The ProXES Chocolate Line PASTRY PORTFOLIO …...Volume/batch kg 10 18 22 35 60 1 2 Technical Data...

Transcript of The ProXES Chocolate Line PASTRY PORTFOLIO …...Volume/batch kg 10 18 22 35 60 1 2 Technical Data...

The ProXES Chocolate Line From Bean to Ganache

the first choice of all chocolatiers worldwide. PASTRY PORTFOLIO

THE FIRST CHOICE OF PASTRY CHEFS

2

Website: www.proxes-chocolate.comEmail: [email protected]: +32 9 3858355

BELGIUM THE KNOWLEDGE CENTRE FOR CHOCOLATE & PASTRY WORLD WIDEThe country of chocolate & pastries in the heart of Europe and your perfect point of contact.

Over 30 years of cutting edge craftsmanship in the chocolate and pastry industry. Our Belgian team specializes in the manufacturing of chocolate and pastries leading you to your perfect machine for your specific requirements. Our team provides you with tailor-made engineering solutions you can rely on.

The ProXES Group combines leaders in process technology under one umbrella!

For ProXES pastry channel we use machinery of

2

Website: www.proxes-chocolate.comEmail: [email protected]: +32 9 3858355

BELGIUM THE KNOWLEDGE CENTRE FOR CHOCOLATE & PASTRY WORLD WIDEThe country of chocolate & pastries in the heart of Europe and your perfect point of contact.

Over 30 years of cutting edge craftsmanship in the chocolate and pastry industry. Our Belgian team specializes in the manufacturing of chocolate and pastries leading you to your perfect machine for your specific requirements. Our team provides you with tailor-made engineering solutions you can rely on.

The ProXES Group combines leaders in process technology under one umbrella!

For ProXES pastry channel we use machinery of

2

ROASTING & CARAMELIZING NUTS MAKING CARAMELS, JAMS, PÂTE DE FRUITS, …

PRECISE

Roasting & caramelizing

to perfection

PROGRAMMING

inPut

of all your recipes

3

Firex CUCIMIX

NEW AND FAST

faster processing ofyour personal recipes

CARAMELFrom soft to

hard caramels

EASY

handling

3

FrymaKoruma Corundum Stone Mills – MK

GRINDING NUTS TO PRALINÉ OR PASTES

CLEANER

increased efficientcleaning process

4

up to 800 kg/h

TIME REDUCTION

High Productivity

QUICK RECIPE CHANGE

the grinding gap

Easily adjust

to a perfectly fluid nut paste

NUT-GRINDING

from roasted/

caramelized nuts

NO METAL TO METAL CONTACT

Your product is groundwithout any metal abrasions

and pastes up to 100 µm

PRECISE

total process controlling praliné

up to 180 µm

4

Stephan Universal Machines – UM

STEPHAN UNIVERSAL MACHINE – THE MOST UNIVERSE MACHINE IN PASTRY

5

ÉCLAIRS & CAKE

(Pâte à choux, cream filling, glace, grinded nuts, …)

every single part youmake with this Stephan

VIENNOISERIE

Optimised structure

DOUGHS &WAFFLES

faster than ever

CREAM FILLINGS

emulsifying & cutting

GANACHE & PRALINÉ

Smooth & tasteful

Mixing at its best

SPREADS & PASTES

All in one processingrecipe independent

MARZIPAN

5

FrymaKoruma CoBall mills – MS

FINE GRINDING PRALINÉ & PASTES UP TO 25 µm

6

EFFICIENT

Time effect to fine grinding

and make your own new

creations

PERSONAL TOUCH

Give the praliné’s & pastes

your personal touch

INNOVATIVE TEMPERATURE SYSTEM

Your Praliné’s & Pastes will neverget overheated

CLEANER

and minimum loss of product

Much more efficient cleanup

SMALL GRINDING GAP

in the mill

Minimal product loss

HIGH TECHNOLOGY

LEVEL

Total control system, economical and quick cleaning

PRECISE

Fine grinding to your personal desires

up to 25 µm Process Control

Smooth & tasteful

6

© copyright all rights reserved by Centho Chocolates

WITH US, YOU CAN

THE WORLDChoc

77

© copyright all rights reserved by Centho Chocolates

WITH US, YOU CAN

THE WORLDChoc

7 © copyright all rights reserved by Centho Chocolates

WITH US, YOU CAN

THE WORLDChoc

7

8 988

8 99999

10

MARZIPAN &PERSIPAN

CARAMEL

DOUGH

ÉCLAIR

OUR VARIOUS APPLICATIONS

11

PRALINÉ &NUT PASTE

JAM &PÂTE DE FRUITS

CAKE AND WAFFLE

www.proxes-chocolate.com

It has never been easier to find your perfect match for your pastry. Just go to our website to find your machinery by using our searching tool.

FIND YOUR

PERFECT MACHINE!

© copyright all rights reserved by Centho Chocolates

10

MARZIPAN &PERSIPAN

CARAMEL

DOUGH

ÉCLAIR

OUR VARIOUS APPLICATIONS

11

PRALINÉ &NUT PASTE

JAM &PÂTE DE FRUITS

CAKE AND WAFFLE

www.proxes-chocolate.com

It has never been easier to find your perfect match for your pastry. Just go to our website to find your machinery by using our searching tool.

FIND YOUR

PERFECT MACHINE!

© copyright all rights reserved by Centho Chocolates

12

FROM ROASTING & CARAMELIZING NUTS TO PRALINÉ & NUT PASTEA faster and better process. A new and easy principle for perfect Belgian style pastry.

FirexSafety, reliability, high quality, money and time-saving is what our Firex-brand CUCIMIX offer. A hyper polyvalent machine that allows you to work automatically and without a constant supervision.

StephanMake your praliné à l’ancienne on your Stephan Universal Machine up to 300 µm. Cutting, mixing, emulsifying in one machine for high efficient product without product losses.

Firex CUCIMIX Roasting and caramelizing nuts.

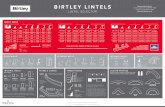

Technical Data

Type Firex CUCIMIX 30 Firex CUCIMIX 70 Firex CUCIMIX 130 Firex CUCIMIX 180 Firex CUCIMIX 310

Dimensions Length 880 1080 1445 1655 1755

Width 677 715 1290 1505 1560

Height 970 940 1030 1030 1030

Power Electric 6.2 kW 9.6 kW 13.5 kW 21 kW 29 kW

Gas n.a. 16 kW 22 kW 33 kW 49 kW

Pan Ø 450 600 700 900 1000

Capacity Lt 30 70 135 190 320

Volume/batch kg 10 18 22 35 60

1

2Technical Data

Type UMC 5 UM 12 UM 24 UM 44 UM 74 UM 130 UM 200

Bowl content l 5 12 30 45 75 130 200

Batch max. l 0.5–2.5 2.5–7 7–18 18–30 30–55 55–90 90–170

Throughput Paste (300 µm) kg/h 2–8 8–20 20–40 40–60 60–80 80–200 200–340

Praliné (300 µm) kg/h 3–15 15–40 40–100 100–180 180–330 330–540 540–1020

13

FrymaKorumaPut the ground nuts from the Stephan UM into the dosing funnel which is installed above the mill inlet. The rotor element turns against the fixed stator at high speed. The product is ground between two corundum stone disks. The milling gap adjustment also allows the stator to be pressed against the rotor with the required pressure.

FrymaKorumaThe opportunity to grind up to 25 µm on your CoBall Mill allows you to achieve an even finer paste than ever before. Aim for the smoothest nut paste efficiently and to your own recipes with your personal touch.

FrymaKoruma MSGet the smoothest paste &

praliné spreads up to 25 µm.

FrymaKoruma MKGrinding:

Paste up to 50 µmPraliné up to 180 µm

3

4

Technical Data

Type MK 95 MK 160 MK 180 MK 250 MK 320

Installed power kW 5.5 11 22 30 45

Dimensions Length mm 680 1030 1030 830 830

Width mm 540 540 540 670 600

Height mm 360 620 620 1000 1220

Weight, approx. kg 100 200 200 400 650

Throughput Paste (50 µm) kg/h 10–50 50–150 150–300 300–600 600–800

Praliné (180 µm) kg/h 10–40 40–125 125–250 250–400 400–550

Technical Data

Type MS 12 MS 18 MS 32 MS 50 MS 65

Grinding chamber volume l 0.5 1 3 8 26

Installed power, approx. kW 3–4 7.5–11 22–37 45–55 75

Dimensions Length mm 885 1160 1560 1800 2320

Width mm 515 1035 1140 1200 1540

Height mm 775 1633 1855 2070 2730

Weight, approx. kg 160 400 800 1750 3100

Throughput Paste (25 µm) kg/h 10–35 35–90 90–250 250–500 500–800

Praliné (25 µm) kg/h 10–20 20–45 45–125 125–250 250–450

12

FROM ROASTING & CARAMELIZING NUTS TO PRALINÉ & NUT PASTEA faster and better process. A new and easy principle for perfect Belgian style pastry.

FirexSafety, reliability, high quality, money and time-saving is what our Firex-brand CUCIMIX offer. A hyper polyvalent machine that allows you to work automatically and without a constant supervision.

StephanMake your praliné à l’ancienne on your Stephan Universal Machine up to 300 µm. Cutting, mixing, emulsifying in one machine for high efficient product without product losses.

Firex CUCIMIX Roasting and caramelizing nuts.

Technical Data

Type Firex CUCIMIX 30 Firex CUCIMIX 70 Firex CUCIMIX 130 Firex CUCIMIX 180 Firex CUCIMIX 310

Dimensions Length 880 1080 1445 1655 1755

Width 677 715 1290 1505 1560

Height 970 940 1030 1030 1030

Power Electric 6.2 kW 9.6 kW 13.5 kW 21 kW 29 kW

Gas n.a. 16 kW 22 kW 33 kW 49 kW

Pan Ø 450 600 700 900 1000

Capacity Lt 30 70 135 190 320

Volume/batch kg 10 18 22 35 60

1

2Technical Data

Type UMC 5 UM 12 UM 24 UM 44 UM 74 UM 130 UM 200

Bowl content l 5 12 30 45 75 130 200

Batch max. l 0.5–2.5 2.5–7 7–18 18–30 30–55 55–90 90–170

Throughput Paste (300 µm) kg/h 2–8 8–20 20–40 40–60 60–80 80–200 200–340

Praliné (300 µm) kg/h 3–15 15–40 40–100 100–180 180–330 330–540 540–1020

13

FrymaKorumaPut the ground nuts from the Stephan UM into the dosing funnel which is installed above the mill inlet. The rotor element turns against the fixed stator at high speed. The product is ground between two corundum stone disks. The milling gap adjustment also allows the stator to be pressed against the rotor with the required pressure.

FrymaKorumaThe opportunity to grind up to 25 µm on your CoBall Mill allows you to achieve an even finer paste than ever before. Aim for the smoothest nut paste efficiently and to your own recipes with your personal touch.

FrymaKoruma MSGet the smoothest paste &

praliné spreads up to 25 µm.

FrymaKoruma MKGrinding:

Paste up to 50 µmPraliné up to 180 µm

3

4

Technical Data

Type MK 95 MK 160 MK 180 MK 250 MK 320

Installed power kW 5.5 11 22 30 45

Dimensions Length mm 680 1030 1030 830 830

Width mm 540 540 540 670 600

Height mm 360 620 620 1000 1220

Weight, approx. kg 100 200 200 400 650

Throughput Paste (50 µm) kg/h 10–50 50–150 150–300 300–600 600–800

Praliné (180 µm) kg/h 10–40 40–125 125–250 250–400 400–550

Technical Data

Type MS 12 MS 18 MS 32 MS 50 MS 65

Grinding chamber volume l 0.5 1 3 8 26

Installed power, approx. kW 3–4 7.5–11 22–37 45–55 75

Dimensions Length mm 885 1160 1560 1800 2320

Width mm 515 1035 1140 1200 1540

Height mm 775 1633 1855 2070 2730

Weight, approx. kg 160 400 800 1750 3100

Throughput Paste (25 µm) kg/h 10–35 35–90 90–250 250–500 500–800

Praliné (25 µm) kg/h 10–20 20–45 45–125 125–250 250–450

14

Stephan Universal MachineUM 200

ÉCLAIRMake all of the various parts of your éclairs on one machine: the choux pastry, the glaçage topping and the flavored cream filling.

MORE ÉCLAIRS: Thanks to the optimization and the perfect mingling of all the ingredients for the choux pastry we learned a new process for 10 % more airy dough creation and a more beautiful baking. It boosts the number of crispy and hollow éclairs with the same ingredients.

FINER ICING: We top the éclair with our self-made ganache glaçage which is more glossier. It is all about the shine of glaçage and the smooth mouthfeel. We aim for the best emulsion.

FILLING: Once our dough is cool and crispy, the pastry is filled with our cream or butter fillings made on our machine. We go for the improved filling and the silky mouthfeel.

ON TOP: In our Firex equipment you can caramelize the nuts to put on top of your personalized éclair.

Technical Data

Type UMSK 24 UMSK 60 UM 130 UM 200

Bowl content l 30 60 130 200

Batch max. l 6–15 15–40 40–90 90–100

Pâte à choux Volume/h 10–80 80–160 160–360 360–680

Crème Filling Volume/h 40–100 100–240 240–540 540–1020

Glaze Volume/h 28–72 72–220 220–360 360–680

Equipment – Accessories Equipment – Optional Features

Main motor Dosing funnel Injection for inert gas via nozzles/direct injection

Condenser unit Parameterprogramming condenser

Discharge valve Heating device

Data recording via USB stick

Liquid dosing

Water dosing device

Vacuum cooling

Double jacketcooling

Special temperingfunctions

Mixing Bafflewall and lid scraper

Double jacketheating

Vacuum pump

VAC

VAC

Stephan Universal MachineUMSK 24 E

15

Technical Data

Type UMSK 24 UMSK 60 UM 130 UM 200 TC 600 TC 850

Bowl content l 30 60 130 200 600 850

Batch max. l 6–15 15–40 40–90 90–100 400 500

Belgian Marzipan kg/h 12–30 30–80 80–180 180–200 800 1000

MARZIPAN & PERSIPANAn “all in one” process for marzipan. The Stephan UM or Combicut helps you to make a fine and tasty marzipan product with a smooth and perfect mouthfeel.

THE STEPHAN PRINCIPLE – Our specially shaped working tools combined with the unique bowl geometry results in quick and enhanced mixing of the ingredients. The ProXES Belgium Knowledge Centre is where we combine fundamental ingredient knowledge and strong partnership with the craftsman and the confectionery industry. The ProXES Belgium Knowledge Centre stimulates the development and optimization of innovative tasty products and processes to encourage the export potential of our producers.

Stephan Universal MachineUMSK 24 E

Stephan Combicut

How it works: vacuum condensing

Oxygen and water

with water without water

Equipment – Accessories Equipment – Optional Features

Main motor Dosing funnel Injection for inert gas via nozzles/direct injection

Heating deviceDouble jacketcooling

Mixing Bafflewall and lid scraper

Double jacketheating

Vacuum pump

Condenser unit

Parameterprogramming condenser

Data recording via USB stick

Liquid dosingWater dosing device

Vacuum coolingVACSpecial temperingfunctions

VAC

14

Stephan Universal MachineUM 200

ÉCLAIRMake all of the various parts of your éclairs on one machine: the choux pastry, the glaçage topping and the flavored cream filling.

MORE ÉCLAIRS: Thanks to the optimization and the perfect mingling of all the ingredients for the choux pastry we learned a new process for 10 % more airy dough creation and a more beautiful baking. It boosts the number of crispy and hollow éclairs with the same ingredients.

FINER ICING: We top the éclair with our self-made ganache glaçage which is more glossier. It is all about the shine of glaçage and the smooth mouthfeel. We aim for the best emulsion.

FILLING: Once our dough is cool and crispy, the pastry is filled with our cream or butter fillings made on our machine. We go for the improved filling and the silky mouthfeel.

ON TOP: In our Firex equipment you can caramelize the nuts to put on top of your personalized éclair.

Technical Data

Type UMSK 24 UMSK 60 UM 130 UM 200

Bowl content l 30 60 130 200

Batch max. l 6–15 15–40 40–90 90–100

Pâte à choux Volume/h 10–80 80–160 160–360 360–680

Crème Filling Volume/h 40–100 100–240 240–540 540–1020

Glaze Volume/h 28–72 72–220 220–360 360–680

Equipment – Accessories Equipment – Optional Features

Main motor Dosing funnel Injection for inert gas via nozzles/direct injection

Condenser unit Parameterprogramming condenser

Discharge valve Heating device

Data recording via USB stick

Liquid dosing

Water dosing device

Vacuum cooling

Double jacketcooling

Special temperingfunctions

Mixing Bafflewall and lid scraper

Double jacketheating

Vacuum pump

VAC

VAC

Stephan Universal MachineUMSK 24 E

15

Technical Data

Type UMSK 24 UMSK 60 UM 130 UM 200 TC 600 TC 850

Bowl content l 30 60 130 200 600 850

Batch max. l 6–15 15–40 40–90 90–100 400 500

Belgian Marzipan kg/h 12–30 30–80 80–180 180–200 800 1000

MARZIPAN & PERSIPANAn “all in one” process for marzipan. The Stephan UM or Combicut helps you to make a fine and tasty marzipan product with a smooth and perfect mouthfeel.

THE STEPHAN PRINCIPLE – Our specially shaped working tools combined with the unique bowl geometry results in quick and enhanced mixing of the ingredients. The ProXES Belgium Knowledge Centre is where we combine fundamental ingredient knowledge and strong partnership with the craftsman and the confectionery industry. The ProXES Belgium Knowledge Centre stimulates the development and optimization of innovative tasty products and processes to encourage the export potential of our producers.

Stephan Universal MachineUMSK 24 E

Stephan Combicut

How it works: vacuum condensing

Oxygen and water

with water without water

Equipment – Accessories Equipment – Optional Features

Main motor Dosing funnel Injection for inert gas via nozzles/direct injection

Heating deviceDouble jacketcooling

Mixing Bafflewall and lid scraper

Double jacketheating

Vacuum pump

Condenser unit

Parameterprogramming condenser

Data recording via USB stick

Liquid dosingWater dosing device

Vacuum coolingVACSpecial temperingfunctions

VAC

16

Technical Data

Type UMC 5 UM 12 UM 24 UM 44 UM 74 UM 130 UM 200

Bowl content l 5 12 30 45 75 130 200

Batch max. l 0.5–2.5 2.5–7 7–18 18–30 30–55 55–90 90–170

Volume l/h 2–8 8–20 20–40 40–60 60–80 80–200 200–340

CAKE & WAFFLEAn all-in one process to produce perfect waffles and all cake ranges.

Stephan Universal MachineUM 74 E

Stephan Universal MachineUM 200

The Stephan Universal Machines economize your production. The improved gluten-processing and the new process generates the possibility to make finer waffles and 10 % more volume of cake with the same amount of ingredients. Our process goes for a better binding of the gluten in the dough. The display offers a clear and general overview of your parameters, e. g. temperature, shear, air contact, timing and speed. Last but not least, our team is specialized in turnkey solutions.

Equipment – Accessories Equipment – Optional Features

Main motor Dosing funnel Injection for inert gas via nozzles/direct injection

Condenser unit Parameterprogramming condenser

Discharge valve Heating device

Data recording via USB stick

Liquid dosing

Water dosing device

Vacuum cooling

Double jacketcooling

Special temperingfunctions

Mixing Bafflewall and lid scraper

Double jacketheating

Vacuum pump

VAC

VAC

17

Technical Data

Type UM 44 UM 130

Bowl content 45 130

Ciabatta kg/h 10–200 75–450

Bread kg/h 10–200 75–450

Sandwiches kg/h 10–200 75–450

Pistolets kg/h 10–200 75–450

Toast bread kg/h 10–200 75–450

Baguette kg/h 10–200 75–450

Stephan Universal MachineUM 130

DOUGHAn all-in one process to produce a perfect dough with the perfect mouthfeel. We offer a solution for an improved rising of the dough with an optimized binding of gluten in 150 seconds.

Bread Sandwiches Pistolets Ciabatta Puff pastry Crumble dough Viennoiserie

Equipment – Accessories Equipment – Optional Features

Main motor Dosing funnel Injection for inert gas via nozzles/direct injection

Condenser unit Parameterprogramming condenser

Discharge valve Heating device

Data recording via USB stick

Liquid dosing

Water dosing device

Vacuum cooling

Double jacketcooling

Special temperingfunctions

Mixing Bafflewall and lid scraper

Double jacketheating

Vacuum pump

VAC

VAC

16

Technical Data

Type UMC 5 UM 12 UM 24 UM 44 UM 74 UM 130 UM 200

Bowl content l 5 12 30 45 75 130 200

Batch max. l 0.5–2.5 2.5–7 7–18 18–30 30–55 55–90 90–170

Volume l/h 2–8 8–20 20–40 40–60 60–80 80–200 200–340

CAKE & WAFFLEAn all-in one process to produce perfect waffles and all cake ranges.

Stephan Universal MachineUM 74 E

Stephan Universal MachineUM 200

The Stephan Universal Machines economize your production. The improved gluten-processing and the new process generates the possibility to make finer waffles and 10 % more volume of cake with the same amount of ingredients. Our process goes for a better binding of the gluten in the dough. The display offers a clear and general overview of your parameters, e. g. temperature, shear, air contact, timing and speed. Last but not least, our team is specialized in turnkey solutions.

Equipment – Accessories Equipment – Optional Features

Main motor Dosing funnel Injection for inert gas via nozzles/direct injection

Condenser unit Parameterprogramming condenser

Discharge valve Heating device

Data recording via USB stick

Liquid dosing

Water dosing device

Vacuum cooling

Double jacketcooling

Special temperingfunctions

Mixing Bafflewall and lid scraper

Double jacketheating

Vacuum pump

VAC

VAC

17

Technical Data

Type UM 44 UM 130

Bowl content 45 130

Ciabatta kg/h 10–200 75–450

Bread kg/h 10–200 75–450

Sandwiches kg/h 10–200 75–450

Pistolets kg/h 10–200 75–450

Toast bread kg/h 10–200 75–450

Baguette kg/h 10–200 75–450

Stephan Universal MachineUM 130

DOUGHAn all-in one process to produce a perfect dough with the perfect mouthfeel. We offer a solution for an improved rising of the dough with an optimized binding of gluten in 150 seconds.

Bread Sandwiches Pistolets Ciabatta Puff pastry Crumble dough Viennoiserie

Equipment – Accessories Equipment – Optional Features

Main motor Dosing funnel Injection for inert gas via nozzles/direct injection

Condenser unit Parameterprogramming condenser

Discharge valve Heating device

Data recording via USB stick

Liquid dosing

Water dosing device

Vacuum cooling

Double jacketcooling

Special temperingfunctions

Mixing Bafflewall and lid scraper

Double jacketheating

Vacuum pump

VAC

VAC

18

CARAMELAn all-in one process to produce perfect delicious soft or hard sweet caramel with a smooth and silky mouthfeel.

We offer solutions which can optimise processes and working times without crystallization. Thanks to the Firex designs and principles. Batch sizes range from 6 litres to 180 litres.

Firex CUCIMIX Firex CUCIMIX

Technical Data

Type Firex CUCIMIX 30

Firex CUCIMIX 70

Firex CUCIMIX 130

Firex CUCIMIX 180

Firex CUCIMIX 310

Dimensions Length 880 1080 1445 1655 1755

Width 677 715 1290 1505 1560

Height 970 940 1030 1030 1030

Power Electric 6.2 kW 9.6 kW 13.5 kW 21 kW 29 kW

Gas n.a. 16 kW 22 kW 33 kW 49 kW

Pan Ø 450 600 700 900 1000

Capacity Lt 30 70 135 190 320

Volume/batch 6/15 15/35 30/65 40/90 70/155

Volume/hour 30 70 130 180 310

19

JAM & PÂTE DE FRUITSAn all-in one process to produce perfect delicious sweet jams and pâtes de fruits with an improved taste and texture.

We offer solutions for optimized stirring and creating jams without the crystallization of sugar. Economize your production with our principles of easy cleaning and faster processing. We offer fast and easy working thanks to the design and the principles of our method which is flexible for a range of batch sizes.

Firex CUCIMIX Firex CUCIMIX

Technical Data

Type Firex CUCIMIX 30

Firex CUCIMIX 70

Firex CUCIMIX 130

Firex CUCIMIX 180

Firex CUCIMIX 310

Dimensions Length 880 1080 1445 1655 1755

Width 677 715 1290 1505 1560

Height 970 940 1030 1030 1030

Power Electric 6.2 kW 9.6 kW 13.5 kW 21 kW 29 kW

Gas n.a. 16 kW 22 kW 33 kW 49 kW

Pan Ø 450 600 700 900 1000

Capacity Lt 30 70 135 190 320

Volume/batch 6/17 15/40 30/70 40/100 70/180

Volume/hour 40 80 140 200 360

18

CARAMELAn all-in one process to produce perfect delicious soft or hard sweet caramel with a smooth and silky mouthfeel.

We offer solutions which can optimise processes and working times without crystallization. Thanks to the Firex designs and principles. Batch sizes range from 6 litres to 180 litres.

Firex CUCIMIX Firex CUCIMIX

Technical Data

Type Firex CUCIMIX 30

Firex CUCIMIX 70

Firex CUCIMIX 130

Firex CUCIMIX 180

Firex CUCIMIX 310

Dimensions Length 880 1080 1445 1655 1755

Width 677 715 1290 1505 1560

Height 970 940 1030 1030 1030

Power Electric 6.2 kW 9.6 kW 13.5 kW 21 kW 29 kW

Gas n.a. 16 kW 22 kW 33 kW 49 kW

Pan Ø 450 600 700 900 1000

Capacity Lt 30 70 135 190 320

Volume/batch 6/15 15/35 30/65 40/90 70/155

Volume/hour 30 70 130 180 310

19

JAM & PÂTE DE FRUITSAn all-in one process to produce perfect delicious sweet jams and pâtes de fruits with an improved taste and texture.

We offer solutions for optimized stirring and creating jams without the crystallization of sugar. Economize your production with our principles of easy cleaning and faster processing. We offer fast and easy working thanks to the design and the principles of our method which is flexible for a range of batch sizes.

Firex CUCIMIX Firex CUCIMIX

Technical Data

Type Firex CUCIMIX 30

Firex CUCIMIX 70

Firex CUCIMIX 130

Firex CUCIMIX 180

Firex CUCIMIX 310

Dimensions Length 880 1080 1445 1655 1755

Width 677 715 1290 1505 1560

Height 970 940 1030 1030 1030

Power Electric 6.2 kW 9.6 kW 13.5 kW 21 kW 29 kW

Gas n.a. 16 kW 22 kW 33 kW 49 kW

Pan Ø 450 600 700 900 1000

Capacity Lt 30 70 135 190 320

Volume/batch 6/17 15/40 30/70 40/100 70/180

Volume/hour 40 80 140 200 360

Let’s Choc the world together

phone +32 9 [email protected]

Mr Simon Meyer is our chocolate specialist who will advise you on how to improve your processes and product quality. He utilises his vast knowledge and rich expertise earned whilst working with small artisanal companies through to the world’s largest and renowned chocolate houses!

With his expert level of knowledge and craftsmanship in chocolate creations, combined with his hands-on expe-rience and realisation of the ProXES machinery range, he will optimise your products to sheer perfection.

01/2

019

– R

ev. I

I Al

l con

tent

is s

ubje

ct to

cop

yrig

ht a

nd is

ow

ned

and

cont

rolle

d by

Pro

XES.

The

con

tent

may

not

be

copi

ed, s

tore

d (in

any

med

ium

), pu

blis

hed

or o

ther

wis

e re

dist

ribu

ted

with

out t

he p

erm

issi

on o

f Pro

XES.

Get in touch with our dedicated pastry technologists team for all your desired solutions and knowledge of specialized pastry manufacturing.

!GET CHOC'ED

UNIQUE CODE FOR

FREE* TRAINING DAY

by Simon Meyer

*by purchasing ProXES equipment