Thermal Gas Mass Flow Measurement and Control...

-

Upload

duongthien -

Category

Documents

-

view

218 -

download

4

Transcript of Thermal Gas Mass Flow Measurement and Control...

Thermal Gas Mass Flow Measurement and Control Instrumentation

EPI produces a wide varietyof thermal instrumentationfor gas mass flow measure-ment and control. Built withover twenty years experi-ence in thermal mass flowmetering design and pro-duction, our thermal flowme-ters and flow switches areknown for superior quality,dependability, ease of use,and durability in real worldapplications.Our Master-Touch™ Familyof thermal gas mass flowme-ters greatly expanded thislegacy by adding a powerfulmicroprocessor to ourproven thermal technologyfor an unparalleled degreeof flexibility, accuracy, andcontrol. Upon its introduc-tion, the Master-Touch raisedthe standard for “smart”technology and it remains atthe forefront of thermal gasmass flow instrumentation.

Sensor Theory andOperationMaster-Touch products include arugged, cleanable, thermal massflow sensor. These units consist of asensor assembly which utilizes twoRTD (Resistance TemperatureDetector) sensing elements. Thesensors are constructed of refer-ence grade platinum, ceramic,glass, and stainless steel. Two plat-inum resistance sensors are built upupon the ceramic substrate andthen given a thin glass coating.The assembly is then slipped into a

stainless steel sheath for rugged-ness, corrosion and abrasion resist-ance. The sensor assembly is large,rugged, insensitive to dirt buildup,and easily cleaned.

During operation, the temperaturesensor constantly measures theambient temperature of the gasand maintains a reference resist-ance on one side of a Wheatstonebridge. The second sensor isforced through self-heating to aconstant temperature above thatof the gas stream and is controlledby the temperature sensor and ourforced null Wheatstone bridgeamplifier. Our bridge circuit is setup with precise resistance valuesto maintain the overheat temper-ature and to counterbalance theprocess gas temperature effects.Optional wide temperatureranges are supported by EPI’spatented µp-controlled sensorbridge.

Since the sensor compensates fortemperature changes and pres-sure effects are negligible, theheated sensor becomes a massflow sensor. Gas mass flow acrossthe heated sensor is measured bythe thermal heat transfer (loss) ofthe sensor. Gas molecules absorbheat while passing the heatedsensor surface. As the velocity ofthe gas is increased, more heat istransferred from the sensor to thegas stream and more power isrequired of the sensor's drive circuitto maintain a constant sensoroverheat temperature. This heat

transfer is directly proportional tothe mass velocity of the gas (den-sity x velocity). The power demandof the flow transmitter is what weuse as our non-linear mass flow ormass velocity transmitter signal.This signal is then linearized for adirect reading of the process flowoutput.

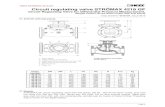

Inline & Insertion StylesThe inline style flowmeter assem-bly includes the flow sensing ele-ment, temperature sensing ele-ment, bridge amplifier/signal out-put board, microprocessor, lin-earizer circuit board, transmitterenclosure, and flow section. Theflow section is specified to matchthe user's flow conduit andplumbed directly in the flow line.This design has the sensing ele-ments mounted in the flow sectionfor exposure to the process gas.

Our inline style flowmeters areavailable in sizes from 1/4" pipethrough 4" pipe and are providedwith threaded male NPT ends asthe standard mounting style forsizes as large as 2 1/2". For sizes 3"and larger, ANSI 150# flanges arestandard. Optional end mountingstyles may be specified, such astube ends, tube end fittings, buttweld ends, flanged ends, etc. asrequired for any size. Pipe sizes inexcess of 4" require insertion stylethermal mass flow meters.

ELDRIDGE PRODUCTS, INC. 2700 Garden Road, Building A Monterey, CA 93940

The insertion style flowmeterassembly includes the flow sensing

element, tem-perature sens-ing element,bridge amplifi-er/signal out-put board,mincroproces-sor, linearizercircuit board,t r a n s m i t t e renclosure, andprobe assem-bly which sup-ports the sens-ing elements.This designrequires the

probe assembly to be inserted intothe process gas flow conduit toallow the process gas to flowacross the sensor assembly. Theinsertion style thermal mass flowmeter probe assemblies may beinserted into any suitable flow sec-tion, pipe, duct, etc.

Our Insertion style thermal massflowmeters are available with 1/2",3/4", or 1" OD probes and may beinstalled with pipe fitting connec-tions or user supplied boredthrough tube fittings. Tube fittings,with or without mounting flange,are also available from the factoryas an option. The tube length mustbe specified upon ordering.

Standard probe lengths are avail-able in 6” increments for lengths of6” to 24”, and in 12” for lengths of24” to 60”.

Integral & RemoteStylesIntegral style flowmeters areassembled with all electrical com-ponents, digital display and powersupply located within one enclo-sure. This enclosure is mounteddirectly to the flowbody (inlinethermal mass flowmeters) or probeassembly (insertion thermal massflowmeters).

Remote style flowmeters areassembled with the flow transmit-ter located in an enclosure that ismounted directly to the flowbody(inline flowmeters) or probe assem-bly (insertion flowmeters). The lin-earizing electronics, digital displayand power supply are remotelymounted for convenient access. Atwo-wire, twisted pair cable is typi-cally used to connect the elec-tronics enclosures.

Flow StraighteningAsemblyAll inline style flowmeters for linesizes of 3/4” and larger include apair of inlet flow conditioners.These conditioners help to improveproblematic, uneven flow profilesby disrupting the gas flow andallowing it to assume a more uni-form profile, without adding anysignificant pressure drop in mostapplications.

Our Master-Touchf l o w m e t e r sinclude infraredcommunicationsvia our LightWIREt e c h n o l o g y .L i g h t W I R E -

enabled flowmeters are used withPCs and laptops runningEPICommunicator™ software viaCommunicator I RS232 or USBadapters, or with Communicator IImodules. The Communicatormodules do not include a ratingfor hazardous-area locations.

T: 800/321-FLOW(3569) F: 831/648-7780 [email protected] www.epiflow.com

Our Master-Touch technolo-gy adds a powerful micro-contoller to our proven sen-sor and bridge circuitry forimproved performanceand user control. The micro-computer performs digitalsignal processing (DSP) func-tions utilizing a high speed,high resolution 16-bit analogto digital converter (ADC), acentral processing unit (CPU)and a high resolution 14-bitdigital to analog converter(DAC). Operations are per-formed in real time whilesupporting simultaneous fullduplex RS232 communica-tions.

Digital SubsystemsFive digital subsystems control theMaster-Touch functions:

1. Analog-to-Digital Converter(ADC) to acquire the data gen-erated by the sensors.

2. Curve Linearizer to transformnonlinear to linear voltages.

3. Digital-to-Analog Converter(DAC) to generate output volt-age from sensor data.

4. Voltage Tracking to performreal-time processing of inputand output signals.

5. EEPROM to store and maintainuser configurable variables.

Major FeaturesEvery Master-Touch flowmeter sup-ports up to Four Separate MeterRanges that can include inde-pendent calibration data for dif-ferent gases, flow ranges, pres-sures, etc. The meter ranges canbe selected through the keypad,a PC, your DCS, or by externalswitching.

The Master-Touch providesContinuous Curve Fitting as themicroprocessor uses a polynomialcurve fit to linearize data into acontinuous linear output with 14-bit precision. The flowmeter vari-ables may be viewed without anyinterruption to the flow signal orelapsed flow totalization.

The Master-Touch also supportsContinuous Tracking andTimestamping of high and low flowrates. These values can be easilyreset as needed.

The user can choose from a vari-ety of Engineering Units while theflowmeter is in operation. All flowrate, accumulated total, alarm,and timestamp information is

automatically converted into thenew units.

User input and control of the field-adjustable, smart transmitter is sup-ported by the four-button touchkeypad or via RS232 I/O communi-cations using EPICommunicator™software.

E-Logger includes a fully func-tional, PC-based data loggerthat works in conjunction withMaster-Touch™ flowmeterswhich have v4.1A and highersoftware. The user can selectfrom a set of categories for thedata collection, the time inter-val for each data "snapshot"and, if necessary, programmedstart and stop times. The data isstored on either the flowmeteror a PC. E-Logger will alsograph the data, and it providestools for analysis of the data.Data files stored on a PC canbe accessed by most commonspreadsheet applications.

ELDRIDGE PRODUCTS, INC. 2700 Garden Road, Building A Monterey, CA 93940

����

�������������� �

������������

��

����

��� �

EPI’s flowmeters have beeninstalled in a wide variety ofprocess control applications,from steel and paper mills toauto manufacturers to phar-maceutical houses, fromnatural gas submetering andcompressed air consump-tion to water & wastewatertreatment plants.

Gas SubmeteringFor many companies, the use ofnatural gas is the obvious choicefor submetering. The gas is typical-ly delivered through large lines atvery high pressure and the gascompany supplies the figures foryour overall consumption. Butbeyond this general custody trans-fer, how much do you know aboutspecific consumption and how areopportunities for cost savingsdetermined? Submetering atselected points will show wherethe gas is used, how much gas isused at each location or workarea, and when each location orwork area is using the gas. This is

the information needed to ana-lyze ongoing expenses and torefine overall usage.

Compressed AirMonitoringIn many facilities, compressed air isone of the primary components ofoverall energy use. As energy costscontinue to rise, accurately track-ing the use of compressed air canproduce direct and immediatebenefits by providing the informa-tion you need to establish a pro-gram that:1) monitors general usage toencourage cost conservation;2) tracks peak usage to deter-mine the optimum compressorcapacity; and3) simplifies the overall instrumen-tation needs through the use ofthermal gas mass flow technology.

EPI flowmeters are the instrumentof choice for compressor distribu-tors and air audit professionalsthroughout the country.

Water & WastewaterTreatmentThe treatment of water and waste-water is a critical element ofmunicipal responsibility. Increasedpublic and private awareness ofwater quality, availability, and costis a driving force behind thedemands for better efficiency andeconomy in these processes.

The use of compressed air is nec-essary to promote optimal bacte-ria growth in aeration basins.Closely controlling the aerationprocess can reduce energy con-sumption by as much as 25%, andaccurate measurement is criticalto achieving this goal.

Monitoring Digester or Bio Gas isequally important. The primaryobjective is to achieve an overallsystem balance. A secondaryobjective is to monitor the excessgas (waste gas) that is used as afuel to power onsite generatorsand pumps, or to create energyfor a more widespread power grid.In addition, monitoring is often arequirement of local, state, andFederal environmental guidelines.

T: 800/321-FLOW(3569) F: 831/648-7780 [email protected] www.epiflow.com

Typical Industrial Applications

AUTOMOTIVE INDUSTRYCompressed air monitoring *Natural gas consumption * Powderpaint air flow * Paint booth/paintoven ventilation

UTILITY SERVICESStack or flue gas * Waste wateraeration * Ventilation systems *Digester gas * Gas flows * Nitrogenpurge * Combustion air * Boilerinlet air

FOOD PROCESSINGDrying air * Ventilation systems *Boiler inlet air * Exhaust gas *Process control * Compressor lines

HVACAir balancing * Duct flows * Energyconservation * Fume hoods *Clean rooms * Laminar flowbenches

LABORATORY AND R & DFlow research * Biomedical studies* University studies * Toxicologystudies * Energy studies * Industrial

Hygiene * Occupational Safety *Experimentation

PETROLEUM & GAS INDUSTRIESCustody transfer * Landfill gasrecovery * Flare gas measurement* Gas mixing * Gas quality studies *Leak testing

RAW MATERIALS INDUSTRIESPulp & paper mills * Mining *Semiconductor manufacturing *Chemical processing * Primarymetals * Plastics & synthetics

Manufacturing applicationstypically require accurate,dependable measurementin an approved industrial-strength package. OurMaster-Touch MP Series isthe answer to this demand.Available in a variety of con-figurations to meet virtuallyany situation, the MP Series isthe instrument of choicethrough the world. All of theMP Series flow transmitters include an explosion-proofenclosure for use in haz-ardous areas. The remotesignal processor enclosuresare for use in non-hazardousarea locations.

Series 8000MP-8100MPMaster-Touch™ Series 8000MP-8100MP flowmeters are inline styleinstruments with the flow transmit-ter mounted on the flow sectionand the signal processor electron-ics remotely mounted in a sepa-rate enclosure. Input power is sup-plied to the remote electronics.This configuration uses only a two-wire connection between the flow

transmitter and the signal proces-sor. Flow sections for pipes ¾" andlarger have flow straighteningscreens as standard. Flow sectionsfor pipes up to 2½" have MNPTends as standard; flow sections forpipes 3" and up have ANSI 150lb.Class flanges as standard.Depending on the line size, a vari-ety of alternatives are available,including ANSI 300lb. and DINflanges, butt ends, sanitary fittings,etc.

Series 8200MPMaster-Touch™ Series 8200MPflowmeters are insertion style instru-ments with the flow transmittermounted on the sensor probeassembly and the signal processorelectronics remotely mounted in aseparate enclosure. This configura-tion uses only a two-wire connec-tion between the flow transmitter

and the signal processor. A varietyof installation options are avail-able, including ball valve retractorassemblies, tube to pipe compres-sion fittings, and probe mountedflanges. Input power is supplied tothe remote electronics.

Series 8600MP-8700MPMaster-Touch™ Series 8600MP-8700MP flowmeters are inline styleinstruments with all electronicsmounted integrally on the flowsection. All input power and signal

output connections are accessiblethrough the double-sided enclo-sure. Flow sections for pipes ¾" andlarger have flow straighteningscreens as standard. Flow sectionsfor pipes up to 2½" have MNPT

ends as standard; flow sections forpipes 3" and up have ANSI 150lb.Class flanges as standard.Depending on the line size, a vari-ety of alternatives are available,including ANSI 300lb. and DINflanges, butt ends, sanitary fittings,etc.

Series 8800MPMaster-Touch™ Series 8800MPflowmeters are insertion style instru-ments with all electronics mountedintegrally on the sensor probeassembly. All input power and sig-nal output connections are acces-sible through thed o u b l e - s i d e denclosure. A vari-ety of installationoptions are avail-able, includingball valve retrac-tor assemblies,tube to pipecompression fit-tings, and probem o u n t e dflanges.

ELDRIDGE PRODUCTS, INC. 2700 Garden Road, Building A Monterey, CA 93940

T: 800/321-FLOW(3569) F: 831/648-7780 [email protected] www.epiflow.com

�������������� ������

��

��

��� � ���� � � �����

�����������

������������

�������������� ������

����� ����� ���

������������

�������������� ������

����� ����� ���

�������������� ������

��

��

��� � ���� � � �����

�����������

SpecificationsLinear signal output 0-5 VDC & 4-20 mARelay Output Two 1-amp, user-selectable alarm

functionsComputer Signal Interface RS232 & RS485

(optional Modbus or HART-compatible)Accuracy, including linearity ±[1% of Rdg + (0.5% + .02%/°C (Ref.: 21°C) with ideal flow profile of Full Scale)]Repeatability ±0.2% of Full ScaleSensor flow response time 1 second (time constant per step change)Turn down ratio 100:1 (15 SCFM/FT2 minimum Reading)Electronics temperature range -40°–85°C (-40°–185°F) Gas temperature range -40°–66°C (-40°–150°F); extended range

available, consult factoryGas pressure effect Negligible over ± 20% of absolute

calibration pressureConduit/probe pressure rating range Vacuum to 500 PSIG standard;

higher pressures, consult factoryInput power requirement 24VDC @ 250mA

115 VAC 50/60 Hz optional230 VAC 50/60 Hz optional

Flow Transmitter power requirements 5 watts or lessWetted materials 316 Stainless Steel

(Hastelloy optional)Standard temperature & pressure 70°F & 29.92" Hg (STP) (Air .075 lb./cubic foot)NIST traceable calibration Standard

For use in hazardous area locations:Class I Division 1 Groups B, C and D; Class II E, F and G; Class III; Type 4X, 7; Ex d IIC; AEx d IIC, IP66; EExd IIC, IP66; T2 (consult factory for T3 or T4).

Certified to US requirements; Certified to Canadian requirements

Certified to European ATEX requirements

* Remote Enclosure (Series 8000MP– 8200MP) for use in Ordinary (Non-Hazardous) area locations: Type 4X, IP66

Series 8000MP-8100MP DesignModel Pipe OD" x L" SCFM8036MP-SSS-133 1/4 x 6 3.508049MP-SSS-133 3/8 x 6 6.008059MP-SSS-133 1/2 x 7 13.08069MP-SSS-133 3/4 x 7 60.08089MP-SSS-133 1 x 8 90.08110MP-SSS-133 1¼ x 10 1508112MP-SSS-133 1½ x 14 2008116MP-SSS-133 2 x 14 3508120MP-SSS-133 2½ x 14 5008124MP-SSS-133 3 x 14 7508132MP-SSS-133 4 x 14 1350

Series 8200MPModel Probe OD" Max L”8240MP-SSS-133 1/2 368260MP-SSS-133 3/4 608280MP-SSS-133 1 84

Series 8600MP-8700MP DesignModel Pipe OD" x L" SCFM8636MP-SSS-133 1/4 x 6 3.508649MP-SSS-133 3/8 x 6 6.008659MP-SSS-133 1/2 x 7 13.08669MP-SSS-133 3/4 x 7 60.08689MP-SSS-133 1 x 8 90.08710MP-SSS-133 1¼ x 10 1508712MP-SSS-133 1½ x 14 2008716MP-SSS-133 2 x 14 3508720MP-SSS-133 2½ x 14 5008724MP-SSS-133 3 x 14 7508732MP-SSS-133 4 x 14 1350

Series 8800MPModel Probe OD" Max L”8840MP-SSS-133 1/2 368860MP-SSS-133 3/4 608880MP-SSS-133 1 84

�

� ��

Higher flow ranges are available, dependent upon process gas and flow specifications. Please consultthe factory for details.

* Remote Enclosure

* Remote Enclosure

In many industries the needfor monitoring gas flow doesnot involve hazardous gasesor potentially dangerousoperating conditions. Theseapplications can includemany water and wastewatertreatment applications, theHVAC industry, the generaluse of compressed air, andmany other applicationsusing air, nitrogen, argon,etc. In these cases, anexplosion-proof electronicsenclosure is not required,and may be considered aneedless expense. To meetthis challenge, EldridgeProducts, Inc. now offers theMaster-Touch™ Family ofmicroprocessor-based ther-mal gas mass flowmeters inan economical configura-tion intended for use in non-hazardous area locations.

Series 8000MPNH-8100MPNHMaster-Touch™ Series 8000MPNH-8100MPNH flowmeters are inlinestyle flowmeters with the flowtransmitter mounted on the flowsection and the signal processorelectronics remotely mounted in aseparate enclosure. Input power issupplied to the remote electronics.This configuration uses only a two-wire connection between the flowtransmitter and the signal proces-sor. Flow sections for pipes ¾" andlarger have flow straighteningscreens as standard. Flow sectionshave MNPT ends as standard.Depending on the line size, a vari-

ety of alternatives are available,including ANSI and DIN flanges,butt ends, sanitary fittings, etc.

Series 8200MPNHMaster-Touch™ Series 8200MPNHflowmeters are insertion styleflowmeters with the flow transmit-ter mounted on the sensor probeassembly and the signal processorelectronics remotely mounted in aseparate enclosure. A variety ofinstallation options are available,including ball valve retractorassemblies, tube to pipe compres-sion fittings, and probe mountedflanges. Input power is supplied tothe remote electronics. This config-uration uses only a two-wire con-nection between the flow trans-mitter and the signal processor.

Series 8600MPNH-8700MPNHMaster-Touch™ Series 8600MPNH-8700MPNH flowmeters are inlinestyle flowmeters with all electronicsmounted integrally on the flow

section. Flow sections for pipes ¾"and largerhave flowstraighten-ing screensas stan-dard. Flows e c t i o n shave MNPTends asstandard. Depending on the linesize, a variety of alternatives areavailable, including ANSI 300lb.and DN flanges, butt ends, sani-tary fittings, etc.

Series 8800MPNHMaster-Touch™ Series 8800MPNHflowmeters are insertion styleflowmeters with all electronicsmounted integrally on the sensorprobe assembly. A variety of instal-lation options are available,including ballvalve retractora s s e m b l i e s ,tube to pipecompress ionfittings, andprobe mount-ed flanges.

ELDRIDGE PRODUCTS, INC. 2700 Garden Road, Building A Monterey, CA 93940

T: 800/321-FLOW(3569) F: 831/648-7780 [email protected] www.epiflow.com

SpecificationsLinear signal output 0-5 VDC & 4-20 mARelay Output Two 1-amp, user-selectable alarm

functionsComputer Signal Interface RS232 & RS485

(optional Modbus and HART-compatible)Accuracy, including linearity ±[1% of Reading + (0.5% + .02%/°C (Ref.: 21°C) with ideal flow profile of Full Scale)]Repeatability ±0.2% of Full ScaleSensor flow response time 1 second (time constant per

step change)Turn down ratio 100:1 (15 SCFM/FT2 minimum Reading)Electronics temperature range -40°–85°C (-40°–185°F) Gas temperature range -40°–66°C (-40°–150°F); extended range

available, consult factoryGas pressure effect Negligible over ± 20% of absolute

calibration pressureConduit/probe pressure rating range Vacuum to 500 PSIG standard;

higher pressures, consult factoryInput power requirement 24VDC @ 250mA

115 VAC 50/60 Hz optional230 VAC 50/60 Hz optional

Flow Transmitter power requirements 5 watts or lessWetted materials 316 Stainless Steel

(Hastelloy optional)Standard temperature & pressure 70°F & 29.92" Hg (STP) (Air .075 lb./cubic foot)NIST traceable calibration Standard

For use in Ordinary (Non-Hazardous) area locations: Type 4X, IP66

Certified to US requirements; Certified to Canadian requirements

�����������

�������������� ������

��������������

�����������

�������������� ������

��������������

�����������

�������������� ������

��������������

�����������

�������������� ������

������������������������

�����������

�������������� ������

������������������������

�����������

�������������� ������

��������������

Series 8000MPNH-8100MPNH DesignModel Pipe OD" x L" SCFM8036MPNH-SSS-133 1/4 x 6 3.508049MPNH-SSS-133 3/8 x 6 6.008059MPNH-SSS-133 1/2 x 7 13.08069MPNH-SSS-133 3/4 x 7 60.08089MPNH-SSS-133 1 x 8 90.08110MPNH-SSS-133 1¼ x 10 1508112MPNH-SSS-133 1½ x 15 2008116MPNH-SSS-133 2 x 20 3508120MPNH-SSS-133 2½ x 25 5008124MPNH-SSS-133 3 x 30 7508132MPNH-SSS-133 4 x 40 1350

Series 8200MPNHModel Probe OD" Max L”8240MPNH-SSS-133 1/2 368260MPNH-SSS-133 3/4 608280MPNH-SSS-133 1 84

Series 8600MPNH-8700MPNH DesignModel Pipe OD" x L" SCFM8636MPNH-SSS-133 1/4 x 6 3.508649MPNH-SSS-133 3/8 x 6 6.008659MPNH-SSS-133 1/2 x 7 13.08669MPNH-SSS-133 3/4 x 7 60.08689MPNH-SSS-133 1 x 8 90.08710MPNH-SSS-133 1¼ x 10 1508712MPNH-SSS-133 1½ x 15 2008716MPNH-SSS-133 2 x 20 3508720MPNH-SSS-133 2½ x 25 5008724MPNH-SSS-133 3 x 30 7508732MPNH-SSS-133 4 x 40 1350

Series 8800MPNHModel Probe OD" Max L”8840MPNH-SSS-133 1/2 368860MPNH-SSS-133 3/4 608880MPNH-SSS-133 1 84

�

� ��

Higher flow ranges are available, dependent upon process gas and flow specifications. Please consultthe factory for details.

EPI’s new thermal FlowAveraging Tubes (FAT™)provide accurate flowmeasurement in large pipesand ducts, offering a cost-effective solution for Heating,Ventilation, and AirConditioning (HVAC) andVariable Air Volume (VAV)applications. The Master-Touch FAT™ probes utilize aflow averaging tube to givea stable flow signal in appli-cations where the flow pro-file is less than ideal, such asdownstream of a bend,valve, tee or obstruction.

TechnologyThe flow averaging tube has anumber of large diameter (0.125”)inlet ports along the length of theupstream impact surface. Theimpact pressure at each inlet portis averaged inside the tube to cre-ate the axial flow through the tubeand across our thermal flow sen-sor. The gas flow then passes backinto the main flow stream throughthe gas return ports located nearthe flow sensing elements.

Because the velocity impact pres-sure follows a square root function,the average velocity pressure in

the FAT™ probe may vary slightlyfrom the average of the velocitiesat each inlet port. Accuracy shiftsdue to anomalies in the actualflow profile or installations in non-circular ducts may be correctedwith a local C-Factor adjustment.

ConfigurationsAs with our other product lines, theMP Series Flow Averaging Tubeshave an explosion-proof enclosuremounted on the probe assembly.The MPNH Series Flow AveragingTubes are intended for use inOrdinary, or non-hazardous, arealocations and have ABS plasticenclosures mounted on the probeassembly. Series 9200MP and9200MPNH instruments have the

flow transmitter enclosure mount-ed on the probe assembly, withthe signal processor electronicsremotely mounted in a separateenclosure. The Series 9800MP and9800MPNH instruments haveall electronics mounted on theprobe assembly.

The connections for input powerand output signals for the Series9200MP and 9200MPNH are locat-ed in the remote electronics. Thisconfiguration uses only a two-wireconnection between the flowtransmitter and the signal proces-sor. All input and output connec-tions for the Series 9800MP and9800MPNH are accessed in theintegral electronics enclosure.

The installation ofthe tubes in thepipe or duct typi-cally uses tube topipe compressionfittings or flangemounts. Multipletubes can beused with aModel 9601MPSystem ControlPanel for an aver-aged output.

ELDRIDGE PRODUCTS, INC. 2700 Garden Road, Building A Monterey, CA 93940

������

�� ����

��������

��������

�� ��� !�"�#$%!&'�&()�"*+�"�

�����������

�������������� ������

��������������

����

������������

�������������� ������

����� ����� ���

������� �������������������

������������

�����������

�������������� ������

Patented

9601MP System Control Panel

EPI’s new thermal FlowAveraging Tubes (FAT™) arenow adapted to inline appli-cations for installations withextremely short straight runssuch as retrofits for existingfacilities or as replacementsfor other metering devices.

InstallationBy itself, EPI's Flow Averaging Tubetechnology significantly reducesthe traditional requirements forstraight, unobstructed upstreampiping. Depending upon the pip-ing configuration, the traditionallyrequired upstream straight run canbe 10, 20, even 50 diameters. Bymeasuring the cumulative flowvelocities across one or moreinside diameters, the FlowAveraging Tubes are far more tol-erant of flow profile problems thanother instrument technologies. Thisallows the required straight run tobe greatly reduced from conven-tional requirements. In fact, byincorporating a Flow Straightening

Assembly, theu p s t r e a mrequirement canbe reduced toas little as threediameters.

Series 9100MP-9100MPNHThe Series 9100MP flow averagingtubes have an explosion-proofflow transmitter mounted on theflow section and the signal proces-sor electronics remotely mountedin a separate, NEMA 4X enclosure.The Series 9100MPNH flow averag-ing tubes have a NEMA 4X flowtransmitter mounted on the flowsection and the signal processorelectronics remotely mounted in aseparate, NEMA 4X enclosure.Input power for both series is sup-plied to the remote electronics.This configuration uses only a two-wire connection between the flowtransmitter and the signal proces-sor. The flow sections have flowstraightening screens as standard.Flow sections include ANSI 150#flanges as standard. For othermounting options, please consultthe factory.

Series 9700MP-9700MPNHThe Series 9700MP flow averagingtubes have all electronics mount-ed on the flow section in an explo-sion-proof enclosure. The Series9700MPNH flow averaging tubeshave all electronics mounted onthe flow section in a NEMA 4Xenclosure. Input power for bothseries is supplied to the remoteelectronics. This configuration usesonly a two-wire connectionbetween the flow transmitter andthe signal processor. The flow sec-tions have flow straighteningscreens as standard. Flow sectionsinclude ANSI 150# flanges as stan-dard. For other mounting options,please consult the factory.

T: 800/321-FLOW(3569) F: 831/648-7780 [email protected] www.epiflow.com

��%+���'�#

��%+��,�"�(�&(� !-�

������������

�������������� ������

����� ����� ���

continued

ELDRIDGE PRODUCTS, INC. 2700 Garden Road, Building A Monterey, CA 93940

SpecificationsLinear signal output 0-5 VDC & 4-20 mARelay Output Two 1-amp, user-selectable alarms Computer Signal Interface RS232 & RS485

(optional Modbus and HART-compatable)Accuracy, including linearity ±[1% of Reading + (0.5% + 0.05%/°C (Ref.: 21°C) with ideal flow profile of Full Scale)]Repeatability ±0.2% of Full ScaleSensor flow response time 1 second (time constant per step change)Turn down ratio 100:1 minimum (but not less than 50 SFPM)Electronics temperature range -40°–85°C (-40°–185°F) Gas temperature range -40°–66°C (-40°–150°F)Gas pressure effect Negligible over ± 10% of absolute

calibration pressureConduit/peobe pressure rating range Vacuum to 150 PSIG standard;

higher pressures, consult factoryInput power requirement 24VDC @ 250mA

115 VAC 50/60 Hz optional230 VAC 50/60 Hz optional

Flow Transmitter power requirements 5 watts or lessWetted materials 316 Stainless SteelStandard temperature & pressure 70°F & 29.92" Hg(STP) (Air .075 lb./cubic foot)NIST traceable calibration StandardMP Series:Class I Division 1 Groups B, C and D; Class II E, F and G; Class III; Type 4X, 7; Ex d IIC; AEx d IIC, IP66; EExd IIC, IP66; T2 (consult factory for T3 or T4).

Certified to US requirements; Certified to Canadian requirements

Certified to European ATEX requirements

* Remote Enclosure (Series 8000MP– 8200MP) and MPNH Series for use in Ordinary (Non-Hazardous)area locations: Type 4X, IP66U. S. Patent No. 6,883,389 Other U.S. & foreign patents pending.

Patented

Series 9100MP DesignModel Pipe OD" x L" SCFM9116MP-SSS-133 2 x 14 14009120MP-SSS-133 2½ x 14 20009124MP-SSS-133 3 x 14 30009132MP-SSS-133 4 x 14 54009148MP-SSS-133 6 x 14 12000Series 9200MPModel Probe OD" Max L”9240MP-SSS-133 1/2 369260MP-SSS-133 3/4 609280MP-SSS-133 1 84Series 9700MP DesignModel Pipe OD" x L" SCFM9716MP-SSS-133 2 x 14 14009720MP-SSS-133 2½ x 14 20009724MP-SSS-133 3 x 14 30009732MP-SSS-133 4 x 14 54009748MP-SSS-133 6 x 14 12000Series 9800MPModel Probe OD" Max L"9840MP-SSS-133 1/2 369860MP-SSS-133 3/4 609880MP-SSS-133 1 84

Series 9100MPNH DesignModel Pipe OD" x L" SCFM9116MPNH-SSS-133 2 x 14 14009120MPNH-SSS-133 2½ x 14 20009124MPNH-SSS-133 3 x 14 30009132MPNH-SSS-133 4 x 14 54009148MPNH-SSS-133 6 x 14 12000Series 9200MPNHModel Probe OD" Max L”9240MPNH-SSS-133 1/2 369260MPNH-SSS-133 3/4 609280MPNH-SSS-133 1 84Series 9700MPNH DesignModel Pipe OD" x L" SCFM9116MPNH-SSS-133 2 x 14 14009120MPNH-SSS-133 2½ x 14 20009724MPNH-SSS-133 3 x 14 30009732MPNH-SSS-133 4 x 14 54009748MPNH-SSS-133 6 x 14 12000Series 9800MPNHModel Probe OD" Max L"9840MPNH-SSS-133 1/2 369860MPNH-SSS-133 3/4 609880MPNH-SSS-133 1 84

�

� ��

* Remote Enclosure

The Series 9000MP MultipointSystems are designed tomeasure air and gas flow insystems where two or moresensing points are requireddue to large cross-sectionalareas. The typical Series9000MP Multipoint Systemincludes one or more Series9000MP Probe and a Series9600MP System ControlPanel. The new APS airpurge system and supportfor multiple C-Factorsmake the Series 9000MPyour complete solution.

TechnologyThe 9000MP flow transmitter probeassembly is the heart of the system.The probe assembly consists of twoor more flow sensors (maximum of5 sensors per probe) mounted in a1½" OD probe shaft. Each sensor ismatched to its own bridge boardand is individually calibrated andlinearized. The bridge board andmicroprocessor for each sensorare mounted outside of the flowduct in an enclosure at the end ofthe probe shaft.

The voltage output from each sen-sor and bridge board set is sent toits own microprocessor board foraccurate linearization of the flowrate signal. The linearized output

signals from the multiple sensors inthe probe are then averaged bythe summer/averager module.Typically, the probe assembly'saveraged output signal is transmit-ted to the remote system controlpanel for grand averaging withthe signals from other probeassemblies. However, flow trans-mitter assemblies may be speci-fied with either one average out-put signal and/or individual signalsto allow individual sensor readingsat the system control panel.

The Series 9601MP system controlpanel is housed in a 12" x 10" NEMA4X fiberglass enclosure. This enclo-sure holds the power supply, thesummer/averager board (requiredfor systems with multiple probeassemblies), and a microprocessorboard for control of the overall sys-tem output signal, and can belocated from as little as a few feetto as much as thousands of feetfrom the transmitter probe assem-blies.

The control panel provides thepower for the probe assemblies.The flow transmitter sends its signalto the control panel over a 4-20mA signal loop. This methodrequires a four wire connectionper probe assembly (power supplypositive, power ground, 4-20 mAaverage output and return). Thecontrol panel provides two analogoutput signals (0-5 VDC and 4-20mA) linearized proportionally tothe grand average flow rate, aswell as RS232/485 digital interfacesfor communication with a PC run-ning EPICommunicator software.The 4-20 mA grand average out-put can drive up to 1200 ohms.Modbus and HART-compatibleoptions are available

Air Purge SystemThe EPI Air Purge System (APS) pro-vides a means of cleaning the sen-sors in applications where dry par-ticulates may build up on the sen-sors and cause problems. A stain-less steel tube is mounted on thedownstream side of the probe sup-port with a pair of outlet holes posi-tioned at each sensor. The tube isconnected to a tap located onthe mounting flange. After basicinstallation of the multipoint systemis complete, a pressurized gas line(typically compressed air) is con-nected to the tap. The pressurizedgas is released at set intervals bythe user to clean the sensor sur-face of any accumulated particu-lates. The frequency and durationof the the purging gas stream canbe controlled by the Master-Touchsoftware or externally by the cus-tomer.

The purge gas must be compati-ble with the process gas. Pre-heat-ing the purge gas to the tempera-ture of the process gas is recom-mended. By pre-heating thepurge gas, one may avoid adhe-sion of certain particulate matterto sensor and probe surfaces.Consult the EPI factory for pre-heating solutions.

T: 800/321-FLOW(3569) F: 831/648-7780 [email protected] www.epiflow.com

continued

Duct Suggested Number Suggested Sensors Total NumberDiameter of Probes per Probe of Sensors

8" – 18" 1 2 2

18" – 24" 1 4 4

24" – 36" 2 2 4

36" – 60" 2 4 8

Larger Ducts and Stacks – Consult factory for configuration options.

Rectangular Ducts – Allow one to two square feet per point. Fewer tra-verse points may be used if a careful study shows that uniformity of flowexists.

ELDRIDGE PRODUCTS, INC. 2700 Garden Road, Building A Monterey, CA 93940

Specifying a Series 9000MPMultipoint SystemThe chart to the right is a guidelinefor how many traverse points aresuggested for a circular duct.Once the average flow rate isdetermined, the factory canspecify the minimum number ofsensors in a Series 9000MPMultipoint System. If the point ofaverage flow cannot be deter-mined, then a simple rule is tospecify the number of pointsbased on the chart.

The greater the number of pointsmeasured, the greater the accu-racy of the final average flow rate.Also note that the accuracy ofany one point becomes of lessimportance to the final accuracyof the total flow rate as the num-ber of points is increased becauseof the averaging method utilized.

����

������������

�������������� �������������������� ������

����� ����� ���

������� ������������������������������������

������������

�����������

�������������� ������

T: 800/321-FLOW(3569) F: 831/648-7780 [email protected] www.epiflow.com

SpecificationsLinear signal output 0-5 VDC & 4-20 mA

Relay Output Two 1-amp, user-selectable alarm functions

Computer Signal Interface RS232 & RS485(optional Modbus and HART-compatible)

Accuracy, including linearity ±[1.0% of Reading + (0.5% + 0.02%/°C (Ref.: 21°C) of Full Scale)]

Repeatability ±0.2% of Full Scale

Sensor flow response time 1 second (time constant per step change)

Turn down ratio 100:1 minimum(but not less than 15 SFPM)

Electronics temperature range -40°–85°C (-40°–185°F);extended temperature optional

Gas temperature range -40°–66°C (-40°–150°F); extended range (All calibrations performed in available, consult factoryAmbient Temp. & Pressure Air)

Gas pressure effect Negligible over ± 10% of absolute calibration pressure

Probe pressure rating range Vacuum to 50 PSIG; higher pressures, consult factory

Input power requirement 24VDC @ 250mA per sensor115 VAC 50/60 Hz optional230 VAC 50/60 Hz optional

Series 9000/9600MP power 5 watts or less per sensorrequirements

Series 9600MP enclosure NEMA 4X fiberglass, 10” x 12” x 6”

Series 9000MP probe enclosure NEMA 4X fiberglass, 8” x 10” x 4”

Wetted materials 316 Stainless Steel

Standard temperature & pressure 70°F & 29.92" Hg(STP) (Air .075 lb./cubic foot)

NIST traceable calibration Standard

������������� ����� �����

�� ������ ������������

�������������� ������ ��������

.����/ ����$%!&'�&(�)�"*+�"��� �/� .���0�.���$!#'�-��+��*�*

'%�!#�"1#�*!2'�%"�����

.���/� �34�������5�6��'�&(����&(�

.���/� �34� !-�&*����

������������

�������������� �������������������� ������

����� ����� ���

������� ������������������������������������

����������������������

�����������

�������������� ������

Series 9000MPModel* Description9001MP-06-01-XX”-DESFC Probe assembly with 1 sensor and hardware9002MP-06-01-XX”-DESFC Probe assembly with 2 sensors and hardware9003MP-06-01-XX”-DESFC Probe assembly with 3 sensors and hardware9004MP-06-01-XX”-DESFC Probe assembly with 4 sensors and hardware9005MP-06-01-XX”-DESFC Probe assembly with 5 sensors and hardware

* (XX” equals probe length)-APS Air Purge System option (added to part number)

Series 9601MPModel Description9601MP-133-1210-DC24 System Control Panel with 24 VDC input power9601MP-133-1210-AC115 System Control Panel with 115 VAC input power9601MP-133-1210-AC230 System Control Panel with 230 VAC input power

2700 Garden Road, Building A

Monterey, CA 93940

Tel: 800/321-FLOW(3569)

Fax: 831/648-7780

www.epiflow.com

Eldridge Products, Inc. Terms and Conditions

Specification NoticeSpecifications contained herein are subject to change without notice. EPI cannot guaran-tee the applicability or suitability of our products in all situations, since it is impossible toanticipate or control every condition under which our products and specifications may beused.

Limited AcceptanceAcceptance of an EPI offer is limited to its terms. Acceptances or confirmations that stateadditional or differing terms from the price quote shall be operative as acceptances, butall additional or differing terms shall be deemed material alterations within the meaning ofCommercial Code Section 2207(2)(b), and notice of objection to them pursuant toCommercial Code Section 2207(2)(c) is hereby given. The laws of the State of Californiagovern the contract and venue is Monterey County. Risk of loss passes F.O.B. EPI factory.Payment due in full in US Dollars within credit terms granted from factory shipment.Additional fees shall include interest on unpaid balances that are outstanding for more thangranted credit terms, plus all collection costs and attorneys' fees incurred in collecting anyoutstanding balance. Any and all additional or differing terms do not become part of thecontract between EPI and any purchaser.

The terms of the offer are expressly limited to the terms detailed in any product brochure orprice quote. Any modification to any of the terms of the offer must be in writing and mustbe signed by an officer of EPI.

Limited WarrantyEldridge Products, Inc. (EPI) warrants its products to be free from defects in materials andworkmanship for one year from the date of factory shipment. If there is a defect, the pur-chaser must notify EPI of the defect within the warranty period. Upon receipt of the defec-tive product, EPI will either repair the defective product, or provide an EPI replacement, orrefund the purchase price of the defective product, at its sole option. EPI MAKES NO OTHERWARRANTY, EXPRESS OR IMPLIED, AS TO THE PRODUCTS. EPI MAKES NO WARRANTY THAT THEGOODS SOLD TO ANY PURCHASER ARE FIT FOR ANY PARTICULAR PURPOSE. FURTHERMORE,EPI MAKES NO WARRANTY OF MERCHANTABILITY WITH RESPECT TO ANY PRODUCTS SOLD TOANY PURCHASERS. There are no other warranties that extend beyond the description on anybrochure or price quote.

Ball Valve RetractorAssemblyOptional ball valveassemblies areavailable throughEPI which allow theremoval of theinsertion style flowtransmitter assem-blies for service,calibration, clean-ing, etc. The valveprovides a meansto seal off leaks ofthe process gas atthe point of inser-tion after the probeassembly has beenremoved.

BVR0812 — ½" borex ¾" NPT x 10" long

BVR1216 — ¾" borex 1" NPT x 11" long

BVR1620 — 1" borex 1¼" NPT x 12" long

Tube-to-Pipe AdapterBored thru tube-to-pipeadapter fittings are alsoavailable from the factory.

TPM0808T — ½" tube x ½"male pipe bored thru fittingwith Teflon ferrule

TPM1212T — ¾" tube x ¾" malepipe bored thru fitting with Teflonferrule

TPM1216T — ¾" tube x 1" malepipe bored thru fitting with Teflonferrule

TPM1616T — 1" tube x 1" male pipebored thru fitting with Teflon ferrule

TPMXXXXS — Same as aboveexcept stainless steel ferrule

80400101 rev. 3

�

� ��