The SPD cooling plant: status and plan of upgrades Rosario Turrisi.

-

Upload

rachel-sims -

Category

Documents

-

view

216 -

download

1

Transcript of The SPD cooling plant: status and plan of upgrades Rosario Turrisi.

The SPD cooling plant:

status and plan of upgradesRosario Turrisi

A bit of history

Evaporative system: it’s a fridge…a bit more complicated Complication arises from the will to regulate output pressure This is because we want to know the evaporation temperature

(pV~T...)

A proof-of-principle plant is installed in Padova-Legnaro: continuous, seamless operation since 3 years: 1 line, shorter (~15 m) pressure tuning via input T/p setting, not a critical

parameter…

Thermodynamical cycle

The position and the length of the segment CD (the capillary) determines the point at which evaporation starts, i.e. the temperature and the available heat capacity (ED segment length)

The red dotted line shows what could be a path if not all liquid becomes vapor

Enthalpy

Pre

ssu

re

coexistenceregion

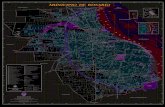

The plant in DSF

A. Undercooled liquid comes out from the condenser

B. Liquid is brought to 2.8 bar C. Enter the capillary, start of pressure dropD. At ~1.9 bar the fluid goes through the

phynox tubeE. A liquid-vapor mix goes to the compressor

inF. …where liquid must not be thereG. Vapor, and only vapor, returns to the

condenser.

A

Most of the problems we have experienced come from the incomplete evaporation of the liquid in this part, where heaters will be installed…

A few problems we have Long-term and massive (5 lines) operation of the plant has been

delayed for a number of (cooling independent, but good) reasons Late start of “serious tests” showed a few problems that prevented

satisfactory long-term runs We had definitely two kinds of problems:

1. occasional2. conceptual

In 1. we put: power cuts. Each and every time a power cut happened, a problem with

the plant showed up. (plc failure, sensors break…) air intake. This causes the EOS of C4F10 to be no more valid, i.e. the

control program “sees” what is there in the condenser is not C4F10 leaks

In 2. we put: not complete evaporation of freon/insufficient fluid volume of the tank:

causes stop of the plant to avoid serious damage of compressor/pumps

The weight drop

10 Kg

line #6 open

line #6 +1,3,9,10 open

The solution: heaters

We installed heaters from DIMECA (single wires, 150 watts each, 220V) in different places, in order to test the half barrel and a few lines (#6, #8)

These heaters have a main limit: the thermal contact with the iron 12mm return line: partial success…

We are investigating: new heaters, a different layout for better thermal

contact different way of installation: longer distance heated

with a lower power density for better efficiency

(Existence of) plan of maintenance/upgrades

Upgrade and maintenance require time and money. The first is what we do not have at all now, so first question: is operation of cooling possible (also on long term) and

safe? The answer is yes to both parts, even with some caveats:

heaters are there and help operation of the half barrel, two lines are connected so one can open just one of them if not all sectors are on

chiller is working, provided water is refilled every week. A new, spare one is sitting aside the old one

a few single lines are available for long-term tests Second question:

is there a well defined plan of maintenance/upgrade? Again the answer is yes (see it in the next slides). It is planned in

order not to interfere with the tests.

Plan of maintenance/upgrades (I) Hardware maintenance

check/replace Schrader valves (those used to vacuum down) check/replace p/T sensors (f.e. in the condenser they give the

wrong p/T relation for C4F10) I suspect 1 or 2 return valves not to work properly, have to be

replaced all the plant is undergoing a check (component by component)

and a leak test safety valves (pressure relief) are going to be re-tuned

Software maintenance switch from local to remote control and vice-versa causes some

problems, as it forces the plant to change its status according to the interface requested (should stay the same). This is being already investigated and solutions are at hand.

Plan of maintenance/upgrades (II) Upgrades

a second compressor is going to be installed, with automatic switching between the two

a bigger tank (condenser) is going to be installed, something with 30% more capacity in order to have a larger safety margin

the “solution of all the problems”: heaters one per line with independent control and temperature reading for real-time

feedback, control from the PLC already investigated the possibility to install in the cavern, a length of some 5 to 10

meters is necessary, tomorrow morning M. Pimenta, A. Di Mauro and me will define the right place for installation

And next? A two-weeks test in DSF is planned. As SPD is already installed (yes!) the

plant will have available a close-to-real load, as 1 sector (#0) 2 dummies (have the same cooling circuit as the real sectors) 7 lines, just the freon lines, with the same pressure drop as the real ones in order

to wash out any doubt about heaters efficiency

Timeline

End of April: SPD in the pit First two/three weeks of may: the plant is taken by ST-CV for

upgrade/maintenance Last week of May/first 1-2 weeks of June: test of the plant in

DSF. June: installation at Point 2

Summary In the last 2 months the cooling plant has been stressed…need a short holiday... A few problems arose, but apart from normal maintenance the complete

evaporation of the liquid is our main concern A plan of upgrades has been discussed and dates fixed with ST-CV, action is

being taken right now Stress test with real load is being prepared