The frequency-controlled continuous-operation unit for ... · The frequency-controlled...

Transcript of The frequency-controlled continuous-operation unit for ... · The frequency-controlled...

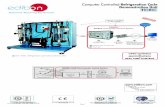

The frequency-controlled continuous-operation unit for machine tools – Compact Power Unit CO3

E 5

.320

.0/0

8.16

2

Thefrequency-controlledCompactPowerUnitCO3formsthe“heart”forthehydraulicsinyourmachinetools.Thefrequency-controlled,continuous-rateddoublepumpoftheCO3reactstoeverydemandspikeandcompensatesimmediately. Inaddition,efficientairflowinthepowerunithousingguaranteesoptimalmotorandoilcooling.Allinall,thisensuresexcellentmachine availability.TheCompactPowerUnitsCO3areconstantlyinuse–literally,becausetheyaredesignedfor continuous operation S1. At the same time,theyrequirelowerdrivepowerthanconventionalpowerunitsandinadditiontakecareofoilconditioningandcooling.ThenewstackingsystemHL,ascompletecontrol logic for the auxiliary functions in machinetools,canbeusedtoextendthefunctions of the power unit.

Theperfectsupplysolution–HLstackingsystem see brochure no. 5.319 – HL stacking system

E 5

.320

.0/0

8.16

Your competent partner for innovative hydraulic solutions in machine tools

The “heart” of your machine tools

Compact Power Unit CO3

Energy efficiency

Suitable for continuous

operation

Quiet running

(optional)

Plug and play

Reliability

High level of integration

Hydr.powerdissipationviaoilcooling

Hydr.powertoloads

HYDAC double-pump set-up compared with single-pump set-up with bypass orifice at 1.5 KW

Power consumption of various power unit concepts compared

Supply to cooler via pressurisedorificebypass

(competition)

Conventional power unit

Powerunitwith pressure-

controlledvariabledisplacementpump

Frequency-controlledCO3 power unit

Supply to cooler via almostunpressurizedbypassflow (CO3doublepump)

Always in actionfor maximum productivity

3

Supply, cooling, oil conditioning in one unit

z Reduceddrivepowerduetofrequency-controlledmotor z Highlydynamicadjustmenttoapplication-basedloadchanges z Optimumfluidpowersupplyviarequirements-basedclosedlooppressurecontrolateachoperatingpoint z Greatercoolingcapacitythanconventionalpowerpackswithbypassoilcooling z Centralisedcoolingofoil,motorandfrequencyinverterviafullintegrationofallcomponents ininnovativehousingandairflow

z Constantmotorcoolingevenatlowdrivespeedsthankstoforcedventilation

z DesignedforoperatingtypeS1 z Veryefficientcoolingwithlowenergyrequirement z Permanentoilcoolingandconditioningthankstodoublepump(bypass-filtrationoptional)

z Completeplasticcompositeencapsulationandlowfrequencyrunningcharacteristicsinstand-byoperationmakethepowerpackbarelyperceptible

z Low noise pump optional

z Simpleandtime-savingcommissioningduetopre-definedelectricalandhydraulicconnections z International connectable

z Componentshavebeenservice-lifetested,provingthemselvesovermanyyearsprovidehighavailability

z TMdesign(tunedmonolithicdesign)andtheconsistentuseofmodernmaterials incombinationenablealowweightandextremelyhighmechanicalandthermalstability

Gen

eral

Innovative air flow for simultaneous cooling of motor, oil and frequency inverter

4

E 5

.320

.0/0

8.16

CO3 Performance

Q/P curve with 2.2 kW motorMeasuredwithν=33mm²/sandoiltemperature40°C

0

2

4

6

8

10

12

14

16

18

20

0 10 20 30 40 50 60 70 80

Flow

rate

[l/m

in]

Pressure[bar]

Q/P curve with 1.5 kW motorMeasuredwithν=33mm²/sandoiltemperature40°C

0

2

4

6

8

10

12

14

16

18

20

0 10 20 30 40 50 60 70 80

Flow

rate

[l/m

in]

Pressure[bar]

Specifications

5

Perf

orm

ance

/spe

cific

atio

ns

1Ph 1.5 KW 1Ph 2.2 KW

Frequency inverterSupply voltage: 200–240 V 200–240 V

Mainsfrequency: 50/60 Hz 50/60 Hz

Ratedcurrentofdevice: 9.0 A 9.0 A

Motor-pump unitRatedpower: 1.5kW 2.2kW

Permissibleflowrate,continuousoperation: 10 l/min 7 l/min

Max.flowrate: 18 l/min 18 l/min

Operating pressure: max. 50 bar max.70barseeQ-Pgraph

Relieving pressure: 55 bar 75 bar

Tankfillingvolume: approx.17l/(approx.30lforoiltankmadefromaluminium,A30)

Tankdischargevolume: approx.10l/(approx.23lforoiltankmadefromaluminium,A30)

Operatingfluid: MineraloiltoDIN51524,Part2

Mediaoperatingtemp.range: -20to+80°C

Ambient temperature range: -20to+35°C

Viscosity range: 10 to max. 380 [mm²/s]

Filtration: To ISO 4406 Class 21/19/16 or better

Protectionclass: IP54toDINEN60034-5

Totalweightwithplasticoiltank: Withoutoilfilling:approx.29kg Withoilfilling: approx.46kg

Totalweightwithaluminiumoiltank: Withoutoilfilling:approx.32kg Withoilfilling: approx.59kg

Alldataissubjecttotechnicalmodifications!Other layouts on request.

Specifications (standard layout)

6

Thebasicpowerunitincludes: zDoublepump(standard) zHydraulicmanifoldwithfixed-settingpressurereliefvalveandcheckvalve z Temperatureswitch,motor z Temperaturesensor,oil z Frequencyinverter zPressuretransmitter z Tankwithoillevelgauge zScrewtypecablegland

Specificexamples:Partno.3956305, CO3FULK17-A-18.0SN-50-63-1,5-BA-F55Partno.3956306, CO3FULK17-A-18.0SN-70-63-2,2-BA-F75

E 5

.320

.0/0

8.16

CO3 basic equipment

CO3 data

7

Bas

ic e

quip

men

t/dat

a

DIMENSIONS

Installation requirements

Canbefastenedtomouldedmountingsurfaces with M10 screws

(2 or 4 pieces)

Innerthread M8x23 for vibration dampers(4x)

air outlet side air inlet side

max.255plasticoiltank

NOTICE:Thepowerunit‘scoolingstrategyisbasedonunobstructedairflowthroughthehousing.Itisthereforevitaltoprovideairinletandoutletopeningsifthepowerpackisinstalledinsideanenclosure.Thepositionsanddimensionsoftherequiredopeningcanbetakenfromtheabovesketch.

zStationaryindustrialenvironment(CategoryC3) zProvideadequateventilation,particularlyontheinletairandtheoutletairside zSetupwithdustprotection.Forahigh-dustenvironment,werecommendusinganeasy-to-removedustprotectionfilter–ideallywiththreelayers,oralternativelywithfourlayersforparticularlyhighdustload(considerreducedcoolingcapacity). zProtectpowerunitfromwet,spraywater,coolinglubricantsandhighhumidity(RHabove85%)

max.230plasticoiltank

max.320alum.oiltank

max.295alum.oiltank

8

Pressure gauge

Pivotable oil draining hose

Dust protection filter (pre-ventilation installation)

Oil level gauge with electrical monitoring

Bypass filter Stat-X (intank)Stat-Xreplacementfilterelement,20µmPartno.3958361

Bypassfilterwithelectrical clogging sensor

Bypassfilterwithvisual cloggingindicator

Oil tank

Oil tray

Vibration dampers GUA + GUB

Fully equipped with aluminium oil tank (without oil tray)

Fully equipped with plastic oil tank (without oil tray)

Basic equipment with plastic oil tank

Partno.:4047450(incl.screwedfittings)

Partno.:3866411

Partno.:3976047(3-layered) 3831117(4-layered)

Partno.:4100572incl. oillevelgauge,1xseal, 1xoildrainingscrew

Partno.:4047957

Set of 4 Partno.:4047445typeGUA Partno.:4047446typeGUB

E 5

.320

.0/0

8.16

CO3 equipment options

GUB (int. thread M8x6)GUA (ext. thread M8x23)

5

7

4

9

8

* Items 4 and 9 cannot be retrofitted – only possible as original equipment

9

Equi

pmen

t opt

ions

Model code

Circuit diagram (manifold type A)

CO3FuL Powerunitwithfrequencyinverted,oil-air-cooled

nospecification:withoutbypassfilter(standard) F20C: bypassfilter20μm+electricalcloggingsensor F20B:bypassfilter20μm+visualcloggingindicator

K17: plasticoiltank,fillingvolume17litres A30: aluminiumtank,fillingvolume30litres(75mmadditionalheight)

A: opticalfillinglevelgaugeFSA/ K: electricalfillinglevelmonitorFSK

18.0: max.flowrateinl/min(+/-10%)

SN: standardpump LN: low-noise pump

50: regulatedpressuresettinginbarat1.5KW 70: regulatedpressuresettinginbarat2.2KW (otherregulatedpressuresettingsonrequest)

63: 1Ph-230Vconnection,frequencyinverter 1,5: motorpowerinkW 2,2: motorpowerinkW

BA =manifoldtypeA(seehydrauliccircuitdiagram) (othermanifoldtypesorhydrauliccircuitsonrequest)

F55 = fixed-settingpressurereliefvalvesetat55bar F75 = fixed-settingpressurereliefvalvesetat75bar (generally 5 bar above pressure setting)

No specification: with screw plug at connection M1 M1/MA1: with pressure gauge (scale 100 bar) at connection M1 M1/MP1: with pressure gauge (scale 10 Mpa) at connection M1

No specification:withoutdustprotectionfilter MLF3: withdustprotectionfilter(3-layered,preferred) MLF4: withdustprotectionfilter(4-layered,high-dustenvironment,considerablyreducedcoolingcapacity)

No specification:withoutvibrationdamper GUA: withvibrationdamper,ext.threadM8x23 GUB: withvibrationdamper,int.threadM8x7

No specification: with screw plug G½" AS: withpivotableoildraininghose

No specification: without oil tray WA: with oil tray (33 ltr.)

CO3FUL - F20B - K17 - A – 18.0SN - 50 - 63 - 1,5 - BA-F55 + M1/MA1 + MLF4 + GUA + AS + WAExample:

1

G 1/2

M

L1(Rp1)

T1(Rp1/2)

L2(Rp1)

6

Q2 Q1

M

FSA

2

max 80°C

P1(G3/8)

M1(G1/4)

M2(G1/4)

MLF

7

P

U

ELFP10

3 4FSK

9

GU8GU 8

Option

Pos. Pos.

5

7

8

1

4

9

65

2

1

79

8 8

3 4

10

E 5

.320

.0/0

8.16

Connection and equipment data

Notices and operating conditions

Designations

zEnsurethattheunitisonlyusedforitsdesignatedpurpose.Donotusethepowerunitforanythingotherthanitsintendedpurpose! z Inallproductlifephases,thecorrespondingworkonthepowerunitmustonlybeperformedbyauthorisedspecialistpersonnel. zOnlyperformworkwhilethepowerpackisinade-energisedanddepressurisedstate. z Forthebypassfiltrationoption,onlytheSTAT-Xfilterelementsdescribedinthisbrochureunderequipmentoptionsmaybeused,topreventelectrostaticcharging. zCO3powerunitsareexclusivelyintendedforuseinstationaryoperationandindustrialapplications. zEnsureadequatecontinuousventilation(inletairandoutletair)intheareaoftheaxialfanandtheoil/airheatexchanger. zPowerunittobesetupinanenvironmentwithlowdustandcorrosionconditions. z Forahigh-dustenvironment,usedustprotectionfilter. zPowerunittobeoperatedonlywithinthecapacitylimitsdescribedinthisbrochure. zOperationonlywithpermittedoperatingmedia. zConnectionandpowersupplyonlyinconjunctionwithpermissiblesingle-phasenetworkswithequipotentialbondingwithinthespecifiedlimits. zHYDACoperationinstructions(drawingno,4153997)appliesinaddition.

LoadhookDi=30mm

Checkvalve

Pressurereliefvalve

Double pump

T1=Rp1/2“tankportbelowoillevel

L1=Rp1“tankportaboveoillevel

P1=G3/8“pressureport

Pressuretransmitter

M1 = G 1/4 gauge port

L2=Rp1“tankportaboveoillevel

2

1

6

NOTES

11

Con

nect

ion

data

/not

ices

HYDAC FLUIDTECHNIK Justus-von-Liebig-Str. GMBH 66280 Sulzbach/Saar Germany

Telephone: +49 6897 509-01 Fax: +49 6897 509-577

e-mail:[email protected] Internet:www.hydac.com

4

E 1

0.11

3.1.

0/01

.10

Global Presence.Local Expertise.www.hydac.com

Cool

ings

Sys

tem

s 57

.000

E

lect

roni

cs 1

80.0

00

Acc

esso

ries

61.0

00

Com

pactHydraulics53.000

FilterS

ystems79.000

ProcessTechnology77.000

FluidFilters70.000

Accu

mul

ator

s 30

.000

E 5

.320

.0/0

8.16

HYDACHeadquartersHYDAC CompaniesHYDACSalesandServicePartners