The Hope Telegraph #3

description

Transcript of The Hope Telegraph #3

The Hope TelegraphISSUE THREE - HOPE TECHNOLOGY - REVOLUTIONARY BICYCLE COMPONENTS

WHAT’S WITH ENDURO? Page 4

IN THIS ISSUE...PEDAL de ALPS Page 12 26” vs 27.5” WHEELS Page 8 HOPE TECHBAR! Page 10

DANNY MAC... What can be said about Danny MacAskill that hasn’t already been? Danny’s meteoric rise to fame is matched by his ability to constantly up his game in a niche he has carved for himself. Who would have thought his flatmate Dave Sowerby breaking his leg would lead to one of the most popular YouTube hits of all time (currently sitting at over 32.5 million to date). It was in the time taking for bones to heal that Dave and Danny, then living together in Edinburgh, decided to produce THE Danny Mac edit. Since those humble beginnings, the quality and budgets have been ramped up a fair few notches. The latest productions have been handled by Red Bull Media House, ensuring only the very best and therefore allowing Danny to concentrate on his riding. Riding at that limit is not without its dangers and since his ‘vs. San Francisco’ video came out in late 2012, Danny has spent much of the last year building up to, or recovering from a fairly major back injury suffered while filming in 2011. While recovering, Danny went out on his Orange Five to get some miles under his legs to get up to full fitness before the Imaginate project started. His Five comes with the usual Hope components continues on Page 2...

out of the box but has been augmented with the addition of the Hope chainguide and for any night time sorties on either bike, the R4 light certainly comes in handy. Danny’s Imaginate project is definitely the most ambitious riding video to date. Red Bull spared no expense in creating his masterpiece, with the concept being entirely his own. 60 filming days alone spread out over six months really does give an idea of the scale of the project. The production effectively took over the Kelvin Hall in Glasgow, former home to the Glasgow Transport Museum. With Red Bull preferring their athletes to produce the ideas, Danny took Imaginate to the next level with railway lines, loop-de-loops and giant playing cards to name a few, all included in the repertoire of obstacles Danny’s imagination was the only real boundary! As with any part of mountain biking that pushes the boundaries of what is seen as possible, riders need kit that is going to stand up to the job. It’s fair to say that Danny’s riding is fairly hard on bikes, with big drops to flat and multiple big lines being a fairly regular occurrence.

It’s hard to miss the Team Green on Danny’s Inspired bike. Since 2007, he’s been running a host of Barnoldswick’s finest CNC’d aluminium. A fairly casual relation-ship exists but one that surely proves the worth of the Hope jewellery. Alongside the Skye frame and fork, the remainder of the parts are cho-sen for performance, strength and reliability. Danny runs mostly stock product dipped in the classic Team Green Hope colours including hubs, headsets, stem spacers and seat clamp. The only custom product is the rear Hope Pro 2 EVO 12mm bolt thru Trials hub which has been specially adapted for Danny’s requirements and frame compat-ibility. The 48t pickup on the Pro 2 EVO trials hub ensures Danny can be confident of getting the power down when making some of the bigger moves which helped to make him famous. The future is certainly bright for the young lad from Skye, especially now his back troubles are hopefully behind him. You’d be a fool to bet against Danny upping his game yet again. Always remember, however, that the rider is only as good as his equipment!

Page 2 Designed, Tested, ManuFACTured... Hope facts and figures: We anodise approximately 2.3 million parts per annum – all by hand!

DANNY MACASKILL - stuff that goes on in Danny’s head!

Page 3

The R1 is a lightweight, compact LED lamp unit that slots into the Vision lighting range between the existing 1 LED and R4 lighting systems. We were being asked to provide a lighting system that offered more light and a wider beam pattern than the AA battery powered 1 LED lamp, but with a lower price tag than the 1000 lumen

R4 lamp. Therefore, we thought it was sensible to develop a product that sits right in the middle of the two. The R1 uses a single LED with a high efficiency TIR optic to focus the entire emission of light into a narrow angle, uniform distribution smooth beam pattern. Punching out over 500 measured lumens on high power, it provides ample light for late evening runs over the fells or low-technical off road mountain bike trails. It’s also ideal as a supplementary helmet mounted light for anyone who wants to double up with a bar mounted main headlight to really flood the trails with light. For those of you familiar with the R4 lamp, it features the same intuitive race and trial sequences to offer six different levels of light, including a flash setting. Again, there is also a low battery warning mode to give you enough time to replace the battery pack or get home safely before the unit shuts down completely. Available as standard with the 2600mAh (2 cell) Li-Ion battery pack gives a running time of 2 hours and 30 minutes in high power. Also available is the EPIC kit with

the larger 5200mAh (4 cell) Li-Ion battery which gives double the running time - 5 hours in high power. Also, the All-Sports kit which includes the 2600mAh battery and the 5200mAh battery, offers you the flexibility of choosing to use either battery pack, depending on the duration or intensity of your activity. All these options include all three mounting methods - the QR bayonet handlebar mount (to fit both standard and oversize bars), helmet mount and head mount harness. The QR bayonet fitting on the R1 lamp unit allows quick and simple changes from one mounting method to the next. For instance, an adventure racer can quickly swap the lamp unit from bike mount to head harness in a matter of seconds, minimising transitional downtime. The lamp housing is fully CNC machined from a solid billet of 2014 T6 Aluminium alloy which provides the most ideal thermal characteristics to dissipate the heat away from the LEDs into the heat sink fins on the rear.

TECH SPEC: • 500 measured lumens. 620 generated lumens.

• Run time of 2.5 hours to 50+ hours with the standard 2600mAh battery.

• High efficiency TIR optic provides a uniform smooth beam pattern.

• Fully CNC machined black anodised Aluminium housing, manufactured in our Barnoldswick factory.

• Weight: from 250g.

• Three QR mounting options included – handlebar, helmet and head mount.

• Compatible with existing battery packs, either the 2600mAh (2 cell) or 5200mAh (4 cell).

w w w. h o p e t e c h . c o m

Page 4 Designed, Tested, ManuFACTured... Hope facts and figures: 87% of hub billet is waste (which is recycled)

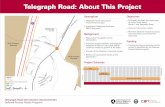

2013 will go down in history as the year enduro broke. The Enduro World Series has taken a rapidly growing discipline and given it a hefty upward thrust. The opening round at Punta Ala had the eyes of the mountain biking world upon it. The fact that the inaugural and subsequent rounds were closely fought and as exciting as everyone had hoped means that the EWS and indeed enduro, is certainly here to stay. This format of racing takes its name from motorcycle enduros, although the format has more in common with car rallies than the time-keeping nature of

most motorcross enduro events. But the term enduro has been applied to many events that don’t follow this format - the mountain bike world hasn’t quite decided what enduro actually is. Many agree the Megavalanche is the original enduro race, and as a result, has attracted a massive numbers of Brits since its inception. Few events follow the Mega format though, creating a massively varied discipline where anyone can shine though, which makes it incredibly appealing. The event can have a whole different vibe depending on location and event organiser as well. Entry requirements are simply a fee, a

mechanically sound bike and a rider obeying the rules, so there really is no barriers to anyone racing on any given bike - racing for the masses! Events like the Trans Provence have cemented enduro’s ability to appeal to all types of rider. The Elite Male podium at Punta Ala consisted of a double DH World Champion, an enduro specialist and one of the greatest 4X riders, while the top 10 at the Trans Provence saw XC racing legends Jeff Kabush and Ralph Naf making their presence felt. What really makes the enduro ball roll at such an impressive speed is the social aspect.

Where the organisers have seen fit to abandon transition and start times, and simply impose a cut-off time, you are the closest you could possibly be to riding with friends on the bike you ride the most. All that differs is race tape, a clock, a podium and potentially more pride at stake. The UK has seen an explosion of enduro events as varied as they are abundant. The UK Gravity Enduro Series is the jewel in the UK enduro scene, with the national series being supported by many different races across the country. Right now, Britain fields one of the strongest group of

riders in the international enduro scene, mirroring that of its more gravity-fed counterpart, downhill racing. While the UKGE visits many of the popular mountain bike haunts, local grassroots events are taking place almost every weekend. What bike to run? Simply rock up with whatever you have got. That said, a 9” travel DH bike is rarely going to cut the mustard at an enduro race, but anything from a hardtail with a decent

suspension fork up to 160mm full suspension will see you in with a shout of beating your mates. Nowadays, those folks gracing the podium will be on a 120-140mm travel full suspension bike with angles that would not have been out of place on DH bikes of the early 2000s. Bikes are becoming lighter and better suited to this discipline. A 1 x 10 speed setup is the norm. A bike that is light and efficient enough for the climbs but slack and composed for the downs is essential. The modern day trail bike is very much tuned into this and what manufacturers are producing these days can handle what would only have been deemed sensible on a downhill bike five years ago. The future for enduro is certainly a bright one. Enduro basically quantifies your normal riding with friends, without having to resort to Strava. Events are cheap and easy to enter, with little specialist equipment needed. The media seems to love the idea and rightly so, plus all the bike manufacturers are churning their pennies into making it hard for us to choose which new spangly bike bit to buy this week. It’s a hard life! Just remember to have fun, as that’s what it’s all about at the end of the day.

Page 5w w w. h o p e t e c h . c o m

Page 6 Designed, Tested, ManuFACTured... Hope facts and figures: Number of staff bikes = 250

• Designed, tested, and CNC machained in Barnoldswick, England.• Light Output: 1,000 measured lumens, 1,446 generated lumens.• Power levels: 6 (two sequences of three), including flashing.• Burn time: 2:30 hrs - 50:00 hrs.• Distance: 105m• Mounting: CNC machined aluminium QR bayonet mount for handlebars, helmet or head harness.• Weight: 338g (std).

w w w. h o p e t e c h . c o m

BELGIAN PUMPTRACK designer Nico Vink doing what he does bestJust like all Hope products the pump track goes through rigorous testing!!!

Pumptracks are one of the best ways to learn and develop bike handling skills for all types of riding - downhilling, trail, XC, BMX and even road and cyclo-cross. The small looping tracks (which resemble mini BMX tracks) are designed to be ridden continu-

ously without the need to pedal. The rider gains momentum and speed by pumping the berms and transitions - it’s a lot harder than it sounds! When we discovered our favourite Belgian World Cup Downhill racer, Nico Vink had recently started a company

with fellow racer Kristof Lenssens, Ride Creations, it seemed a no brainer - we needed our own test track. What better way to test our products and keep the staff fit than build our own pumptrack at the rear of the factory? Four days of digging, shaping and a few Leffe beers

later, Nico and Kristof finished the Hope pumptrack.

Now all we need is a Top Gear style leader board - time to get some laps in!

Page 7w w w. h o p e t e c h . c o m

Pete Scullion, freelance journalist and experienced mountain biker, gives us his take on the very topical 26” v 27.5” wheel size debate: “The following might seem like an awfully sensible, and possibly boring, take on the wheel size debate, but it does need to be taken objectively. It’s impossible to argue that simply bolting a certain wheel size into a bike will define its overall ride characteristics, especially when, in many cases, the differences between 26” and 27.5” are not that great. Regardless of where you stand on wheel size and your preference therein, 27.5” is certainly going to be around for a while. That said, it’s likely we’ll not see 26” disappear overnight. Some bike manufacturers have dropped 26” entirely from their ranges, while some of the biggest producers of mountain bikes have yet to adopt the 27.5” wheel size in theirs. So, 27.5” (650b) is nothing new to the cycling industry. Kids’ road and CX bikes have been using this wheel size for years and gained commercial success from doing so. The use was almost purely practical however to allow geometry to remain consistent with the step down from 700c.

With 27.5” only really making a major appearance in 2013, it seems daft to suggest that 26” might all of a sudden become the cause of a major manhunt. Almost 30 years of mountain biking precedes its appearance, and there must be untold millions of 26” wheels in circulation as I write this. In fact, I have four pairs myself. With the three big players erring on the side of caution with the latest wheel size it would seem even the OE market isn’t letting go of 26” just yet. Untold millions of Taiwanese dollars have been invested in 26” wheels, their ancillaries and marketing year-on-year. It would be madness to allow them to die when the going is so good. On the flip side, the diameter of one’s wheels seems to be the most divisive debate on-going. V-brakes were imagined to be able to explode rims and suspension forks were initially regarded with suspicion at first, but both came very quickly to be taken as normal. The 27.5” wheels are certainly hot right now and in fact, many riders seem to be taken by this size over the 29” as the lesser of two evils. It appears all eyes are on the 27.5” as the latest and greatest to come out of the moun-

Page 8 Designed, Tested, ManuFACTured... Black anodising takes 1hr 35mins… Silver by comparison takes 35mins

Page 9w w w. h o p e t e c h . c o m

tain bike machine. Certainly the media have taken to it with many of the bikes taking top honours appear to be shod with this slightly larger wheel. However, it will take more than a wheel of one’s chosen diameter to create the perfect bike. The 26” bikes have yet to reach their zenith, and two other wheel sizes are unlikely to happen across the holy grail of bike design overnight. It is still very much possible to create a terrible bike regardless of wheels as there are so many other factors determining wheth-

er a bike rides well before personal preference is taken into account. Maybe the real test of any divisive component is its use in competition. Competition is where all great products shine, and where poorly conceived ideas are put to bed. So far in the 2013 World Cup season, none of the top 10 ranked Elite Male UCI DH riders have used anything but 26” wheels. Discounting wheels for a moment, those who won titles in 2012 are far from newcomers and this brings me to the title of this piece. 2012’s Elite Male

World Champion, Greg Minnaar is one of our sport’s most talented and successful riders, full stop. Rachel Atherton is hardly new to the podium in the Elite Women’s field either. The 2013 Enduro World Series rounds have been won by owners of the Rainbow Stripes and a few other decorations between them. Of course I’m talking about Fabien Barel, Nico Vouilloz and Tracey Mosley, all legends of mountain biking. I think what I’m getting at is that wheel size is very much down to the

squidgy organic bit atop the bike. Riding bikes is all about having fun, even better if your bike feels so comfortable beneath you that you almost forget it is there. Wheel size, like bar width, stem length, saddle height, brake lever position, bar rotation, clips/flats, suspension setup and everything else you can change to suit on a bike, must surely be personal preference.

If it feels good, then run it!”

Brakes, Grips, Stems, Headsets...this is the extensive range that Hope is able to offer for your bicycle cockpit. Handlebars seemed the only missing link to tie all our control components together. After all, how difficult can bending a piece of tube be? One of our in house designers previously worked in the handlebar industry for over eight years and knows exactly what it takes to design, develop and test such a safety critical component. It’s no secret that these handlebars are not manufactured by ourselves (as many of you are aware). It is a fact, however, that all the market leaders

(and O.E.M.) aluminium mountain bike handlebars come from a small handful of factories in the Far East. So, why are we following the rest of them and going against the whole ethos of Hope Technology (manufactured in Barnoldswick, England)? The set-up costs and specialist equipment required to manufacture alumini-um taperwall bars is astronomical. Taperwall tube manufacture is done via manipulation of raw material and requires many years of practice, experience and testing to fine tune the process. Jumping into this niche pro-cess could make or break a company and as we are not a raw materials

manufacturer we have decided to leave the processing to the experts with our guidance. So what makes our bars different from the rest? With our vast knowledge in this product, combined with our state of the art computer software and testing lab, we started from scratch to meet the demands and feedback of our riders. It was evident from day one that we wanted a super wide yet super stiff handlebar to take the abuse of Downhill / Freeriding. Test data was compiled from competitors products as a benchmark which gave us the information we required to input into our design program. Using F.E.A. software (Finite Element Analysis) we were able to replicate the high stress areas in the handlebar and begin manipulating bends, wall sections and weights to minimise these stress concentrations and achieve our per-fect design. Material wall sections have all been optimised to increase strength in high stress areas and remove material where it is not required, to reduce weight. It was then up to our overseas manufacturer to replicate this specifically for us using their state of the art equipment. We were very meticulous in selecting the correct manufacturer for our handlebar and will not compromise on the quality of the product. Our manufacturer is a specialist in what they do and have come across every imaginable problem to overcome the

issues associated with taperwall tube manufacture, ironing out all issues over the many years they have been in business.

To attain the fantastic results we have achieved, all testing was carried out in our in-house test lab, giving us complete control to have comparable tests every time. Bespoke test equipment and fixtures were designed and developed in-house to allow us to set our own standard well beyond the industry equivalent. Unlike most test centres / manufacturers, each bar we test is mounted to solid steel fixtures to remove any deflection during testing

This is just one of our bespoke testing machines used here for fatigue testing. We are able to replicate years of riding in the space of a few days over the worst terrains imaginable, up to the point of destruction.

Centre Positional Grid aids setting bars accurately in the stem.

F.E.A. showing high stress point on conventional bars

F.E.A. showing much lower stresses on the Hope Techbar

Page 10 Designed, Tested, ManuFACTured... Hope facts and figures: Aluminium bars used per annum: 32,857 metres = 20.7 miles = 19,327 bike lengths

which an aluminium equivalent would produce, giving us a worst case scenario. By doing so we have achieved an astonishing performing bar at a good weight for its discipline which has outperformed all other handlebars we have tested. Periodic destruction testing and extensive 100% inspection is given to every handlebar that leaves our Barnoldswick factory, to reassure that every bar is manufactured to Hope quality. We would not put our name to anything other than perfection.

TECH SPEC:• Designed for Downhill / Freeride Use.

• Manufactured from 7050 Aluminium.

• Shot peened finish for increased fatigue life.

• 800mm Wide in 10, 20 and 30mm rises.

• 31.8mm clamping diameter with 70mm of width for ultra wide stems.

• 5° Upsweep by 7° Backsweep.

• Weights from 310 grams (10mm rise version).

• Optimised wall sections and distinctive shape allows for increased strength in higher stress areas.

• Super stiff construction for increased stability and improve control.

• Positioning grids for setup of components.

• Cut-off marks to reduce handlebar width.

Derived from riders, customers and employee feedback, combined with in-depth market research and past grip development, a lock-on handlebar grip seemed a natural choice to add to our already extensive range of new components. You may ask ‘how can you possibly improve a handlebar grip?’ Well, you would be surprised to hear how much negative feedback you can receive regarding equivalent

products on the market. In an ideal world we would all like slip free handlebar grips without the locking mechanism so that we have more surface area to hold, and no uncomfortable obstructive aluminium locking collars at either end of the grip. In reality, lock-on grips are the way forward for convenience and ease of assembly. No adhesive is required to bond the grips to the handlebar, and for brakes and shifter which must be removed by sliding the clamp off the end of the handlebar, lock-on grips are essential for re-using time after time. Like all our products, attention to detail has been carried out throughout the entire development process, from design and material selection, right down to the custom fasteners and extensive testing. The inner plastic core is the foundation of the grip manufactured from a high impact composite, providing give on impact yet holding the entire assembly firmly in place. The core material has been optimised to provide more rubber material to be moulded on top for greater feel without the need to increase the grip diameter.

This unique take on the lock-on grip combines 100% quality British manufacturing with a distinctive, robust and lightweight design providing a slip free grip with maximised surface area for hand contact.

TECH SPEC:• High impact resistant inner plastic core.

• CNC’d billet aluminium locking rings.

• Soft durable rubber moulding from one end of the grip to the other.

• Custom forged stainless steel fasteners.

• Integrated CNC’d billet

aluminium bar ends.

• Length: 135mm (including bar ends).

• Diameter: 30mm.

• Weight: 94g pair SL Version (including all fasteners and bar ends).

• Colours: Available in translucent Black, White, Green & Red.

• 100% manufactured in the UK.

Page 11

Lever Positional Grids help accurately place lever symetrically

w w w. h o p e t e c h . c o m

Hope was delighted to be able to support a very special charity project that recently reached a successful conclusion after almost a year in the planning. A quick glimpse of the team photo (above) could fool you into initially thinking that you are looking at five proficient cyclists, but that would be slightly stretching the truth. In fact, the five guys pictured in their Hope gear are actually friends linked by their motorcycle background and driven by a common cause. Back in early 2006 Paul Dixon, a renowned builder from the Lake Dis-

trict, and his family became acquainted with a specialist children’s hospice called Derian House. They spent valued time at the facility in Chorley, Lancashire during the short life of their son Harry. Sadly, Harry lost his fight against Spinal Muscular Atrophy (SMA) Type 1, a genetic disorder which affects the motor neurons in the spinal cord, at just fourteen-weeks-old. Seven years on Paul decided the time was right to give something back to Derian House, so he called upon a close group of friends to support him in a once in a lifetime adventure. Already a keen cyclist, he hatched the

slightly questionable idea of riding from Chorley to Nice via France’s most famous mountain range. The aptly named Pedal de Alps project rapidly became reality as Paul recruited his team of non-cyclists to add an extra twist to the challenge. The first name on the team sheet was a certain Dougie Lampkin who although is a motorcycle legend due to his 12 World titles, he had little prior pedigree when it came to pedalling. Next, Dougie’s cousin James, an expert British motorcycle champion in his own right, but again a cycle virgin, was on the list. And the line up was

completed by Dougie’s manager Jake Miller and Hope’s very own Woody Hole, both of whom had not thrown a leg over a crossbar in years - so ideal team members! With the initial route plotted, the sheer scale of the challenge became apparent. The 1000 mile journey to France from Derian House in Chorley would begin with the relatively short dash of 130 miles to Hull, where the team would board the ferry bound for Zeebrugge in Belgium. Once on the other side of the English Channel the route would take the squad south where they planned

NORTH YORKSHIRE training rides became the norm before the trip started in ernest

Page 12 Designed, Tested, ManuFACTured... Hope facts and figures: Every single aluminium part is polished with ground walnut shells

Page 13

FOR A GREAT CAUSE : Derian House to Nice.

to arrive in Geneva, Switzerland a few days later. There, the landscape would change drastically, meaning the guys would have to fight their way over the towering Alps before arriving in the French seaside city of Nice at the end of at least 12 extremely testing days. Serious about reaching their goal, the team immediately began an intensive training schedule that included many dark and cold hours in the saddle through the winter months in the hills of North Yorkshire. Slowly, but surely,

with more and more miles under their belts they became more familiar with their pedal powered machines having previously spent a lifetime riding petrol propelled bikes. And all the planning, training and sheer determination finally paid dividends when the team successfully completed the long and arduous journey from the North of England to the South of France in August and raised over £10000 for Derian House. The money means that families such

as Paul’s can continue to benefit from the specialist care provided by this truly wonderful facility. Speaking about this incredible achievement Dougie Lampkin explained, “Managing to make it to Nice was an amazing and special feeling, and one that meant a great deal, especially to Paul and his family. I am extremely proud to have been a part of this project and to have shared this journey with such a great group of guys. This definitely ranks up there with the best of my achievements.” Donations can still be made by

visiting www.justgiving.com/pedaldealps

or by sending cheques payable to Derian House to Pedal de Alps HQ, 3 The Old Court House, Tenterden Street, Bury, UK BL9 0ALFor further information please call + 44 (0) 161 763 6660email [email protected] visit www.pedal-de-alps.com

WINTER TRAINING rides in the epic Lancashire/Yorkshire landscape.

Woody Hole, Jake Miller, Dougie Lampkin, James Lampkin and Paul Dixon.

w w w. h o p e t e c h . c o m

STEVE PEAT circa 1995ish

Q1: What’s your secret to maintain-ing motivation for training and rac-ing over such a long career, especially given the level of success you have achieved?

A: That’s an easy one - don’t take your-self too seriously! I’ve seen many guys come and go because they suddenly decide to live and breathe it. I like to ride my bike and find it fun, if I keep training sessions fun it all slots into place.

Q2: Do you think you will ever be able to stop racing in some form?

A: I certainly HOPE not! Whether it’s just racing my kids round our pump track I am sure I’ll still be doing it at a late age!

Q3: You’ve been lucky to ride with a few characters over your career- Shaun Palmer, Rob Warner, Nico Vouilloz, Greg Minnaar... who has been (a) the toughest competitor to race against? and (b) the best person to have a few beers with?

A: As daft as it sounds, Warner was a tough cookie when it came to British National Champs! He didn’t give a shot about any other race but would lift his game to be National Champ! Ha ha He’s a good drinking partner but Palmer would take the biscuit for most fun!

Q4: Courses such as Kaprun, Big Bear and Nevegal were all on the circuit when you started to race World Cups. How do those courses compare to those on the current circuit?

A: In their day they were all tough; Nevegal was a little ahead of its time as in technical rocky stuff, Kaprun was flat out fun. They would still be tough today but were certainly different beasts to what we train for today.

Q5: What has been the most meaning-ful moment of your career?

A: It’s got to be the World Champs.

Q6: What do you think of the enduro hype?

A: All hype init! Ha ha. I think it’s a great discipline and will be great once it settles down a bit.

Q7: Any up and coming riders you’ve got your eyes on?

A: We have a great scene in the UK with many young talents. I have my eye on a few but I’ll keep the good ones close to my chest! Ha ha

The new Hope Tech 3 master cyl-inder is soon to replace the existing Hope Tech Evo master cylinder. We have kept the key features of the Tech Evo master cylinder and worked to improve the ergonomics and integration on the handlebars. The Tech 3 master cylinder can operate all the calipers from our range and offers a slight increase of power of about 5% over the Tech Evo. Popular design features of Tech Evo remain the same, such as the reach and bite point control (BPC) adjustability. The piston is actuated by a cam and a roller system to eliminate any free play and initial friction. The classic split clamp design makes the master cylinder easy to install on the handlebars without having to remove anything else. Hope Tech 3 - Some riders have previously commented on the rela-tive bulkiness of the Tech and Tech Evo master cylinders, sometimes mak-ing it hard to fit the master cylinder around already clogged up handlebars (shifters, fork and shock lockouts, telescopic seat post controls etc). We have worked hard to make the new Tech 3 master cylinder easier to

integrate on the bars although it does entail losing the ambidextrous design. The Tech 3 master cylinder is now directly compatible with any Shimano I-Spec type shifter meaning no extra mount is required to attach the shifter to the master cylinder. For those using SRAM shifters we have designed a slick and minimalistic direct mount adaptor. A few changes on the hydraulic and mechanical ratios means we have gained about 5% of power over the Tech Evo master cylinder whilst keeping the control and modulation.

TECH SPEC:• “On the fly” BPC (bite point control) and Reach adjustment

• Direct compatibility with Shimano I-Spec shifter

• Direct mount available for SRAM shifters

• 5% power increase over TECH Evo master cylinder

• Handed master cylinders for better integration on the handlebars

• New piston dust cover design

• New reservoir diaphragm design

Page 14 Designed, Tested, ManuFACTured... Hope facts and figures: 58 CNC machines

w w w. h o p e t e c h . c o m Page 15

w w w. h o p e t e c h . c o m

• 100% UK manufacture.

• Ergonomic design.

• Slip-free locking mechanism.

• Fully moulded grip providing more surface area for hand contact.

• CNC billet aluminium locking rings and end caps

LOCK-ON HANDLEBAR GRIPS

Serious motorcycle racers and enthusiasts face many of the same dilemmas as their biking and cycling counterparts. Possibly the most dominant question for most riders is how to get the perfect power to weight ratio... When Lincolnshire based, Moto 3 Championship rider, Sam Burman took delivery of her Honda Moto 3 bike one look at the rear brake was all it took for her to decide it had to go. Far too heavy for the task in hand, she replaced it with a Hope Tech V4 Vented rotor set up. Obvious for us, it might not be the first thing that a motorcyclist would think of. Sam and her right hand man Marcus have been cyclists for a long time. Sam uses a road bike as a major part of her training and the pair of them are making serious inroads into the local KOMs on Strava. As a result of their long standing relationship with cycling Sam and Marcus have been using Hope products for many years. The next question is how on earth do you attach a mountain bike brake

to a full on race motorcycle? Easy. You get a CNC operator to make you the adaptor brackets and you’re sorted! Sam is a CNC operator for TATA Steel and her main sponsor is WNT machine tools. Perfect, a bit of measuring, a few drawings and a couple of trips to WNT head office in Sheffield to use their state of the art demo machines and the necessary pieces of machined billet aluminium were soon fettled to give the desired result. The 2013 season has got off to a great start with the highlights so far being a 4th place finish in the Moto 3 class, Sam’s best qualifying position on the start grid and a couple of wins at local club meetings. Never one to rest on her laurels Sam is working hard on improving her bike set up and her personal fit-ness. No doubt the results will improve as the season goes on as she gets fully acquainted with the new Honda.Action photo by Ste Gilbert @ www.planet2d.com, all others by Nick Hill @ www.nmdesign.co.uk

Page 16 Designed, Tested, ManuFACTured... Hope facts and figures: Total number of countries we sell to = 40

CALIPER

EVO

GASTOFLAT

GIANT

HOPE

HOPTON

HOSE

IMAGINATE

INNERLEITHEN

OLIVE

ORANGE

PUMPTRACK

SHROUD

SPECIALIZED

HOPE WORD SEARCH

Sam on the gas with her Hope Tech V4 equipped Moto 3 Honda