The Milling Machine. Care and Maintenance of Milling Cutters The life of a milling cutter can be...

-

Upload

alexis-mccoy -

Category

Documents

-

view

239 -

download

3

Transcript of The Milling Machine. Care and Maintenance of Milling Cutters The life of a milling cutter can be...

The Milling Machine

Care and Maintenance of Milling Cutters

• The life of a milling cutter can be greatly prolonged by intelligent use and proper storage.

• Take care to operate the machine at the proper speed for the cutter being used, as excessive speed will cause the cutter to wear rapidly from overheating.

• Take care to prevent the cutter from striking the hard jaws of the vise, chuck, clamping bolts, or nuts.

• Whenever practical, use the proper cutting oil on the cutter and workpiece during operations, since lubrication helps prevent overheating and cutter wear.

• Keep cutters sharp. Dull cutters require more power to drive and this power, being transformed into heat, softens the cutting edges. Thoroughly clean and lightly coat milling cutters with oil before storing.

• Place cutters in drawers or holders so that their cutting edges will not strike each other.

• Never operate a cutter backwards.

ChecklistBefore you enter work area

Put on safety glassesTie back loose hair and clothingRemove jewelry including rings, bracelets, and

wristwatches Do not use any piece of equipment until instructor has

demonstrated proper operational procedures and individual safety rules

Do not use any equipment or tools that are broken and report any broken equipment or tools immediately

ChecklistBefore machining a part

While setting up work, install the cutter last to avoid being cut.When installing or removing milling cutters, always hold

them with a rag to prevent cutting your hands.Make sure you have the correct tool for the job.Secure the tool properly.Make sure all tool positions have been properly

initialized.Verify the NC program on the computer before

machining.Remove all loose parts and pieces from the machine.Remove adjusting keys and wrenches from the machine.Close the safety shield.

ChecklistBefore machining a part

Perform a dry run.Set the spindle motor switch to lowest manual speed

setting.Make certain there is no work piece in place.Run the NC program to make sure all the moves make

sense before running the program with a work piece in place.

After completing the dry run, properly secure the work piece to the machine.

Keep fluids away from all electrical connections, electronic or electrical devices, the computer, and nearby electrical outlets.

ChecklistWhile machining a part

Do not touch moving or rotating parts. Do not place or remove anything from the work area while

machine is running. Press the Emergency Stop button before re-opening the

safety shield. Only open the safety shield after the spindle has stopped

rotating. Press the Emergency Stop button whenever changing

tools or mounting or removing a work piece. Pull the Emergency Stop button out only after closing the

safety shield. Keep all unauthorized persons away from the work area. Always leave work area clean and orderly.

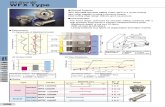

CNC Speed and Feed Capabilities

Super Prolight 1000

Linear Feed Rate– 0.1 – 75 ipm – (2 – 1905 mm/min)

Circular Feed Rate– 0.1 – 75 ipm – (2 – 1905 mm/min)

X,Y Rapid Feed– 75 ipm – (1905 mm/min)

Z Rapid Feed– 75 ipm – (1905 mm/min)

Speed Range– 0 - 5,000 RPM

Prolight 1000Linear Feed Rate

– 0.1 – 25 ipm – (2 – 635 mm/min)

Circular Feed Rate– 0.1 – 18 ipm – (2 – 457 mm/min)

X,Y Rapid Feed– 50 ipm – (1270 mm/min)

Z Rapid Feed– 40 ipm – (1016 mm/min)

Speed Range– 0 - 5,000 RPM

CNC Prolight

Z Axis Stepper Drive Motor

Safety ShieldCross SlideSpindle MotorSpindle HeadX Axis Stepper

Drive MotorY Axis Stepper

Drive Motor

1

2

3

4

5

6

7

14

5

2

3

6

7

Manual Control Panel

• Manual Spindle Speed

• Emergency Stop

• Manual to CNC Switch

Adjusting a Machinist Vise

Other Vises / Hold DownsLow Profile Clamping Kit

Step Blocks and Strap Clamps 2 Axis Pneumatic Vise

One Axis Pneumatic Vise

Loading / Changing a Quick Change Collet

• Move the Z axis to a safe location

• Press the emergency button

• Open the safety

shield

• Insert the chuck

lock pin

Loading / Changing a Quick Change Collet

Milling Bits

Engraver

Long End Mill

Double End Bit

Roughing End Mill

Edge Finder in Tool Holder

Specialty Tools Common Tools

Machine Zero / Home

+X

-X

+Y

-Y

+Z

-Z

Part Zero

+X

-X

+Y

-Y

+Z

-Z

CNC Machine Axes

-X

+X

-Y

-Z

+Z

+Y

PRZ – Part Reference

Zero– Origin– 0,0,0

Xp

Yp

Part Reference Zero (PRZ) Position

D= tool diameter

(0,0,0) PRZ Position

Work Piece

Xm

Ym

Machine Axes

Part Axes- y offset = D/2

Top View - x offset = D/2

Cutting Tool

(0,0,0) PRZ Position

Xp

Zp

Note: x offset = y offset = D/2z offset= 0

Front View

Work Piece

Part Reference Zero (PRZ) Position

Checking PRZSend the Mill to a point above the x and Y zero to make sure the center of the cutting tool is over the top front corner.

Using an Edge Finder

True Spin

Not Touching Material

Offset Spin (Jump)

Touching Material

Edge finders are used to find X & Y Edge, not Z (Top) Surface

Tool Library

Tool SetupThe first step in setting up a tool library is to home the machine. The homing process will send the mill to a known position along all three axes. Follow the steps below to home the machine.

•Select Setup in the menu bar and then Set/Check Home

•Hold the Control key and type H

•Right click on the Jog Control Panel and select Set/Check Home

•Select the Home icon from the tool bar

Home

Tool Height Offsets

Tool Height Offset

Where does the mill spindle go when it is directed to a height of .5?

When a tool offset is established, the control program calculates its height move using the offset.

Tool Setup WizardA wizard is available for setting up tools. Select Tool - Setup Tool Wizard from the main menu.

The first tool established a reference height.

Click Next

Tool Setup Wizard

To put the reference tool in the spindle, click here.

Click on Next.

Tool Setup Wizard

After inserting the reference tool, use the jog control panel to put the end of the cutting tool on the top of the block.

Offset gage - Works as a continuity check. The light shines when a complete circuit is made by touching the tool and table.

Click Next to continue.

Tool Setup Wizard

You’re Done! Note that the Z coordinate in the Position Panel changes to zero. The current height is now the reference point. All other tools heights will now be compared to this.

Remove the Reference tool and then select Next.

Tool Setup Wizard

If the tool library has other tools defined, you may now select them to set the tool height offset.

If the tool is not in the library, you will need to set it up.

Setting Up the Tool Library

Select the tool number. This will be identified as tool 1 (M06T1).

Type in a tool description.Enter the

diameter.

Setting Up the Tool Library

Select the type of tool.

A Bull Mill has a nose radius on its corners - Define the radius here.

An End Mill has a flat bottom. Center cutting is recommended since plunging is often required.

Setting Up the Tool Library

Select the type of Tool

Define the taper angle

An engraving tool is a type of tapered cutter.

A Standard Drill (118° Point).

A Ball Mill has a constant radius (1/2 diameter) on its end.

Define the diameter at its end point

Setting Up the Tool Library

Load the tool in the spindle and set the parameters.

Setting Up the Tool Library

Jog the machine so the tool is touching the top of the reference point (Tool offset Gage)

Setting Up the Tool LibrarySet the tool Height offset by clicking Current Z.

Setting Up the Tool Library

Note that the position panel shows a z height of zero. The control software has calculated the difference between the reference tool and tool 1.

Setting Up the Tool Library

Tool Height offset

Setup Tool LibraryStation locations are used for mills equipped with automatic tool changers.

Number of teeth (flutes) in the cutting tool.

Identify tool material (high speed steel is a good general purpose tool).

Always apply any changes before continuing to the next tool.