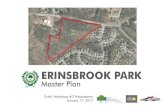

Third Workshop Presentation

-

Upload

technology-robotix-society -

Category

Documents

-

view

214 -

download

0

description

Transcript of Third Workshop Presentation

www.robotix.in

Third Fresher’s Workshop

www.robotix.in

Basic Parts Of A Mobile Robot Locomotion system Power supply system Actuators Sensory devices for feedback Sensor Data processing unit Control system

www.robotix.in

PotentiometerPotentiometer

www.robotix.in

CapacitorsCapacitors

www.robotix.in

IR LED

www.robotix.in

LED: an inner view

www.robotix.in

Diode

www.robotix.in

Current Flow in a Diode

www.robotix.in

Multimeter

www.robotix.in

POWER SUPPLY (RECTIFIER CIRCUIT)

www.robotix.in

IC7805/ IC7812

1 - Input 2 - Ground 3 - Output

www.robotix.in

THE RECTIFIER CIRCUIT

www.robotix.in

USES OF RECTIFIER CIRCUIT

To convert Alternating Current to Direct Current.

We get Alternating Current as Power Supply in our homes, but electronic components in robots use Direct Current.

www.robotix.in

STEPS OF CONVERTING AC TO DC

First the Transformer, converts 220V AC to 12V AC.

The Diodes rectify the current in a single direction.

The Capacitor then normalizes the current.

The little distortions are further rectified by the IC7805.

www.robotix.in

End Actuators

They convert the electrical energy into meaningful mechanical work

Mechanical output can be rotational or linear (straight line)

Motors provide rotational motion Electromagnets provide linear motion

www.robotix.in

Motors are of various kinds

AC Motors : Not used much in robotics Stepper Motors : For controlled rotation DC Motors : Finds extensive general use Servo Motors : DC motor with in built feedback

& error compensation

www.robotix.in

DC Motors

As the name suggests, a motor which uses a DC (Direct Current) power

Can run in both directions Speed Controllable

www.robotix.in

DC Motor Working

Direction of rotation controlled by polarity of current / voltage

Speed of rotation controlled by average energy (power) fed to the motor

www.robotix.in

DC Motor Specifications Operating Voltage : Recommended voltage for

powering the motor Operating Current : Current drawn at a certain load

on the shaft Stall Current : Maximum current drawn, when

motor not allowed to rotate Stall Torque : Rotation force needed to hold the

motor in stall condition

www.robotix.in

DC Motor Characteristics Free running torque & current are ideally zero Increased load implies, increased torque, current

drawn & power consumption Power supplied by a motor is the product of

output shaft’s rotational velocity & torque DC Motors are high–speed, low-torque devices Using gears, the high speed of the motor is

traded off into torque

www.robotix.in

DC Motor Characteristics Zero speed at

maximum load (stall torque)

Highest speed while free running (zero load)

Highest power at half speed & half load

www.robotix.in

DC Motor Drivers These are current amplifying circuits A low current control signal is converted into a

proportionally higher current signal that can drive the motor

Power Transistors can switch high currents. The ICmax is usually of the order of Amps as compared to small signal transistors which have ICmax in mA

www.robotix.in

DC Motor Direction Control H – Bridge Circuit Diagram

S1

S3

S2

S4

M1 2

VCC

www.robotix.in

H – Bridge Working

www.robotix.in

Electronic Direction Control H – Bridge Circuit Diagram

www.robotix.in

Sensors Analogous to human sensory organs Eyes, ears, nose, tongue, skin Sensors help the robot knowing its

surroundings better Improves its actions and decision making

ability Provides feedback control

www.robotix.in

LDR - Light Dependent Resistor Made of cadmium

sulphide Resistance between two

terminals vary depending on the intensity of light

Can be used to differentiate contrast colours

www.robotix.in

Comparator

www.robotix.in

Light Sensing Module using LED-LDR combination

Sensor Interfacing

www.robotix.in

Bump Detector Module

www.robotix.in

An Example - Line Follower A line follower is a robot

capable of tracking a line drawn on a surface

Optical sensors capture the line position at the front end of the robot

The robot is steered to keep it always over the line

www.robotix.in

Block Layout of Line Follower

www.robotix.in

Line Following Algorithm

All the sensors are assigned some weight such as

Sensor 1 = a1 = 3Sensor 2 = a2 = 2Sensor 3 = a3 = 1Sensor 4 = a4 = -1Sensor 5 = a5 = -2Sensor 6 = a6 = -3

www.robotix.in

DC Motor Speed Control Circuit

Input is the operating voltage & control signal Output is a part of the operating voltage depending

upon the control signal

www.robotix.in

DC Motor Speed Control Cont…

Controlling the current by passing it through a variable resistor is not advisable as it is extremely energy inefficient

A trick is done to achieve reduced average power

Power is supplied to the motor in short intermittent bursts, as explained further

www.robotix.in

Duty Cycle Fundamentals

www.robotix.in

Duty Cycle Contd…

The time period (τ) is the duration after the voltage waveform repeats itself

Duty Cycle is the % time of τ, the voltage is equal to the operating voltage

The average voltage is equal to the ‘Duty Cycle’ % of the Operating Voltage

www.robotix.in

Pulse Width Modulation PWM is a technique using which we can

modify the duty cycle of a waveform depending upon an input control voltage

This forms the backbone of our speed control circuit

It can be easily implemented using the popular multipurpose IC 555, used widely for hobby electronics

www.robotix.in

L293D – Pin Diagram

THANK YOU