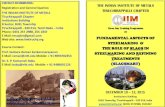

The Indian Institute of Metals Tiruchirappalli Chapter EVENING COURSE ON

description

Transcript of The Indian Institute of Metals Tiruchirappalli Chapter EVENING COURSE ON

The Indian Institute of Metals

Tiruchirappalli Chapter

EVENING COURSE ON

HEAT TREATMENT PROCESSES,

TECHNIQUES & APPLICATIONS

(IIMT EC 001)

For Details Contact

M. ThirugnanasambandamCourse DirectorManager (HRDC)BHELTiruchirappalli-14Mail: [email protected]: 94439 05283

G. RajendranHon. Treasurer (IIMT)Manager (OP&C)BHEL Tiruchirappalli-14Mail: [email protected]: 94425 03075

N. RajasekaranHon. Secretary (IIMT)Dy. Manager (WRI)BHELTiruchirappalli-14Mail: [email protected]: 94425 03065

THE INDIAN INSTITUTE OF METALSTiruchirappalli ChapterInstitutions Building

B Sector, BHEL Township Tiruchirappalli - 620 014

Tamil Nadu – INDIA

Mail: [email protected]

DURATION & TIMING

From February 2, 2009

to

February 8, 2009

Monday to Friday : 17.15 hrs to

20.45 hrs

Saturday : 16.15 hrs to 20.45

hrs

Sunday : 08.30 hrs to 16.30

hrs

COURSE FEE

Non member of IIM - Rs. 2000/-

Member of IIM - Rs. 1600/-

Students - Rs. 1500/-

Non residential programme.

The course fee is inclusive of study

material, dinner / lunch and tea.

MODE OF PAYMENT

The amount may be paid by cash or by

a cheque / DD drawn in favour of:

“Indian Institute of Metals,

Tiruchirappalli chapter”, payable at

Tiruchirappalli. Please add Rs. 50/- for

outstation cheque.

OBJECTIVES OF THE COURSE

The course is conceived with an objective to impart knowledge on various heat treatment processes, the methods and the relevant equipment, significance of heat treatment, interpretation of codes and standards, surface treatment processes, etc. with case studies and class room lectures. There are sessions about materials and their classification, materials processing methods, carbon steels, iron carbon diagram as well as on TTT diagram.

FACULTY The sessions will be handled by the specialists from BHEL, WRI, NIT and practicing engineers in the field of heat treatment and materials processing.

PARTICIPANT PROFILE

The practicing engineers and supervisors, diploma holders as well as engineering degree holders can attend the programme.

VENUE

The classes will be conducted at

S K Mazumder Hall

Institutions Building

B Sector, BHEL Township

Tiruchirappalli - 620 014

COURSE CONTENTS

Ø Classification of Materials

Ø Iron Carbon Diagram & TTT diagram

Ø Materials processing methods

Ø Carbon Steels & Their Properties

Ø Heat treatment & its effects on properties

Ø Pre heat, Post heat and PWHT of welds

Ø Residual Stresses and Distortion during materials processing

Ø Stress Relieving

Ø Normalising and Annealing

Ø Hardenability & Hardening methods Ø Do’s and Don’ts in furnace operations

Ø Surface Treatment Methods

Ø Quality assurance in Heat Treatment

Ø Local Heat Treatment Methods & Procedure for Local Heat Treatment

Ø Interpretation of codes / standards

Ø Instrumentation for Heat Treatment

Ø Case Studies & Discussion