

and requirements. Factors are soil condition, climate, axle passing and load

requirements need to be considered and addressed.

NanoTerra is happy to assist you with the most cost-effective and eco-friendly

construction plan and calculation with NT BASE and NT TOP.

We look forward to hearing from you!

Protect your eNVIroNMeNt

1514

NanoTerra AGInfanteriestr. 19 · Building 680797 Munich · Germany Phone +49 (0) 89 215 45 40 30 [email protected] www.nanoterra.net