Theory and Application of Conductivity

Transcript of Theory and Application of Conductivity

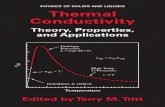

BACKGROUNDConductivity is a measure of how well a solutionconducts electricity. To carry a current a solution mustcontain charged particles, or ions. Most conductivitymeasurements are made in aqueous solutions, andthe ions responsible for the conductivity come fromelectrolytes dissolved in the water. Salts (like sodiumchloride and magnesium sulfate), acids (l ikehydrochloric acid and acetic acid), and bases (likesodium hydroxide and ammonia) are all electrolytes.Although water itself is not an electrolyte, it does havea very small conductivity, implying that at least someions are present. The ions are hydrogen and hydroxide,and they originate from the dissociation of molecularwater. See Figure 1.

Conductivity is not specific. It measures the totalconcentration of ions in solution. It cannot distinguishone electrolyte or ion from another.

Not all aqueous solutions have conductivity. Solutionsof non-electrolytes, for example sugar or alcohol, haveno conductivity because neither sugar nor alcoholcontains ions nor do they produce ions whendissolved in water.

APPLICATIONS OF CONDUCTIVITYConductivity measurements are widely used in industry.Some important applications are described below.

• Water treatment. Raw water as it comes from a lake,river, or the tap is rarely suitable for industrial use. Thewater contains contaminants, largely ionic, that if notremoved will cause scaling and corrosion in plantequipment, particularly in heat exchangers, coolingtowers, and boilers. There are many ways to treatwater, and different treatments have different goals.Often the goal is demineralization, which is theremoval of all or nearly all of the contaminants. Inother cases the goal is to remove only certain contam-inants, for example hardness ions (calcium andmagnesium). Because conductivity is a measure ofthe total concentration of ions, it is ideal for monitoringdemineralizer performance. It is rarely suitable formeasuring how well specific ionic contaminants arebeing removed.

Conductivity is also used to monitor the build up ofdissolved ionic solids in evaporative cooling watersystems and in boilers. When the conductivity getstoo high, indicating a potentially harmful accumula-tion of solids, a quantity of water is drained out of thesystem and replaced with water having lower conductivity.

• Leak detection. Water used for cooling in heatexchangers and surface condensers usually containslarge amounts of dissolved ionic solids. Leakage ofthe cooling water into the process liquid can result inpotentially harmful contamination. Measuring conduc-tivity in the outlet of a heat exchanger or in the con-denser hotwell is an easy way of detecting leaks.

• Clean in place. In the pharmaceutical and food andbeverage industries, piping and vessels are periodical-ly cleaned and sanitized in a procedure called clean-in-place (CIP). Conductivity is used to monitor both theconcentration of the CIP solution, typically sodiumhydroxide, and the completeness of the rinse.

• Interface detection. If two liquids have appreciablydifferent conductivity, a conductivity sensor can detectthe interface between them. Interface detection isimportant in a variety of industries including chemicalprocessing and food and beverage manufacturing.

• Desalination. Drinking water desalination plants,both thermal (evaporative) and membrane (reverseosmosis), make extensive use of conductivity to moni-tor how completely dissolved ionic solids are beingremoved from the brackish raw water.

THEORY AND APPLICATION OFCONDUCTIVITY

TheoryApplication Data SheetADS 43-018/rev.D

January 2010

FIGURE 1. Salts, acids, and bases are elec-trolytes. They dissolve in water to form ions.Although water is not an electrolyte, a very smallconcentration of hydrogen and hydroxide ions arealways present in pure water.

NaCl Na+ + Cl

- salt

acid HCl H+ + Cl

-

base NaOH Na+ + OH

-

water H2O H+ + OH

-

2 Rosemount Analytical

UNITSThe units of conductivity are siemens per cm (S/cm).Derived units are µS/cm (one millionth of a S/cm) andmS/cm (one thousandth of a S/cm). S/cm is the sameas the older unit mho/cm. Certain high purity waterindustries, primarily semiconductor and pharmaceuti-cal, use resistivity instead of conductivity. Resistivity isthe reciprocal of conductivity. The units are MΩ cm.Figure 2 shows the approximate conductivity of sometypical electrolyte solutions.

MEASUREMENT OF CONDUCTIVITYThere are two types of conductivity measurement:contacting and inductive. The choice of which to usedepends on the amount of conductivity, the corrosivenessof the liquid, and the amount of suspended solids.Generally, the inductive method is better when theconductivity is high, the liquid is corrosive, or suspendedsolids are present.

Contacting Conductivity

Most contacting conductivity sensors consist of twometal electrodes, usually stainless steel or titanium, incontact with the electrolyte solution. See Figure 3. Theanalyzer applies an alternating voltage to the elec-trodes. The electric field causes the ions to move backand forth producing a current. Because the chargecarriers are ions, the current is called an ionic current.The analyzer measures the current and uses Ohm’slaw to calculate the resistance of the solution (resis-tance = voltage/current). The conductance of the solu-tion is the reciprocal of the resistance.

The ionic current depends on the total concentration ofions in solution and on the length and area of the solu-tion through which the current flows. The current pathis defined by the sensor geometry, or cell constant,which has units of 1/cm (length/area). Multiplying theconductance by the cell constant corrects for the effectof sensor geometry on the measurement. The result isthe conductivity, which depends only on the concen-tration of ions.

Although the cell constant has a geometric interpreta-tion (length divided by area), it is rarely calculatedfrom dimensional measurements. In most designs theelectric field is not confined between the electrodes,so the actual length and area are greater than predict-ed. In practice, the cell constant is measured against asolution of known conductivity. The cell constant is theratio of the known conductivity (µS/cm) to the mea-sured conductance (µS).

The usual conductivity range for a contacting sensor is0.01 to 50,000 uS/cm. Because a given cell constantcan be used only over a limited range, two, possiblythree, cell constants are required to cover the entirerange. Common cell constants are 0.01/cm, 0.10/cm,1.0/cm, and 10/cm. Higher conductivity samplesrequire larger cell constants.

Typically, the cell constant is measured at the factory,and the user enters the value in the analyzer when thesensor is first put in service. Cell constants changevery little during the life of the sensor; however, thecell constant should be periodically checked, andthe sensor recalibrated if necessary.

Some contacting sensors have four electrodes. SeeFigure 4. In the four electrode measurement, the ana-lyzer injects an alternating current through the outerelectrodes and measures the voltage across the innerelectrodes. The analyzer calculates the conductanceof the electrolyte solution from the current and voltage.Because the voltage measuring circuit draws very littlecurrent, charge transfer effects at the metal-liquidinterface are largely absent in four-electrode sensors.As a result, a single four-electrode sensor has a muchwider dynamic range than a two-electrode sensor,roughly 1 to 1,4000,000 µS/cm. Like the two-electrodesensor, the four-electrode sensor has a cell constant,which depends on the area, spacing, and arrangementof the current and voltage electrodes.The cell constant

.01 .1 1 10 100 1 10 100 1µS/cm µS/cm µS/cm µS/cm µS/cm mS/cm mS/cm mS/cm S/cm

I I I I I I I I I

UltraPure Water

Good QualityDistilled Water

Excellent QualityRaw Water

.05% NaClSea Water

30% H2SO4

FIGURE 2. The graph shows the conductivity ofpure water, distilled water, and typical electrolytesat 25°C. Distilled water has greater conductivity thanpure water, because it is always contaminated withatmospheric carbon dioxide, which dissolves inwater to form the weak electrolyte, carbonic acid.

FIGURE 3. In the two electrode conductivity mea-surement, the motion of ions in the electric fieldcarries current through the solution. Coupling ofthe ionic and electronic current occurs at the inter-face between the metal electrode and the solution.The interface can be thought of as a capacitor withthe metal electrode being one plate and the adja-cent electrolyte being the other. The alternatingvoltage causes the capacitor to charge and dis-charge, allowing the current to cross the interface.

electrolyte solution

electrodes

A

electronic current

AC voltage

ionic current

+

Rosemount Analytical 3

is measured at the factory, and the user enters thevalue in the analyzer at startup.

Contacting conductivity measurements are restrictedto applications where the conductivity is fairly low(although four-electrode sensors have a higher endoperating range) and the sample is non-corrosive andfree of suspended solids. Two-electrode sensors areideal for measuring high purity water in semi-conductor,steam electric power, and pharmaceutical plants.

Inductive Conductivity

Inductive conductivity is sometimes called toroidal orelectrodeless conductivity. An inductive sensor con-sists of two wire-wound metal toroids encased in acorrosion-resistant plastic body. One toroid is the drivecoil, the other is the receive coil. The sensor isimmersed in the conductive liquid. The analyzerapplies an alternating voltage to the drive coil, whichinduces a voltage in the liquid surrounding the coil.The voltage causes an ionic current to flow proportion-al to the conductance of the liquid. The ionic currentinduces an electronic current in the receive coil, whichthe analyzer measures. The induced current is directlyproportional to the conductance of the solution. SeeFigure 5.

The current in the receive coil depends on the numberof windings in the drive and receive coils and the physicaldimensions of the sensor, which defines the volume ofsample through which the ionic current flows. Thenumber of windings and the dimensions of the sensorare described by the cell constant. As in the case ofcontacting sensors, the product of the cell constantand conductance is the conductivity.

The walls of the tank or pipe in which the sensor isinstalled also influence the cell constant—the so-calledwall effect. A metal (conducting) wall near the sensorincreases the induced current, leading to increasedconductance and a corresponding decrease in the cellconstant. A plastic or insulating wall has the oppositeeffect. Normally, wall effects disappear when the dis-tance between the sensor and wall reaches roughlythree-fourths of the diameter of the sensor. See Figure6. Because some degree of wall effect is present inmost installations, factory-determined cell constants areof little use. For accurate results, the user must calibratethe sensor in place in the process piping.

The inductive measurement has several benefits.

First, the toroids do not need to touch the sample.Thus, they can be encased in plastic, allowing thesensor to be used in solutions that would corrodemetal electrode sensors. Second, because inductivesensors tolerate high levels of fouling, they can beused in solutions containing high levels of suspendedsolids. As long as the fouling does not appreciablychange the area of the toroid opening, readings will beaccurate. By contrast, even a light coating of depositon a contacting sensor will cause an error. Finally,inductive sensors are ideal for measuring solutionshaving high conductivity. High conductivity solutionsproduce a large, easily measured induced current inthe receive coil.

Inductive sensors do have drawbacks. Chiefly, theyare restricted to samples having conductivity greaterthan about 15 µS/cm. They cannot be used formeasuring low conductivity solutions.

current electrodes voltage

electrodes

V

current electrode

current electrode

FIGURE 4. In the four electrode conductivity mea-surement, the analyzer injects current between theouter electrodes and measures the voltage dropcaused by the resistance of the electrolytebetween the inner electrodes.

ap

pa

ren

t co

nd

uctivity

distance to wall

metal walls

plastic walls 3/4 of sensor diameter

FIGURE 6. For typical sensors, wall affects disap-pear when the clearance between the sensor andwall is 1 – 1 ½ in (25 – 37 mm).

drive receive

toroid

wire

ionic current in sample

analyzer measures

current induced in the receive coil

analyzer generates AC drive voltage

FIGURE 5. Both coils are encased in a single sensorbody and overmolded with plastic. The coils must becompletely submerged in the process liquid.

4 Rosemount Analytical

TEMPERATURE AND CONDUCTIVITYIncreasing the temperature of an electrolyte solutionalways increases the conductivity. The increase issignificant, between 1.5 and 5.0% per °C. To compen-sate for temperature changes, conductivity readingsare commonly corrected to the value at a referencetemperature, typically 25°C. All process conductivitysensors have integral temperature sensors that allowthe analyzer to measure the process temperature andcorrect the raw conductivity. Three temperature cor-rection algorithms are in common use.

• Linear temperature coefficient

• High purity water or dilute sodium chloride

• Cation conductivity or dilute hydrochloric acid

No temperature correction is perfect. Unless the com-position of the process liquid exactly matches themodel used in the correction algorithm, there will bean error. In addition, errors in the temperaturemeasurement itself will lead to errors in the correctedconductivity.

Linear temperature coefficient

The linear temperature correction is widely used. It isbased on the observation that the conductivity of anelectrolyte changes by about the same percentage forevery °C change in temperature. The equation is

C25 is the calculated conductivity at 25°C, Ct is the rawconductivity at t°C, and α is the linear temperaturecoefficient expressed as a decimal fraction. Although asingle temperature coefficient can be used with rea-sonable accuracy over a range of 30° or 40°C, accura-cy can be improved by calculating a coefficient specifi-cally for the sample temperature. Approximate rangesfor linear temperature coefficients are shown below:

High purity water

The high purity water correction assumes the sampleis pure water contaminated with sodium chloride(NaCl). The measured conductivity is the sum of theconductivity from water and the conductivity from thesodium and chloride ions.

Figure 7 also shows how the high purity water correc-tion works. Point 1 is the raw conductivity. The firststep is to subtract the conductivity of pure water at themeasurement temperature from the raw conductivity.The result is point 2, the conductivity of sodium andchloride. Next, the conductivity of sodium and chloride

is converted to the value at 25°C, point 3. Finally, theconductivity of pure water is added to the result to givethe corrected conductivity at 25°C, point 4.

Cation conductivity

The cation conductivity temperature correction isunique to the steam electric power industry. Cationconductivity is a way of detecting ionic contaminationin the presence of background conductivity caused byammonia or neutralizing amines, which are added tothe condensate and feedwater to elevate the pH andreduce corrosion. In cation conductivity, the aminesare removed and the ionic contaminant is convertedto the equivalent acid, for example sodium chloride isconverted to hydrochloric acid.

The cation conductivity model assumes the sample ispure water contaminated with hydrochloric acid. Thecorrection algorithm is more complicated than thehigh purity water correction because the contributionof water to the overall conductivity depends on theamount of acid present. Hydrochloric acid suppress-es the dissociation of water, causing its contributionto the total conductivity to change as the concentra-tion of hydrochloric acid changes.

CALIBRATIONThere are two ways to calibrate conductivity sensors.The sensor can be calibrated against a solution ofknown conductivity or it can be calibrated against apreviously calibrated sensor and analyzer. Normally,the sensor should be calibrated at a point near themidpoint of the operating range calibration changesthe cell constant.

Calibration against a standard solution

Calibration against a standard solution is straightfor-ward. Place the sensor in the standard and adjust theanalyzer reading to match the known conductivity. Toeliminate temperature related errors, disable tempera-ture compensation and calibrate using the conductivity

acids 1.0 – 1.6 % per °C

bases 1.8 – 2.2 % per °C

salts 1.8 – 3.0 % per °C

FIGURE 7. The total conductivity is the sum of theconductivity from water and sodium chloride ions.The large increase in the conductivity of water astemperature increases is caused primarily by theincreased ionization of water at high temperature.

C25 = Ct

––––––––1 + α(t-25)

of the standard at the measurement temperature.Most conductivity standards are solutions of potassiumchloride, so even if temperature and conductivity dataare not on the label, the data are readily available inreference books.

Conductivity standards are susceptible to contaminationfrom atmospheric carbon dioxide. Carbon dioxidedissolves in water forming carbonic acid and increas-ing the conductivity by as much as 1.5 µS/cm. Tominimize contamination errors, avoid using standardswith conductivity less than about 150 µS/cm.

Calibration against a referee sensor and analyzer

The best way to calibrate a process sensor against areferee is let the process liquid flow through thesensors connected in series and adjust the processreading to match the referee analyzer. Turning offtemperature compensation in both analyzers elimi-nates temperature compensation errors. To ensurethe temperature is the same at both sensors, keepsample flow high and tubing runs short. Use cleaninterconnecting tubing to avoid contamination.Because the system is protected from atmosphericcontamination, the method is ideal for calibratingsensors used to measure low conductivity samples.

An alternative procedure is to take a grab sample ofthe process liquid and measure its conductivity in theshop or laboratory. Because the sample temperatureis likely to change during the measurement, tempera-ture compensation is required. It is important that thetemperature measurement in both the process andreferee analyzers be accurate and that the tempera-ture correction algorithms be identical. Grab samplecalibration is, of course, unsuitable for samples havinglow conductivity.

MEASURING CONCENTRATIONAlthough conductivity is non-specific, if certainconditions are met, it can be used to measure theconcentration of electrolyte solutions. Examples aremeasuring the concentration of CIP (clean in place)chemicals and measuring the concentration of acidand caustic solutions used to regenerate ion exchangedemineralizers.

To infer concentration from conductivity severalrequirements must be met:

1. The liquid must contain a single electrolyte or theelectrolyte of interest must be the major contributor tothe conductivity. For example, when cation exchangeresin is regenerated with sulfuric acid, the concentrat-ed acid is diluted with service water to between 2 and12% (90,000 to 490,000 µS/cm). The highest the ser-vice water conductivity is likely to be is 800 µS/cm,making the worst case error about 1%.

2. There must be a measurable change in conductivityover the concentration range, and the conductivitymust be increasing or decreasing over the range.

Figure 8 shows a graph of conductivity versusconcentration for a typical electrolyte and the rangeover which concentration can be inferred from con-ductivity. Not all curves have the maximum shownin the graph, but many do. Some electrolytes, forexample, sulfuric acid, have curves with two maxima.

3. Suff icient data must be available to al low atemperature coefficient to be estimated. If the dataare not available in reference books, they must bedetermined experimentally.

SENSORS, ANALYZERS, AND TRANSMITTERSRosemount Analytical offers contacting and inductivesensors, analyzers, and transmitters to meet mostindustrial needs and applications. For more informa-tion consult the product data sheets listed below andon the next page.

measurable measurable

CONTACTING SENSORS (All two-electrode except 410VP)

Model Description PDS

140 General purpose, retractable 71-140 series

141 General purpose, screw in 71-140 series

142 General purpose, screw in 71-140 series

400 and 400VP General purpose, screw in 71-400

402 and 402VP General purpose, retractable 71-400

403 and 403VP Sanitary flange 71-403

404 Flow through 71-400

410VP Four-electrode sanitary flange 71-410VP

INDUCTIVE (TOROIDAL) SENSORS

Model Description PDS

225 Sanitary flange 71-225

226 General purpose, large toroid opening 71-226/228

228 General purpose, small toroid opening 71-226/228

222 Flow through w/bolted flange connections 71-222

242 Flow through w/bolted flange connections 71-242

245 Flow through with sanitary connections 71-245

Rosemount Analytical 5

FIGURE 8. Conductivity can be used to measureconcentration over either of (but not both of) thetwo ranges shown.

Credit Cards for U.S. Purchases Only.

The right people,the right answers,right now.

ON-LINE ORDERING NOW AVAILABLE ON OUR WEB SITEhttp://www.raihome.com

8

Emerson Process Management

2400 Barranca Parkway

Irvine, CA 92606 USA

Tel: (949) 757-8500

Fax: (949) 474-7250

http://www.raihome.com

© Rosemount Analytical Inc. 2010

All Rosemount Analytical analyzers and transmittersare compatible with the sensors listed above, with theexception of the 410VP sensor, which is compatibleonly with the 1056. All instruments feature linearslope, high purity water, and cation temperaturecorrections. Built-in conductivity-concentration curvesare available for sodium hydroxide, hydrochloric acid,sulfuric acid (two ranges), and sodium chloride (except54eC). All analyzers have a custom curve feature thatcalculates a conductivity to concentration curve fromuser-entered data.

ANALYZERS AND TRANSMITTERS

Model Description PDS

1056 Four-wire, dual input, dual output 71-1056

54eC Four-wire, single input, dual output 71-54e

Xmt-C andXmt-T

Two-wire, single input, single output 71-Xmt

5081-C and5081-T

Two-wire, single input, single output, explosion proof

71-5081