The Journal of Plastinationjournal.plastination.org/archive/jp_vol.29.1/jp_vol.29.1_july17... ·...

Transcript of The Journal of Plastinationjournal.plastination.org/archive/jp_vol.29.1/jp_vol.29.1_july17... ·...

The official publication of the International Society for Plastination

The Journal of Plastination

I SSN 2 311 -77 61

Volume 29 (1); July 2017

Corrosion Cast of

Bronchopulmonary

Segments – p5

3-D Reconstruction of the

Retrobulbar Orbital Septa

Using Biodur E12®, – p8

Biodur® S10/S3 and

S15/S3 at “Room

Temperature”: a viscosity

study – p15

The Use of Vacuum

Forced Impregnation of

Gum Arabic Solution in

Biological Tissues for

Long-Term Preservation

– p19

Room temperature

Impregnation with Cold

Temperature Biodur®

Silicone: A Study of

Viscosity – p26

IN THIS ISSUE:

The Journal of Plastination

ISSN 2311-7761 ISSN 2311-777X online The official publication of the International Society for Plastination

Editorial Board:

Rafael Latorre Murcia, Spain

Scott Lozanoff Honolulu, HI USA

Ameed Raoof. Ann Arbor, MI USA

Mircea-Constantin Sora Vienna, Austria

Hong Jin Sui Dalian, China

Carlos Baptista Toledo, OH USA

Philip J. Adds Editor-in-Chief Institute of Medical and Biomedical Education (Anatomy) St. George’s, University of London London, UK

Robert W. Henry Associate Editor Department of Comparative Medicine College of Veterinary Medicine Knoxville, Tennessee, USA

Selcuk Tunali Assistant Editor Department of Anatomy Hacettepe University Faculty of Medicine Ankara, Turkey

Executive Committee: Rafael Latorre, President Dmitry Starchik, Vice-President Selcuk Tunali, Secretary Carlos Baptista, Treasurer

Instructions for Authors

Manuscripts and figures intended for publication in The Journal of Plastination should be sent via e-mail attachment to: [email protected]. Manuscript preparation guidelines are on the last two pages of this issue.

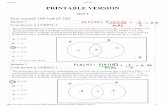

On the Cover: Parasagittal section of orbit, stained with fresh Gomori’s trichrome. From 3-D Reconstruction of the

Retrobulbar Orbital Septa Using Biodur E12® by Adds PJ, McCarthy P, Uddin J, Gore S.

The Journal of Plastination 29(1):1 (2017)

Journal of Plastination Volume 29 (1); July 2017

Contents

Letter from the President, Rafael Latorre 2

Letter from the Editor, Philip J. Adds 3

Corrosion Cast of Bronchopulmonary Segments, Ramkrishna, V. and Leelavathy, N.

Leelavathy, N

5

3-D Reconstruction of the Retrobulbar Orbital Septa Using Biodur® E12, Adds P. J., McCarthy P., Uddin J. and Gore S.

8

Biodur® S10/S3 and S15/S3 at “Room Temperature”: a viscosity study, Adds P. J. 15

The Use of Vacuum Forced Impregnation of Gum Arabic Solution in Biological Tissues for Long-Term Preservation, Satte, M. S. , Ali, T. O. and Mohamed, A. H. Y. Room temperature Impregnation with Cold Temperature Biodur® Silicone: A Study of Viscosity, Sora, M-C Instructions for Authors Statement of Publication and Research Ethics

19

26

30

32

The Journal of Plastination 29(1):2 (2017)

LETTER FROM THE

PRESIDENT

Dear Friends,

On behalf of the International Society for Plastination (ISP), I would like to thank

you for your participation in the 12th International Interim Conference on

Plastination, in Durban, South Africa, 2017. Forty-five delegates from fourteen

different countries participated in the Conference. My special gratitude goes to

those of you who agreed to present a poster or oral communication: your

contribution is very special and vital to maintain high standards in our Society.

It was a great pleasure to be in Durban during that time, and I would like to thank

The College of Health Sciences, University of KwaZulu- Natal, Durban, South

Africa, and especially the efforts of Dr. Azu Onyemaechi and his local team in

organizing this congress. I know it has not been easy; there have been many

hours of coordinated work to get everything prepared. I know from experience

that organizing these kinds of conferences, together with a workshop, takes a

great deal of effort. In addition, in this case, Dr. Onyemaechi has also had to

combine this with a move to a new job in a different University.

This has been the first conference of the International Society for Plastination in

South Africa: a challenge for the ISP governing committee, so we have all held

weekly meetings with the local organizers to help them develop the best

conference possible. For this reason, I would especially like to thank the work

done by Drs. Carlos Baptista, Robert Henry, and Dmitry Starchik. Without their

help this congress would not have been possible.

The group of experts who were responsible for the theoretical sessions and the

hands-on stations during the workshop ensured the success of this congress.

Thank you very much for accepting this collaboration because I know that it is

not easy to reconcile this with both academic and family agendas.

The Conference was very interesting, but what is more important is that we had

a very good ambience; the interaction during social events was wonderful, and

this was only possible because we had the best Event Manager, Ms. Janine

Meyer-Hoffmann. Thank you very much for all you did for us during those days,

and thank you for your dedication to make everything in this meeting such a big

success.

We have all learned many things from each other, we have had the opportunity

to discuss very interesting topics about plastination techniques and the

applications of plastination, as well as to establish interesting collaborations.

Now we all have new ideas and projects in our minds to carry out in the near

future, and therefore to present new results next summer in Dalian.

Thank you very much.

Rafael Latorre

President

Rafael Latorre, DVM, PhD

The Journal of Plastination 29(1):3 (2017)

LETTER FROM THE EDITOR

These Things Take Time: PubMed indexing update

Dear Colleagues,

The Medline Review Application Form for The Journal of Plastination was submitted to

the National Library of Medicine (NLM) Literature Selection Technical Review Committee

on August 14th, 2015. Our Journal was reviewed by the Committee in October 2016, and

last November I received a letter from the NLM informing us that unfortunately The

Journal of Plastination had not scored highly enough to be recommended for inclusion in

MEDLINE.

I requested feedback from the Committee, and received a very helpful document

detailing the scoring. Analysis of the scores will be very helpful in driving improvements

for our next application. A score of 3.75 out of 5 must be achieved for a journal to be

recommended for indexing; ours scored 2.5. Clearly, there is work to be done.

On the positive side, the Journal scored well in the ‘Scientific Merit’ category for our

authors and their institutions, and for our external peer review process. In terms of the

‘Importance’ of the Journal, we scored ‘high’ for Researchers, Educators and Students,

but only ‘moderate’ for its importance to clinicians, which is not too surprising, since we

make no claims for it being a clinical journal.

One area where we did not score well was in ‘Ethics Policies/Statements’, as there were

no explicit policies on conflicts of interest, human and animal rights, informed consent,

or ethics. This has been rectified in this issue, which includes, for the first time, a

detailed statement on publication and research ethics. I would urge all contributing

authors to read this carefully, as it sets out the ethical standards under which the

Journal will continue to operate.

In their comments, the assessors indicated some areas for improvement, including the

high rate of acceptance of unsolicited articles, and the fact that many articles have very

few references.

It is the aim of the Editor and the Officers of the ISP to address these issues as quickly as

possible and re-apply to the NLM for inclusion in Medline/PubMed. Over the coming

year we shall be making every effort to raise the standard of the Journal so that our next

application is met with more success. The fundamental issue remains, however: without

PubMed indexing, we will not attract enough high-quality papers; without high-quality

papers, we will not achieve PubMed indexing!

In the meantime, I have attempted to get the journal included in Google Scholar. This

has met with mixed, and rather random success. A search for papers published in

“Journal of Plastination” yields 25 results (of which some are citations) and includes

papers from both the Journal of Plastination and its earlier incarnation, the J Int Soc

Philip J. Adds, MSc, FIBMS, SSFHEA

The Plastination Journal (29):4 (2017)

Plastination. At this stage it is obviously far from complete, but it’s a start.

I shall be giving further updates in forthcoming issues of The Journal of Plastination.

Until then, it is of the upmost importance for the future of the Journal that we continue

to publish high quality, peer-reviewed research papers and reviews, and I would urge all

readers of the Journal to consider submitting their research to The Journal of

Plastination. Instructions for Authors are included at the end of this issue.

With best wishes,

Philip J Adds

Editor-in-Chief

The Journal of Plastination (29):5-7 (2017)

TECHNICAL REPORT

Corrosion Cast of Bronchopulmonary Segments

Ramkrishna, V

Leelavathy, N

.

Department of Anatomy

Sapthagiri Institute of

Medical Sciences and

Research Center

Chikkasandra, Hesaragatta

Main Road Bengaluru-

560090 Karnataka, India

ABSTRACT: The tracheo-bronchial tree is rather difficult for anyone to understand without visual aids. Luminal

corrosion casts made of silicone sealant material give a better orientation that aids understanding.

Many different materials like gelatin and different types of silicone, and different methods such as

injecting the solutions with a syringe and a gun have previously been used in cast preparation.

Some methods are costly, and some are difficult to carry out, requiring much care in the

procedures. In the present study, the sealant material “WACKER GP” general purpose silicone

sealant, (Wacker® Wacker Chemie AG Munich, Germany), which is low in cost and easily

available in hardware shops, has been used. The method adopted to inject the silicone using an

injection gun is relatively very easy. The prepared bronchial tree cast was found to be safe to

handle, soft, flexible and has long-lasting durability. The cost of preparation is very low compared

to other methods.

KEY WORDS: Bronchopulmonary segments; corrosion cast; hydrochloric acid; silicone; silicone

gun.

* Correspondence to : Dr. Leelavathy N, Department of Anatomy, Sapthagiri Institute of Medical Sciences and Research Center Chikkasandra, Hesaragatta Main Road Bengaluru- 560090 Karnataka, India, e-mail: [email protected]

Introduction

A corrosion cast of the lungs demonstrates the three-

dimensional anatomy of the internal structure of lungs,

which is necessary to understand the branching pattern

of the bronchopulmonary tree. This helps in surgical

management of lung disorders, helps anatomy students

to understand the orientation of the branching pattern of

the tracheo-bronchial tree up to the level of the alveoli,

and also helps in other medical specialties. Knowledge

acquisition by students may occur faster as they employ

multiple senses to both see and feel actual

representation of each organ. Lung conceptualization of

difficult physiological processes is made easier.

Students’ knowledge, clinical examination and diagnostic

skills are enriched accordingly.

Various authors have described the use of different

materials to prepare corrosion casts of the bronchial

tree, for example 12% warm gelatin solution, ‘Dr. Fixit’

silicone sealant, and GP silicone sealant (Tompsett,

1970; Menaka, 2007; Prasad, 2009; Casteleyn et al.,

2009). Since there is a continuous decrease in the

luminal size as the tree divides, the material must be

able to reach the terminal end up to the level of the

alveoli. The material should be easy to inject without any

harmful effects to the individual doing the procedure;

must solidify while remaining flexible when the cast is

prepared; should be economical and cheap; and should

be easy to procure with the other necessary materials.

Bearing in mind the above factors, our corrosion cast

was made using quite cheap and economical silicone

sealant material, which is commonly used for sealing

roof leakages.

Materials and Methods:

1.“WACKER GP” general purpose silicone sealant,

(Wacker® Wacker Chemie AG Munich, Germany), 220

ml tube, sufficient for a cast of one set of lungs (Fig. 1).

2.Gun for injecting silicone (re-usable) (Fig. 1).

3.Fresh lungs from human body or from sheep/ goat/

buffalo from slaughter house. If the fresh lungs cannot

be used immediately, they can be kept in the freezer

without fixing in formalin, until they can be used.

4.2.5 L of concentrated hydrochloric acid, Assey-36.46

(Nice Chemicals), sufficient to prepare 4 casts.

5.Balloon inflation pump (re-usable) (Fig. 1).

The lungs used in this study were from sheep, and were

obtained from the local slaughter house. The lungs were

TECH

NIC

AL R

EPO

RT

6 Ramkrishna and Leelavathy

Figure 1: The balloon inflation pump, silicone gun, and

silicone sealant tube before the infiltration procedure.

first washed with running water, and were then inflated

with the balloon inflation pump until the organ resumed

its fully inflated condition in the original anatomical

position. It was then allowed to deflate. The silicone

sealant tube was fixed in the gun and the lever was

pressed slowly to force the silicone into the trachea (Fig.

2).

Figure 2: The infiltration gun and tube of silicone during

the infiltration procedure

The trachea was then gradually milked downwards as

the silicone was forced into the lungs, until the surface of

the lungs appeared as a patchwork of rosettes and

became uneven. Care must be taken not to spill the

silicone, and to allow it to drain slowly into the bronchial

segments. The lungs were then suspended overnight to

allow the silicone to solidify. Finally, the lungs were

immersed in concentrated hydrochloric acid, Assey-

36.46 (Nice Chemicals) overnight, or allowed to

decompose naturally in a water bath under running tap

water. The parenchyma gets digested in one night when

the lungs are immersed in hydrochloric acid, and the

cast should then be washed thoroughly in running water

and then allowed to dry. Natural decomposition of the

parenchyma may take 4 to 7 days for the decomposition

of the soft tissue. The parenchyma is then washed off

leaving behind the cast. The dry specimen can be

displayed in the museum or used for teaching.

Results

The tracheo-bronchial tree cast after digestion showed

the branching pattern clearly. The bronchi in both right

and left lungs were clearly divided. The right lung

showed tracheal bronchi and the main bronchus divided

in to apical and diaphragmatic bronchi. The left lung

showed only apical and diaphragmatic bronchi. The

branching pattern from the trachea to fine bronchioles

was clearly visible (Fig. 3).

Figure 3: The tracheo-bronchial tree cast made with

Wacker® “WACKER GP” general purpose silicone

sealant, (Wacker Chemie AG Munich, Germany), using

sheep’s lungs.

Corrosion Cast of Bronchopulmonary Segments 7

The final prepared cast was soft, flexible, non-toxic and

safe to handle. The cast is long-lasting and durable, and

can be used for teaching or for museum purposes (Fig.

3).

Discussion

When compared to other techniques, the method

described here is found to be both cheaper and easy to

do. The material is easily available and is cost-effective

when compared to other methods. Hartmann and

Groenewald (2014) have used ‘Mold Max’ 30 RTV

silicone, durometer shore 30A hardness, viscosity

25000cps, mixed with silicone thinning fluid to reduce

the viscosity by 50%. These chemicals have to be

imported and are not always easily available in India;

thus they may not be cost-effective. Henry (2000) used

RTV silicone with its catalyst to fill the airways and then

allowed to stand for 24 hours. Later it is boiled for 24 to

48 hours to remove soft tissue. Any remaining tissue

was further treated with 10-20% H2O2. RTV silicone is

available in India, but the catalyst is not available, and

has to be imported. Rakesh Narayanan (2015) used

LAPOXTM epoxy resin with hardener to prepare the

bronchial cast. The disadvantage of this method is that

the epoxy resin and hardener reaction is exothermic,

hence care has to be taken while mixing. The procedure

needs to be done quickly after mixing the resin with the

hardener, otherwise the solution will solidify. The cast

prepared is hard and brittle, but has the advantages of

good shape and durability.

Finally, comparing with the above methods, the method

described here using silicone sealant is simple, without

any adverse effects, and is safe to handle and prepare.

The specimen is flexible and durable (Fig. 3). It can be

handled freely for teaching or mounted for display.

Conclusion:

1. The method described here is relatively very

easy and safe. There is no need for mixing any catalyst

and then reloading the mixture to inject. It needed only a

single tube of silicone which was injected directly into the

trachea using the silicone gun.

2. It is cost-effective, whether the cast is prepared

with or without hydrochloric acid. But when both

decomposition methods are taken in to consideration,

the silicone gun and the balloon inflation pump are re-

usable equipment, for which the cost need not be

included, so the cost of a cast of a set of sheep’s lungs

with natural decomposition is the cheapest, even if it

takes few days to decompose, as compared to

hydrochloric acid as a decomposing agent.

References:

Casteleyn C, Doom M, Cornillie P, Breugelmans S, Van

Loo D, Van den Broeck W, Simoens P. 2009: Application

of corrosion casting at Ghent University. Abstract in 5th

meeting of the Young Generation of Veterinary

Anatomists held at Department of Pathobiology. Faculty

of Veterinary Medicine, Utrecht University, Netherlands,

May 21-22.

Hartman MJ, Groenewald HB. 2014: Silicone cast in situ:

a technique to demonstrate the arterial supply of the

female reproductive organs of an African Lion (Panthera

leo). J Plast 26: 11-25.

Henry RW. 2008: Tracheobronchial cast preparation. J

Int. Soc. Plastination 23:30-39.

Menaka R, Joshi Hemant, Ramkrishna V. 2007:

Corrosion cast of bronchial tree and air sacs of domestic

fowl. Indian J Vet Anat 19: 63-64.

Prasad RV. 2009: Silicone bronchial tree corrosion cast

of domestic animals. Abstract in 5th meeting of the

Young Generation of Veterinary Anatomists held at Dept

of Pathobiology, Faculty of Veterinary Medicine, Utrecht

University, Netherlands, May 21-22.

Rakesh Narayanan V. 2015: Preparation of low cost

bronchopulmonary airway cast. J Anat Soc India 64:

162-165.

Tompsett DH. 1970: Anatomical techniques. 2nd edition,

E and S Livingstone, London.

The Journal of Plastination (29): 8-14 (2017)

ORIGINAL RESEARCH

3-D Reconstruction of the Retrobulbar Orbital Septa Using Biodur E12®

1Adds PJ

1McCarthy P

2Uddin J 2Gore S

1Institute of Medical and

Biomedical Education

(Anatomy), St Georges,

University of London

London, UK.

2Adnexal Service,

Moorfields Eye Hospital,

London, UK

ABSTRACT:

The aim of this study was to develop a method of visualising the septa that divide the

retrobulbar fat body in the human orbit. Epoxy resin embedding has previously been

used to visualise the branching pattern of the intra-orbital arteries. Creating a 3D

reconstruction of the orbital septa would elucidate the detailed structure and

orientation of the fat septa, giving valuable information to the ophthalmic surgeon.

Formalin-fixed human orbits were dissected, decalcified, dehydrated in acetone at -20°

C, and impregnated with Biodur® E12 epoxy resin. Sections of 0.3 mm thickness were

cut with a slow-speed diamond saw. The sections were then stained for elastin and

collagen, and photographed with a digital SLR camera. The images were then used to

create a 3D digital reconstruction of the fat septa using ‘Reconstruct’, a free editor for

serial section microscopy. A number of different staining methods were trialled.

Lillie’s modified haematoxylin and eosin, Lillie’s trichrome, and modified Miller’s

elastin stain were found to be unsuitable. Gomori’s trichrome was found to give the

clearest visualisation of the soft tissues, and permitted the structures to be traced in

order to create a 3-D image. However, timings had to be extended to allow the stains

to penetrate the sections, and final colors were not always as expected.

Embedding in E12, combined with a Gomori’s trichrome stain is a repeatable method

to visualise the architecture of the retrobulbar fat septa. A digital 3D model was

created from the stained sections allowing individual structures to be isolated and

manipulated. The 3D model can be used to study the morphology of the orbital fat

septa in detail.

KEY WORDS: orbital fat; retrobulbar septa; epoxy embedding; plastination; epoxy; 3-D

reconstruction *Correspondence to: Philip J Adds, Institute of Medical and Biomedical Education (Anatomy), St Georges, University of London, Cranmer Terrace, London SW17 0RE, UK. Telephone +44(0) 2087255208, email: [email protected]

Introduction

As well as providing bony protection for the eyeball, the

orbit contains soft tissue structures that provide the

dynamic support required for controlled eye locomotion.

The primary role of the orbital fat is to help support the

globe, and also to act as a shock absorber, reducing

damage during trauma. Its role as an energy store is

secondary, as the volume of the fat body remains

constant except in cases of extreme starvation

(Bremond-Gignac et al., 2004; Gaudiani et al., 2012).

The distribution of fat within the orbit however, is not

uniform: it is divided into compartments by fibrous septa.

The septa contain nerves and blood vessels, as well as

providing a framework for the orbital fat lobules. They

also provide a pulley system, connecting the extra-ocular

muscles (EOMs) to each other and to the orbital

periosteum (Koornneef, 1988), and there is evidence

that some septa may contain smooth muscle that may

play a part in binocular alignment (Miller et al., 2003)

(Fig. 1).

3-D Reconstruction of the Retrobulbar Orbital Septa 9

Figure 1. Diagram of sagittal section through human

orbit. Arrow indicates retrobulbar fat and septum.

(Modified from: Orbital connective tissue and fat.

http://clinicalgate.com/the-orbit-and-accessory-visual-

apparatus)

Restriction of locomotion is present in a significant

number of patients following orbital decompression

surgery due to muscular interactions (Richter et al.,

2007). This is due to the fact that removal of the

connective tissue causes an impairment in the function

of the EOMs by taking away their supportive structure

(Koornneef and Zonneveld, 1985)

The intricacies of the distribution and make-up of the fat

septa, how they contribute to fine eye movement and

how they are linked to loss of function post-

ophthalmopathy and trauma are not well understood.

This is mainly due to the fact that their complex

branching structure is very difficult to visualise.

The epoxy resin E12 is hard, transparent and has

excellent optical qualities. E12 plastination has been

used previously to study the connective tissue of the

spine (Johnson and Barnett, 2005), the ankle (Sora et

al., 2004), and the pelvis (Sora, 2007). The hardness of

the epoxy-embedded tissues enables slices less than 1

mm thick to be cut, retaining much structural detail, and

permitting 3-D reconstructions to be made (Sora, 2007).

E12 resin-embedding of the human orbit has also been

used successfully to visualise the path of the ethmoidal

arteries, and to create a 3D model (Adds & Al-Rekabi,

2014). In their study, Adds and Rekabi (2014) cut

sections 0.3 mm thick that were then stained directly; in

the study reported here, we followed the same method

to visualise the retrobulbar connective tissues.

Materials and Methods

The human orbit specimens were taken from cadavers

donated to the Anatomy Department of St. George’s,

University of London, U.K. Consent for anatomical

examination and research had been given under the

Human Tissue Act (2004). Nine orbits were used, from 6

cadavers. There were 4 females and 2 males, age range

67 – 97 years. None of the cadavers showed any sign of

orbital pathology.

The orbits were removed from the cadaver and

separated into left and right with a bandsaw. Dissection

was then carried out to remove excess bone and soft

tissue, leaving the orbital walls intact.

i. Decalcification.

Prior to dehydration, the individual orbits were

decalcified by immersion into 20x their volume of 10%

formic acid. The end point of decalcification was

assessed by weighing the specimens before and during

the calcification process (Mawhinney et al., 1984). A 5%

loss of weight was chosen as the end point, so that the

soft tissue did not become damaged due to prolonged

immersion in acid. This took approximately 72 hours.

ii. Dehydration.

Each orbit was then immersed in 10x its volume of 100%

acetone. The acetone was pre-cooled to -20°C prior to

immersion of the specimen. The pots containing the

specimens and acetone were then sealed and placed in

a freezer at -20°C.

The acetone was replaced twice with 72 hours between

each change. Total dehydration time was 6 days. After

the last change the specimens were removed from the

freezer and allowed to equilibrate at room temperature.

Specimens were left in room temperature acetone for a

further 24 hrs for degreasing.

iii. Impregnation

The impregnation resin was a mixture of Biodur® E12

resin, E6 hardener and E600 accelerator. The ratio of

each of the components used was 100 : 50 : 0.2

respectively (Sora 2007).

The specimens were submerged in the resin and placed

into a Heraeus vacuum oven at 30 °C for 24 hrs. No

vacuum was applied for this period to allow the resin to

equilibrate. After 24 hrs the pressure was decreased

10 Adds et al.

every hour to 550 Mbar, 425 Mbar, 320 Mbar and 210

Mbar, for the first 4 hours respectively.

For the final 2 hours of impregnation the temperature

was increased to 60°C while the pressure was once

again reduced to 100 Mbar and then 25 Mbar. The

viscosity of the impregnation mixture has an inverse

relationship with temperature meaning that for the final

two hours when the temperature is increased to 60°C, its

viscosity decreases enabling the resin to penetrate the

specimen more effectively. During the final hour the

resin impregnation mixture could be seen to bubble and

splash violently, as a result of its decreased viscosity.

iv. Curing

Once impregnation was complete the specimen was

submerged in freshly made epoxy mixture in a plastic

mould. If full impregnation has been achieved, the

specimen should sink to the bottom of the container. The

mould was then placed into an oven at 65 °C for at least

6 days, being checked every day, until the epoxy resin

had set. Once the block had hardened it was removed

from the oven and left to cool to room temperature. The

block can then be removed from the plastic mould (Fig.

2).

Fig. 2. A right orbit following impregnation and curing.

The resin block has been removed from the plastic

mould. Note the excellent optical qualities of the epoxy

resin.

v. Sectioning

The resin block was first trimmed with a bandsaw to a

final size of approximately 35 x 35 x 60 mm then

clamped in a Buehler Isomet slow-speed saw with a 0.4

mm x 127 mm circular diamond blade. The blade was

cooled with Buehler ‘Cool 2’ lubricant during cutting to

avoid heat damage during sectioning. Sequential sagittal

sections of 0.3 mm were cut; each section was rinsed

with distilled water, blotted dry and numbered with a

pencil.

vi. Staining

Histology staining trials were carried out on individual

sections, with the following stains:

Lillie’s modified haematoxylin and eosin (Lillie 1954),

Lillie’s trichrome (Lillie’s Trichrome for muscle and

collagen, 2005), modified Miller’s elastin stain (Miller,

1971), and modified Gomori’s trichrome (Gomori, 1950;

IHCWORLD, 2003a, b, c). The stained sections were

examined for color differentiation and clarity. The

Gomori’s trichrome was found to give the best results

(see Appendix for details).

The sections were stained for 1 hour, 4 times the

recommended time. This was in order to allow

penetration into the section. Fresh stain should be made

up for each batch of sections, to preserve the strength

and intensity of the stain. After staining, the sections

were mounted on to HiQA™ super mega plain

microscope slides using Cargille™ type BF immersion

oil.

vii. Imaging

Digital images of each of section were taken with a

Nikon D3100 DSLR camera fitted with a Sigma 105mm

F2.8mm macro lens. The camera was mounted on a

camera stand above a fixed light source. A steel ruler

was included in the first image of each batch to act as a

calibration reference when scaling the 3D model.

viii. Image processing

After photographing, the brightness and contrast of each

image was adjusted using Windows photo editor so that

all the fat septa could be seen and differentiated from

the surrounding tissue. The order was also checked to

make sure that the sections were in the correct

sequence. The images were then imported as a series

into ‘Reconstruct’, a freely distributed 3D imaging

software package obtain able from:

http://synapses.clm.utexas.edu/tools/reconstruct/reconst

ruct.stm (Fiala, 2005). Structures of interest were traced

manually in each image (optic nerve, globe, extra-ocular

muscles, orbital walls, and fibrous septa) (Fig. 3). Once

all the traces were complete, they were rendered into a

3D model by the imaging software. .

3-D Reconstruction of the Retrobulbar Orbital Septa 11

Figure 3. Sagittal section of the orbit showing colored

traces: collapsed globe (pink), superior rectus (purple),

superior oblique (yellow), medial rectus (red), inferior

oblique (blue) and the retrobulbar fat septa (green)

Results

The embedding procedure produced blocks of resin that

were hard, transparent and with good optical qualities

(Fig. 2). The sections that were produced were of good

quality and able to be stained directly. However, it must

be borne in mind that because of the thickness of the

saw blade, 0.4 mm of tissue was lost with every cut.

Staining met with mixed success. The modified H & E

stain was found to stain the septa only faintly, making it

extremely difficult to pick out the fine septa when tracing

the images (Fig. 4a). The Lillie’s trichrome was found to

be taken up by the resin, giving the whole section an

intense yellow coloration that obscured the tissues of

interest. There was also very little variation in soft tissue

staining, with everything staining a uniform brown color

(Fig. 4b). The modified Miller’s elastin stain was found to

cause the resin to buckle and crack, as the embedded

tissue absorbed alcohol and expanded. Furthermore the

stain was found to have precipitated on the slide and

collected in cracks in the resin, giving rise to numerous

artefacts that obscured genuine staining (Fig. 4c).

Figure 4: a. section stained with H&E; b. section stained

with Lillie’s trichrome; c. section stained with modified

Miller’s stain.

With Gomori’s trichrome, it was found that the soft tissue

structures were stained clearly and consistently (Fig. 5),

although the intense red progressively faded with

repeated use making the Celestine blue counterstain

more obvious (Fig. 6). It is therefore recommended that

a fresh batch of stain should be made up for each orbit.

It was also necessary to leave the slides in the stain for

longer than the recommended period in order for the

stain to be taken up fully by the section. However,

leaving the slides immersed for over 4 hours can cause

the tissue to expand and buckle, cracking and distorting

the section. Gomori’s trichrome was found to stain

collagenous structures well, but red-brown, rather than

the expected green. This change in staining colour and

tissue variation was evident in all the stains tested,

suggesting that epoxy impregnation can affect the way

tissues react to stains.

Figure 5. Parasagittal section of orbit, stained with fresh

Gomori’s trichrome.

12 Adds et al.

Figure 6. Parasagittal section of orbit, stained with

Gomori’s trichrome, after repeated use. Note the

dominance of the Celestine blue counterstain.

The images of the sections stained with Gomori’s

trichrome proved adequate for tracing the soft tissue

structures so that an accurate 3-D model of the

retrobulbar septa was produced (Fig. 7). Other important

soft-tissue structures of the orbital cavity were also

traced and colored (Fig. 8). The rendered model can be

rotated in 3D space as well as having structures

removed and isolated. The septa that have been traced

in each section can also be separated and rotated on

their own.

Figure 7. Reconstructed retrobulbar fibrous septa, four

different views. A rotating 3D video of the isolated septa

can be found at https://youtu.be/rjRXqFxyT4M.

Figure 8. A full rendering of the final 3D model showing

(a) medial, and (b) posterior views of the orbit: globe and

optic nerve (pink), superior rectus (lilac), medial rectus

(grey), inferior rectus (red), lateral rectus (violet),

superior oblique (yellow), inferior oblique (blue), bone

(orange), retrobulbar septa (green).

Discussion

E12 epoxy resin imbedding was found to be a very

reliable method for creating orbit sections with excellent

optical qualities. It was also found to create very little

specimen distortion as the hardness of the block meant

that structural relationships remained consistent

throughout the sectioning process. Gomori’s trichrome

proved to be an effective stain to highlight the septa and

other soft-tissue structures within the orbit, enabling the

structures of interest to be traced on the computer

screen.

It was a notable finding of this study that embedding the

specimens in epoxy resin instead of paraffin wax

changed how the stains functioned. The protocols for

histological staining are generally intended for wax-

embedded microtome sections of 10 µ thickness or less.

We found firstly, that staining times had to be increased

to allow the stain to penetrate the relative thick section,

and, secondly, that the colours of the different stained

tissues were markedly different from those described in

the protocols given for paraffin wax-embedded

specimens. This variation seems to contradict the work

of Johnson and Barnett (2005), in which the staining

protocols for spinal soft tissues did not have to be

altered for epoxy-embedded sections.

Due to limitations of time and materials, 3-D

reconstruction could only be carried out on a single orbit,

however, the resulting image clearly shows the

complexities of the fibrous support network of the

interlobular septa. The image can be rotated and

manipulated in 3-D space, giving ophthalmic surgeons

an unparalleled view of the area into which they operate.

3-D Reconstruction of the Retrobulbar Orbital Septa 13

Future studies will compare images from different

individuals to assess the degree of individual variation in

the distribution pattern of the septa.

Furthermore, in this study, the septa and other soft

tissue structures were traced manually with the mouse

on the computer screen, which was a very time-

consuming and painstaking process. For future

investigations, the authors intend to investigate the use

of imaging software that can automate the process by

automatically selecting structures of the same color.

Limitations

This method of cutting semi-thin sections with a slow-

speed diamond saw means that for every 0.3 mm-thick

section that is cut, 0.4 mm will be lost due to the

thickness of the blade. At best then, this method

samples the specimen at 0.7 mm intervals. Another

problem was that the tissues stained a different colour to

what was expected, which meant that it was not possible

to rely on the colour of the stain to identify the tissue.

Conclusion

In conclusion, E12 plastination combined with a modified

Gomori’s trichrome stain provides a reliable method for

visualising the connective tissue fat septa, as well as

other soft tissue structures, of the orbit. This method

could therefore be used with a greater number of orbits

to find variations in the connective tissue architecture. It

could also be used to ascertain whether these tissues

make up a dynamic network which has a uniformity

between individuals, providing vital support to the globe

and communicating with the other structures within the

orbital cavity to allow controlled locomotion.

Appendix

Gomori's trichrome stain:

distilled water --------------------- 200.0 ml

chromotrope 2R (CI 16570) ------- 1.2 g

light green SF (CI 42095) ----------- 0.6 g

dodecatungstophosphoric acid --- 1.6 g

glacial acetic acid ------------------- 2.0 ml

Dissolve each reagent separately in 50 ml aliquots of the

distilled water, then mix all four solutions together. Allow

to stand overnight, filter into a reagent bottle. The stain

keeps well.

References

Adds PJ, Al-Rekabi A. 2014: 3-D reconstruction of the

ethmoidal arteries of the medial orbital wall using

Biodur® E12. J Plast 26: 5-10.

Bremond-Gignac D, Copin H, Cussenot O, Lassau J-P,

Henin D. 2004: Anatomical histological and mesoscopic

study of the adipose tissue of the orbit. Surg Radiol Anat

26: 297-302.

Fiala, JC. 2005: Reconstruct: a free editor for serial

section microscopy. J Microscopy 218: 52-61

Gaudiani JL, Braverman JM, Mascolo M, Mehler PS.

2012: Ophthalmic changes in severe anorexia nervosa:

a case series. Int J Eating Dis 45: 719-721.

Gomori, G. 1950: Aldehyde fuchsin: a new stain for

elastic tissue. Am J Clin Path 20: 665

IHCWORLDa. Gomori’s trichrome staining protocol for

connective tissues. Available at:

http://www.ihcworld.com/_protocols/special_stains/gomo

ri's_trichrome_ellis.htm (Accessed: 7 March 2016).

IHCWORLDb. Hematoxylin and Eosin (HE) staining

protocol. Available at:

https://www.ihcworld.com/_protocols/special_stains/h&e

_ellis.htm (Accessed: 7 March 2016).

IHCWORLDc. Miller’s elastic staining protocol. Available

at:

http://www.ihcworld.com/_protocols/special_stains/miller'

s_elastic_ellis.htm (Accessed: 7 March 2016).

Johnson G, Barnett R. 2005: A comparison between

epoxy resin slices and histology sections in the study of

spinal connective tissue structure. J Int Soc Plastination

15: 10-13.

Koornneef L. 1988: Eyelid and orbital fascial

attachments and their clinical significance. Eye 2: 130-

134.

Koornneef L, Zonneveld F. 1985: Orbital anatomy; the

direct scanning of the orbit in three planes and their

bearings on the treatment of motility disturbances of the

eye after orbital “blow-out” fractures. Acta Morphol Neerl

Scand 23:229-24 .

14 Adds et al.

Lillie RD. 1954: Histopathologic Technic and practical

Histochemistry 3rd ed. United States: McGraw-Hill Inc.

Lillie’s Trichrome for muscle and collagen. 2005:

Available at:

http://stainsfile.info/StainsFile/stain/conektv/tri_lillie.htm

(Accessed: 8 February 2016).

Mawhinney WH, Richardson E, Malcolm AJ. 1984:

Control of rapid nitric acid decalcification. J Clin Pathol

37: 1409-1413.

Miller JM, Demer JL, Poukens V, Pavlovski DS, Nguyen

HN, Rossi EA. 2003: Extraocular connective tissue

architecture. J Vision 3: 240-251

Miller P. 1971: An elastin stain. Med Lab Technol 28:

148-149.

Orbital connective tissue and fat. Available at:

http://clinicalgate.com/the-orbit-and-accessory-visual-

apparatus/ (accessed 7/9/2016)

Richter DF, Stoff A, Olivari N. 2007: Transpalpebral

decompression of endocrine ophthalmopathy by

intraorbital fat removal (Olivari technique): experience

and progression after more than 3000 operations over

20 Years. Plast Reconstr Surg 120: 109-123.

Sora M-C, Strobl B, Staykov D, Förster-Streffleur S.

2004: Evaluation of the ankle syndesmosis: a

plastination slices study. Clin Anat 17: 513-517.

Sora M-C. 2007: Epoxy plastination of biological tissue:

E12 ultra-thin technique. J Int Soc Plast 22: 40-45.

The Plastination Journal 29 (1): 15-18 (2017)

ORIGINAL RESEARCH

Biodur® S10/S3 and S15/S3 at “Room Temperature”: a viscosity study

P.J. ADDS

Institute of Medical and

Biomedical Education

(Anatomy), St Georges,

University of London

London, UK.

ABSTRACT: “Room temperature” silicone plastination has the twin advantages of reduced cost and simplicity

of set-up. At its best it can yield specimens which are the equal of those produced by low-

temperature impregnation. However, the increase in viscosity of the polymer at room temperature

leads to a shortened life of the polymer/chain-extender mixture. While the effect of temperature

on the rate of thickening of the reaction mixture is generally recognised, no quantitative data have

hitherto appeared in the literature. What do we mean by “room temperature”? In this study, daily

maximum and minimum ambient laboratory temperatures were monitored over six months in a

UK laboratory, and the viscosity of Biodur 10/S3® and S15/S3® polymer mixes were measured

over the same time period.

Results show that seasonal fluctuations in ambient temperature had a marked effect on the rate

of increase in viscosity in the samples tested. S10/S3 showed a gradual increase in viscosity up

to a critical level (around 30-40 Pa s), at which point the increase became exponential. The

viscosity of S15/S3 was particularly affected by a rise in mean laboratory temperature, with one

sample becoming unusable within 25 days.

Room temperature impregnation appears to be an attractive option for reasons of safety and

economy, and this is the method currently employed at St. George’s, University of London.

However, there are significant cost implications due to the shortened shelf-life of S10/S3. S15/S3

is not suitable for use at room-temperature.

KEY WORDS: room-temperature plastination; polymer; viscosity

Correspondence to: Philip J Adds, Institute of Medical and Biomedical Education (Anatomy), St Georges, University of London, Cranmer Terrace, London SW17 0RE, UK. Telephone +44(0) 2087255208, email: [email protected]

Introduction

Plastination as a method of producing long-lasting, high-

quality anatomical specimens has become widely used

in biomedical curricula around the world (Fasel, 1988;

Latorre et al., 2004; Lozanoff, 2004; Mansor, 1996;

Riederer et al., 2004; von Hagens et al., 1987). Many

institutions, finding their resources being ever more

stretched, have turned to plastination to preserve one of

their most valuable resources: embalmed cadaveric

specimens. The recommended methodology involves

low-temperature dehydration in acetone, then silicone

impregnation under vacuum at -15 to -20º C (von

Hagens, 1985, de Jong & Henry, 2007). However, it is

possible to produce specimens of equivalent or near-

equivalent quality by impregnation with silicone polymer

at room temperature (Kularbkaew et al., 1996;

Miklošová, 2002; Raoof, 2001; Zheng et al., 1996; de

Jong and Henry, 2007; Sagoo & Adds, 2013). This may

be seen as an attractive option by institutions for which

the capital cost of setting up a low-temperature facility,

or for whom the stringent Health and Safety

requirements which the use of large quantities of

acetone inevitably engenders, may prove a deterrent.

The potential drawbacks of the room-temperature

process are increased shrinkage of the specimen, and

increasing viscosity of the polymer/chain-extender

reaction mixture. Increasing viscosity is an inevitable

consequence of adding chain-extender (Biodur® S3) to

the silicone polymer (Biodur® S10 or S15), however the

rate of increase in viscosity is known to be slower at

lower temperatures, enabling the reaction mixture to

remain viable for longer. At room temperature the

increase in viscosity is accelerated, though no data

currently exist to demonstrate this quantitatively;

similarly, there are no data in the literature showing how

the rate of increase in viscosity is related to differences

in ambient temperature. Although the term “room

temperature” is frequently encountered in the literature,

its meaning will obviously vary depending on climate,

time of year, and the presence, or lack, of air-

conditioning in the laboratory.

This study aimed to provide the raw data which show

how the viscosity of the silicone/chain extender mixtures

OR

IGIN

AL R

ESEAR

CH

16 Adds

changes over time, and how this change is related to

ambient temperature in a UK laboratory over a period of

6 months.

Materials and Methods:

The daily maximum and minimum ambient laboratory

temperatures were recorded on a digital

maximum/minimum thermometer (RS Components Ltd.)

over a period of six months, from the end of December

through to the end of June (i.e. from winter to summer in

the U.K.). Concurrently, viscosity measurements were

carried out on separate samples of Biodur S10/S3

(100:1) and S15/S3 (100:1). To determine the viscosity

of the polymer, steel ball bearings of known mass and

diameter were dropped into a cylinder of polymer of

known height. The time taken for the ball bearings to

sink to the bottom of the cylinder was recorded using an

Oregon scientific digital stop-watch (RS Components

Ltd.). Each reading was recorded three times, i.e. three

ball bearings were dropped separately and timed on

each occasion, and the mean calculated. The height of

the column was measured in between each reading to

take into account the displacement of the individual ball

bearings. The time taken for the ball bearings to reach

terminal velocity was considered to be negligible and

was disregarded.

The density of the ball bearings was calculated from

their mass and diameter. The density of the polymer was

calculated from the mass of a known volume. From

these values the viscosity of the polymer could be

calculated thus:

Viscosity η = 2(Δρ)ga2 /9v in Pa.s (Pascal seconds)

Where:

Δρ = density (sphere) – density(liquid)

g = acceleration due to gravity (10 ms-1)

a = radius of sphere

v = velocity of sphere through liquid.

The viscosity data were then plotted against

temperature.

Results

1. Viscosity results for S10/S3

Figure 1. Maximum/minimum laboratory temperatures

and viscosity of two samples of Biodur S10/S3 (S10/S3

1, S10/S3 2); a, b represent the length of time taken in

each case for the polymer mixture to reach a viscosity of

40 Pa.s.

The maximum and minimum laboratory temperatures

showed a general seasonal variation, with the trend,

unsurprisingly, being towards warmer conditions in the

summer. From December to March, the minimum was

generally between 16 – 18º C, and the maximum was

generally between 20 – 22 º C. From March to June

there was a marked increase in both maximum and

minimum temperatures up to peaks of 26º C (maximum)

and 22º C (minimum) (Fig. 1).

During the test period, two samples of Biodur S10/ S3

were prepared at a ratio of 100:1 by volume, the first at

the start of the test period, and the second around three

months later. In both cases, the initial viscosity was 0.73

Pa.s. Both samples showed an initial period of gradually

increasing viscosity, until, at around 40 Pas, the increase

became exponential. Readings continued to be taken up

to around 150 Pas, after which the sample was

discarded.

The time taken, in each case, for the polymer mix to

reach a viscosity of 40 Pa s is represented by the

horizontal lines “a” and “b” on Figure 1. This period was

__________________________________________________ 1http://www.spacegrant.hawaii.edu/class_acts/Viscosityte.html

accessed 12.06.2017

The Plastination Journal 29 (1): 15-18 (2017)

89 days for the first sample of S10/S3, and 66 days for

the second sample.

The longer period of 89 days, represented by the line “a”

on graph 1, occurred during the cooler winter months,

while the shorter period of 66 days (line “b” on graph 1)

occurred during the warmer spring and summer weather.

The mean laboratory temperature for the first test period

was 18.82º C, and the mean for the second period was

21.51º C.

2. Viscosity results for S15/S3

Figure 2. Viscosity of two samples of S15/S3 stored at

room temperature, and maximum and minimum

laboratory temperatures

Figure 2 shows the viscosity of two different samples of

Biodur® S15/S3 over time, compared to maximum and

minimum laboratory temperatures. The first sample of

S15/S3 was prepared in March and the second in May.

The viscosity of the first sample increased from 0.032

Pas at t0 to 29 Pas in a period of 59 days. This

represents an increase of over 9 x 104 %. The viscosity

of the second sample increased from 0.032 at t0 to 386

Pas in 25 days, an increase of 1.2 x 106 %. The mean

temperature during the first test period was 19.9º C.

During the second test period the mean temperature

was 21.75º C.

Discussion:

It is well known that Biodur® silicone/chain extender

mixtures will become gradually more viscous over time

and that this thickening will be more rapid at room

temperature than at -25º C. Up to now, however,

quantitative data on the effect of temperature on the

viscosity of the reaction mixture has not been available

in the literature. In this study, we supply the raw data on

time, temperature and viscosity for Biodur® S10 and

S15 at ambient temperatures.

The increase in viscosity in both samples of S10/S3

followed a similar pattern. There was an initial period of

gradual increase, followed by an exponential phase once

a critical viscosity level was reached. Once this critical

level is passed, it is clear that the mixture will rapidly

become unsuitable for use. The time taken to reach this

point differed in the two samples tested in this study. The

first sample, prepared in December, took 89 days to

reach a viscosity of 40 Pa.s, while the second sample,

prepared in April, took only 66 days. From Figure 1 it can

be seen that the second test period coincided with an

overall increase in laboratory temperature, from a mean

of 18.82º C in the preceding 90 days, to 21.51º C during

the test period.

Biodur S15/S3 is initially significantly less viscous than

S10/S3, with a viscosity approaching that of water (Lide,

2002). The two test samples of S15/S3 showed very

different behaviours over time. The viscosity of the first

sample rose quite slowly from 0.032 to 29.0 Pa.s over a

period of 59 days. At this point the polymer had become

thick and sticky and unsuitable for further use. The

viscosity of the second sample rose much more rapidly

from 0.032 to 386.0 Pa s over a period of only 25 days

(Fig. 2), by which time it had become almost solid.

Again, the second test period coincided with an increase

of ambient laboratory temperature, from an average of

19.9º in the first period, to 21.75º C in the second.

It is clear, then, that a slight increase in temperature can

have a significant effect on the longevity of the reaction

mixture during room temperature impregnation with

Biodur® S10/S3 and S15/S3. The effect of temperature

on the S10/S3 mixtures in this study was considerably

less marked than the effect on the S15/S3 samples.

In conclusion, while room temperature plastination may

appear to be an attractive option for reasons of cost,

space and safety, there is inevitably an increased

turnover of polymer due to the more rapid thickening of

the reaction mixture, and this will lead to higher costs of

consumables when compared to a cold-temperature set

up. Because of its susceptibility to warm temperatures,

S15 appears to be unsuitable for room-temperature

plastination.

18 Adds

References

De Jong K, Henry RW. 2007: Biodur S10/15 technique

and products. J Int Soc Plastination 22: 2-14

Fasel J, 1988: Use of plastinated specimens in surgical

education and clinical practice. Clin Anat 1: 197-203.

Kularbkaew C, Cook P, Yutanawiboonchai W, von

Hagens G. 1996: Plastinated pathology specimens at

room temperature in Thailand. J Int Soc Plastination, 19:

48.

Latorre R, Garcia-Sanz MP, Gil F, Moreno M, Agut A,

Quiñonero JM, Lozano E, Herrero J, Hernández-Pina F,

Fenandes-Seródio H, Henry R. 2004: Evaluation of

plastinated organs as a resource for improvement of the

teaching-learning processes. J Int Soc Plastination 19:

48.

Lide DR, editor 2002: CRC Handbook of chemistry and

physics, 83rd ed. CRC Press, London.

Lozanoff S. 2004: Plastination: A tool for education. J Int

Soc Plastination 19: 11.

Mansor O. 1996: Use of plastinated specimens in a

medical school curriculum. J Int Soc Plastination 11: 16-

17.

Miklošová M. 2002. Plastination of pathologic specimens

via room temperature S10. 11th Int Conf Plast, San

Juan, Puerto Rico.

Raoof A. 2001: Using a room-temperature plastination

technique in assessing prenatal changes in the human

spinal cord. J Int Soc Plastination 16: 5-8.

Riederer B, Musumeci E, Duvoisin B, Lang F. 2004:

Plastination, a useful tool on teaching clinical anatomy. J

Int Soc Plastination.

Sagoo MG, Adds PJ. 2013: Low-temperature

dehydration and room-temperature impregnation of brain

slices using BiodurTM S10/S3. J Plastination 25: 3-8

Von Hagens G. 1985: Heidelberg plastination folder:

Collection of all technical leaflets for plastination.

Heidelberg: Anatomisches Institut 1, Universitat

Heidelberg.

Von Hagens G, Tiedman K, Kriz W. 1987: The current

potential of plastination. Anat Embryol, 175: 411-421.

Zheng TZ, Weatherhead B, Gosling J. 1996: Plastination

at room temperature. J Int Soc Plastination, 11: 33.

The Journal of Plastination 29 (1): 19-25 (2017)

TECHNICAL REPORT

The Use of Vacuum Forced Impregnation of Gum Arabic Solution in Biological Tissues for Long-Term Preservation

Mahmoud Sheikh Satte

1

Tahir Osman Ali2

Abdel Hafeez Yagoub

Mohamed3

1, 3

Anatomy Department,

Medical College, Najran

University, Najran,

55461, KSA

2Anatomy Department,

College of Graduate

Studies, National Ribat

University, Khartoum,

12214, Sudan.

ABSTRACT:

The objective of this study was to search for an economical, effective, and safe method of tissue

preservation compared to the high-cost standard plastination technique currently used for

preservation of human and animal tissues. This study was conducted on 144 specimens of adult

sheep, divided into 11 experimental groups and one control group; each group contained 12

specimens of four halves of kidneys, hearts and brains. The experimental groups were preserved

in eleven different concentrations of gum Arabic solutions, made of a mixture of gum Arabic

powder, glycerine and distilled water, while the control group was preserved in silicone-S10 as

the standard method of plastination used in tissues preservation. The innovative use of forced

impregnation and vacuum to “infuse” the gum Arabic solution was the successful mechanism

used in this new technique. It borrows the key step of the plastination technique, that is, forced

impregnation to impregnate the biological tissues with gum Arabic solution. The results of the

current study revealed durable, realistic preserved specimens with permanent, clear, anatomical

features. In conclusion, gum Arabic solution can be used as a low-cost and safe preservation

method for teaching anatomy in medical and veterinary colleges, comparable to silicone-S10

plastination, but less expensive.

KEY WORDS: gum Arabic solution, forced impregnation, preservation, kidneys, hearts, brains.

Correspondence to: Dr. Mahmoud S Satte, Anatomy Department, Medical College, Najran University, Najran, 55461, KSA. Telephone: +966553125185 E-mail: [email protected]

Introduction

Preservation of tissues in their natural state, or close to

the original, has helped enormously in medical and

veterinary medical education. There are several

methods for preservation of cadaveric and animal

organs and bodies; gum Arabic and some local materials

such as natron (hydrated sodium carbonate) and herbs

were used traditionally by the ancient Egyptians to

preserve dead bodies (Rosengarten, 1969; Abdel-

Maksoud and El-Amin, 2011). Centuries later, formalin

solutions have been used for fixation of tissues,

however, formalin has many health hazards (Abdullahi et

al., 2014). Plastination was introduced as a safe

technique for preservation of cadavers by von Hagens in

1979.

In standard silicone plastination, the tissues are fixed in

formalin (5 to 20%), dehydrated in acetone, impregnated

in curable silicone-S10 resin and finally cured with S6

(Biodur®). The plastinated specimens were found to be

more durable and odorless, showing features similar to

the original, however, this procedure is relatively

expensive (von Hagens et al., 1987; Grondin, 1998; De

Jong and Henry, 2007).

Gum Arabic, or Acacia gum, is a natural polymer

produced from wild trees of Acacia senegal or Acacia

seyal which mainly grow in the African region. The

chemical structure of the gum Arabic is composed

largely of high molecular weight glycoprotein and

polysaccharide; therefore, these components are water-

soluble natural polymers (Shanmugam et al., 2005).

Gum Arabic is used in food and pharmaceutical

industries as an emulsifier and long-term stabilizer (Garti

and Reichman, 1993). Gum Arabic solution is prepared

from a mixture of gum Arabic powder, glycerine, and

distilled water, which are inexpensive substances

(Duaqan & Abdullah, 2013; Alkarib et al., 2015). The

physical properties of gum Arabic solution, such as

flexibility and viscosity, can be enhanced by the addition

of plasticizing agents such as ethylene glycol, glycerine,

polyethylene, and glycol (Wyasu and Okereke, 2012;

Alkarib et al., 2016). To our knowledge, gum Arabic has

not previously been used for preservation of biological

tissues for the purpose of education in the medical field.

Therefore, the main objective of this study was to assess

TECH

NIC

AL R

EPO

RT

20 Satte et al.

the feasibility of using gum Arabic solution for production

of affordable and safe, preserved biological tissue.

Materials and Methods

Specimen collection and fixation

A total of 72 fresh organs (24 hearts, 24 kidneys and 24

brains) of adult sheep were collected from an abattoir.

The organs were transferred in an icebox to the

dissection room, and then washed under running tap

water to clean blood clots and fat. Each organ was cut

sagittally into two halves to give a total of 144

specimens. The specimens were divided into 12 groups,

with each group containing 12 specimens (4 halves of

kidneys, 4 halves of hearts, and 4 halves of brains).

Each group of specimens was placed in a plastic

container with a tight lid, and fixed in 10% formalin for 3

days (Srisuwatanasagul et al., 2010).

Dehydration

After fixation, the specimens were dehydrated in three

changes of pure acetone for 10 days at room

temperature. The acetone replaces the tissues fluid and

removes excess fat. The concentration of acetone of the

successive changes was measured by using a

hydrometer (Fisher brand, USA). When the final acetone

concentration remained 99 % or above, and unchanged

for a period of time, the specimens were considered

dehydrated (De Jong and Henry, 2007; Elnady, 2016).

Preparation of gum Arabic solutions and curable

silicone-S10

Eleven gum Arabic solutions of different concentrations

were prepared from pure gum Arabic powder (Acacia

senegal, Natural Gum, Sudan), distilled water and pure

glycerine (Chiangrai Agro-Industry Co. Ltd., Thailand,

99.5% USP Grade). Two litres of each solution were

kept in plastic containers of 3 litres capacity. The

silicone-S10 (Silicones Inc., High Point, USA) was mixed

with catalyst-S3 (Silicones Inc., High Point, USA) at

100:1 ratio, and was used as a control (Suganthy and

Francis, 2012) (Table 1).days.

Immersion of specimens in gum Arabic solutions

and curable silicone-S10

After fixation and dehydration, the first eleven groups of

specimens were submerged in gum Arabic solutions,

while group 12 specimens were submerged in silicone-

S10/S3 mixture as shown in Table 1. The specimens

were left in the different solutions for two days to

equilibrate before the forced impregnation process. The

submerged specimens for each group were covered by

stainless steel grid to avoid the samples floating.

Intermittent forced impregnation

Forced impregnation was used for the replacement of

acetone in the specimens with the gum Arabic solutions

(for the experimental groups) and a curable polymer (for

the control group). The submerged groups of specimens

were transferred to the vacuum chamber (Mopec, USA)

connected to a vacuum pump (Mopec, USA,

HP200D11001) for forced impregnation at room

temperature. The vacuum caused the acetone to

vaporize from the specimens creating spaces in the cell

for the gum Arabic solutions and polymers to diffuse into.

The vacuum pressure was gradually decreased to 6 mm

Hg. Vacuum was maintained for 4 days (5 hours daily)

for the experimental groups and one week for the control

group. Impregnation was considered completed when

there were no air bubbles coming out from the

specimens (Suriyaprapadilok and Withyachumnarnkul,

1997).

Forced Impregnation of Gum Arabic 21

Post-Impregnation

After forced impregnation, the specimens were removed

from the impregnation solution, and excess gum Arabic

solution and polymer was allowed to drain. The

specimens in each group were then arranged on a

stainless steel plate for comparison and photography.

Curing

One day after forced impregnation, the control group

was transferred to a closed gas curing chamber at room

temperature, and cured with catalyst S6 (two times daily,

10 minutes, for three days) until the specimens were

hardened (De Jong and Henry 2007). The experimental

specimens were allowed to harden by atmospheric air at

room temperature for one week.

Qualitative Analysis

The anatomical features of the specimens in each group

were noted and recorded before and after preservation

for comparison among the different groups of

specimens.

Results

The specimens preserved in gum Arabic solutions were

clean, odorless and flexible. The specimens have

maintained their original anatomical features and details

until now, nine months after their preparation. The fine

anatomical features and details of the specimens were

clearly maintained in all groups preserved in gum Arabic

solutions, and were similar to that of the control group,

except for group 11 specimens which showed slightly

unclear morphological details (Figs. 1, 2, 3).

Fig.1: Images of fresh, preserved and plastinated adult

sheep kidneys. Fresh kidney (F). Gum Arabic solution

preserved kidneys (1-11). Silicone-S10 plastinated

kidney (12). Renal cortex, pyramids, renal calyces and

renal pelvis are labeled with letters a, b, c, and d

respectively.

22 Satte et al.

The internal and external anatomical features that were

considered for comparisons among the different groups

of specimens were: the appearance of the cortex,

pyramids, calyces, and pelvis of the kidneys (Figs. 1a,

1b, 1c, 1d), and the atria, ventricles, cardiac valves with

attached chordae tendinae, and septa for the hearts

(Figs. 2a, 2b, 2c, 2d), while the appearance of the

anatomical features of the cerebral cortex, corpus

callosum, thalamus, pons, cerebellum and medulla

oblongata were considered for the brains (Figs. 3a, 3b,

3c, 3d, 3e, 3f).

Fig.2: Images of fresh, preserved and plastinated adult

sheep hearts. Fresh heart (F). Gum Arabic solution

preserved hearts (1-11). Silicone-S10 plastinated heart

(12). The atria, valves and their attached chordae

tendinae, septum and ventricles are labeled with letters

a, b, c, and d respectively.

Discussion

Plastination is a modern safe technique in which

polymers are used to replace tissue water and preserve

tissues in a state nearest to the original form (von

Hagens, 1979; von Hagens et al., 1987). The high cost

of silicone resin, and the increasing demand for

plastinated organs in medical and veterinary colleges

encourages the search for low-cost alternative materials

for the preservation of biological tissues for teaching of

gross anatomy. In this study, gum Arabic solutions

prepared from a mixture of gum Arabic powder,

glycerine and distilled water were used for preservation

of adult sheep organs. Gum Arabic is a natural

agricultural product, while glycerine is an industrial by-

product of soap manufacturing; both materials are safe,

nontoxic, inexpensive and available in poor countries,

moreover, gum Arabic solution has very good physical

properties such as elasticity and viscosity (Alkarib et al.,

2016).

Specimens preserved in gum Arabic solutions in the

current study were realistic, odorless, dry, and flexible,

and can be stored at room temperature on shelves for a

long period with minimal aftercare. These facts are in

agreement with silicone plastinated specimens

(Pendovski et al., 2008; Suganthy and Francis, 2012).

Forced Impregnation of Gum Arabic 23

Fig.3: Images of fresh, preserved and plastinated adult

sheep brains. Fresh brain (F). Gum Arabic solution

preserved brains (1-11). Silicone-S10 plastinated brain

(12). The cerebral cortex, corpus callosum, thalamus,

pons, cerebellum and medulla oblongata are labeled

with letters a, b, c, d, e and f respectively.

In cold temperature plastination techniques, specimens

are dehydrated at -22o C to -25o C, and this needs

refrigeration (Pendovski et al., 2008; Darawiroj et al.,

2010). However, in the present study, specimens were

dehydrated at room temperature, which reduced the cost

of purchasing deep freezers as in the cold temperature

technique.

Forced impregnation at room temperature of small

specimens such as porcine hearts in curable silicone-

S10 was completed in more than one week (Darawiroj et

al., 2010). In the present study, impregnation of the

specimens in gum Arabic solution needed only 5 hours

vacuum pump daily for 4 days, which indicates that gum

Arabic solution needs a shorter time for the forced

impregnation process, and will moreover, lead to an

extended life of the plastination equipment.

De Jong and Henry (2007) mentioned that specimens

are placed in a closed curing chamber, containing the

cross-linking curing agent S6, for more than one week to

ensure curing and hardening, however, in the current

study specimens were hardened at room temperature

without being cured in silicone-S6. This further reduces

the cost of tissues preservation in gum Arabic solutions

compared to the silicone plastination process. A

24 Satte et al.

previous investigation revealed that gum Arabic

solutions are not susceptible to fungal growth (Alkarib et

al., 2016). In the present study, the final preserved

specimens were stored on shelves at room temperature

for nine months without showing any fungal growth on

their surfaces.

Increasing the amount of the plasticizing agent

(glycerine) in the mixture improves the elasticity and

viscosity of the gum Arabic solution by decreasing the

water content (Wyasu and Okereke, 2012). This

coincided with the fact that the best-preserved

specimens obtained in the present study were those

impregnated in gum Arabic solutions with a high

glycerine content (solutions 1-10) which made the

preserved specimens more flexible.

Appropriate amounts of gum Arabic, glycerine, and

water in the impregnation mixture are important factors

that affect the final result. Hence, the best results were

observed when the impregnation mixture contained less

than 110 g/L gum Arabic powder, 30% to 80% of

glycerine and less than 70% water. This was very

obvious in group 11 specimens that had been preserved

in gum Arabic solution which contained 227 g/L gum

Arabic powder, 10% glycerin and 90% water (Figs. 1, 2,

3). In this group, the specimens were less flexible, and

showed poor anatomical features. In general, the

specimens preserved in gum Arabic solution were more

flexible and less brittle (specially the brain tissues) in

comparison with the silicone-plastinated specimens.

In conclusion, gum Arabic solutions can be used for

production of inexpensive, safe and durable preserved

specimens that can be used for teaching of gross

anatomy and neuroanatomy in medical and veterinary

colleges. However, further investigations are

recommended about the efficiency of gum Arabic

solutions for preservation of whole body and large size

body specimens.

References

Abdel-Maksoud G, El-Amin A. 2011: A review on the

materials during mummification processes in ancient

Egypt. Medit Arch Archaeometry 11: 129-150.

Abdullahi M, Zagga AD, Iseh KR , Amutta SB, Aliyu D.

2014: Nasal response from formaldehyde exposure

used as cadaver preservative among pre-clinical

medical students in a Nigerian medical college. Int J Otol

Head Neck Surg 3:173-178.

Alkarib SY, Khaleel AA, Nurein MA. 2016: Gum Arabic

acacia for manufacturing of hard & soft empty capsules

in Sudan. World J Pharm Pharmaceutical Sci 5:219-327.

Alkarib SY, Mohamedelhassan DE, Abubakr ON. 2015:

Evaluation of gum Arabic solution as a film coating

former for immediate release oral tablet formulation. J

Pharm Pharmaceutical Sci 5:32-41.

Darawiroj D, Adirekthaworn A, Srisuwattanasakul S,

Srisuwattanasakul K. 2010: Comparative study of

temperatures used in silicone impregnation of porcine

hearts plastination. Thai J Vet Med 40: 433-436.

De Jong K, Henry RW. 2007: Silicone plastination of

biological tissue: cold temperature technique BiodurTM

S10/S15 Technique and products. J Int Soc Plast 22: 2-

14.

Duaqan E, Abdullah A. 2013: Utilization of gum Arabic

for industries and human health. Am J Appl Sci 10:1270-

1279.

Elnady FA. 2016: The Elnady technique: an innovative,

new method for tissue preservation. Altex 33: 237-242.

Garti N and Reichman D. 1993: Hydrocolloids as food

emulsifiers and stabilizers. Food Struct 12: 411-426.

Grondin G. 1998: Plastination: a modern approach to

chiropractic teaching. J Can Chiropr Asso 42: 107-112.

Pendovski L, Petkov V, Popovska F, Ilieski V. 2008:

Silicone plastination procedure for producing thin,

semitransparent tissue slices: a study using the pig

kidney. J Int Soc Plast 23:10-16.

Rosengarten F. 1969: Ancient Egyptian and Arabian

beginnings (from about 2600 BC). The Book of Spices,

Jove Publ., Inc., New York. P: 23–96.

Srisuwatanasagul K, Adirekthaworn SSA, Darawiroj D.

2010: Comparative study between using acetone and

absolute alcohol for dehydration in plastination

procedure. Thai J Vet Med 40: 437-440.

Shanmugam S, Manavalan R, Venkappayya D,

Sundaramoorthy K, Mounnissamy VM, Hemalatha S,

Ayyappan T. 2005: Natural polymers and their

applications. Nat Prod Rad 4: 478-481

Suganthy G, Francis DV. 2012: Plastination using

standard S10 technique - our experience in Christian

Medical College, Vellore. J Anat Soc India 61: 44-47.

Forced Impregnation of Gum Arabic 25

Suriyaprapadilok L, Withyachumnarnkul B. 1997:

Plastination of stained sections of the human brain:

comparison between different staining methods. J Int

Soc Plast 12: 27-32.

von Hagens G. 1979: Impregnation of soft biological

specimens with thermosetting resins and elastomers.

Anat Rec 194: 247-256.

von Hagens G, Tiedemann K, Kriz W. 1987: The current

potential of plastination. Anat Embryol 175: 411-421.

Wyasu G, Okereke NZJ. 2012: Improving the film

forming ability of gum Arabic. J Nat Prod Plant Resour

2:314-317.

The Plastination Journal 29 (1): 26-29 (2017)

ORIGINAL RESEARCH

Room temperature Impregnation with Cold Temperature Biodur® Silicone: A Study of Viscosity.

Mircea-Constantin Sora

Centre for Anatomy and

Molecular Medicine,

Sigmund Freud Private

University, Vienna,

Austria.