The Code of Conduct on the premises of Grupa LOTOS … · ORGANISATION OF SITE FACILITIES,...

Transcript of The Code of Conduct on the premises of Grupa LOTOS … · ORGANISATION OF SITE FACILITIES,...

The Code of Conduct on the premises of Grupa LOTOS S.A.

2

TABLE OF CONTENTS1. IMPORTANT TELEPHONE NUMBERS .................................................................................................. 5

2. REQUIREMENTS FOR CONTRACTORS ................................................................................................ 6

3. VIOLATION OF SAFETY RULES, REGULATIONS AND STANDARDS .............................................. 6

4. HAZARDS WITHIN THE AREA OF LOTOS .......................................................................................... 7

5. TRAININGS .............................................................................................................................................. 11

6. PROHIBITED ACTIVITIES ..................................................................................................................... 12 6.1 Prohibition of open fire use and smoking ................................................................................................................ 12 6.2 Prohibition of bringing and consumption of alcohol and drugs ....................................................................... 12 6.3 Prohibition of taking photographs, filming ............................................................................................................ 13 6.4 Prohibition of bringing weapons and dangerous items ..................................................................................... 13 6.5 Prohibition of mobile phone use, radio telephone use and use of other transmitting device .................. 13 6.6 Prohibition of transporting people and equipment on vehicles unsuitable for transport ......................... 14 6.7 Prohibition of blocking access to buildings, roads and fire-fighting infrastructure ................................... 14 6.8 Prohibition of traffic within the area of peripheral protection .......................................................................... 15

7. TRAFFIC RULES .................................................................................................................................... 16 7.1 Entrance onto the site .............................................................................................................................................. 16 7.2 Entering and exiting the site .................................................................................................................................. 16 7.3 Material assets flow .................................................................................................................................................. 17 7.4 Traffic within the site ............................................................................................................................................... 17

8. FIRE PROTECTION .............................................................................................................................. 22 8.1 Chemical alert ........................................................................................................................................................... 22 8.2 Assembly points and weather vanes .................................................................................................................. 24 8.3 Proceeding in emergency situations ................................................................................................................... 24 8.4 Evacuation from buildings and premises .......................................................................................................... 26 8.5 Drills in the scope of reaction to malfunctions and other threats ...................................................28

9. ORGANISATION OF SITE FACILITIES, CONSTRUCTION SITE AND WORK .................................. 28

10. RULES OF TRANSPORT, STORAGE, FILLING VEHICLE TANKS AND MACHINES USING FUEL FROM CONTAINERS ...................................................................................................... 31 10.1 Transport of fuel in containers .............................................................................................................................. 31 10.2 Storage of fuel in containers ................................................................................................................................... 31 10.3 Filling a tank of a vehicle or a machine using fuel from containers .............................................................. 32

11. SAFETY OF WORK ............................................................................................................................... 32 11.1 Control and inspections of working conditions ................................................................................................ 32 11.2 Individual protection measures, protective clothing and shoes .................................................................. 33 11.3 Hazardous chemical substances and mixtures ................................................................................................ 34 11.4 Written permits ........................................................................................................................................................ 35 11.5 Hazardous energies – LOTO system .................................................................................................................. 38 11.6 Work in confined spaces ........................................................................................................................................ 39 11.7 Health and Safety Analysis .................................................................................................................................... 43 11.8 Work on heights ....................................................................................................................................................... 45 11.9 Crane works ................................................................................................................................................................ 51 11.10 Earthworks – excavations ..................................................................................................................................... 54 11.11 Work comprising a fire hazard .............................................................................................................................. 55 11.12 Tools, machinery and technical equipment ....................................................................................................... 60 11.13 Order and cleanliness ............................................................................................................................................... 61 11.14 Electricity ................................................................................................................................................................... 62 11.15 Radiation protection ................................................................................................................................................ 63

12. REPORTING HAZARDOUS EVENTS .................................................................................................. 64

13. PHYSICAL SAFETY .............................................................................................................................. 66

14. ENVIRONMENTAL PROTECTION ....................................................................................................... 67 14.1 Waste management ................................................................................................................................................ 67 14.2 Water-wastewater management ......................................................................................................................... 69 14.3 Air protection ............................................................................................................................................................ 70 14.4 Ground surface protection ..................................................................................................................................... 70 14.5 Media management ................................................................................................................................................. 70

3

The LOTOS Group attaches a lot of significance to safety of persons working and staying on the area of the enterprise. Safety at work and health protection belong to our priori-ties. We abide by the principle that “no work is as impor-tant and urgent as not to be delivered safely”.

We apply the “zero tolerance” rule for disregarding the ru-les and non-observance of the requirements in the scope of widely understood safety at work, health protection, physical safety and fi re prevention.

WE SUPPORT SAFETY

4

The Code of Conduct on the premises of Grupa LOTOS S.A. (hereinafter also referred to as The Code of Conduct):• it replaces The Code of Conduct on the premises of Grupa LOTOS S.A., edition no. 7

of June 2010,• includes internal requirements and rules of appropriate conduct on the premises

of Grupa LOTOS S.A. and its subsidiary companies (hereinafter also referred to as Grupa LOTOS, LOTOS Group, LOTOS),

• Is intended for the employees of Contractors and Subcontractors (hereinafter referred to as Contractors) staying and carrying out works on the premises of Grupa LOTOS S.A.. and its subsidiary companies, located in Gdańsk at ul. Elbląska 135, ul. Benzynowa, ul. Michałki 25 and within the area of water intake in Przejazdowo.

Each person present on the area of LOTOS Group is strictly obliged to follow the effective legal regulations and internal requirements of the company. Violation of these require-ments may result in sanctions, including financial penalties and/or permanent loss of the right to be present within the area of the company.

5

1. IMPORTANT TELEPHONE NUMBERS

Phone calls dialed directly from stationary telephones connected to internal network of Grupa LOTOS

Alarm Center of LOTOS Straż 81 09 (from the stationary telephone connected to the in-plant network of Grupa LOTOS) 81 99

Site Dispatcher 81 04

Shift Leader of LOTOS Ochrona 72 27

Planning and Control Maintenance Department 71 14

Planning and Mechanical Maintenance Department 82 76

Master of the Main Power Supply Point Servicing of Power Distribution Network 70 13

Radiation Protection Inspector 84 32

Material passes (tools, equipment, etc.) 74 09

Settling dates and places of trainings 72 30 (on the general rules of safety in force in Grupa LOTOS) 72 31

Fuel Terminal Dispeatcher 75 96

When dialing from outside internal telephone network of the Grupa LOTOS one should first enter 58 308… and then continue with suitable digits.

dialing code to Poland +48dialing code to the Pomorskie province 58

EMERGENCY PHONE NUMBER

998fire, failure, accident, other threat

(only from stationary telephones connected

to the internal network of Grupa LOTOS)

+48 508 998 998fire, failure, accident,

other threat

(only from mobile phones)

6

2. REQUIREMENTS FOR CONTRACTORS

A Contractor signing a contract with LOTOS Group is obliged to observe and continuously monitor the effective legal regulations as well as rules and standards of conduct within the area of the company, in particular those related to occupational safety, fire protec-tion and physical safety, provided in contractual stipulations or on the Requirements of LOTOS Group for Contractors website at the address: http://kontrahenci.lotos.pl.

In case of cooperation with subsidiary companies of LOTOS Group, the Con-tractors and its Subcontractors are obliged to know, monitor and observe effective legal regulations as well as rules and standards of conduct within the area of such companies.

A Contractor is obliged to ensure that its employees and Subcontractors that execute work know and obey the rules of conduct on the premises of LOTOS. The Contractor is responsible for their employees and employees of their Subcontractors and further Subcontractors ac-cording to the same rules which apply to their own employees.

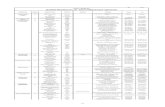

3. VIOLATION OF SAFETY RULES, REGULATIONS AND STANDARDS

The rules of proceeding in cases in which the Contractor does not obey LOTOS Group regulations are regulated in:• stipulations of contracts signed between

the Contractor and Grupa LOTOS S.A./subsidiary company

• in the Qualification scale of misde-meanours for external companies’ em-ployees that is binding at the premises of Grupa LOTOS S.A. (hereinafter also referred to as Table of penalties)

Taryfikator wykroczeń dla pracowników firm zewnętrznych

obowiązujący na terenie Grupy LOTOS S.A.

Wydanie z dnia 30-10-2015 r. 1 z 8

I. Wykroczenia związane z naruszeniem zasad bezpieczeństwa fizycznego

ALK

OHO

L, Ś

RO

DK

I O

DU

RZA

JĄC

E

Próba wejścia/przebywanie na terenie Grupy LOTOS S.A. (zwanej dalej GL S.A.) pod wpływem alkoholu lub środka odurzającego

Zawartość alkoholu we krwi > 0,2 ‰ lub obecność środków odurzających

Bezterminowy zakaz wstępu na teren GL S.A.

Próba wniesienia/posiadanie alkoholu na terenie GL S.A. 1-szy raz Zakaz wstępu na teren GL S.A. na 1 miesiąc 2-gi i kolejny raz Zakaz wstępu na teren GL S.A. na 3 miesiące

PAPI

ERO

SY Palenie papierosów, e-papierosów w miejscu niewyznaczonym

Każdorazowo Zakaz wstępu na teren GL S.A. na 3 miesiące

DRO

GO

WE

Przekroczenie prędkości

o 11 – 30 km/h

1-szy raz - pisemne oświadczenie osoby popełniającej wykroczenie, składane niezwłocznie w dniu popełnienia wykroczenia w przedmiocie przyznania się do popełnienia wykroczenia i stosowania się w przyszłości do zasad obowiązujących na terenie GL S.A. 2-gi i kolejny raz - zakaz wstępu na teren GL S.A. na okres 14 dni

> 30 km/h 1-szy raz - zakaz wstępu na teren GL S.A. na okres 14 dni

2-gi i kolejny raz - zakaz wstępu na teren GL S.A. przez 1 miesiąc

Spowodowanie kolizji drogowej

1-szy raz Zakaz prowadzenia pojazdów mechanicznych na terenie GL S.A. przez 3 miesiące

2-gi i kolejny raz Zakaz prowadzenia pojazdów mechanicznych na terenie GL S.A. przez 6 miesięcy Spowodowanie wypadku drogowego

Każdorazowo Zakaz wstępu na teren GL S.A. na okres od 6 miesięcy do 24 miesięcy, w zależności od skali zagrożenia i skutków zdarzenia1

Naruszenie zakazu prowadzenia pojazdów mechanicznych 1-szy raz Zakaz wstępu na teren GL S.A. na 3 miesiące 2-gi i kolejny raz Zakaz wstępu na teren GL S.A. na 12 miesięcy

Jazda bez zapiętych pasów bezpieczeństwa, jazda bez włączonych świateł zewnętrznych, używanie podczas prowadzenia pojazdu telefonu komórkowego w sposób niezgodny

z przepisami, nie ustąpienie pierwszeństwa przejazdu

1-szy raz 1-szy raz - pisemne oświadczenie osoby popełniającej wykroczenie, składane niezwłocznie w dniu popełnienia wykroczenia w przedmiocie przyznania się do popełnienia wykroczenia i stosowania się w przyszłości do zasad obowiązujących na terenie

1 Decyzję w zakresie wysokości kary podejmuje Szef Biura Bezpieczeństwa i Ochrony Grupy LOTOS S.A.

7

4. HAZARDS WITHIN THE AREA OF LOTOS

Grupa LOTOS is a company with high levels of risk related to occurrence of an industrial mal-function. The following hazards may be encountered at the site:• fire hazard,• explosion hazard,• toxic hazard,• radiation hazard,• hazards involving physically harmful, biological and chemical hazards such as noise,

hot media, high pressure and contact with chemicals,• hazards related to hazardous works, like work on heights, works in excavations, in confined

spaces, such as e.g. tanks, reactors,• other highly hazardous works such as transport work, operation of machines or electric

equipment.

FIRE-EXPLOSION HAZARDS

Petroleum and its derivatives are highly flammable liquids, which are difficult to extinguish when on fire. They also create high explosion hazards. Gaseous hydrocarbons and vapours of liquid hydrocarbons cre-ate an explosive mixture when mixed with air in a certain proportion.

Evaporation of an even small amount of liquefied gases or flammable liquids results in large amounts of flammable vapours, which form

Explosion hazard zone (EX zone) is a production area characterised by presence of gases, vapours or mists, which form mixtures with air, leading to a potentially explo-sive atmosphere. The EX zone includes locations marked with information boards from the edge of the sidewalk, throughout entire production installations, the tank farm, locations of product filling and unloading.When entering the EX zone, requirements related to e.g. protective clothing and shoes, equipment used, necessity of having written entrance permits or work permits must be observed.

EX

8

explosive mixtures. For example, only 1 litre of liquid propane after evaporation forms, under specific conditions 260 litres of an easily explosive mixture.

In most cases, these mixtures are heavier than air, thus they may remain for even a few days in terrain depressions, such as moulds with pipelines, excavations or sewage discharges. Because of their flammable and explosive properties, in case of contact e.g. with flame, me-chanical or electrostatic spark they may very easily ignite and explode.

HAZARDOUS SEWAGE SYSTEMSIn cases of potential tightness loss of an installation or a pipeline, hydrocarbons heavier than air may travel long distances and accumulate, for example in sewage drainages and other terrain depressions. In case of an explosion, a dangerous ejection of drainage grates may occur, within a large range, resulting in hazards to human health and life and in mate-rial damage.

HOT MEDIA AND HIGH PRESSURES Technological processes take place under high pressures and in high temperatures. Installation leakages may lead to a medium release under the pressure of several tens of bars and a temperature exceeding 300ºC. The released substance may also self-ignite.

HYDROGEN The production process uses also hydrogen – a flammable and explosive gas. If the instal-lation has a leakage, it is ejected under high pressure and self-ignites. It becomes dangerous in case fire, as it burns with a colourless and invisible flame. Contrary to most hydrocarbons, it is lighter than air and rises in the atmosphere.

TOXIC HAZARDS – HYDROGEN SULPHIDEHydrogen sulphide is the gas posing the big-gest toxic hazard because of its occurrence in large quantities. It is a colourless, toxic and flammable gas. When emitted during a malfunction, it can be smelled only in low concentrations due to characteristic smell of „rotten eggs”. At higher concentrations it is undetectable – it damages the sense of smell, in extreme cases causing death even after a single breath.

9

OXYGEN DEFICENCY IN CONFINED SPACES Oxygen is necessary for life, thus it is extremely important to ensure whether the inhaled air has an appropriate content of that element. Too low oxygen content in air may not be detected with human senses, and its victims are usually unaware of the danger. Oxygen may become depleted in confined spaces, which is caused by presence of inert gases such as nitrogen or carbon dioxide, displacing oxygen from the available space. These gases act without a warning, leading to mental capacity impairment, loss of situational awareness, and a quick loss of consciousness at lower contents. Oxygen content below 18% becomes hazardous for human beings. Below 10% it is impossible to move – on cannot walk, stand or even crawl. Loss of consciousness occurs without prior warning signs and without pain. After a few minutes, brain damage and death occur, unless immediate CPR is provided.

IONIZING RADIATIONWithin the LOTOS premises, hazards related to invisible ionising radia-tion are present mainly during control works, such as e.g. radiological tests of weld quality (X-ray testing). Equipment containing radioactive sources or sources of ionizing radiation may be operated only by appro-priately prepared and trained individuals familiar with the operation of the equipment, actions undertaken during a malfunction and covered by systematic medical care.

Additionally, produc-tion installations 440, 450 and 920 are equipped with control devices containing radioactive sources – isotopes Cs-137 and Sr-90. Contractors working on these in-stallations are obliged to follow instruc-tions from LOTOS, and to obtain a writ-ten permission. Such locations are marked with safety signs, and systematic measure-ments do not show any radioactive con-taminations.

10

In addition to mentioned hazards, the following hazards may be encountered within the area of LOTOS, e.g.:

If you feel unwell, weak, feel nausea or other symptoms, do not neglect them. They may be caused by contact with substances

hazardous to your health, and even life.

NOTIFY YOUR SUPERIOR IMMEDIATELY OF THE SYMPTOMS

gas cylinders

hanging objects

falling objects

explosive zone

the risk of head injury

limitheight

rotating elements

dangerfall

dangerstumbling

slipperysurfaces

high levelnoise

deductionby car

deductionby train

car collision collisionwith train

EX

11

5. TRAININGSDetailed requirements are specified in a resolution related to a pass-based system of traffic of personnel and vehicles at sites of Grupa LOTOS S.A.

TRAINING FOR CONTRACTORS ABOUT HAZARDS TO SAFETY AND HEALTH Before starting work within the area of LOTOS Group, the Contractors are obliged to undergo a training providing information about hazards to safety and health, as well as discussing rules of conduct and safe execution of works within the area of the company.

The training is directly provided by a specialist of the Health and Safety Office of Grupa LOTOS or by a designated employee of a subsidiary company. The training is valid for the period of 3 years, and has to be repeated after this time. Employees with intermittent employment with breaks over 12 months are trained again. Dates and locations of the aforementioned trainings should be agreed upon with an employee of LOTOS Ochrona Sp. z o.o. (hereinafter referred to as LOTOS Ochrona) at the Pass Office.

WARNING! The training may not be considered to be a Health and Safety training by external companies in the sense conforming to the Polish law. It also does not inclu-de all safety regulations related to work provided by external companies, which result from national regulations related to this field, and which should be strictly followed and obeyed within the LOTOS area.

14 days before the expiration date of this training, during entrance onto the LOTOS area, the employee of the Contractor will be halted by the control point (turnstile). This situation requires a visit at the Pass Office in order to be able to enter the site and to obtain information from an employee of LOTOS Ochrona) about the approaching training validity deadline and about the need to repeat the training.

TRAININGS PROVIDED BY THE CONTRACTOR The employee supervisor of the Contractor is obliged to perform, every day, before his su-pervised employees start work, a short safety training (documented with a signature of the trainer), during which he or she informs the employees about their daily tasks, hazards gene-rated by their work and about how to protect themselves against such hazards.

12

6. PROHIBITED ACTIVITIES

6.1 Prohibition of open fire use and smoking

Prohibition of open fire use without permission and smoking prohibition are in effect within LOTOS areas. Smok-ing is permitted only in the designated locations, marked with the ”smoking is allowed here” (Polish: „Tu wolno palić”) signs. If the smoking area is not clearly indicated outdoors, smoking is allowed within the maximum radius of 2 metres from the sign informing that smoking is permitted here.

Smoking in other locations, premises and vehicle cabins is prohibited. These rules also apply to e-cigarettes. Usage of gas stoves, sources of sparks and electric equipment inside vehicle cabins is also prohibited.

WARNING! It is also forbidden to enter the EX zones, i.e. areas of production installa-tions, the tank area and the filling spaces with matches, lighters and any other devices used in order to light a cigarette/spark a fire. This prohibition does not apply to equip-ment which must be used for technological, repair or investment purposes.

6.2 Prohibition of bringing and consumption of alcohol and drugs

It is forbidden to bring and consume alcohol and drugs, or entering and remaining present under their influence.

On request of a LOTOS Ochrona employee, every person suspected to be under influence of alcohol is

obliged to undergo an alcohol test Indicating presence of alcohol in exhaled air.

ADDITIONAL TRAININGS OF THE CONTRACTORS The Contractor is obliged to delegate their employees/subcontractors for additional tra-inings related to occupational safety, provided according to rules and on dates specified by LOTOS representatives.

13

WARNING! An individual in a state after alcohol consumption or drunk will not be permitted to enter the LOTOS area or will be immediately escorted out of the site by a LOTOS Ochrona employee. Such an individual will also be permanently banned from entering the LOTOS area, according to stipulations contained in the ‘Qualification scale of misdemeanors for external companies’ employees that is binding at the premises of Grupa LOTOS S.A. Additionally, a financial penalty will be imposed on the employer of the employee under the influence of alcohol, according to the contract signed with the Contractor.

6.3 Prohibition of taking photographs, filming

Taking photographs, filming of sites by individuals oth-er than LOTOS employees may take place only within a contract, e.g. for professional purposes, such as work progress documentation. All other filming needs re-quire an approval of the chief of Security Office of

Grupa LOTOS (and in cases of LOTOS graphic mark use, also of the Brand Management Office).

WARNING! Individuals taking photographs/filming within the production installa-tions, at product filling locations, within the tank farm, namely within explosion hazard zones (EX zones) is obliged to obtain a written permission, according to the procedure of conduct during execution of work on the basis of a written permission.

6.4 Prohibition of bringing weapons and dangerous items

It is prohibited to bring weapons (of all types), knives, combat batons, sharp tools, explo-sives/flammable materials and other dangerous items a controller and/or uncontrolled and unintended use thereof may violate personal well-being and/or pose a hazard to life, health or freedom of individuals working and present within the LOTOS area.

6.5 Prohibition of mobile phone use, radio telephone use and use of other transmitting devices

Use of mobile phones and other electronic, transmitting devices is considered as having an active electric device.

14

It is prohibited to use mobile phones and other electronic, transmitting devices: • At production installations, at product filling locations, within the tank farm, • In designated office premises, conference rooms, control rooms, server rooms, technical

premises for automation, teletechnical rooms and IT system rooms, • Other premises/locations provided with a sign „prohibition of mobile phone use” or „switch

the mobile phone off”.

It is prohibited to bring mobile phones, radio telephones and other transmitting, electronic equipment into the explosion hazard zones (EX zones), unless they are provided with ap-propriate certificates.

Such equipment can be used in social-office premises, warehouses, workshop-repair prem-ises and in generally available traffic routes, unless signs inform otherwise. .

WARNING! All prohibitions listed in paragraphs 6.1 - 6.5 also apply to cabins of vehicles entering the LOTOS area.

6.6 Prohibition of transporting people and equipment on vehicles unsuitable for transport

It is prohibited to transport people using vehicles unsuited for transport of people, such as e.g. platforms of goods vehicles. Passengers may be present on a semi-trailer of a vehicle, if it is adapted for passenger transport. The number of individuals who may be present inside a vehi-cles cabin should match the number specified in vehicle documentation. It is also prohibited to transport e.g. equipment, devices or technical gas

cylinders in a manner contradicting effective legal regulations.

During driving, the driver is obliged to have a personal and vehicle pass (SKD card) and authorisations for driving the vehicle and to present them, on request, to LOTOS Ochrona employees and the Health and Safety officers.

6.7 Prohibition of blocking access to buildings, roads and fire-fighting infrastructure

It is prohibited to block the access to fire-fighting infrastructure, including i.e. hydrants, Manual Fire Warning Devices or connections to semi-fixed extinguishing installations.

15

If a vehicle is parked incorrectly, LOTOS Ochrona has the right to apply a lock on wheels of the vehicle and execute the consequences related to violation of safety rules and regulations effective on the site.

All roads within the refinery are fire routes, which means they may not be blocked without

a written permission.

6.8 Prohibition of traffic within the area of peripheral protectionDetailed requirements are regulated in a procedure related to rules of conduct during work based on written permissions.

A peripheral protection system is implemented within the site. Complete traffic prohibition is in effect in locations marked as ”Unauthorised access and passage prohibited”.

If a work must be done within the peripheral protection area, it is necessary to obtain a written permission from the site manager, confirmed by a Shift Manager of LOTOS Ochrona, prior to the commencement of work. During such work, the Contractor is obliged to protect teletech-nical equipment against dirt and damage. The end of such work and restoration of the initial state by the Contractor should also by confirmed by the Shift Manager of LOTOS Ochrona.

NIEUPOWAŻNIONYM WSTĘP I PRZEJŚCIE

WZBRONIONE

”Unauthorised access and passage

prohibited”

16

7. TRAFFIC RULES

7.1 Entrance onto the site Detailed regulations are provided in the resolution related to the pass system of personal and vehicle traffic.

Entrance onto the site is possible only on the basis of a single-use/temporary electronic pass (personal SKD card), issued by LOTOS Ochrona.

Individuals applying for a permanent/temporary SKD card for a Contractor are first obliged to participate in a training about general safety rules within the area of the company (p. 5 of the Code of Conduct).

Presence of Contractors within the protected area is possible from Monday to Saturday, at 5:00-22:00. Each entrance or presence after 22:00 or on statutory holidays requires a written confirmation, signed by a LOTOS supervisor, handed over to the Shift Manager of LOTOS Ochrona.

WARNING! Every individual with a pass MUST have their personal ID with them at all times during entrance/passage through the gate leading onto the site area.The personal SKD card is also an identifier the employee is obliged to wear outside their clothing, in a visible location. In case of work performed on production installations, it is permitted to place the personal SKD card inside the clothing.

The card is assigned to the individual and each use of the card is recorded. The card may not be used by others. It is issued for a specific period of time and must be extended or returned after said period (after execution of all work on the site) to the Pass Office of LOTOS Ochrona. If the card is lost, LOTOS Ochrona must be informed immediately.

7.2 Entering and exiting the site Detailed regulations are provided in the resolution related to the pass system of personal and vehicle traffic.

Documents, which together authorise the entrance of mechanical vehicles onto the LOTOS site area, include:• Personal SKD card of the driver,• SKD card of the vehicles, and in cases of vehicles without a log book, SKD card for a con-

struction machine,• Driving licence for vehicle that is in use,

NameSurname

COMPANY NAME

17

• Log book of the vehicle with valid technical examinations allowing the vehicle to be used in traffic,

• Valid general civil liability insurance policy of the vehicle owner (including construction machines) (so called vehicle insurance),

• Valid ADR certificate– in case of vehicles transporting hazardous goods.

Entering vehicles should be marked with company names. It is permitted to place a plate with a legible name of the company

behind the windshield of the vehicle.

During driving and parking, the vehicles pass should be placed behind the windshield, in a manner enabling

its identification data to be read.

7.3 Material assets flow Detailed regulations are provided in a resolution related to a traffic system for material assets.

Incoming transport/bringing in and outgoing transport/removal of material assets owned by the Contractor (e.g. machines, power tools, furniture, office equipment, etc.) takes place on the basis of ”OM” material passes.

When material assets are brought onto/removed from the LOTOS area, the employee of LOTOS Ochrona at the entrance gate must be presented with appropriate authorisation documents, detailed in the ”OM” pass, for inspection.

7.4 Traffic within the site

7.4.1 Vehicles and pedestrians The provisions of the Road Traffic Code are in force on the area of enter-prise. The maximal admissible speed for vehicles is 40 km/h (20 km/h within the Fuel Terminal) and may be locally lim-ited to even lower speeds.

18

WARNING! It is forbidden to enter the area using motorcycles and mopeds. Other trans-portation measures e.g. bicycles must be in good technical condition, ensuring safety of the driver and of other traffic users. Individuals riding a bicycle shall be obliged to wear clothing with light reflecting elements.

The driver is obliged to have documents required for the driver/vehicle, including authorisa-tions to their presence within the LOTOS area, and to present them on request of employees of LOTOS Ochrona and of the Health and Safety services.

The following regulations, i.e., must be obeyed when driving:• Road signs should be obeyed,• Headlights/day lights should be switched on,• Safety belts of all travellers should be used,• The driver may not use a mobile phone which is not equipped with a loudspeaker system,• It is prohibited to enter, park and stay within the explosion hazard zones (EX zones) without

a written permission,• Vehicles with height exceeding the value indicated on signs may not enter the site (also

applies to transported cargo),• Attention must be paid to pedestrians, cyclists, engine-driven vehicles or electric vehicles

of melex type,• The shortest permitted route leading to the destination location should be selected,• Vehicles may be parked only at indicated locations.

Local speed control. LOTOS Ochrona is equipped with a device recording

vehicle speed.

All on-site roads running north to south are marked with letters – for example, as roads A-B, C-D and running west to east, with numbers – for example, road 1-2, 2-3.

19

Traffic is possible only on generally available roads, namely such which are not marked with signs ”Traffic prohibited in both directions”, ”No entry” or information provided below a sign ”No unauthorised entry”.

Pedestrians crossing a road use pedestrian crossings where available and pay attention to oncoming vehicles. Walking alongside a road is permitted using sidewalks, if no sidewalk is present, walking on the left side of the road is permitted, with no more than two people walking alongside each other simultaneously.

If it is necessary to enter an area closed to traffic, namely marked with prohibition signs (see above) it is necessary to obtain written permission of the owner of the site, remembering about traffic being permitted only on roads indicated in the permission, and about a prohibition of parking within such areas. If works are necessary within such area, the individual issuing the permission issues a permission for work or records the re-spective entrances in the ”Register of individuals present on the site”.

WARNING! Only Diesel vehicles may enter the area of filling stations and liquid gas storage tanks.

Traffic lights are installed at the junction of A-B and 4-5 roads, next to the LOTOS Straż (Fire Brigade) building. If the lights start emit-ting pulsating, red light, the driver is obliged to stop the vehicle as close to the right edge of the road as possible and wait for the traffic lights to return to their normal condition.

Traffic lights are also installed at other locations e.g. at the junction of 5-6 and C-9 roads, along the D3 road, etc. Start-up of the traffic lights means a strict entrance prohibition into the area located behind the traffic lights.

20

7.4.2 Heavy road equipment Taking into account large quantities of electric, telephone cables as well as the control and automation system located underground, it is recommended to avoid entrance and placement of heavy road equipment outside roads or provided concrete yards. If it is necessary to enter such areas, in narrow, tight passages during manoeuvres of large vehicles, always use help of others, who may be able to help with the manoeuvres.

7.4.3 Railroad area Detailed requirements are regulated in the safety rules instruction for traffic within the rail-road area.

Employees of the Contractor may be present and move within the railroad area:• Working according to a permit/entry into the „Register of individuals present on the site”, • Selecting the shortest route for traffic, if possible running perpendicular to the track axis

(taking special care whilst doing so), • Equipped with warning vests and head protection measures (industrial protective helmet).

Basic safety rules:• If an approaching train is seen, move to a safe distance i.e. at least 1.5 m from the external

edge the track on which the train is moving, face the train and observe its passage,• Do not walk into he middle of the track, but on the edge between the two tracks, maintaining

safe distance from external edges of the tracks,• When crossing the tracks, do not step on the top of the tracks/mobile parts, as it may result

in a foot slip/trapping and injury.

It is prohibited to cross and run across railroad tracks directly before the oncoming train, as well as directly after its passage.

Railroad area is an area including railroads, buildings, sites and equipment (including land provided for them) intended for railway management, operation, maintenance and for traffic purposes.

21

7.4.4 Railwaycrossings Drivers are obliged to stop vehicles before the STOP sign at railway crossings and to ensure that driving may be continued.

In case of multi-track crossings, never drive onto the track directly af-ter a train crossing. Wait until the train drives off to a distance allowing to make sure that no trains are travelling down the other tracks.

Never overtake other vehicles when crossing a railroad.

7.4.5 Zamknięcie dróg

Road closure and diversion indications require an agreement/approval of: • In case of public roads

– LOTOS Straż, LOTOS Ochrona and the Property Management Department,

• For internal roads – LO-TOS Straż, LOTOS Och-rona.

The Contractor is oblige to provide signs, making diversion-related agree-ments, as well as placement of warning lights before dusk.

Road closure is a road blockade (e.g. by placing a crane, digging a excavation, installation of a scaffolding lowering the passage height below 4.2 m), which prevent or make pas-sage of LOTOS Straż more difficult.

22

8. FIRE PROTECTION

Each individual present or working within the LOTOS area is obliged to:• ensure appropriate evacuation conditions, i.e.: do not

block, do not obstruct, do not dig within evacuation, traffic and fire routes, access roads to sites (without the required, written permits) and approaches to fire ex-tinguishers, extinguishing aggregates and fire-fighting equipment,

• ensure access (minimum width of 1 metre) to fire extin-guishers and extinguishing aggregates, as well as appro-priate access to fire-fighting equipment,

• do not block roads, passages and access roads to sites, storage yards, access spaces to buildings, pedestals and emergency ladders, passages and exits from buildings, entrances to higher levels of technological installations, etc.

8.1 Chemical alert

A chemical alert may be announced because of an actual chemical alert or during safety drills. Management of the Contractor is strictly obliged to make their employees and sub-contrac-tors familiar with stipulations of the Chemical alert instruction and to observe them in case of a chemical alert.

WARNING! If a message about drills is announced, the alert should be treated as if it was an actual, real situation. Follow the effective regulations and strictly follow orders of the individual in charge of the rescue operations.

A chemical alert cancels all issued permits for work and all permits for entrance onto the area of installation and tanks, recorded in the ”Register of individuals present on the site”.

A chemical alert applies to everyone present within the area for which it was announced.

The supervision of the Contractor is obliged to know the exact number of individuals present within the area of work. When the alarm is announced, the supervisor checks whether all their supervised employees left the hazardous area. If someone is missing, they immediately report it to the person in chargé of the rescue actions.

Complete prohibition of vehicle driving and smoking is effective within the hazardous area.

23

INSTRUKCJA ALARMU CHEMICZNEGO OGŁOSZENIE:

3-minutowy przerywany sygnał:

3-krotna zapowiedź słowna z głośników:

„Uwaga, uwaga ! Ogłaszam alarm chemiczny o skażeniu (podać rodzaj skażenia) dla (podać teren, na którym obowiązuje alarm). Należy ewakuować się na punkt zborny nr…..”

meldunek przekazany siecią telefoniczną lub przez gońca.

W PRZYPADKU OGŁOSZENIA NALEŻY: przerwać wszystkie wykonywane prace (niezależnie od posiadanego zezwolenia na prace)*, wyłączyć pracujące maszyny i urządzenia*, zatrzymać pojazd jak najbliżej prawej krawędzi drogi, wyłączyć silnik (pozostawić kluczyk w stacyjce), przestrzegać całkowitego zakazu palenia tytoniu, ewakuować się na bezpieczną odległość (na wskazany w komunikacie punkt zborny lub inne

wskazane miejsce, w kierunku prostopadłym do kierunku wiatru)*.

ODWOŁANIE:

3-minutowy sygnał ciągły:

3-krotna zapowiedź słowna z głośników: „Uwaga, uwaga ! Odwołuję alarm chemiczny o skażeniu dla … (podać teren)”

meldunek przekazany siecią telefoniczną lub przez gońca.

CHEMICAL ALERT INSTRUCTION

ANNOUNCING:

discontinuous sound lasting 3 min:

verbal announcement repeated three times: ‘Attention! Attention! I announce the chemical alert caused by the contamination…(specify a type of contamination, the area for which the alarm is given). One should be evacuated to assembly point no..’

report delivered through telephone network or by messenger.

IN CASE OF CHEMICAL ALERT ANNOUNCEMENT, ONE MUST:

discontinue any work (independently of held written permit to work)*, switch off all machines and equipment*, park the vehicle as close to the right side of the road as possible, turn off the engine (leave keys in the

ignition switch), smoking completely forbidden, evacuate at a safe distance (proceed to assigned assembly point or other specified location

perpendicularly to wind direction)*.

CALLING OFF:

continuous siren signal sound lasting 3 minutes:

verbal announcement repeated three times: ‘Attention! Attention! I call off the chemical alert for… (the specified area)’.

report delivered through telephone network or by messenger.

* - nie dotyczy obsługujących instalacje, którzy postępują zgodnie z instrukcją technologiczną/does not apply to operators on installation,

who are acting according to technological instruction

10s 25-30s 10s 25-30s 10s syrena przerwa syrena przerwa syrena

syrena - 3 minuty

10s 25-30s 10s 25-30s 10s siren pause siren pause siren

siren - 3 minutes

INSTRUKCJA EWAKUACJI

W przypadku ogłoszenia ewakuacji ludzi z obiektu za pomocą sygnałów dźwiękowych i/lub komunikatu słownego należy: - zachować spokój i nie wywoływać paniki, - zamknąć drzwi od pomieszczeń (nie na klucz), - bezzwłocznie udać się do najbliższego bezpiecznego wyjścia ewakuacyjnego, - ewakuować się zgodnie z kierunkami znaków ewakuacyjnych, - w przypadku odcięcia dróg ewakuacji gromadzić się w pobliżu okien, tarasów itp., - w przypadku silnego zadymienia poruszać się w pozycji pochylonej (głowa jak najniżej), - przestrzegać zakazu korzystania z wind osobowych, - udać się do wyznaczonego miejsca zbiórki (np. punktu zbornego), - nie wracać do pomieszczeń/obiektu bez zgody kierującego ewakuacją, - stosować się do poleceń kierującego ewakuacją, - jeśli pozwolą na to warunki i rozwój sytuacji, na końcu ewakuować mienie. Osoby z zewnątrz ewakuują się pod nadzorem pracowników im towarzyszącym. Przełożony każdej komórki organizacyjnej zobowiązany jest sprawdzić czy wszystkie osoby (w tym osoby zewnętrzne) przebywające w pomieszczeniach zostały ewakuowane. Informację o ilości ewakuowanych osób należy niezwłocznie przekazać kierującemu ewakuacją lub osobie przez niego wyznaczonej.

EVACUATION INSTRUCTION

In case of fire alarm announcement by means of sound signals and verbal notice one should: - keep calm, do not panic, - close the doors (no key-lock), - proceed immediately to the nearest safe emergency exit from the building, - during evacuation follow the evacuation signs, - gather near the windows and staircases in case of being cut off from the emergency exits, - in case of high smoke concentration proceed in crouching position (head as low as possible), - do not use the lift during the evacuation, - proceed to assigned assembly point, - do not come back to rooms/buildings without agreement of a person commanding rescue

operations, - obey emergency orders given by a person in charge of rescue operations, - finally, if conditions and situation are relevant, evacuate personal property. Persons from outside shall evacuate under supervision of their companions. The supervisor of organizational unit shall check if all persons inside (incl. external persons) have been evacuated. Information about the number of evacuated persons should be reported to the person in charge of rescue operations or designated person.

24

8.2 Assembly points and weather vanes

Employees gather at assembly point announced by the alerting individual. Once everyone arrives, the supervisor of the Contractor checks the presence of their employees. If any of the employees is missing, they notify the person in charge of the rescue operation about the fact.

Evacuate to the assembly point indicated in the announcement. If the assembly point is not defined, evacuate in a direction

perpendicular to the direction of the wind (crossing the wind).

8.3 Proceeding in emergency situations

The management of the Contractor is strictly obliged to get all its employees and sub-con-tractors familiar with stipulations of the Alarm instruction and to ensure that rules contained therein are observed in cases of malfunctions or other hazards (including fire, explosions, chemical malfunction, accident, etc.).

PLEASE REMAIN CALM AND DO NOTCAUSE PANIC DURING A HAZARDOUS SITUATION.

REMEMBER! Calling the emergency number specified in the aforementioned Instruction, please provide your name, surname and the telephone number, and you may disconnect only if instructed to do so by the individual accepting the information.

Assembly points comprise designated and marked assembly points for everyone pre-sent in the area where a malfunction of other hazard occurred.

25

INSTRUKCJA ALARMOWA

1. ALARMOWANIE

W przypadku powstania awarii (np. pożar, wybuch, awaria chemiczna), naruszenia zasad bezpieczeństwa fizycznego i ochrony (np. podejrzana paczka, niewypał, niewybuch, napad, informacja o podłożonej bombie), klęski żywiołowej, wypadku lub innego miejscowego zagrożenia należy zachować spokój i nie wywoływać paniki. Każda osoba przebywająca na terenie Grupy LOTOS S.A. zobowiązana jest natychmiast zaalarmować:

- osoby znajdujące się w strefie zagrożenia

- PUNKT ALARMOWY LOTOS Straż z tel. stacjonarnych:

z tel. komórkowych: lub

w przypadku pożaru uruchomić ręczny ostrzegacz pożaru

Alarmując telefonicznie należy podać: rodzaj zagrożenia (pożar, niewypał/niewybuch, inne), miejsce zdarzenia (obiekt, zakład, instalacja), czy zagrożone jest życie ludzkie, swoje imię i nazwisko oraz numer tel. kontaktowego.

UWAGA ! Rozłączyć się należy dopiero po potwierdzeniu przyjęcia zgłoszenia.

2. POSTĘPOWANIE

W przypadku awarii, klęski żywiołowej, wypadku, innego miejscowego zagrożenia Do czasu przybycia jednostki straży pożarnej akcją kieruje pracownik, który pierwszy zauważył zagrożenie, następnie prowadzący zmianę/gospodarz obiektu. Równolegle z alarmowaniem należy organizować pierwszą pomoc przedlekarską, akcję gaśniczą oraz ewakuację ludzi z zagrożonych obszarów.

W przypadku naruszenia zasad bezpieczeństwa fizycznego i ochrony Nie należy wykonywać zbędnych czynności, które mogłyby narazić życie lub zdrowie człowieka. Czekać na przybycie pracowników ochrony.

Z chwilą przybycia kierującego działaniem ratowniczym Każda osoba, niezależnie od zajmowanego stanowiska, podporządkowuje się jego poleceniom. Osoba dotychczas kierująca akcją przekazuje kierującemu działaniem ratowniczym informację o zaistniałej sytuacji, podjętych działaniach technologicznych i ratowniczych oraz występujących zagrożeniach.

998508-998-998

26

If you do not have a phone and the situation requires calling emergency services, use the nearest Fire Warning device, a and wait in a visible location for the arrival of emergency services.

Operation of the Manual Fire Warning Device depends on its type and includes:

8.4 Evacuation from buildings and premises

If evacuation from buildings and rooms is necessary, stipulations contained in the Evacuation instruction must be strictly followed.

or breaking the glass and pushing the button inside

breaking the glass and the button is activated automatically

CAUTION! Names and surnames of indivi-duals designated for evacuation in buildings and definitions of the location of the nearest assembly points are provided at the respec-tive entrances to these buildings.

27

INSTRUKCJA EWAKUACJI

W przypadku ogłoszenia ewakuacji ludzi z obiektu za pomocą sygnałów dźwiękowych i/lub komunikatu słownego należy: - zachować spokój i nie wywoływać paniki, - zamknąć drzwi od pomieszczeń (nie na klucz), - bezzwłocznie udać się do najbliższego bezpiecznego wyjścia ewakuacyjnego, - ewakuować się zgodnie z kierunkami znaków ewakuacyjnych, - w przypadku odcięcia dróg ewakuacji gromadzić się w pobliżu okien, tarasów itp., - w przypadku silnego zadymienia poruszać się w pozycji pochylonej (głowa jak najniżej), - przestrzegać zakazu korzystania z wind osobowych, - udać się do wyznaczonego miejsca zbiórki (np. punktu zbornego), - nie wracać do pomieszczeń/obiektu bez zgody kierującego ewakuacją, - stosować się do poleceń kierującego ewakuacją, - jeśli pozwolą na to warunki i rozwój sytuacji, na końcu ewakuować mienie. Osoby z zewnątrz ewakuują się pod nadzorem pracowników im towarzyszącym. Przełożony każdej komórki organizacyjnej zobowiązany jest sprawdzić czy wszystkie osoby (w tym osoby zewnętrzne) przebywające w pomieszczeniach zostały ewakuowane. Informację o ilości ewakuowanych osób należy niezwłocznie przekazać kierującemu ewakuacją lub osobie przez niego wyznaczonej.

EVACUATION INSTRUCTION

In case of fire alarm announcement by means of sound signals and verbal notice one should: - keep calm, do not panic, - close the doors (no key-lock), - proceed immediately to the nearest safe emergency exit from the building, - during evacuation follow the evacuation signs, - gather near the windows and staircases in case of being cut off from the emergency exits, - in case of high smoke concentration proceed in crouching position (head as low as possible), - do not use the lift during the evacuation, - proceed to assigned assembly point, - do not come back to rooms/buildings without agreement of a person commanding rescue

operations, - obey emergency orders given by a person in charge of rescue operations, - finally, if conditions and situation are relevant, evacuate personal property. Persons from outside shall evacuate under supervision of their companions. The supervisor of organizational unit shall check if all persons inside (incl. external persons) have been evacuated. Information about the number of evacuated persons should be reported to the person in charge of rescue operations or designated person.

28

8.5 Drills in the scope of reaction to malfunctions and other threats

If drills in the scope of reac-tion to malfunctions and other threats (including building evacuation) are taking place in the area, all employees of the Contractor are obliged to participate in such drills, stop working and strictly observe the commands of the person in charge of the rescue operation.

REMEMBER! In case of drills:• Always behave as if it was an actual hazard,• If you are within an area in which an alert or evacuation has been announced, you are

obliged to participate in the drills,• Resume work once the drills are finished.

9. ORGANISATION OF SITE FACILITIES, CONSTRUCTION SITE AND WORK

Detailed regulations are provided in the procedure on supervision of material assets.

Within the LOTOS area, the Contractor may organise their own site facilities and create, as well as to cre-ate temporary construction structures like containers, under the condition that such structures meet re-quirements specified and accepted by LOTOS.

Site facility is a designated piece of the area comprising temporary administration--social facility, including temporary construction sites (from the point of view of needs of the Contractors, site facilities also include temporary storage and installation yards, equipment washing stations, crane stations, etc.).

29

It is prohibited to place administration and social containers, such as offices, dining rooms and locker rooms within the area of production

installations, and at product filling locations.

In order to organise site facilities, the Contractor must develop a „Plan of facility locations and organisation” (hereinafter referred to as the Facility Plan) containing the following information:• The period of land reservation for site facility, agreed upon with the Owner/Host (the area

within which the facility is supposed to be constructed),• Contact data of the person responsible for site facility,• Target locations of site facilities provided and drawn in a map level of scale, specifying

distances from existing buildings and structures. The map used during the Facility Plan preparation, containing the form of required agreements, may be obtained each time from the General Plan Team of Grupa LOTOS,

• Description of destination of sites comprising the facility, .e.g.: social container, ware-house (its intended use), workshop, installation yard, storage yard, etc.,

• The location and amounts of hazardous substances stored: technical gas cylinders, flam-mable paints and varnishes (specifying storage means and protective measures),

• A declaration confirming:– that an adequate amount and type of fire extinguishers have been provided (extinguishers

containing at least 12 kg of the extinguishing medium) adapted to extinguishing the group of fires which may occur at a given site, within the given area, as well as fire blankets,

– that no hazardous materials are stored in the containers, also including technical gas cylinders,

– ensuring that the structure of the containers will be made of inflammable materials,– the layout and marking of fire-fighting equipment locations, according to the appropri-

ate, effective standards and regulations,– storage (outside containers) of the aforementioned hazardous materials, including

a clause that these materials: - will be stored safely (e.g. under a metal, transparent outdoor roofing installed next to

the container),- will be protected against falling,- empty cylinders will be stored separately from full cylinders,- will be marked with information and safety signs (including: explosion hazard, prohi-

bition of open fire use and smoking),– that appropriate evacuation conditions have been provided (appropriate number and

width of exits, their marking according to appropriate, effective legal regulations, roads and entrance gates to the facility),

– placement of a sign prohibiting use of open flame and smoking, in visible locations, and marking the mains switch according to the appropriate, effective legal regulations,

– placement of an instruction of proceeding in cases of fire, including a list of emergency telephone numbers effective within the LOTOS area, and an information which facility user should be informed in case of a fire.

30

The Contractor is obliged to fence site facilities, mark them with a board containing the name of the company, address and name of the responsible individual and the contact telephone number (containers located outside the facility area must also be marked), together with

emergency telephone numbers effective within the LOTOS area.

The facility plan should be agreed upon in writing with the following officers, observing thespecified order:

Host of the area (Site Manager) where the facilities are to be provided,

Electrical Maintenance Department of Grupa LOTOS S.A. – a confirmation that the facili-ties should be connected to power cable grids or an entry containing information about a lack of such a connection,

Instrumentation Maintenance Department of Grupa LOTOS S.A.– a confirmation that the facilities should be connected to a teletechnical installation or an entry containing informa-tion about a lack of such a connection,

Utility Production Complex of Grupa LOTOS S.A. – a confirmation that the facilities should be connected to a tap water and/or utility water installation, steam, compressed air and nitrogen installations and/or if the facilities are to be connected. If it is impossible to provide a connection to a sanitary wastewater installation, the Contractor must provide their employees with portable sanitary facilities,

LOTOS Straż,

Health and Safety Office of Grupa LOTOS S.A. – confirmation of extinguisher layout and fire protection conditions,

Property Management Department of Grupa LOTOS S.A. – in order to determine the need to sign a lease agreement and to hand the land over in case of a lease,

General Plan Team of Grupa LOTOS S.A. – registering the location of the facility.

Hazardous materials, such as fuels, may be stored within the area of the facilities, only in amounts which do not exceed the daily demand.

The Contractor will be responsible for damage caused to equipment and installations located within the area handed over to them – from the time the site facility starts its operation until the formal return of the area. It is also obliged to remove site facilities, order the area (includ-ing removal of power supply and/or telephone lines) and to return it after the end of their work (order).

31

10. RULES OF TRANSPORT, STORAGE, FILLING VEHICLE TANKS AND MACHINES USING FUEL FROM CONTAINERS

10.1 Transport of fuel in containers

• A single vehicle may transport up to four containers of oil, with a maxi-mum capacity of 200 dm3 each, or a single petroleum container with a capacity up to 200 dm3.

• Containers should be located and fixed on the vehicle during transport such that they do not change their relative location during transport and that they are protected against friction, shock, tipping over and falling off the vehicle.

• The vehicle must be provided with an efficient ground and be additionally equipped with a single powder extinguisher GP 12kg ABC.

• Transport of containers with fuel may take place only using vehicles intended for transport of goods.

• Containers intended for transport of fuels must be marked with a „Flammable liquid mate-rials” warning label, according to ADR requirements.

10.2 Storage of fuel in containers

• Empty containers or containers containing fuels should be stored under outdoor roofs or within premises provided with efficient ventilation.

• It is prohibited to use open flame and spark sources within a radius of 10 m from the loca-tion of fuel storage.

• A GP 12kg ABC powder extinguisher and a fire blanket must be provided next to the storage location, and their location should be marked according to the effective Polish Standard.

• The storage location for fuel should be marked with safety signs, according to the Polish Standard: „Fire hazard – Flammable materials” and „Prohibition of open flame use – Smok-ing prohibited”.

Hazardous materials of fuel type may be stored in containers within facilities only in the amount necessary for operation

of its equipment for a day.

Container is a steel or aluminium, non-corroded drum, undama-ged, with the possibility of locking the container tightly, or a jerry adapted to fuel transportation.

32

10.3 Filling a tank of a vehicle or a machine using fuel from containers

• Filling of a tank of a vehicle or a machine with fuel must take place outdoors, with the vehi-cle engine and other installations of the vehicle switched off.

• Filling of a tank of a vehicle or a machine with fuel from a drum may take place only using a special pump designed for the purpose. Complete tightness of the fuel pumping equipment must be ensured.

• It is prohibited to use open flame and spark sources within a radius of 10 m from the cur-rently filled tank of the vehicle or machine.

• The location where the tank of the vehicle or machine is filled with fuel must be organised (secured) such that any fuel spillages do not result in soil contamination.

A GP 12 kg ABC powder vehicle and a fire blanket should be provided at the location where the vehicle/machine tank is filled with fuel.

11. SAFETY OF WORK

11.1 Control and inspections of working conditions

• The supervisors of the Contractor are obliged to provide information and present documents speci-fied in the Contract, in this document or resulting from legal regulations, to LOTOS representatives performing the inspection.

• Each non-conformity found during the inspection is recorded by visiting individuals in a manner effec-tive within LOTOS.

• The Contractor is obliged to remove the non-conformities found immediately, within deadlines defined verbally or specified in inspection reports. If it is impossible to remove the non-conformity found, posing a hazard to health or life of employees immediately, the LOTOS inspector orders work to be suspected until the non-conformity is removed.

• The supervisors of the Contractor are obliged to participate in meetings with LOTOS rep-resentatives, at times locations specified by the aforementioned individuals. Issues re-lated to Health and Safety, fire protection and physical safety, as well as work execution and non-conformities found during workplace inspections/reviews are discussed and analysed.

REMEMBER! The supervisors of the Contractor are obliged to systematic inspections of work safety at workplaces.

33

11.2 Individual protection measures, protective clothing and shoes

During:• Work including exposure to harmful or hazardous factors, • Presence or work execution within areas marked with information boards (installed at

the edge of the hazardous area) installed at the entrances to explosion hazard zones (EX zones) i.e. at production installations, within the tank area, at the location where products are dosed

it is mandatory to use protective clothing, protective shoes and indi-vidual protection measures:

appropriate for the location and type of work.

• If an employee works or is present within the explosion hazard zones (EX zones), they are obliged to use personal protec-tion measures indicated on signs, placed on information boards, or which were list-ed in the written permission for execution of the particular work. They are always obliged to:– wear, as an obligation, an industrial

safety helmet and safety goggles, – use hearing protection within the indi-

cated areas (if no area is designated, within the entire area); and protective gloves should be worn always during work,

– have and know the rules of operation of an efficient evacuation mask, remembering that the protective clothing and shoes used must have documented anti-static properties, and the shoes should be provided with steel toes.

It is absolutely prohibited to put on, remove and wear unbuttoned clothing, as well as to clean, wipe or brush clothing

within the explosion hazard areas zones (EX zones).

head ears eyes air hands face body feet passages

34

The clothing must thoroughly cover the torso, arms and legs, must have all its buttons and zips buttoned, and sleeves

and leg pants may not be rolled.

• It is prohibited to work wearing damaged clothing and/or work in tops and jackets with short/rolled sleeves.

• The protective clothing should be legibly and permanently marked with the company name.• The management of the Contractor is obliged to provide, on its own:

– Trainings for their employees, related to proper use of pro-tective clothing and shoes as well as personal protection measures,

– The required protective clothing with anti-static properties, protective shoes and personal protection measures accord-ing to the work performed by their employees.

High visibility jacketsIndividuals:• Working in the evening and at night on internal roads of the site,• Working on tracks and within their 5-metre surroundings,• Working as hook operators,• Executing works with ionizing radiationare obliged to wear high visibility jackets (provided with anti-static properties within the ex-plosion hazard zones), marked with the name of the company.

11.3 Hazardous chemical substances and mixtures

• In case of work with hazardous chemical substances/mixtures, extreme care must be ob-served at all times.

• The Contractor is obliged to:– Get their employees familiar with instructions for safe use of chemical substances and

mixtures used by these employees, provided in respective Material Safety Data Sheet (MSDS),

– make MSDSs available at all times for employees obliged to use protection measures according to the recommendations provided in the sheets.

Personal protection measures specified in Material Safety Data Sheets must be used during contact and when handling hazardous substances/mixtures and

when working with them.

• Material Safety Data Sheets for LOTOS products are available to the Contractors on the following website www.lotos.pl

35

• Particular attention must be paid to warning signs and symbols provided on packaging. All packaging of chemicals must be provided with appropriate labels informing about con-tents, potential hazards and influence on organs exposed to the particular substance.

11.3.1 Strictly controlled conditions • Production and use of semi-ready products takes place within the LOTOS Group under

strictly controlled conditions. According to the requirements of the European legislation (REACH):– A substance is strictly controlled using technical measures during all stages of its exist-

ence, including production, cleaning and maintenance of installations, sampling, testing, loading and unloading of equipment and containers, cleaning and storage of wastes,

– Control and handling procedures are used in order to minimise emissions and all related hazards and exposures,

– The substance is handled only by trained and authorised personnel, – In case of installation cleaning and maintenance, before opening and entering a system,

special procedures are used, such as cleaning and washing,– In cases of accidents or if waste is generated, during cleaning and maintenance of instal-

lations, control and handling procedures are used in order to minimise emissions and related hazards and exposures,

– Procedures related to substance handling are well documented and strictly controlled by the entity managing the production site.

• If work is performed on installations generating/processing products under strictly con-trolled conditions, the Contractor is obliged to get their employees familiar with the afore-mentioned requirements and observe them.

11.4 Written permitsDetailed requirements are regulated in the procedure on rules of proceeding during work based on written permits.

Written permit for work is a document issued by the authorised employee, defining conditions of safe work.

36

All hazardous work is performer on the basis of written permits, issued by an entity issuing permits, within the area of which

the work will be performed.

Types of written permits:

• Permit for works in the explosion hazardous zone, with the use of fire and sparks creat-ing devices and within confined spaces,

THE CONTRACTOR APPLYING FOR THIS PERMIT TYPE IS OBLIGED TO FILL PART II OF THE PERMIT.

• Permit for entry of vehicles, • Permit for closing roads Permission for

a road closure, ROAD CLOSURE MEANS A ROAD BLOCK-ADE (E.G. BY A PLACED CRANE), WHICH PREVENTS/MAKES PASSAGE OF LOTOS STRAŻ VEHICLES DIFFICULT.

• Agreement on the earthwork performance conditions,

• Permit no for the supply of water from the fire-fighting network for other uses,

• Permit for switching off the fire sensors in-stallation,

• Permission for switching off the Manual Fire Warning Devices (ROP).

In case of work within the limits of railway tracks (2.2 m from the track axis, horizontally and 4.9 m from the track, vertically), the permit must be accepted by an employee of the Operation Department of Gdańsk LOTOS Kolej. The Contractor is responsible for obtaining the permit of LOTOS Kolej.

The Contractor may start work only after a written permit is obtained and all conditions and requirements contained therein are met.

Permits may be collected only by individuals supervising work of the Contractor, including foremen.

Before a permit is issued, the Contractor is obliged to provide the individual issuing such a per-mit with information about hazards generated by the performed work and information about methods of employee protection against such hazards (Part II of the written permit).

Część II zezwolenia nr ……

GKL.48.01.00.00/F2 cz. II wyd. 8

1 Nazwa firmy .............................................. Liczba osób …………… nr tel. ..............................

2 Imię i nazwisko Wykonawcy ..............................................................................................................

3 Rodzaj wykonywanych prac ........................................................................................................................................................... ………………………………………………………………………………………………………………….. ........................................................................................................................................................... ………………………………………………………………………………………………………………….. …………………………………………………………………………………………………………………..

4 Wykorzystywane narzędzia: drabina rusztowanie narzędzia ręczne wiertarka wkrętarka szlifierka spawarka wentylator rozdzielnica wciągarka zwyżka koparka dźwig n/d Inne:……………………………………………………………………………………………………………..

5 Wykorzystywane materiały niebezpieczne: ciecze palne ciecze żrące ciecze toksyczne gazy palne gazy żrące gazy toksyczne n/d

Inne:………………………………………………………………………………………………………………

6 Zagrożenia generowane przez wykonywaną pracę: iskry otwarty ogień pyły hałas upadające

przedmioty otwory wysokie/niskie

temperatury promieniowanie

n/d Inne:……………………………………………………………………………………………………………

7 Zabezpieczenie terenu:

wygrodzenie terenu osłonięcie prac spawalniczych

oznakowanie miejsca upadających przedmiotów

osłonięcie przed upadającymi przedmiotami

zabezpieczenie przed spadającymi iskrami

gaśnica 12 kg typu ABC + koc gaśniczy n/d Inne:……………………………………………………………………………………………………………..

8 Środki ochrony indywidualnej chroniące przed zagrożeniami generowanymi przez wykonywaną pracę:(poza obowiązkowymi środkami wymienionymi na tablicach informacyjnych przed instalacjami)

szelki bezpieczeństwa

gogle przyłbica rękawice specjalistyczne

maski p/pyłowe maska z doprowadzeniem świeżego powietrza

aparaty na sprężone powietrze

n/d

Inne:……………………………………………………………………………………………………………..

9 Praca w zbiorniku: Tak Nie (Jeśli wybrano „Nie” pkt a-e pozostają niewypełnione)

a) Nr ABP ………………………………. b) Asekuracja stała: Tak c) Rodzaj sygnalizacji: wzrokowy słuchowy linka d) Wymuszony nadmuch świeżego powietrza: Tak Nie e) Oświetlenie: 24V f) Zasilanie: transformator separacyjny

Oświadczam, że osoby wykonujące prace będą przestrzegały postanowień zezwolenia na pracę

Zapoznałem się z zagrożeniami generowanymi przez wykonywane prace i sposobami zabezpieczenia przed nimi

.......................................... podpis Wykonawcy

................................................ podpis Wystawiającego zezwolenie

37

The party issuing the permit specifies the type of performer work, crossing out redundant phrases from the title. They also define validity time for the permit and a number of people performing the specified work. If a condition required for work to be performed includes additional permits, this information will also be included in the issued permit.

The Contractor confirms on the permit form that they know the work conditions and that they will respect said conditions and perform only work which is included in the permit.

Each change of conditions specified in the permit requires

a new permit to be issued.

Any changes, amendments or deletion in the approved documents are prohibited,

under the condition of stopping all currently performed work.

The Contractor is responsible for:• Coordination of all work performed according to the permit, Performance, if necessary, of

a Health and Safety Analysis (hereinafter referred to as HS Analysis or HSA), informing their supervised employees about the HSEA in a documented manner and provision of a permit to the Permit Issuer,

• Protection of locations as agreed upon with the Permit Issuer, including traffic routes, against unauthorised access of individuals the performed work generates hazards for,

• Ensuring that Health and Safety rules and regulations are obeyed, together with rules of work performed by their supervised employees according to the obtained permits,

• Obtaining the required approvals and agreements, specified in the work permit form,• Personal supervision of executed work, having the permit at the location and time of work,• Specifying protection measures which should be used by the employees during work as

a protection against hazards generated by the type of the performed work,• Providing their supervised employees with appropriate group and individual protection

measures and with proper use thereof,• Use of protective measures listed in the permit by their supervised employees, in the full

provided range,

dniaKomórka organizacyjna

/ZEZWOLENIE NA PRACE NR / ZEZWOLENIE NA PRACE NRW STREFIE ZAGROŻENIA WYBUCHEM, Z UŻYCIEM OGNIA,

WEWNĄTRZ PRZESTRZENI ZAMKNIETEJ**Z UŻYCIEM URZĄDZEŃ I NARZĘDZI ISKRZĄCYCH**niepotrzebne skreślić

WEWNĄTRZ PRZESTRZENI ZAMKNIETEJZ UŻYCIEM URZĄDZEŃ I NARZĘDZI ISKRZĄCYCH,niepotrzebne skreślić Praca podlega systemowi LOTO NIETAK

1 WYSTAWIAJĄCY ZAZWOLENIE – Imię i nazwisko: podpis1. WYSTAWIAJĄCY ZAZWOLENIE Imię i nazwisko: podpis

: :Zezwolenie obowiązuje w dniu: od godz.* ,do godz.*

na obiekcie/terenie w zakresiena obiekcie/terenie w zakresie

przy urządzeniuprzy urządzeniu

nr haka

nr kłódkinr kłódki

tel.Nazwa Firmy Wykonawcy

2 ZABEZPIECZA WYSTAWIAJACY ZEZWOLENIE2. ZABEZPIECZA WYSTAWIAJACY ZEZWOLENIE

A. Opróżnione z medium:*

B

p

j śli i tOdł i *B. jeśli inne,to:Odłączenie:*

C. Przedmuchanie:* jeśli inne,to:j ,

D. Podanie napięcia:*

Odłączenie napięcia:* podpis lub nr hakanazwisko i imię elektryka:Odłączenie napięcia: podpis lub nr hakanazwisko i imię elektryka:

E. ,jeśli inna częstotliowść, to co (należy podać)Analizy:*

F Wyłączenie czujek płomienia/kabli termoczułych*

*WF. Wyłączenie czujek płomienia/kabli termoczułych WY

G. Oznakowanie miejsca pracy/odcięć procesowych*

YBR

H Zabezpieczenie terenu sposób zabezpieczenia:*

RA

Ć

H. Zabezpieczenie terenu, sposób zabezpieczenia:

Ć W

I. Kontrola miejsca wykonywania prac:* :, częstotliwość kontroli:

WŁA

Kontrolujący: od godz do godz : podpis

AŚC

Imię i nazwisko· Kontrolujący: od godz. do godz. : podpis IWE

Imię i nazwisko

· Kontrolujący: od godz. do godz. : podpisImię i nazwisko

E

ją y g g p p

J Z ż i bi kt

ę