THE NEW ADVANCED TEST RIG CONSTRUCTION

Transcript of THE NEW ADVANCED TEST RIG CONSTRUCTION

11/22/2016 2

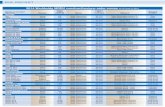

Engine requirements

Cruising

Idling High

Power

A

B C

D

100 0 ma/mamax

f = 1

Rich

Lean

11/22/2016 2

1. Starting or Ideal range.

2. Economy range.

3. Power range.

11/22/2016 3

1. Starting or Ideal range.

the engine required a rich mixture and the F/A ratio must be generally

reduced from this point during warm up period, until engine starts

running normal F/A ratio.

Here: the throttle is almost closed.

2. Economy range.

the engine required a lean mixture and the flame speed is low so that

spark advance should be made especially when load be decrease.

Here: for maximum economy A/F ratio be 16:1.

3. lower range.

the engine required a rich mixture and the throttle valve is fully open.

Note:- For Rich Mixture:-

Flame temperature is reduced --- due to incomplete combustion.

Cylinder temperature is reduced.

Made an internal coolant and prevent valves failure.

11/22/2016 4

The intake system consists of an intake manifold, a throttle, intake valves,

and either fuel injectors or a carburetor to add fuel.

The intake system:-

Air Cleaner

Carburetor

Throttle

Fuel pump Filter

Fuel Tank Fresh Air

for SI engine, the liquid fuel and air are generally mixed outside the engine

and homogeneous mixture of air- fuel vapor enters the engine through the

induction system.

The intake system consists of an intake manifold, a throttle, intake valves,

and either fuel injectors or a carburetor to add fuel.

The intake system:-

11/22/2016 6

• To meter the liquid fuel as required by the engine

• Atomize the fuel and mix it with the air stream

• Enable the engine to run smoothly in all engine operating conditions.

Carburetor Functions

11/22/2016 8

Float chamber:

It is meant for storage of fuel.

.تحافظ على مستوى معين للوقود فاذا ذاد عن حد معين تغلق العوامة•

".الشرقان " فان الوقود ياتى مباشرة من الطرمبة الى الكاربيراتير فيحدث للمحرك مايسمى ب ... اذا فسدت العوامة •

Venture:

It is used to generate the pressure drop required to supply the fuel – air ratio at all

operating conditions.

Throttle Valve:

It is used to control the amount of mixture required by the engine for all operating

conditions.

Note:-

The relation between the throttle valve and pressure drop:

اى ان فرق الضغط يذداد فيذيد Ventureيذداد الفرق فى الضغط الموجود عند ال Throttleكلما ذادت فتحة ال

.كمية الهواء و الوقود المسحوبة

11/22/2016 9

Simple Carburetor problems

• Idling circuit

• Acceleration (Response time)

• Chock (Cold starting)

Simple Carburetor

For meeting the demand of the engine under all conditions of operation.

The following additional devices are added to the simple carburetor:-

Main metering system

Idling system

Power enrichment or economizer system

Acceleration pump system

choke

11/22/2016 10

Main metering system:-

The main metering system of carburetor should be so designed as to supply a nearly constant fuel-air over a wide range of operation. This A/F ratio = 15.6 for best economy at full throttle.

The following automatic compensating devices are incorporated in the main metering system:-

i. Air bleeding device.

ii. Auxiliary valve carburetor.

iii. Auxiliary port carburetor.

11/22/2016 12

Idling system:-

As earlier discussed that at idling and low load an engine requires a rich mixture having about air-fuel ratio 12:1. so that a separate idling jet must be incorporated in the basic carburetor.

The idling jet consists of a small fuel

line from the float chamber to a point

on the engine side of the throttle, this

line contains a fixed fuel orifice.

11/22/2016 13

Power enrichment or economizer system:-

At the maximum power range of operation from 75% to 100% load, a device should be available to allow richer mixture (F/A about 0.08) to be supplied despite the compensating leanness.

The meter rod economizer is a device provides a

large orifice opening to the main jet when the

throttle is opened beyond specified limit. The rod

may be tapered or stepped.

An economizer is a valve which remains closed at

normal cruise operation and gets opened to supply

enriched mixture at full throttle operation. It

regulates the additional fuel supply for the above

operation.

11/22/2016 14

Acceleration pump system:-

Acceleration is a transient phenomenon. In order to accelerate the engine rapidly, a very rich mixture is required which a simple carburetor may not be able to supply.

An acceleration pump consists of a spring-

load plunger. Also is provided a linkage

mechanism so that when throttle is rapidly

opened the plunger moves into the cylinder

and forces an additional jet of fuel into the

venture.

11/22/2016 15

Choke:-

A choke is simply butterfly valve located between the entrance to the carburetor and the venture throat.

When the choke is partly closed, large pressure drop occurs at the venture throat, would normally result from the amount of air passing through the venture throat.

The very large carburetor depression at the throat inducts large amount of fuel from the main nozzle and provides a very rich mixture.

11/22/2016 17

1 2 3

Air

1 2 3

Fuel

Assumptions:

• Incompressible flow

• No Heat transfer

• Frictionless flow

• No external work

• Distance between venture inlet and throat

is negligible

Calculation of F/A ratio

A. For air

Apply Bernoulli equation between 1 and 2

2

2

2

2

21

2

1

1

1

22gZ

VPgZ

VP

Calculation of F/A ratio

11/22/2016 18

1 2 3

Air

1 2 3

Fuel

)1....(..........2

2

2

1

2

2

2

1

2

221

21

VVPVVPP

a

a

a

a

Apply continuity equation

factorapprouchA

AWhere

A

A

P

V

A

AV

P

A

AVV

P

inFrom

A

AVVVAVA

a

a

a

a

a

a

2

1

2

2

1

2

2

2

1

22

2

2

1

22

2

2

2

1

221222111

1

1

2

122

12

)2....(..........

Calculation of F/A ratio

11/22/2016 19

1 2 3

Air

1 2 3

Fuel

11

2

1

2

A

A

If A1>>> A2

a

aPV

22

Actual velocity:

If Ca = flow coefficient

Ca = Va)act / Va)th

Ca < 1 → V2)act < V2)th

Mass flow rate:

aaaa

aaaa

a

aaaaaa

PC

PC

PCVACm

2

2

222

Calculation of F/A ratio

11/22/2016 20

f

a

f

a

f

a

f

a

f

a

P

P

A

A

C

C

m

m

F

A

1 2 3

Air

1 2 3

Fuel

B. For Fuel

fffff PCm 2

Similarly as air

Calculation of F/A ratio

11/22/2016 21

Nozzle tip (x)

h1

P1 x

P2

Pf = (P1 + gh) – (P2 + gx + gh)

= (P1 - P2 ) – gx

Pf = Pa - gx

If x = 0 Pf = Pa

Why nozzle tip?

• To reduce fuel wastage due to vibration.

• To reduce fuel wastage due to inclination.

11/22/2016 22

Problems associated to carburetors

a. Manifold wetting

b. Carburetor icing

c. …………………

11/22/2016 22

11/22/2016 24

1. What is carburetor icing ? 2. Why carb ice is a problem? 3. What factors affecting carb icing? 4. How can carb ice be prevented?

Problems associated to carburetors Carburetor icing

11/22/2016 24

11/22/2016 25

carburetor icing

It is the formation of ice in the throat of a carburetor as the result of

cooling by expansion and evaporation of gasoline.

1. What is carburetor icing ?

carburetor icing is an icing condition which can affect any carburetor under

certain atmospheric conditions. While it applies to all carburetors, it is only

really a problem in association with piston-powered aircraft, particularly

small single-engined light aircraft.

11/22/2016 25

11/22/2016 26

carburetor icing

Carb icing occurs when there is humid air, and the temperature drop in the

venturi causes the water vapour to freeze. The ice will form on the surfaces of

the carburetor throat, further restricting it. This may increase the venturi effect

initially, but eventually restricts airflow, perhaps even causing a complete

blockage of the carburetor. Icing may also cause jamming of the mechanical

parts of the carburetor, such as the throttle butterfly valve.

2. Why is carb ice a problem?

11/22/2016 26

11/22/2016 27

carburetor icing

Factors affecting carb icing include:

Current Temperature

Dew point

Relative Humidity

Altitude

3. What factors affecting carb icing?

Carburetor icing chart.

11/22/2016 27

11/22/2016 28

carburetor icing

Aircraft powered by carbureted engines are equipped with carburetor heat

systems to overcome the icing problem.

4. How can carb ice be prevented?

11/22/2016 28

11/22/2016 29

carburetor icing

There are two kinds of induction system icing: carburetor icing, which

affects engines with carburetors, and air intake blockage, which affects both

carbureted and fuel injected engines.

Induction icing accidents top the charts as the number one cause of icing

accidents in aircraft engines working by IC Engines.

Induction System Ice

In a normally aspirated engine, the carburetion process can lower the

temperature of the incoming air as much as 60 degrees Fahrenheit (15.5 oC). If

the moisture content is high enough, ice will form on the throttle plate and

venturi, gradually shutting off the supply of air to the engine. Even a small

amount of carburetor ice will result in a power loss, indicated by reduced rpm

with a fixed-pitch propeller and a loss of manifold pressure with a constant

speed propeller, and may make the engine run rough.

11/22/2016 29