The Enduring Benefits of Eccentric Disc Pumps · The Enduring Benefits of Eccentric Disc Pumps Page...

Transcript of The Enduring Benefits of Eccentric Disc Pumps · The Enduring Benefits of Eccentric Disc Pumps Page...

Page 1The Enduring Benefits of Eccentric Disc Pumps

As the 20th century dawned, the second Industrial

Revolution, also known as the Technological Revolution,

was moving ahead full steam. The Bessemer steel process

had become the first inexpensive way to mass-produce

steel from pig iron, which resulted in a building boom.

Automobiles were on the way to becoming a more common

sight on the streets of major cities than horse-drawn

carriages. The gas lamp was making way for the more

efficient and safer incandescent light bulb.

At that time, Frenchman Andre Petit had just graduated

from the renowned Ecole Centrale Engineers’ College in

Paris with a degree in engineering. Taking a job in the gold-

mining industry, he found himself traveling throughout

central Asia, even as far as China. He also found himself

wondering how he could improve the operational

performance and reliability of the industrial pumps that

were used to transfer water and other produced liquids out

of gold mines.

By 1906, he had perfected the answer, which he called the

“eccentric movement principle” of pump operation, which

he proved would succeed where other pump technologies

fail. Petit was so confident in the potential of this new

pump technology that he formed his own company, which

he named Mouvex® and headquartered in Paris, France.

More than a century later, Mouvex, which relocated its

operations in 1974 to a 100,000-square-foot manufacturing

complex in the city of Auxerre, southeast of Paris, remains

a global leader in outfitting a wide array of industries

with eccentric disc pumps for use in transfer applications

that require constant flow rates, leak-free operation and

accurate dosing.

Surveying the FieldAs Petit began the search for a better pump design,

internal gear and lobe-style were the preeminent pump

technologies. These workhorse pumps proved perfectly

capable of handling basic liquid-transfer operations, but

both styles featured shortcomings that would ultimately

compromise an operation’s efficiency, reliability, and cost-

effectiveness over time.

more than a century after its invention, andre petit’s eccentric movement principle continues to set the global standard in efficient and consistent liquid-product transfer

By Christophe Jovani

March 2012

Page 1

The Enduring Benefits of Eccentric Disc Pumps

Page 2 The Enduring Benefits of Eccentric Disc Pumps

Gear pumps use the meshing of their gears to pump fluids

by displacement. Because of this style of operation, from

day one the pump’s gears are constantly contacting each

other as they move the fluid. This causes the gears to wear,

which increases the clearances between the gear teeth,

in the process reducing the pump’s flow capacity and

volumetric consistency while increasing the probability that

efficiency- and energy-robbing product “slip” will occur.

Additionally, as gear pumps wear they must operate at a

higher speed in order to maintain the desired flow rate.

This array of operational deficiencies will not only decrease

the pump’s performance and reliability, but also increase

maintenance occurrences and downtime, and the amount

of energy needed to power the pump, which will result in

an overall higher cost of operation.

The design and operation of lobe-style pumps forces the

pumped material to flow around the interior of the

pump’s casing, which allows them to offer continuous-flow

and dry-run capabilities, and gives them the ability

to handle not only fluids, but a wide range of solids,

slurries and pastes.

However, lobe pumps also feature a series of inherent

operational inefficiencies. Much like gear pumps, because of

their method of operation lobe pumps will wear constantly.

This wear means that the internal clearances in the pump’s

housing will become greater, resulting in reduced flow

capacity and volumetric consistency over time, along with

an increase in product slip.

In addition, lobe pumps have two shafts that need to be

sealed, which doubles both seal expenses and the potential

for leakage. Also, their self-draining requires vertical

porting, which can decrease volumetric consistency by

20% or more. Finally, they must operate at greatly reduced

speeds in order to handle high-viscosity liquids, while they

experience diminished performance when handling low-

viscosity liquids.

To the RescuePetit identified those challenges that the users of gear and

lobe pumps were facing in optimizing their operations

and found a solution in the eccentric movement principle.

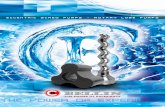

Basically, Petit’s eccentric disc pumps feature a disc that

is placed inside a pump cylinder. The disc is driven by an

eccentric bearing that is installed on the pump shaft, thus

creating four distinct pumping chambers that increase and

decrease in volume as the disc is rotated by the eccentric

bearing, producing both suction and discharge pressures

as the chambers move in pairs that are 180 degrees apart.

This method of operation ensures that the fluid passes

through the pump at a constant and regular flow rate.

This design also means that eccentric disc pumps do not

need mechanical or dynamic seals in order to operate.

They do not need mechanical seals because, even though

they are driven by a standard rotating drive, the off-center

shaft that rotates the disc allows each point of the disc to

move at the same speed. This means that the drive end

of the pump’s shaft is located on a different plane than

the tip end of the shaft that actually drives the pumping

Nearly 70 years after the company’s founding in 1906, in 1974 Mouvex® relocated its eccentric disc pump manufacturing operations to a 100,000-square-foot facility in Auxerre, France, a suburb of Paris.

Originally used in the tar, asphalt and bitumen industries, Mouvex’s family of eccentric disc pumps has evolved to the point where they are ideal for handling any type of liquid efficiently and effectively, from water to slurries.

The Enduring Benefits of Eccentric Disc Pumps

mechanism. Attached to the shaft are bearings that are

enclosed in a hermetically sealed metal bellows or rubber

boot. So, when the shaft rotates, the bellows or rubber boot

does not rotate, but, rather, flexes in an eccentric circle.

Eccentric disc pumps operate similar to that of a peristaltic

pump, but without the need for any hoses, which can

often fall victim to their own inefficiencies. During

operation, the pump’s disc is driven by the eccentric

movement of the shaft, allowing product to flow through

both the pump’s inner and outer chambers. This style of

operation eliminates any possibility of pulsation within the

pumped liquid, and since the pump does not depend on

clearances to facilitate product flow, any slip is negligible.

Additionally, with the pump needing no mechanical seals,

there are no surfaces present where products that are

difficult to seal and prone to crystallization can adhere and

cause damage, which eliminates a maintenance concern.

Speaking of maintenance, eccentric disc pumps also

feature simple, clean-in-place/sanitize-in-place (CIP/SIP)

operation that does not require vertical drain porting.

In most cases, the CIP process begins with a water flush

with concentrations of different cleaning solutions, such

as a mild caustic, and perhaps a reheating of solutions

that are circulated through the pump, piping and valves,

concluding with a final rinse. In some cases, steam is used

in place of water or other cleaning solutions.

It is important to minimize the amount of residual product, especially if it is expensive or hazardous, that remains in

the pump and piping prior to starting the CIP cycle. For

optimum cleaning of sticky or viscous products, the flow

rate through the pump is generally between 20 and 200

gpm (76 and 757 lpm) depending on the pump model, and

less for thinner, easier-to-handle products.

In CIP applications, the pumps can be arranged in a series

to take advantage of their unique “disc/cylinder” design.

Because the pressure at the pump inlet is higher than at

the outlet, the disc lifts from the pump cylinder, permitting

passage of the water or cleaning solutions to flow through

the pump, thoroughly cleaning the pump chambers. This

unique feature eases the cleaning process and reduces

cycle times so the pump can be put back into operation as

quickly as possible.

In 1997, Mouvex was purchased by global manufacturer

Dover Corporation and incorporated as a subsidiary to

American pump manufacturer, Blackmer®, Grand Rapids,

MI. In 2008, Mouvex, along with Blackmer, became a

part of the Dover Corporation’s Pump Solutions Group

(PSG®), a conglomeration of the world’s leading pump

manufacturers. In conjunction with these changes,

Mouvex has continued to refine Andre Petit’s eccentric

movement principle. Today, the company offers several

families of eccentric disc pumps that have proven reliable

in a wide range of applications, including:

n C-Series – Designed without mechanical seals,

packing or magnets, which eliminates product leakage

and cost-prohibitive maintenance and downtime.

Self-priming and dry-run capable with outstanding

volumetric efficiency at low linear speed. Output not

affected by variations in product viscosity. Clean-in-

place capability allows the pump to be flushed and

cleaned in place without disassembling. Designed per

EHEDG recommendations and carries 3A approval and conformity with ATEX certification.

n A-Series – Features exceptional self-priming

capabilities that enable dry-running and pipe-clearing.

Automatic clearance make-up system maintains initial

performance level over time without the need for

Page 3

Eccentric Disc Pumps Lobe Pumps

n Superior mechanical performancen Consistent performance over timen Can strip lines of residual productn Provides low product shear

n Less mechanically effectiven Expensive to repairn Unable to strip the linesn Higher product shear

Comparison of Eccentric Dics Pumps Vs Lobe Pumps

www.mouvex.comMouvex HeadquartersZI la Plaine de Isles, 2 rue des Caillottes

F-89000 Auxerre, FranceT +33 (0) 3 86 49 86 30 • F +33 (0) 3 86 46 42 10

adjustment. Constant output maintained even

as product viscosities and delivery pressures vary.

Can handle viscous, non-lubricating, volatile or

delicate liquids with no shear.

n S-Series – Zero-leakage operation thanks to a design

that features no mechanical seals, packing or magnetic

drive. The transmission is protected by an FDA-

approved tasteless, high-resistance elastomer sleeve.

Designed for clean-in-place or cleaning by hand

thanks to easy-opening operation. Ideal for base-frame

mountings due to small size and low weight. 3A and

ATEX approved.

n SLC-Series – Totally seal-less design with shaft

“sealed” by a double stainless-steel bellows, resulting

in a reduced number of pump components and easier

maintenance. Volumetric performance sustains high

efficiency levels, consistent flow rates and gentle liquid-

handling over the life of the pump. 3A, EHEDG, ATEX

and TUV certified.

n Micro-C Series – Stainless-steel construction meets

the sanitary requirements of 3A and EHEDG. Small

footprint allows easy integration into existing

production setups. Leak-free operation without the

need for magnetic couplings or mechanical seals.

Self-adjusting for mechanical wear with excellent

self-priming, line-stripping and dry-run capabilities.

Operation is not affected by viscosity and pressure

variations. ATEX certified in dry operation.

nCC20 – An excellent vehicle-mounted solution for

loading and unloading road tankers. Constant and

smooth delivery allows total draining of hoses, even

over long distances. Versatile enough to also be used as

a ground-based unit.

ConclusionWhile the first industries that embraced Petit’s eccentric

disc technology were those that produced tar, asphalt

and bitumen, over the years the eccentric disc pump has

proven to be a reliable piece of equipment for use in a wide

range of industries. Today, Mouvex eccentric disc pumps

are a prominent component in critical product-transfer

applications in the global Chemical, Energy, Sanitary and

Military markets. Andre Petit’s dream of developing a more

efficient and reliable pumping technology has resulted in

the creation of a pump style that, in some way, continues

to benefit the world’s inhabitants more than a century after

its invention.

ABOUT THE AUTHOR:

Christophe Jovani is the Marketing Manager for Mouvex®,

a member of Dover Corporation’s Pump Solutions Group (PSG®),

Downers Grove, IL, USA. He can be reached at

+33 (0) 386 4986 81 or [email protected]. Headquartered

in Auxerre, France, Mouvex was incorporated in 1906 and is

a leading manufacturer of positive displacement pumps and

compressors for the transfer of liquids or dry-bulk products

worldwide. Mouvex is a member of PSG, which is comprised of

several leading pump companies, including Almatec®, Blackmer®,

EnviroGear®, Griswold™, Mouvex®, Neptune™, RedScrew® and

Wilden®. You can find more information on Mouvex at

www.mouvex.com and PSG at www.pumpsg.com.

Page 4

Today, Mouvex eccentric disc pumps are a first-choice component in critical product-transfer applications in the global Chemical, Energy, Sanitary and Military markets.