Thermal Analysis Module 6. Training Manual January 30, 2001 Inventory #001441 6-2 Thermal Analysis...

-

Upload

oliver-mckinney -

Category

Documents

-

view

214 -

download

0

Transcript of Thermal Analysis Module 6. Training Manual January 30, 2001 Inventory #001441 6-2 Thermal Analysis...

Thermal Analysis

Module 6

January 30, 2001

Inventory #001441

6-2

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

Training ManualThermal Analysis

• In this chapter, we will briefly describe the procedure to do a steady-state thermal analysis.

• The purpose is two-fold:

– To reiterate the typical analysis steps that were introduced in Chapter 4.

– To introduce you to thermal loads and boundary conditions.

• Topics covered:

A. Overview

B. Procedure

C. Workshop

January 30, 2001

Inventory #001441

6-3

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

Training Manual

Thermal Analysis

A. Overview

• Thermal analyses are used to determine the temperature distribution, thermal gradient, heat flow, and other such thermal quantities in a structure.

• A thermal analysis can be steady-state or transient.

– Steady-state implies that the loading conditions have “settled down” to a steady level, with little or no time dependency. Example: An iron that has already reached the desired temperature setting.

– Transient* implies conditions that are changing with time. Example: A casting in the process of cooling down from molten metal to solid.

* Not covered in this course

January 30, 2001

Inventory #001441

6-4

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

Training Manual

Thermal Analysis

...Overview

• Thermal loading conditions can be:

Temperatures Regions of the model where temperatures are known.

Convections Surfaces where heat is transferred to (or from) surroundings by means of convection. Input consists of film coefficient h and bulk temperature of the surrounding fluid Tb.

Heat flux* Surfaces where the heat flow rate per unit area is known.

Heat flow* Points where the heat flow rate is known.

Heat generation* Regions where the volumetric heat generation rate is known.

Radiation* Surfaces where heat transfer occurs by means of radiation. Input consists of emissivity, Stefan-Boltzmann constant, and optionally, temperature at a “space node.”

Adiabatic surfaces “Perfectly insulated” surfaces where no heat transfer takes place.

* Not covered in this course

January 30, 2001

Inventory #001441

6-5

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

Training Manual

Thermal Analysis

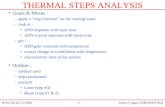

B. Procedure

• The procedure to do a steady-state thermal analysis is similar to that for a static stress analysis:

– Preprocessing

• Geometry

• Meshing

– Solution

• Loading

• Solve

– Postprocessing

• Review results

• Validate the solution

• Setting GUI preferences (Main Menu > Preferences) to Thermal may be helpful.

January 30, 2001

Inventory #001441

6-6

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

Training Manual

Thermal Analysis - Procedure

Preprocessing

Geometry

• Can either be created within ANSYS or imported.

• Details of both methods will be covered later.

January 30, 2001

Inventory #001441

6-7

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

Training Manual

Thermal Analysis - Procedure

...Preprocessing

Meshing

• First define element attributes: element type, real constants, and material properties.

Element type

• The table below shows commonly used thermal element types.

• There is only one DOF per node: TEMP

2-D Solid 3-D Solid 3-D Shell Line Elements

Linear PLANE55 SOLID70 SHELL57 LINK31,32,33,34

QuadraticPLANE77 PLANE35

SOLID90 SOLID87

Commonly used thermal element types

January 30, 2001

Inventory #001441

6-8

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

Training Manual

Thermal Analysis - Procedure

...Preprocessing

Material properties

– Minimum requirement is thermal conductivity, KXX.

– Specific heat (C) will be needed if internal heat generation is to be applied.

– ANSYS-supplied material library (/ansys57/matlib) contains both structural and thermal properties for a few common materials, but we recommend that you create and use your own material library.

– Setting preferences to “Thermal” limits the Material Model GUI to display only thermal properties.

Real constants

– Primarily needed for shell and line elements.

January 30, 2001

Inventory #001441

6-9

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

Training Manual

Thermal Analysis - Procedure

...Preprocessing

• Then mesh the geometry.

– Save the database.

– Use the MeshTool to create the mesh. The default smart-size level of 6 produces a good initial mesh.

• This completes the preprocessing step. Solution is next.

January 30, 2001

Inventory #001441

6-10

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

Training Manual

Thermal Analysis - Procedure

Solution

Loading

• Prescribed Temperatures

– DOF constraints for a thermal analysis

– Solution > -Loads-Apply > Temperature

– Or the D family of commands (DA, DL, D)

• Convections

– These are surface loads

– Solution > -Loads-Apply > Convection

– Or the SF family of commands (SFA, SFL, SF, SFE)

January 30, 2001

Inventory #001441

6-11

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

Training Manual

Thermal Analysis - Procedure

...Solution

• Adiabatic Surfaces

– “Perfectly insulated” surfaces where no heat transfer takes place.

– This is the default condition, i.e, any surface with no boundary conditions specified is automatically treated as an adiabatic surface.

• Other possible thermal loads:– heat flux (BTU / (hr-in2)

– heat flow (BTU / hr)

– heat generation (BTU / (hr-in3)

– radiation (BTU / hr)

January 30, 2001

Inventory #001441

6-12

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

Training Manual

Thermal Analysis - Procedure

...Solution

Solve

• First save the database.

• Then issue SOLVE or click on Solution > -Solve- Current LS.

– Results are written to the results file, jobname.rth, as well as to the in-memory database.

• This completes the solution step. Postprocessing is next.

January 30, 2001

Inventory #001441

6-13

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

Training Manual

Thermal Analysis - Procedure

Postprocessing

Review Results

• Typically consists of contour plots of temperature, thermal gradient, and thermal flux.

– General Postproc > Plot Results > Nodal Solu… (or Element Solu…)

– Or use PLNSOL (or PLESOL)

January 30, 2001

Inventory #001441

6-14

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

Training Manual

Thermal Analysis - Procedure

...Postprocessing

• A useful option for contour plots in 3-D solid models is isosurfaces — surfaces of constant value. Use the /CTYPE command or Utility Menu > PlotCtrls > Style > Contours > Contour Style.

January 30, 2001

Inventory #001441

6-15

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

Training Manual

Thermal Analysis - Procedure

...Postprocessing

• Validate the Solution

• Are temperatures within the expected range?

– You can generally guess the expected range based on prescribed temperatures and convection boundaries.

• Is the mesh adequate?

– Just as in the case of stresses, you can plot the unaveraged thermal gradients (element solution) and look for elements with high gradients. These regions are candidates for mesh refinement.

– If there is a significant difference between the nodal (averaged) and element (unaveraged) thermal gradients, the mesh may be too coarse.

January 30, 2001

Inventory #001441

6-16

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

INTR

OD

UC

TIO

N T

O A

NS

YS

5.6

- Part 1

Training Manual

Thermal Analysis - Procedure

C. Workshop

• Refer to your Workshop Supplement for instructions on:

W3. Axisymmetric Pipe with Fins