The Pasteurization Process

Transcript of The Pasteurization Process

8/9/2019 The Pasteurization Process

http://slidepdf.com/reader/full/the-pasteurization-process 1/20

The Pasteurization Process

A Brief History:

Though not as well-known as the man who gave his name to this process, Italian

biologist Lazzaro Spallanzani (1729-1799, right) laid the groundwork for germtheory by showing that microbes do not just 'appear' spontaneously.

His early work with the heat sterilization of food in the 1760's formed the basis

for research done by French chemist Louis Pasteur (1822-1895) nearly a century

later.

In the 1850's, Pasteur (below, right) began to examine why products like wine and beer

sometimes went sour during the fermentation process. This led to his discovery that the

souring was caused by certain unwanted strains of bacteria and yeast, or 'germs,' as he called

them.

Taking a cue from Spallanzani, he found that heating below boiling, then rapidlycooling wine, killed the spoilage organisms busily trying to turn it into vinegar.This heat sterilization process, dubbed 'pasteurization' (not 'pasture-ization' as

some call it), was first proposed for use on milk in 1886 by German agriculturalchemist Franz von Soxhlet.

The first commercial pasteurization machines came on-line in the mid-1890's and remained

the standard for decades. Recently, ultra-high temperature pasteurization, commerciallyavailable since 1948, has become more common due to the increased shelf-life and total

sterilization it gives milk.

Types of Pasteurization:

There are basically two methods of pasteurization in use today- batch and

continuous flow.

In the batch process (batch pasteurizer, right) , a large quantity of milk is held

in a heated vat at 149°F./65°C. for 30 minutes, followed by quick cooling toabout 39°F./4°C.

In the continuous flow process (continuous flow pasteurizer, below, right)-also known as

HTST, for high temperature, short time, milk is forced between metal plates or through pipes

heated on the outside by hot water.

While flowing under pressure, the milk is held at 161°F/72°C. for at least

16 seconds. Before being chilled back to 39°F./4°C. or cooler, it flows

through a heat exchanger to pre-warm cold milk just entering the system.

Effects of Pasteurization:

8/9/2019 The Pasteurization Process

http://slidepdf.com/reader/full/the-pasteurization-process 2/20

The ultimate goal in heat treating milk is the destruction of all pathogenic or disease-causingmicrobes. Usually (but not always), assuming the machinery is functioning properly, the

process accomplishes this task effectively.

Numerous studies have shown, however, that bad bugs are not the only thing destroyed by

the heat: delicate proteins, enzymes, immune factors, hormones, vitamins, mineral

availability- all undergo definite changes during the heating process. No one seriouslydisputes this fact.

What is not clear though, due to conflicting science and belief systems, is to what extent the

food value of the milk is actually impacted. When man-made nutrients (often inferior to their

natural form) must be added back in to replace those destroyed by heat, there is no argument.

The quality of the milk has suffered.

And who speaks for the hundreds of factors and components present in raw milk, known and

unknown, that synergistically create a whole, healing food?

What truly becomes of raw milk's many natural hormones, immune modulators and enzymes

if, say, certain other key substances designed to assist their proper function are ultimatelydestroyed (and not replaced)?

Is the calcium our bodies absorb from pasteurized dairy somehow altered so that it goes to

places other than needed or wanted? The unanswered questions continue to pile up...

Raw milk is an incredibly complex substance, the science of which we've still only begun totweeze apart. Bear in mind, also, that the majority of milk research from the mid 1940's on

has been, and continues to be, performed using pasteurized product.

There's no question that pasteurization, while far from flawless, is a valuable and necessary

process, especially where factory-farmed milk is concerned, but the ability to buy andconsume clean, living foods with their myriad bits and pieces intact should also be an option

for those who so choose.

Not All Raw Milk Is The

Same!

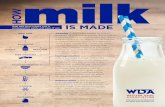

How can that be? It all comes from cows, right? Yes, but

that's where the similarity ends. The truth is, there are actuallytwo types of raw milk here in America: the one meant to be

consumed directly from the cow, and the one that absolutelymust be pasteurized first due to the conditions under which it

was produced.

The ideal raw milk is taken straight from animals fed only

fresh, organic, green grass, rapidly cooled to somewhere

around 36-38 degrees F., and bottled. That's it. No processing,

8/9/2019 The Pasteurization Process

http://slidepdf.com/reader/full/the-pasteurization-process 3/20

just filtration, and cooling. Most milk produced today undergoes some form of processing before it reaches the consumer.

Diet is a major factor in the quality of raw milk. Studies have shown that over-feeding

starchy grains can affect the acidity of the cow's stomach environment and change fat and

nutrient levels (1,2).

Raw milk from cows fed a large component of grain is just not as optimal a food as grass-fed

and lacks many of milk's self-protective properties. Milk like this, potentially more easily

contaminated, should be tested regularly, as should all raw milk, for that matter.

Many non-grass foods (such as soy and alfalfa) contain compounds that mimic the actions of the female hormone, estrogen (3). While these can cause cows to produce more milk than

they normally would (and thus increase profit per animal), some studies have called intoquestion possible impacts on animal health and nutrient content of the milk.

Cows are ruminants, with a complex digestive system designed to break down cellulose, a

type of structural sugar indigestible to humans, and other substances found in the cell walls of

grasses and other green plants they're likely to encounter while grazing.

Prior to the advent of organized agriculture about 10,000 years ago, there simply weren't

fields of grain growing wild, upon which animals could munch. As mentioned above, a heavy

starch load of grain can alter the usual conditions in a cow's rumen (stomach) and affect the

composition of its milk.

Milk from grass-fed cows has amazing properties, one of which is the

presence of naturally produced antimicrobials in solution (5). Another is

the production of a beneficial fatty acid known as CLA, short for

Conjugated Linoleic Acid (6,7).

Countless studies have shown that CLA has many potential health benefits. For comparison,

grain-fed cows have as little as one fifth the CLA in their milk as grass-fed (8).

Some raw milk can make you very, very ill. Drinking milk destined for the pasteurizer before

it's sterilized can be like playing Russian roulette, but with ALL the barrels loaded. Why?

Mainly because cleanliness standards are far lower for milk which will eventually be heat

treated.

In large operations, there simply isn't enough open pasture land to contain and grass-feed

hundreds of animals, so they're often confined in manure-laden pens.

Supercows, bred for hyperactive pituitary glands or injected with stimulant hormones (suchas Posilac) produce an elevated quantity (as high as 13 gallons) of milk daily, leading to

inflamed teats. This condition, known as mastitis, pumps high numbers of white blood cells,

or pus, into the milk (9).

Supercows don't live nearly as long as naturally bred animals- perhaps they're lucky in that

respect...

8/9/2019 The Pasteurization Process

http://slidepdf.com/reader/full/the-pasteurization-process 4/20

Add the potential of toxic drug residues, antibiotics, larvicides (10), pesticides (11,12),fertilizers and heavy metals (13) and you have quite a witches brew. Many of the outbreaks

of food related illnesses blamed on raw milk can be traced to just such product somehow bypassing the pasteurization process.

You can see why humans have no business consuming raw milk produced by the large

factory farm complexes that dominate the industry today. It's simply not safe for humanconsumption before it's processed.

The role of unclean raw milk in human illness is undeniable. Knowing that not all raw milk is

the same is the first step in knowing which questions to ask when you seek it out for yourself

and your family. In the following clip, Dr. William Campbell Douglass sheds more light on

how to inform yourself about raw milk and nutrition.

What's in Raw Milk?

Just what is in raw milk? Think of it is as an oil/water emulsion.

It's also known in some circles as a colloidal suspension.

To make every gallon of milk, a cow must pump from 600-800

gallons of blood through her udder. Think of that next time you

pour yourself a glass. That cow poured her heart into it!

Whole raw milk's composition varies slightly among cow species,

type of food and other conditions, so the figures below (and, at

right, from a commercial raw milk dairy) are only

approximations.

Here's a rough breakdown in percent of total volume:

Water 87.3%

Milk Fats 3.9%

Non-fat Solids (Protein, Milk Sugar, Immune Factors, etc.) 8.8%

8/9/2019 The Pasteurization Process

http://slidepdf.com/reader/full/the-pasteurization-process 5/20

A. Casein Proteins (~80% of Total Milk Protein-TMP)1. Alpha s1 [30.6%]

2. Alpha s2 [8.0%]

3. Beta [28.4%]

4. Kappa [10.1%]B.Whey Proteins (~20% of TMP)

1. Alpha lactalbumin [3.7%]2. Beta lactoglobulin [9.8%]

3. Bovine Serum Albumin (BSA) [1.2%]4. Immuoglobulins [2.1%]

5. Proteose peptone [2.4%]

Milk Sugar (Lactose) 4.6%

Minerals 0.65%

Calcium

Phosphorus

Magnesium

Potassium

Sodium

Zinc

Chlorine

Iron

Copper

SulfatesBicarbonates

Trace Elements

Acids 0.18%Citric

FormicAcetic

8/9/2019 The Pasteurization Process

http://slidepdf.com/reader/full/the-pasteurization-process 6/20

LacticOxalic

Vitamins/Enzymes 0.12%

Raw Milk Fats:

Few words are as highly charged in the food world as "fat." Perhaps "lipid" would be a better

word. Please see my Fat Primer for images and more information on this wonderful, energy-laden food group.

In milk, more than 95% of the fats form into spherical shaped objects called globules from

0.1 to 15 microns in diameter (that's pretty tiny- a micron is a millionth of a meter, or roughly

25,400 to the inch.)

Just over 98% of the lipids in milk are in the class known as triglycerides- a glycerol

molecule (glycerin) with three fatty acids (of various lengths and saturations) attached. There

are ten major fatty acids found in milk to varying degree:

Butyric Acid 4 (# of Carbon atoms)

Caproic Acid 6Caprylic Acid 8

Capric Acid 10

Lauric Acid 12

Myristic Acid 14

Palmitic Acid 16

Stearic Acid 18

Oleic Acid 18:1 (one double bond)

CLA 18:2 (two double bonds)

8/9/2019 The Pasteurization Process

http://slidepdf.com/reader/full/the-pasteurization-process 7/20

Milk also contains cholesterol, another controversial and dreaded word. For the most part, it'slocated in the cores of fat globules, and amounts to roughly 0.3% of all milk lipids. The less

we get in our diets, the more our bodies make on their own. Check out my Cholesterol Primer to get the straight scoop on why this much-maligned substance is essential to our health.

Raw Milk Proteins:

Proteins are complex molecules comprised of long chains of amino acids. Depending on

interactions between some of the amino acids, the molecules can twist into helical formations

or pleated sheets (secondary structure). Tertiary proteins undergo further coiling and folding.

When clustered together somewhat spherically, they are known as globular proteins. Fibrous

tertiary proteins are formed when two or more long strands of amino acids form links along

their length.

The caseins, normally highly digestible in the intestinal tract, are relatively heat stable. Being

secondary in structure, and so without much complex structure to unravel, they survive the

heat of pasteurization (145-160 deg. F.) fairly well. After ultra-high temperature (UHT)

pasteurization (280-305°F./138-152°C.) their fate is uncertain.

The whey proteins,including the immunoglobulins, are very sensitive to heat (heat labile) and

denature well below the heat of normal pasteurization.

Incidentally, the denaturation of whey protein affects the whiteness of milk. Milk gets whiter

after it's processed.

By the way, did I mention that not all raw milk is the same? It's not. Check my About Raw

Milk page to find out why.

Milk Sugar:

Lactose, the first carbohydrate most baby mammals ever taste, is actually made up of two

simple sugars, glucose and galactose, making it a disaccharide. Cow's milk hovers at around

5% lactose (human milk averages a bit higher at just over 7% by comparison). It's got a fairly

low glycemic index (doesn't boost insulin levels very quickly) and so is better tolerated by

diabetics.

As some people age, their levels of lactase, the enzyme needed to digest lactose, drop

significantly. When they consume heat treated dairy products with no remaining food enzyme

activity, they lack sufficient lactase to break the milk sugar down, and suffer numerous

unpleasant symptoms, notably gas and bloating. Not fun. But raw milk, with live, friendly

lactobacilli, has its bacterially-produced lactase intact, so chances are good these folks may

be able to tolerate it.

Another way to enjoy the benefits of dairy with almost none of the lactose, is to eat fermented

products such as yogurt and kefir . The friendly microbes, during the fermentation process,

have consumed pretty much all the lactose, turning it into the sour tasting lactic acid that's

such a powerful antimicrobial agent.

Raw milk cheeses are another tasty way to enjoy dairy without the lactose. Again, most of the

lactose is consumed in the fermentation process.

8/9/2019 The Pasteurization Process

http://slidepdf.com/reader/full/the-pasteurization-process 8/20

Minerals in Raw Milk:

The mineral content of milk varies with a host of conditions as well. Soil quality,

geographical location, species of cow, health of the animal- all these factors and more come

into play.

Accesibility to raw milk's mineral content is dependent upon its enzymes and other factors

remaining functional. Here are some approximate values for mineral levels in the average

quart of raw milk:

Mineral Content per quart (Typical range):

Sodium__330-850mg

Potassium__1040-1600mg

Chloride__850-1040mg

Calcium__1040-1225mg

Magnesium__85-130mg

Phosphorus__850-940mgIron__280-570ug

Zinc__1880-5660ugCopper__95-570ug

Manganese__19-47ugIodine __~245ug

Fluoride__28-207ugSelenium__4.7-63ug

Cobalt__0.47-1.23ug

Chromium__7.5-12.3ug

Molybdenum__17-113ug

Nickel__0-47ug

Silicon__700-6600ug

Vanadium__trace-290ug

Tin__38-470ug

Arsenic__19-57ug

Vitamins in Raw Milk:

Raw milk contains every known fat and water soluble vitamin. To get them all, make sure

you drink whole raw milk or you'll miss those lost in the skimming process.

Vitamin C levels, already fairly low in cow's milk (typically less than 20mg/quart- about half

the level found in human milk), have been shown to drop further when exposed to ultravioletlight such as from sunlight or fluorescently lights. Store it in the dark at home, and ask your

store to look into UV filters for their cold-case lights. Here are some approximate but typical

amounts of vitamins found in raw milk:

Vitamin Content per quart (Approximate):

A__375ug

C__19mg

8/9/2019 The Pasteurization Process

http://slidepdf.com/reader/full/the-pasteurization-process 9/20

D__38IUE__940ug

K__47ugB1__425ug

B2__1650ug

Niacin__850ug

B6__470ugPantothenic acid__3300ug

Biotin__33ug

Folic acid__52ug

B12__4.25ug

Enzymes in Raw Milk:

Yet another controversial topic, and important enough to deserve a website all its own, the

enzymes in raw milk are crucial in making it the valuable healing food it is.

The arguments range from their having no digestive benefit because they can't withstand the

acid environment of the stomach, to outright denial of their existence.

No one can truthfully or knowingly deny that these powerful but fragile protein-basedsubstances are in milk for a purpose. Getting people to agree on that purpose is another

matter entirely!

To understand their importance, it's helpful to know what enzymes are, and what they do in

foods and in our bodies.

Basically, enzymes are complex forms of protein (made out of amino acids) that can change

(catalyze) other substances without taking part in the reaction themselves. In digestion, for

instance, they help break down starches, fats and proteins into chunks the body can use.

Here's a list of the more important enzymes in raw milk:

AmylaseCatalase

Lactase-(through bacterial synthesis)Lactoperoxidase

LipasePhosphatase

8/9/2019 The Pasteurization Process

http://slidepdf.com/reader/full/the-pasteurization-process 10/20

More About Enzymes

Enzymes are complex proteins that facilitate, catalyze or speed up chemical reactions. The

precise order of amino acids in the proteins from which they're made determines their shape,

and their shape determines their function.

Typically, each enzyme does just one thing, so there are just about as many enzymes as there

are different things for them to do. Without taking part themselves, they make possible

hundreds of thousands of processes in our bodies: they can chop things up (hydrolases), put

things together (ligases), split double bonds between atoms (lyases), and move chemical

groups from molecule to molecule (transferases). If it's a biochemical reaction, there's an

enzyme involved.

Enzymes have a life-span, just like other living things. Some only live for twenty minutes or

so, while others can live for many weeks before some other enzyme comes along and sealstheir fate.

The slowest-acting known enzyme, lysozyme (an anti-bacterial enzyme found in raw milk),can process about thirty molecules a minute. Pretty fast, but compared to carboanhydrase, a

600,000 molecules/second speed demon, it's just an amateur... I'll bet the quick one is the

twenty minute wonder mentioned above!

Every living organism needs enzymes to survive. Without them life would pretty much be

impossible: the wrong substances would be made, reactions would happen too slowly- in

other words, without enzymes, you'd die. And speaking of death, enzymes play a role there,

too.

All plant and animal cells contain little sacs of digestive enzymes called lysosomes. When thecells die, these bags eventually break open and self-digestion begins. We know it as decay,

but you can, say, throw the chicken or fish into the fridge and stave things off for a bit.

So now you know about food's own complement of digestive enzymes that help our bodies

break it down. Heating food above 118°F./48°C. destroys most of these natural helpers,

forcing us to make our own digestive enzymes to get at the nutrients. Having to make our

own digestive enzymes puts an extra burden on our pancreas, which is typically busy enough

with other metabolic needs.

I consider food enzymes to be right next to proteins, carbohydrates and fats, in importance. A

fourth major food group, if you will. The late enzyme expert, Dr. Edward Howell, believed

that life-span was related to the rate at which an organism's enzyme potential was exhausted.

He felt the increased use of food enzymes (either from raw foods or supplements) reduced therate of enzyme potential exhaustion.

Raw milk, especially that from grass-fed cows, has a full complement of the very food

enzymes Dr. Howell held in such high regard. The short list below is far from

comprehensive, and by no means implies that everyone is on the same page regarding

enzymes.

8/9/2019 The Pasteurization Process

http://slidepdf.com/reader/full/the-pasteurization-process 11/20

This much is certain, though: heating milk substantially above the body temperature of a cowundeniably causes changes in its ingredients. Higher heat = more changes. Unwanted changes

or not depends on who you ask and who pays his or her salary.

AMYLASE:

An ingredient in saliva and pancreatic juice as well as raw milk , amylase breaks down starch,glycogen and other related carbohydrates. It's also the most commonly found enzyme in

plants, particularly abundant in sweet potato, corn and starchy grains like oats, wheat and

barley. It appears to be inactivated by the pasteurization/homogenization processes.

CATALASE:

Involved with waste management on the cellular level, catalase rids cells of hydrogen peroxide (H2O2), an unwanted by-product of cellular metabolism. A strong oxidizer, H2O2

can wreak havoc in the cellular environment. Catalase quickly locks onto it and cleaves it intooxygen and water. It appears to be inactivated at temperatures above 158° F./70°C.

LACTASE:

Lactase (a member of the beta-galactosidase group of enzymes) splits milk sugar (lactose)

into the two simple sugars glucose and galactose. Found exclusively in mammalian milk,

lactose is only one sixth as sweet as cane or beet sugar (sucrose).

Many people lose the ability to make lactase as they mature, so must either get it in their food

or take supplements to avoid unpleasant side effects (lactose intolerance). Other folks, from

regions in Europe, Africa, India and the Middle East, through a helpful genetic mutation,

produce the enzyme in their intestinal tracts, even as adults. The lactase in raw milk, present

from bacterial synthesis, appears to be inactivated by the pasteurization/homogenization

processes.

LACTOPEROXIDASE:

Identical to the peroxidase found in saliva and gastric juice, lactoperoxidase teams up with

two other substances found in varying levels in milk (oxidized thiocyanate and hydrogen

peroxide) to form an antimicrobial complex. I'd imagine there's tough competition from

catalase for any free hydrogen peroxide floating around...

Lactoperoxidase appears to be fairly heat resistant at normal pasteurization temperatures

(roughly 50% is inactivated in milk held at 158° F./70°C. for 20 minutes) but is completely

inactivated at 176°F./80°C. in just 5 minutes. Lysozyme, the anti-microbial slow-poke

mentioned above, is present in much lower quantities than lactoperoxidase.

LIPASE:

Actually a class of water-soluble enzymes, lipases break down fats (triglycerides) into fatty

acids, and improve utilization of lipids throughout the body. Disruption of the fat globules, as

in homogenization, can lead to rancidity if lipase isn't destroyed first. Pasteurization makes

short work of it. It's normally inactive in raw milk until triggered by the proper pH in the

digestive tract.

8/9/2019 The Pasteurization Process

http://slidepdf.com/reader/full/the-pasteurization-process 12/20

PHOSPHATASE:

A key enzyme in accessing two of milk's important minerals, phosphorus and calcium, phosphatase hydrolyses (breaks down with water) complex compounds in milk (called

phosphate esters) to release phosphorus ions. Optimal calcium absorption is dependent on

proper ratios of phosphorus and magnesium.

Phosphatase is completely destroyed at the lowest typical pasteurizing temperatures (which

are also the highest needed to kill pathogenic bacteria). Food processors test for the total

absence of phosphatase to determine if pasteurization was successful. Presumably, its

absence also makes getting phosphorus and calcium out of the milk more difficult for our

bodies.

The Fat Primer

If you're afraid of butter, use cream.

-Julia Child (1912-2004)

The subject of fats is downright confusing, no doubt about it. My aim with the Fat Primer is

to take some of the mystery out of this high energy food group (9 calories/gram, 28g/ounce!)

by giving you a basic, easy to grasp look at the world of fat.

To understand fats, you need to be willing to endure a little bit of chemistry. Don't worry! I'll

keep it simple and use lots of pictures. Many apologies in advance to my chemistry profs for

leaving out so many details!

Let's start with the raw materials for all fats: carbon, hydrogen and oxygen. Certain atoms can

hold on to, or 'bond' with other elements. Carbon, for instance, has 4 bonds available. Oxygen

has two, hydrogen, only one.

Seems simple enough, but what a dizzying array of things you can make with just these three simple

elements! We'll stick with the fats for now, though, and consider one last thing about carbon. Two

carbon atoms next to each other can share either one or two bonds in the fats you're likely to find in

raw milk:

8/9/2019 The Pasteurization Process

http://slidepdf.com/reader/full/the-pasteurization-process 13/20

The type of bond determines the number of hydrogens each carbon can hold. The two carbons to

the left, above, held together by a single bond, are said to be 'saturated' because they're holding all

the hydrogens they can. That's all saturated means. Nothing to do with being wet!

The two carbons above on the right, connected by a double bond, are 'unsaturated' becauseeach could possibly hold on to one more hydrogen if they weren't busy being so friendly with

one another.

Because of the interactions of adjacent atoms, fatty acids with only single bonds tend to be

straight and more stable than those with double bonds.

Molecules tend to kink where there's a double bond- the main reason saturated fats like butter

and lard are solids at room temperature (the straight chains fit together tightly), and vegetable

oils with their multiple double bonds are liquids (the kinks keep them from packing as

closely)- think of uncooked, parallel spaghetti vs. elbow macaroni, for instance.

The building blocks of all fats are called fatty acids. Simply put, they're chains of carbon

atoms connected like beads on a string, with hydrogen atoms on each carbon and an acid

(carboxyl) group on one end.

The number of carbon atoms in each fatty acid chain, the type of bonds between the carbons,

and how many hydrogens the carbons are holding on to, all determine the type of fat and itscharacteristics. Fatty acids with one double bond in the chain are called monounsaturated ,

with two or more, polyunsaturated .

8/9/2019 The Pasteurization Process

http://slidepdf.com/reader/full/the-pasteurization-process 14/20

Most fats in our bodies and foods are in the form of 'triglyceride' molecules = one glycerol (or

glycerin, a sugar alcohol) + three fatty acids attached:

High levels of triglycerides in the blood have definitely been linked to the potential for heart disease.

8/9/2019 The Pasteurization Process

http://slidepdf.com/reader/full/the-pasteurization-process 15/20

Their source is not from fats in the diet though, but rather from excess carbohydrates not burned for

energy.

Overeating sugar or white flour products causes a spike in insulin, the hormone which,

besides controlling blood sugar, also triggers the formation of fats destined for storage. The

fats in raw milk aren't the problem. It's the half a bag of chocolate chip cookies you're

dunking in it that's setting you up for circulatory grief...

To complicate things a bit further, and because chemistry wouldn't be chemistry if it didn't

throw the occasional curveball, unsaturated fats can have different shapes or configurationsdepending on which side of the double bond the hydrogens end up.

This concept is important because the shape of the whole triglyceride molecule, and thus it's

properties and characteristics, is affected by what happens at each double bond.

As you can see, in a 'cis' (pronounced 'siss') formation, the hydrogens are on the same side.With 'trans' formations, they're on opposite sides of the double bond. The linear stick and

letter figures I've been using don't really show the true shapes of the cis/trans unsaturatedfatty acids accurately. In actuality, as mentioned above, there's a lot of bending going on

whenever double bonds enter the scene.

8/9/2019 The Pasteurization Process

http://slidepdf.com/reader/full/the-pasteurization-process 16/20

Trans fatty acids have been in the news quite a bit recently, especially now that food manufacturers

have to disclose their presence on package labels, but we have to backtrack a bit to see why.

When vegetable oil processors thought it would be cool to make their products stay solid at

room temperature, like butter and lard, they came up with a process called h ydrogenation

which yielded margarine and shortening. C risco, by the way, of which I must have eaten a

ton in baked goods when I was a kid, is hydrogenated cottonseed or soybean oil.

Nobel Prize winner Paul Sabatier (1854-1941, at right) is considered the father of the

hydrogenation process. He discovered in 1897 that the metal, nickel, catalyzes, or

facilitates, the attachment of hydrogen to carbon compounds.

In the actual process, workers heat the oil to very high temperatures and bubble

hydrogen gas through it in the presence of nickel or some other catalytic metal. Since the vegetable

oils are unsaturated, they can take on a few more hydrogens.

When they do, the molecule stiffens, and the fat is now closer to a solid. They can control just

how firm it gets by how long they pump the gas through. That's why you'll sometimes see theterm 'partially hydrogenated' on ingredient labels.

What also happens during hydrogenation, or later, during high heat cooking with the

processed oils, is the formation of molecules so strangely configured that they're completely

unsuitable for use in our bodies.

As an added bonus, the double bonds in these foreign fatty acids are easily broken, allowing

the formation of free radicals- highly reactive molecules with an unpaired electron, just

looking for something to grab on to.

Promotion of breast cancer, heart disease, diabetes, weakened immune systems and hormonal

dysfunction are just some of the maladies for which studies have implicated these unnatural

trans fats.

The point I'm trying to make in presenting all this information is that, yes, there are bad fats, but there are good fats, as well. Consider that the traditional fats eaten by our ancestors, and

cultures around the world, were more often saturated than not, but that cardiovascular disease

was almost unknown before the introduction of hydrogenated vegetable oils.

Our bodies badly need saturated fats- they make up half or more of our cell walls, they

bolster our immune systems, nourish our heart muscle, carry important fat soluble vitamins

and antioxidants, and, in the case of butter, contain anti-fungal, anti-microbial and anti-cancer

agents.

Here's the good news: the saturated fats in clean, raw milk can do all of that for you, and

much, much more.

8/9/2019 The Pasteurization Process

http://slidepdf.com/reader/full/the-pasteurization-process 17/20

Fatty Acids In The Cow

These are the major fatty acids found either in milk or the cow's rumen. Please see my CLA page for more on that very special fatty acid. Total carbon atoms and double bonds are noted

- for example, C 3:0 means three total carbon atoms, no double bonds. Absence of double bonds indicates total saturation of carbons with hydrogen. The first three are known as the

volatile fatty acids (VFA's):

Acetic Acid (C 2:0):

Propionic Acid (C 3:0):

Butyric Acid (C 4:0):

8/9/2019 The Pasteurization Process

http://slidepdf.com/reader/full/the-pasteurization-process 18/20

Caproic Acid (C 6:0):

Caprylic Acid (C 8:0):

Capric Acid (C 10:0):

Lauric Acid (C 12:0):

8/9/2019 The Pasteurization Process

http://slidepdf.com/reader/full/the-pasteurization-process 19/20

Myristic Acid (C 14:0):

Palmitic Acid (C 16:0):

Stearic Acid (C 18:0):

Oleic Acid (C 18:1):

8/9/2019 The Pasteurization Process

http://slidepdf.com/reader/full/the-pasteurization-process 20/20

Linoleic Acid (C 18:2):