THERMOSTATIC SHOWER VALVE PRODUCT MANUAL · THERMOSTATIC SHOWER VALVE PRODUCT MANUAL INSTALLER...

Transcript of THERMOSTATIC SHOWER VALVE PRODUCT MANUAL · THERMOSTATIC SHOWER VALVE PRODUCT MANUAL INSTALLER...

1

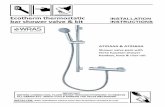

V8/3THERMOSTATICSHOWER VALVE

PRODUCT MANUAL

INSTALLERPlease leave manual with user for future

reference to unit operation and maintenance.

2

INTRODUCTION

Meynell mixing valves are manufactured within a BS : EN ISO 9001accredited Quality System.

DESCRIPTION

The Meynell V8/3 range of thermostatic shower valves provideaccurate temperature control and flow rates to single and multipoint*installations. *(Multipoint - use V8/3 Lockshield model only)

With effect from June 1997 all relative Meynell mixers will havesuffix 3 after the product name. This states that the mixer hasbeen certified for use in UK Healthcare premises as a CLASSTHREE VALVE meeting the requirements of the UK NationalHealthcare Services (NHS) Model Engineering Specification.Where this product is to be used in such an installation pleaserefer to the ‘NHS Requirements Booklet’ for detailed informationon its application, commissioning and maintenance.

SAFETY : WARNINGS

Meynell products are precision engineered and should givecontinued safe and controlled performance, provided:

1. They are installed, commissioned, operated and maintained inaccordance with manufacturers recommendations, and

2. Periodic attention is given, when necessary, to maintain theproduct in good functional order.

The function of a thermostatic mixing valve is to deliver waterconsistently at a safe temperature. In keeping with every othermechanism, it cannot be considered as functionally infallible and assuch, cannot totally replace the vigilance of supervisory staff wherethat is necessary. Provided it is installed, commissioned, operatedand maintained within manufacturers recommendations, the risk offailure, if not eliminated, is reduced to the minimum achievable.

3

CONTENTS CHECKCheck the contents of the box are included before installation.

Exposed Models

4

CONTENTS CHECKCheck the contents of the box are included before installation.

Recessed Models

5

INDEXSPECIFICATIONNotes ............................................................................... 6Normal Operating Conditions ......................................... 7Operating Parameters: Pressures And Flow Rates ....... 7Temperature Control ....................................................... 8Plumbing Connections .................................................... 8Standards and Approvals ............................................... 8Dimensions...................................................................... 9

INSTALLATION REQUIREMENTS............................... 10

INSTALLATIONGeneral .......................................................................... 13Shower Control Removal .............................................. 13Reverse Outlet Connector ............................................ 14Fixing to wall .................................................................. 15Recessed Fitting ........................................................... 16

COMMISSIONING ........................................................ 18

OPERATION.................................................................. 19

FAULT FINDER ........................................................ 20/21

MAINTENANCE ............................................................ 22

SPARE PARTS .............................................................. 23

CUSTOMER SUPPORT ................................ Back Cover

6

SPECIFICATIONNotes

1. The installation, commissioning and maintenance carried outin accordance with instructions supplied by the manufacturer,and must be conducted by designated, qualified andcompetentpersons.

2. Installations must comply with UK Water Regulations/Bye-laws(Scotland), Building Regulations or any particular regulationsand practices, specified by the local water supplier.

3. Meynell products should give continued safe and controlledperformance, provided:

- installation, commission, operation andmaintenance specifications are according torecommendations.

- frequent attention given, as necessary, to maintainthe product in good functional order. Guidelinessupplied with product recommended bymanufacturer.

4. Warning: Continued use of this product in operating conditionsoutside the limits listed can severely impair performance andreduce expected life, and can introduce inherent risks to enduser.

7

Normal Operating ConditionsConsider as:

- inlet maintained pressures are nominally balanced

- daily usage 1-6 hours

- installation and usage environment not subject toextremes of temperature, unauthorised tampering orwilful abuse.

Operating Parameters: Pressures And Flow Rates

For optimum performance, maintained supply pressures should benominally equal.

Maximum Pressure Loss Ratio: 10:1

Minimum Maintained Pressure: 0.1 bar. (= 1 metre head fromunderside of cold tank to outlet of shower fitting)

Maximum Static Pressure: 10 bar.

8

Temperature Control

Minimum temperature differential between hot and outlettemperature: 10°C

Optimum temperature control range: 35 - 45°C

Maximum hot water temperature: 85°C (for safety, a recommendedhot water storage temperature maintained below 85°C and forablutionary installations at between 60 to 65°C).

The performance specification outlined below is achieved with outletblend temperature set between 35 - 45°C and supplies of 15°C coldand 65°C hot with nominally equal pressures.

- Outlet blend temperature is maintained within 2°Cwith a 10°C change in hot or cold supply.

- Thermostatic shut down to seepage within 2seconds if cold supply fails. This is achieved only ifthe hot supply temperature is 10°C above the setoutlet blend temperature.

Plumbing Connections

Inlet connectors are 15 mm compressionOutlet connector is 1/2” BSP Male or 15 mm compression

Hot (H) and Cold (C) inlets are clearly marked and must beconnected this way.

9

DIMENSIONS

161

117

55 Max

35 Min

65

35

122.5

Dimensions in millimetres

Exposed model

Recessed model

10

INSTALLATION REQUIREMENTS

Gravity Fed shower - The shower MUST be fed from a cold watercistern and hot water cylinder providing nominally equal pressure.

Key to symbols

Isolating valveMixingValve

Twin ImpellerPump

TemperingValve

Pressure ReducingValve

Single Impeller Pump

Overflow

11

Unvented mains pressure shower - The shower can be installedwith a unvented, stored hot water cylinder. Only “a competentperson” as defined by the Building Regulations may fit this type ofsystem.

Gas heated shower - The shower MUST be installed with a gaswater heater or combination boiler of a modulating design. Amodulating boiler is one that the draw off rate is indirectly controllingthe gas flow to the boiler, producing a relatively constant hot watertemperature.

Cold Hot

12

Mains pressurised instantaneous hot water shower - Theshower installed with systems of this type is supplied hot water via atempering valve, this provides relatively constant hot water and theshower will compensate for temperature changes should they occur.

Pumped shower - The shower can be installed with an inlet pump(twin impeller). The pump must be installed on the floor next to thehot water cylinder. Ensure hot cylinder vent pipe is arranged asshown to enable air separation.

30º-60º

90º

13

INSTALLATIONGeneral

Carry out installation according to instructions supplied, and must beconducted by designated, qualified and competent person.

1. Before starting installation, ensure that all site requirementscorrespond to information given in the SPECIFICATIONsection.

2. Do not install product in a position where it could becomefrozen.

3. The mixing valve should be installed in a position for easyaccess for maintenance.

4. Accessible isolating valves must be provided for maintenance.

5. The supply pipework must be thoroughly flushed to removeany debris before connection.

Shower Control Removal

1. Insert 2.5 mm hexagon keysupplied into side of showercontrol.

2. Loosen screw only to allowremoval of shower control.

3. Refit in reverse order.

For lockshield model.

1. As above.

2. To refit, ensure anti-rotationslots are engaged on lug onbody (arrow).

14

Reverse Outlet Connector

If shower outlet needs reversed (e.g. bottom outlet to top outlet):

1. Remove small cap (if fitted)

2. Using an 1/2” hexagon key remove sealing plug and outletconnector opposite.

3. Swap around and refit, if changing from flat connector tocompression ensure ‘o’seal is changed around.

4. Refit in reverse.

15

Fixing to wall

1. Decide on a suitableposition for mixer where allusers can operate. Themixer and shower fittingposition must provide aminimum of 25 mm betweenhandset and bath/trayspill-over level. This is toprevent backsiphonage.

2. Remove wall bracket fromrear of mixer by looseninggrubscrew with hexagon key(supplied) on theunderside of mixer.

3. Use bracket to mark 3 holepositions. Drill wall andinsert suitable wall plugs(not supplied) for No.10woodscrews.

4. Locate mixer on wall bracketand use hexagon key totighten grubscrew.

16

Recessed Fitting

1. Determine the routes of theincoming hot and coldsupply pipework. They canbe rising or falling supplies.

2. Determine the route for theoutlet pipework. Whenconnecting shower kit to theoutlet should be to the sideand above the mixer toensure flexi-hose hangscorrectly and does notobstruct the shower control.The outlet can be sited onthe right or on the left, as sitedictates.

3. Mark suitable routes for inletand outlet pipework.

4. Cut away plasterboard andbrick work to a depth ofbetween 60 mm to 80 mm.Depth should be 67 mm min/ 87 mm max including finishwall thickness (tiles or faciaboard).

5. Fix mixer to wall (see Fixingto wall).

6. Make connections to mixeras shown to inlets andoutlets.

ColdHot

Outlet

Shower

17

7. Plaster and tile up to shower,leaving a maximum diameterhole around shower of125 mm.

8. Fit sealing grommet to innerdiameter of concealing plate,remove protective backingfrom one side of foamwasher and affix to rear ofconcealing plate.

9. Remove shower control (seeearlier section), Try platefitting on shower to ensureall rough edges are covered.

10. Remove plate, and peel thesecond protective backingfrom the foam washer andrefit pushing equally on plateto ensure adhesive backingis fully sealing the perimeterof plate.

11. Refit shower control.

18

1. Loosen grubscrew in theside of shower control with2.5 mm hexagon keysupplied.

2. Turn shower control tomaximum setting, (forlockshield model turn onseperate outlet device fittedeg. stopvalve).

Let temperature stabilise.

3. Remove shower controlcompletely.

4. If the temperature measuredneeds to be adjusted, insertthe 2.5 mm hexagon key intothe centre of valve head.

5. Turn the hexagon keyanticlockwise to increasethe temperature, orclockwise to decreasetemperature.

6. Refit shower control and turnoff mixer (on lockshieldmodel turn off outlet device),reposition shower controlwith brand horizontal.

Commissioning must be carried out according to instructionssupplied, and must be conducted by designated, qualified andcompetent person.

COMMISSIONING

Lockshield model

19

OPERATION

Temperature selection (not lockshield model)

The mixer has one control to set temperature and works in asequence:

Off ! Cold ! Tepid ! Pre-set Maximum

The temperature is indicated with numbers, lining the numbers withposition mark on body selects a relative temperature from 0 to 7.

20

FAULT FINDER

Symptom

1. Only hot or coldwater from mixeroutlet.

2. Fluctuating or reducedflow rate.

3. No flow rate from mixeroutlet.

4. Blend temperature drift.

5. Maximum blendtemperature setting toohot or too cold.

Cause/Rectification

a. Inlet supplies reversed (hot supply to coldsupply).

b. No hot water reaching mixer.c. Check strainers and inlet/outlet fittings for

blockage.d. Installation conditions continuously outside

operating parameters: refer toSPECIFICATION, and 2.e. below.

Normal function of the thermostatic control whenoperating conditions are unsatisfactory;

a. Check strainers and inlet/outlet fittings forblockage.

b. Make sure minimum flow rate is sufficient forsupply conditions.

c. Make sure the maintained inlet pressures arenominally balanced and sufficient.

d. Make sure the inlet temperatures differentialsare sufficient.

e. (Subsequent to rectification of supplyconditions) Check thermostatic performance; renew Piston Assembly if necessary.

a. Check strainers and inlet/outlet fittings forblockage.

b. Hot or cold supply failure.

Indicates operating conditions changed.

a. Refer to symptom 2. above.b. Hot supply temperature fluctuation.c. Supply pressures fluctuating.d. Seal damage or wear. Renew seals.

a. Indicates incorrect maximum temperaturesetting; refer to COMMISSIONING section.

b. As symptom 4. above.

21

Cause/Rectification

Seal wear or damage.

a. Obtain Seal Kit, renew all seals.

a. (Too low) Refer to symptom 2.a-e. above.b. (Too low) Insufficient supply pressures.c. (Too high) Supply pressure too high.d. (Too high) Refer to symptom 2.a-e. above.

Symptom

6. Water leakingfrom mixer body.

7. Flow rate too highor too low.

22

MAINTENANCEGeneral

Meynell products are precision engineered and should givecontinued safe and controlled performance, provided:

1. They are installed, commissioned, operated and maintained inaccordance with manufacturers recommendations.

2. Periodic attention is given, when necessary, to maintain theproduct in good functional order. Recommended guidelines aregiven below.

Preventative/Precautionary Maintenance

(Planned Maintenance Programmes)The frequency and extent of attention required will vary according toprevailing site and operational conditions however, the followingguideline schedule is suggested to cover average duty and siteconditions:

Six-monthlyBlend temperature: check for correct blend setting. Reset asnecessary.

Performance: check blend temperature against a known datum(relative COMMISSIONING procedure), by isolating cold watersupply.

Function: any in-line or integral check valves, strainers are cleanand in good working order.

LubricantsImportant: Use silicone-only based lubricants. Do not use oilbased or other lubricant types as rapid deterioration of seals mayoccur.

Standard silicone-only based lubricants may be used on static sealsand threads to assist refitting.

23

SPARE PARTS

1 SPSL0006J CARTRIDGE ASSEMBLY2 SPPE0007P CONCEALING PLATE CHROME

A SPSK0051J SEAL KIT

24

CUSTOMER SERVICEGuaranteeThis product is guaranteed against both faulty materials and manufacturing process for a period ofone year from date of purchase, provided that the product has been installed correctly and used inaccordance with the instructions in this manual.

Any part found to be defective during the guarantee period will be replaced or repaired - at ouroption - without charge, provided that the product has been properly used and maintained.

Routine cleaning and maintenance should be carried out in accordance with instructions supplied.

The product should not be modified or dismantled except by a person authorised by Kohler Mira Ltd.Your statutory rights are not affected by this guarantee.

Customer Service PolicyIf within the guarantee period the product does not function correctly, first check the fault findinganalysis in the manual to see if the difficulty can be resolved.

Failing this, please contact your installer to check that the product has been installed andcommissioned in accordance with this manual.

If the fault can not be resolved, please contact the Customer Service Department who will try toassist, or will arrange a local Service Engineer or Agent to call and arrange a visit.

Within the guarantee period there will be no charge for parts or labour if the fault concerned is due tothe product. However, the guarantee does not cover difficulties due to incorrect installation ormisuse.

During the service visit yourself or a responsible person should be present at all times. If theService Engineer or Agent can not gain access at the prearranged time a callout charge may bemade.

Payment for the Service visit, if applicable, should be made direct to Service Engineer or Agentusing Access, Visa or cheque supported by a banker’s card.

Spare PartsFunctional spare parts are available for your products maintenance. Items can be identified fromspares drawing inside manual, please contact Customer Service to confirm spare and details of aspares stockist for your area. Your product serial number or date mark (if available) may be usefulto identify parts.

Meynell ValvesCromwell RoadCheltenhamGloucestershireGL52 5EPTel: 01242 262888Fax: 01242 282595

BS EN ISO 9001 : 1994Reg. No. FM 14648

Meynell is a registered trade mark ofKohler Mira Ltd.The company reserve the right toalter product specifications withoutnotice.

© Kohler Mira Ltd, November 2001P3291/1