The influence of emulsifiers on the heat shock stability ... · ous ice cream freezer (WCB Ice...

Transcript of The influence of emulsifiers on the heat shock stability ... · ous ice cream freezer (WCB Ice...

The influence of emulsifiers on the heat shock stability of ice cream

TP

25

11

-1e

3

AbsTrAcT

The influence of emulsifiers (mono-diglycerides) on the heat shock stability of ice cream was studied in samples with varying levels of overrun, i.e. 60%, 100% and 140%. Investigations were made to evaluate the size distribution of air bubbles and ice crystals, melting resist-ance, solvent extractable fat and sensory properties in fresh ice cream samples and samples subject to heat shock. Emulsifiers were seen to increase heat shock stability, melting resistance and air bubble stability and give a finer distribution of air bubbles. Unsaturated emulsifiers provided the best melting resistance. High air content protected ice cream from ice crystal growth when emulsifiers were present. Low air content produced inferior melt-ing resistance.

InTroducTIon

Good quality ice cream is generally as-sumed to contain small air cells and ice crystals, resulting in increased creaminess and reduced iciness (1).

The air bubbles in the ice cream foam structure are thermodynamically unstable and may be destabilised by dispropor-tionation, drainage and coalescence (2). Air bubble coalescence is an important mechanism for quality deterioration in ice cream. Foam stability may be improved by the adsorption of partially coalesced fat droplets to air bubbles (3, 4, 5) or by raising the level of viscosity by “harden-ing” the product (1, 5).

Ice crystal size is a critical attribute governing the texture of ice cream and other frozen desserts. Ice crystals larger than 55mm (X50,0) result in a coarse and icy texture if present in sufficient number (6, 7).

A coarse ice cream structure can result from heat shock during frozen storage or temperature fluctuations during distribu-tion, product mishandling or processing at non-optimal conditions. This can cause large ice crystals and air bubbles to form. Further deterioration can be identified by air channel formation and shrinkage (8).

This paper deals mainly with the influence of air cell structure/air phase volume (% overrun) on ice crystal growth in ice cream with 60%, 100% and 140% overrun. Emulsifiers such as mono-diglycerides and hydrocolloids can stabilise the air structure in ice cream and slow the growth of ice crystals. For this reason, the effect of saturated and un-

saturated monoglycerides on heat shock stability was evaluated. This included a study of air cells and ice crystals in fresh ice cream samples and samples subject to heat shock.

The effect of heat shock treatment on the melting resistance and sensory properties of ice cream is also reported, with a particular focus on the difference between saturated and unsaturated monoglycerides.

MATerIAl And MeThods

FormulationsThe recipes used for the trials is shown in table 1 below.

coMposITIon, % 1 2 3

Water 63.95 63.55 63.92

Butter oil concentrate (AMF) 8.00 8.00 8.00

Skimmed milk powder 8.60 8.60 8.60

Whey powder 2.90 2.90 2.90

Sucrose 12.00 12.00 12.00

Glucose syrup solids, 32 DE 4.00 4.00 4.00

Emulsifier no. 1 0.37 - -

Emulsifier no. 2 - 0.37 -

Stabiliser blend 0.18 0.18 0.18

Vanilla Flavouring 3000 0.30 0.30 0.30

Colouring 0.10 0.10 0.10

Total 100.00 100.00 100.00

Total fat 8.10 8.10 8.10

Total MSNF 11.00 11.00 11.00

Total dry matter 35.80 35.80 35.45

Emulsifier no. 1 is saturated mono-diglycerides of fatty acids (saturated MG) from Danisco.

Emulsifier no. 2 is partially unsaturated mono-diglycerides of fatty acids (unsaturated MG) from Danisco.

The stabiliser blend from Danisco is a blend of the following stabilisers: locust bean gum, sodium alginate, guar gum and carrageenan.

Paper presented at Inter-Ice 2000, Solingen, November 2000.N.M. Barfod1, H. Rohenkohl2, F.H. Christensen1 & M. Nielsen1.

1 Danisco A/S, Brabrand, Denmark, 2 Deutsches Institut für Lebensmitteltechnik, Quakenbrück, Germany.

Table 1. Recipes for the ice cream samples.

4

Ingredients•ButteroilconcentratefromArlaFoods•Skimmedmilkpowder(MILEX® 240)

from Arla Foods•Standardwheypowder(Domovictus

100) from Domo Food Ingredients•Purecrystallinesaccharosefrom

Danisco •Glucosesyruppowder,32DE

(CPUR 01934) from CERESTAR•VanillaFlavouring3000fromDanisco•Colourings(water-solubleAnnatto

A-320-WS) from Chr. Hansen A/S

processing procedureThe skimmed milk powder, whey powder and a dry blend of sugar, glucose syrup solids and emulsifier/stabiliser blend were dissolved in the water and heated to 50°C; flavour and colour were added and the mix rehydrated for 30 minutes. The fat was melted and mixed with the water phase while being heated to 85°C/30 sec. and then homogenised on a homog-eniser (Lab 1250, APV Rannie) with a LW head at 78°C/180 bar. Subsequently, the emulsion was cooled to 5°C, aged overnight (approximately 24 hours), and frozen and whipped into ice cream with a constant overrun of 60%, 100% and 140% (for sample no. 3, it was only possible to achieve a maximum overrun of 100%) and an outlet temperature of –5.0°C using a Technohoy MF50 continu-ous ice cream freezer (WCB Ice Cream, Denmark). The ice cream was filled into 0.25 litre cartons and hardened in a hard-ening tunnel at –35°C for 24 hours. The ice cream was then stored at –25°C. The temperature of the ice cream was raised to and maintained at –18°C for 24 hours before being analysed.

Half of the different samples were subject to heat shock treatment. This involved tempering and storing the products in a freezer at –18°C. After tempering, the products were placed in a heat shock freezer where the temperature varied between –20°C and –5°C every 6 hours. The products were kept in this freezer for 7 days. Both

ice cream samples stored at a constant temperature and those subject to heat shock were analysed.

Ice cream analysisThe following analyses were performed on the ice cream samples:

Sensory analysisThe ice cream was evaluated by six trained people from the ice cream group at Danisco, Denmark.

Meltdown determinationThe melting rate (drip rate) was measured using the method described in technical memorandum no. 2520 from Danisco (9).

A rectangular piece of ice cream (125cc, dimension: approx. 100mm x 50mm x 25mm), which had been stored at –18°C for at least 24 hours, was weighed and placed on a grid in a room with a constant temperature

of 22°C+/–1°C. The grid was placed above a 500ml glass beaker placed on an analytical balance.

The analytical balance was linked to a computer which registered the weight of the ice cream once every 2 minutes and calculated the amount of melted ice cream as a function of time. After 2 hours a graph of melting behaviour could be drawn.

Solvent extractable fat (SEF)The amount of de-emulsified fat was expressed as solvent extractable fat and calculated according to the method described in technical memorandum no. 2517 from Danisco (10).

A 25g sample of frozen ice cream was weighed directly into a number of 100ml cylinder glasses. The ice cream samples were thawed for approximately 2 hours and 30ml heptane filled into each cylinder glass. The lid was carefully closed and the cylinder glasses placed on a rotator.

sAMple code

eMulsIFIer / sTAbIlIser sysTeM

overrun %

sTorAge condITIons

1A saturated MG 60 constant –18°C

1B saturated MG 100 constant –18°C

1C saturated MG 140 constant –18°C

2A unsaturated MG 60 constant –18°C

2B unsaturated MG 100 constant –18°C

2C unsaturated MG 140 constant –18°C

3A no MG 60 constant –18°C

3B no MG 100 constant –18°C

sAMple code

eMulsIFIer / sTAbIlIser sysTeM

overrun %

sTorAge condITIons

1A-H saturated MG 60 heat shock

1B-H saturated MG 100 heat shock

1C-H saturated MG 140 heat shock

2A-H unsaturated MG 60 heat shock

2B-H unsaturated MG 100 heat shock

2C-H unsaturated MG 140 heat shock

3A-H no MG 60 heat shock

3B-H no MG 100 heat shock

Table 2a. Description of the ice cream samples.

Table 2b. Description of the ice cream samples.

5

Rotation: 15 times at 30rpm, followed by 2 minutes’ rest to avoid mix on the sur-face, then rotation 10 times. The samples were left standing for approximately 60 minutes for separation.

The heptane phase is levered into a ml conical flask which had been dried to-gether with a pumice for 1 hour in an in-cubator at 105°C and then weighed. The heptane phase was evaporated in a sand bath. This extraction process was re-peated twice more, excluding the last 10 rotations. After the final evaporation, the conical flasks were dried in the incubator at 105°C for 4 hours.

Ice crystal and air bubble size distribu-tion – SEMThe structure of the samples was analysed by scanning electron micros-copy (SEM) using the cryo-break tech-nique. Afterwards the surface was etched by sublimation of some surface water for a few seconds. The samples were prepared at –25°C in a freezing room. Small pieces of the centre of the samples were taken using a scalpel. These pieces were fixed in the sample holder which was then placed in a closed chamber to transfer the sample to the preparation unit of the microscope. The sample on the sample holder was quickly inserted in the preparation unit and cooled to about –180°C within a few seconds by liquid nitrogen under vacuum. This very rapid temperature decrease is necessary to guarantee no further growth of the exist-ing ice crystals and that no visible new ice crystals are formed. At this temperature the sample was broken using a knife and a smooth surface obtained. Afterwards the surface was etched for a few sec-onds for better visualisation of the ice crystals. The sample was then spattered

with a thin gold layer to enable electron microscopy.

After this preparation, the sample was transferred directly to the microscope for structure analysis. The temperature was kept at –160 to –180°C using liquid nitrogen. A magnification of 100x and 200x was used. On the photographs the magnification is given by a bar, which represents a length of 100mm. With a few samples a higher magnification of 3,000x was used to study the air serum interface in detail. On these photographs the magnification is expressed by a bar representing a length of 10mm.

Ice crystal and air bubble size distribu-tion were calculated by image analysis (NIH Image 1.6) of the photos. Particle segmentation was carried out manually. Clustered ice crystals separated by the continuous phase were calculated as single crystals. Clustered ice crystals with-out a visible separation were analysed as one crystal. After segmentation of areas, which refer to ice crystals or air bubbles, the particle size distribution of the ice crystals and air bubbles was computed. The sizes were calculated as diameters of a sphere with the same projection area.

Number and volume distribution were calculated. A characteristic value is the mean particle size, used to compare dif-ferent particle size distributions. This size is called x50,0 (number distribution) or x50,3 (volume distribution). In relation to this mean value, 50% of the total number or volume of the dispersed particles have smaller diameters and 50% larger.

Further characteristic particle diam-eters are:x10,0 or x10,3 10% of the total number or volume of particles have smaller diameters and 90% larger x90,0 or x90,3 90% of the total number or volume of particles have smaller diameters and 10% larger Spani width of the distribution X90,i - X10,i X50,i

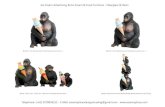

Figure 1 shows the structural elements subject to image analysis.

resulTs And dIscussIon

sensory evaluationConstant temperature storageThe samples made with unsaturated MG (sample 2) were the creamiest and had the highest body and warmest eating properties. The samples made without emulsifiers were the least creamy and had the least body and coldest eating properties. The creaminess and warm eating properties of the ice cream increased with a higher overrun.

After heat shockThe quality of all the samples decreased following heat shock treatment. The samples without MG showed signs of shrinkage and had the least body and coldest eating properties and were least creamy. The samples made with 140% overrun were fluffy and large air bubbles were visible on the surface. The quality of the ice cream made with saturated and unsaturated MG was comparable.

solvent extractable fatSolvent extractable fat (SEF) was used to quantify the amount of de-emulsified fat in the ice cream samples. Increased SEF figures usually indicate higher creaminess and improved melting resistance. For normal bulk ice cream (with 100% over-run) a SEF figure of around 10 is normal. Both increased mechanical treatment of ice cream (lower drawing temperature from the freezer) and a higher degree of emulsion destabilisation (use of emulsi-

Calculation:

Per cent solvent extractable fat =

gram solvent extractable fat x 100 x 100 25 x F

F = Per cent fat in ice cream sample

Figure 1. Scanning electron microscopy of ice crystal (C) sizes and air bubbles (A).

6

fiers such as mono- and diglycerides) produce higher SEF figures.

Table 3 shows the influence of overrun and emulsifiers on SEF.

Table 3 shows that unsaturated MG produced a much higher level of de-emulsified fat than saturated MG. Ice cream without MG produced practically no extractable fat, which means very little fat agglomeration.

Meltdown determinationConstant storage temperatureFigures 2A, B and C show the melting behaviour of ice cream with different levels of overrun prior to heat shock. In ice cream with 60% overrun (figure 2A), melting resistance improved only slightly using saturated MG, compared to ice cream without MG. Further improve-ment was achieved using unsaturated MG.

In ice cream with 100% overrun (figure 2B), melting resistance improved consid-erably using saturated MG, compared to ice cream without MG. Further improve-ment was achieved using unsaturated MG.

In ice cream with 140% overrun (figure 2C), melting resistance was improved when unsaturated MG was used, com-pared to ice cream with saturated MG.

Melting resistance improved when overrun was increased from 60% to 100% and when saturated and unsatu-rated MG were used. But there was no improvement in the melting resistance of ice cream without MG. Increasing

the overrun from 100% to 140% also improved the melting resistance of ice cream made with saturated and unsatu-rated MG.

After heat shockFigures 3A, B and C show the melting behaviour of ice cream with various degrees of overrun after heat shock.

The melting resistance of all the sam-ples subject to heat shock was inferior compared to the other samples. The samples with unsaturated MG were least affected by heat shock treatment.

Mechanism behind improved melting resistance with unsatu-rated MgIn ice cream production unsaturated MGs result in drier extrusion and slower meltdown properties than saturated MGs. Unsaturated MGs have a more destabilising effect on the emulsion of ice cream mix, as can be seen by the higher SEF figures in the analysis. Further differences between unsaturated and saturated MGs have recently been stud-ied in great detail (11). This work showed the two MG types differ in their effect

overrun 60% 100% 140%

Sample 1 with saturated MG

6.5% 9.0% 10.7%

Sample 2 with unsaturated MG

15.7% 19.5% 22.0%

Sample 3 without MG

0.7% 0.5% –

Table 3. Solvent extractable fat measured in the ice cream samples.

Figure 2. Meltdown of ice cream with different levels of overrun before heat shock.

Melted in per cent100

80

60

40

20

00 20 40 60 80 100 120

Minutes at 22°C

No MG

Saturated MG

Unsaturated MG

A: 60% overrun

Melted in per cent100

80

60

40

20

00 20 40 60 80 100 120

Minutes at 22°C

No MG

Saturated MG

Unsaturated MG

b: 100% overrun

Melted in per cent100

80

60

40

20

00 20 40 60 80 100 120

Minutes at 22°C

Saturated MG

Unsaturated MG

c: 140% overrun

Figure 3. Meltdown of ice cream with various degrees of overrun after heat shock.

Melted in per cent100

80

60

40

20

00 20 40 60 80 100 120

Minutes at 22°C

No MG Saturated MG

Unsaturated MG

A: 60% overrun

Melted in per cent100

80

60

40

20

00 20 40 60 80 100 120

Minutes at 22°C

No MG Saturated MG

Unsaturated MG

b: 100% overrun

Melted in per cent100

80

60

40

20

00 20 40 60 80 100 120

Minutes at 22°C

Saturated MG

Unsaturated MG

c: 140% overrun

7

on the crystallisation of the fat globules in the mix. Saturated MG preserves fat’s globular state while unsaturated MG induces fat crystal growth penetration on the fat globule surface. This phenomenon is shown in figure 4. The protruding fat crystals are much more efficient in stabilising air bubbles than round fat globules. When using harder fats, such as hardened palm kernel oil, a complete transformation of fat globules to fat crystal plates can be observed (11).

Using saturated MG the fat may have insufficient surface area to stabilise the foam on extrusion via a complete fat network. This is what can be seen to the left in figure 5.

Using unsaturated MG there may be a surplus of fat globules/crystals as indi-cated to the right in figure 5. Calculations indicate the fat surface area may increase up to 10 times when a fat globule is transferred to a fat crystal platelet. Hard fat thus makes it possible to observe air bubbles stabilised by multi-layers of pure fat crystal platelets.

The difference between unsaturated and saturated MGs in terms of func-tionality is believed to be due to their behaviour in ternary systems containing water, emulsifier and triglyceride oil (11). It is also related to the differences observed in binary systems of emulsifier and water (12).

In short, unsaturated MGs react more with water at 5°C than saturated MGs, resulting in water penetration into the surface layers of the fat globules and leading to protein desorption and crystal-lisation of super-cooled fat. Water pen-etration into the oil phase is increased by an increasing dosage of unsaturated emulsifier (13).

Air bubble and ice crystal size distribution analysis by seMThe characteristic particle diameters of the number and volume distributions are summarised in tables 4 and 5.

Figure 4. Transmission electron microscopy of ice cream mix with saturated and unsaturated MG, respectively.

With saturated monoglycerides

Round fat globules (F).

With unsaturated monoglycerides

Large protruding crystals (C) more than 1µm long and round fat globules (F).

Figure 5. Scanning electron microscopy of ice cream mix with saturated MG and unsaturated MG, respectively.

With saturated monoglycerides

Strong adsorption of fat globules (F) to air bubbles (A), with only a few fat globules (F) in serum phase (S) leading to reduced meltdown stability. I: ice crystal.

With unsaturated monoglycerides

Coherent structure of coalesced fat globules (F) in serum phase (S) which improves meltdown stability. A: air bubble; I: ice crystal.

F

F

1.0µm

sAMple code X50,0 X10,0 X90,0 spAn0 X50,3 X10,3 X90,3 spAn3

1A 16.44 6.60 50.44 2.67 59.80 34.61 88.84 0.91

1B 16.13 6.78 50.89 2.73 71.13 35.30 125.52 1.27

1C 18.77 7.08 61.00 2.87 82.08 41.59 113.65 0.88

2A 10.41 5.73 57.07 4.93 70.53 39.81 99.27 0.84

2B 16.83 6.87 48.78 2.49 62.90 32.94 98.83 1.05

2C 15.88 6.56 58.26 3.26 82.45 40.77 187.58 1.78

3A 23.45 12.14 74.67 2.67 88.61 48.45 131.77 0.94

3B 38.00 13.63 122.90 2.88 136.23 79.34 185.45 0.78

1A-H 20.11 7.08 69.80 3.12 101.38 48.30 155.40 1.06

1B-H 19.25 6.69 90.50 4.35 125.27 60.95 167.12 0.85

1C-H 17.00 6.65 73.93 3.69 120.08 59.08 178.19 0.99

2A-H 8.27 5.48 79.75 8.98 106.78 67.90 154.20 0.81

2B-H 9.69 5.78 94.80 8.94 110.60 73.53 161.66 0.80

2C-H 9.30 5.72 91.60 9.23 143.82 91.59 180.21 0.62

3A-H 54.00 9.11 136.20 2.35 136.73 88.10 181.74 0.68

3B-H 89.60 9.83 196.00 2.08 199.78 103.52 266.59 0.82

Table 4. Characteristic air bubble diameters.

1.0µm

8

effects of overrun on air bubble size distribution In general, a higher overrun increased the sizes of the larger fraction of air bubbles both before and after heat shock, see figure 6 for results with saturated monoglyceride.

effects of heat shock on air bub-ble and ice crystal size distribu-tionFigure 7 shows the effect of heat shock on the growth of ice crystals and air bub-bles in the 3 samples with 100% overrun.

Both ice crystals and air bubbles grew after heat shock, although to a much lesser degree in the samples with emulsi-fiers.

Air bubble sizeThe number distributions of the air bub-bles were characterised by slightly smaller air bubble diameters in the samples with unsaturated emulsifier than those with saturated emulsifiers. In terms of volume distribution the differences were not significant.

After heat shock, there was a change to a bimodal distribution of the air bubbles in samples with unsaturated emulsifier. That means both the number

of very small air bubbles (lower x50,0-value) and the diameters of the large air bubbles increased. This is a typical effect of diffusion. In volume distribution, no dif-ferences could be detected between the samples with unsaturated and saturated emulsifiers.

In the ice cream samples which contain only a stabiliser blend but no emulsifiers very large air bubbles were seen in number and volume distribution. After heat shock, a strong increase was ob-served in air bubble size in number and volume distribution over the whole range of particle diameters. This indicates that both diffusion processes and coalescence lead to air bubble growth.

In general, increasing air bubble sizes were observed with increased over-run, both before and after heat shock. However the samples with emulsifiers produced much finer air distribution than the sample without emulsifier. The sample without emulsifiers had very large air bubbles both under constant temperature storage and after heat shock. For comparison purposes, the mean volume diameter x50,3 of the air bubble size distribution in the 3 samples is shown as histograms in figure 8.

The small air bubbles contribute more to number distribution. The extreme difference between samples 1 and 2 with emulsifiers and sample 3 without emulsifiers in stabilising small air bubbles is shown in figure 9.

In figure 10 SEM pictures show the sta-bilising effect of MGs on small air bubbles.

Ice crystal sizeThe sample with saturated MG and the lowest overrun (1A) contained the smallest ice crystals and sample 1C with an overrun of 140% the largest when stored under constant conditions. During heat shock, there is a strong growth in ice

sAMple code X50,0 X10,0 X90,0 spAn0 X50,3 X10,3 X90,3 spAn3

1A 27.91 13.93 47.25 1.19 44.36 27.20 60.32 0.75

1B 33.11 15.02 61.26 1.40 55.39 35.04 82.22 0.85

1C 32.54 14.48 60.27 1.40 58.46 34.42 83.48 0.84

2A 34.50 16.40 58.40 1.22 52.91 34.00 72.84 0.73

2B 27.80 14.54 52.20 1.35 52.24 29.40 82.56 1.02

2C 23.38 11.56 47.40 1.53 46.39 27.09 64.08 0.80

3A 32.46 18.16 54.51 1.12 50.59 31.29 73.04 0.83

3B 33.83 16.50 64.25 1.41 70.47 37.94 114.92 1.09

1A-H 42.40 18.80 68.00 1.16 62.58 40.50 90.53 0.80

1B-H 49.33 26.47 81.80 1.12 74.18 46.69 96.08 0.67

1C-H 39.63 22.00 65.50 1.10 60.12 38.18 100.32 1.03

2A-H 44.91 20.05 74.27 1.21 69.68 44.23 103.97 0.86

2B-H 47.80 19.91 76.60 1.19 69.30 46.21 96.18 0.72

2C-H 39.93 19.94 66.18 1.16 60.48 38.53 86.70 0.80

3A-H 54.88 27.50 104.00 1.39 96.65 54.99 115.48 0.63

3B-H 64.25 34.67 111.33 1.19 96.90 60.31 119.73 0.61

Table 5. Characteristic ice crystal diameters.

Figure 6. Scanning electron microscopy of ice cream with saturated monoglyceride. A: air bubble; C: ice crystal.

constant –18°c - 100% overrun

constant –18°c - 140% overrun

constant –18°c storage - 60% overrun

9

crystal size in the samples with overruns of 60 and 100%. The higher overrun of 140% seems to protect the ice crystals from growth – sample 1C contained the smallest ice crystals.

In samples 2 with unsaturated MG both after storage under constant conditions and after heat shock storage, the sample with the highest overrun shows the smallest ice crystal diameters in number and volume distribution. This also indicates high overrun protects against ice crystal growth.

Figure 7. Scanning electron microscopy of ice cream at 100% overrun – effects of heat shock. A: air bubble; C: ice crystal.

With unsaturated Mg

constant –18°c storage

With saturated Mg

heat shock –20°c/–5°c storage for 7 days

no Mg

X50,3µm

250

200

150

100

50

060 100 140

sMG

Constant –18°C Heat shock

60 100 140 60 100uMG NoMG

Figure 8. Mean volume diameter X50,3 of air bubble size distribution.

X50,0µm

100

80

60

40

20

060 100 140

sMG

Constant –18°C Heat shock

60 100 140 60 100uMG NoMG

Figure 9. Mean number diameter X50,0 of the air bubble size distribution.

Figure10. Scanning electron microscopy of ice cream with 100% overrun. A: air bubble; C: ice crystal.

constant –18°c storage - with unsaturated Mg (many small air bubbles)

constant –18°c storage - no Mg (few small air bubbles)

constant –18°c storage - with saturated Mg (many small air bubbles)

10

In samples 3 containing only a stabiliser blend but no MG, the number distribu-tion of the ice crystals is in the same range as samples 1 and 2. The volume distribution shows a greater amount of large ice crystals. The heat shock treat-ment of samples 3 caused strong ice crystal growth, which can be seen both in number and volume distribution.

Sample 3B with an overrun of 100% and very large air bubble diameters con-tained larger ice crystals than sample 3A with an overrun of 60%, but after heat shock the ice crystals in the sample with 60% overrun grew considerably.

For comparison purposes, the mean volume diameter x50,3 of the ice crystal size distribution for samples 1, 2 and 3 are shown as histograms in figure 11.

conclusIons

Ice cream with unsaturated MG con-tained more destabilised fat than ice cream with saturated MG. Ice cream without MG had no destabilised fat. Increased melting resistance was found with increasing fat destabilisation (sam-ples with unsaturated MG were better than samples with saturated MG). Fat destabilisation resulted in highly stable small air bubbles.

This study shows that a higher overrun leads to larger air bubble diameters. Heat shock treatment causes air bubble and ice crystal growth.

In the system where the air bubbles were not stabilised by agglomerated fat (sample 3 without MG), the heat shock treatment caused strong air bubble and ice crystal growth, so the critical mean ice crystal diameter of 55mm (X50,0) was reached. This created a rough, icy mouthfeel. Single, very large air bubbles can lead to shrinkage in samples subject to further storage.

In samples 1 and 2 with MG, where the air bubbles were stabilised by agglomer-ated fat, the samples with the highest overrun of 140% showed the smallest ice crystal diameters after heat shock. Thus, high air content seems to protect the ice crystal from growth. Flores & Goff (1999) reported similar results and found that “higher overruns reduced ice crystal sizes, whereas lower overruns had no impact on distributions, because they did not affect the microstructure of the frozen product” (14).

It was difficult to differentiate between the two emulsifier/stabiliser systems studied with regard to effects on ice crystal size distribution. Concerning air bubble growth, a tendency towards a change to bimodal air bubble distribution was seen in samples 2 made with unsatu-rated MG. In samples 1 made with satu-rated MG growth over the whole range of air bubble diameters was detected.

reFerences

1. Turan, S. (1997). IOP Industrial Proteins 4 (2) 10.2. Dickinson, E. (1992). An Introduction to Food Colloids, Oxford University Press. 3. Walstra, P. et al (1984). Dairy Chemistry and Physics, Wiley Interscience, p. 279.4. Brooker, B.E. (1993). Food Structure 12 (1) 115.5. Goff, H.D. (1997). J Dairy Sci 80, 2620.

6. Arbuckle, W.S. (1986). Ice Cream, 4th Edn., AVI Westport CT.7. Berger, K.G. et al (1972). The Structure of Ice Cream - Part 1, Dairy Industries 8, 1972.8. Turan, S. (1999). Dairy Industry International 64, 27.9. Determination of the melting rate of ice cream, Technical Memorandum no. 2520, Danisco.10. SEF Figures - solvent extractable fat, Technical Memorandum No. 2517, Danisco. 11. Barfod, N.M. et al (2000). Proceedings of the 2nd International Symposium on Food Rheology and Structure. Eds. P. Fischer, I. Marti, E.J. Windhab, ETH Zürich, Switzerland.12. Krog, N. Chapter 4, p.141. In Food Emulsions (third edition 1997). Eds. S.E. Friberg and K. Larsson.13. Krog, N. (1989). J Dispersion Sci & Tech 10, 483.14. Flores, A.A. and Goff, H.D. (1999). Ice Crystal Size Distributions in Dynamically Frozen Model Solutions and Ice Cream as Affected by Stabilizers, Journal of Dairy Science 82, 1399-1407.

X50,3µm

100

80

60

40

20

0

Figure 11. Mean volume diameter X50,3 of the ice crystal size distributions.

60 100 140sMG

Constant –18°C Heat shock

60 100 140 60 100uMG NoMG

07.07

danisco A/sEdwin Rahrs Vej 38

DK-8220 Brabrand, DenmarkTelephone: +45 89 43 50 00

Telefax: +45 86 25 10 [email protected]

The information contained in this publication is based on our own research and development work and is to the best of our knowl-edge reliable. Users should, however, conduct their own tests to determine the suitability of our products for their own specific purposes and the legal status for their intended use of the product. Statements contained herein should not be considered as a warranty of any kind, expressed or implied, and no liability is ac-cepted for the infringement of any patents.