The Challenges of Wastewater Structural Degradation and Mitigation Strategies

-

Upload

awchesterton -

Category

Engineering

-

view

220 -

download

1

Transcript of The Challenges of Wastewater Structural Degradation and Mitigation Strategies

Addressing Infrastructure Corrosion in the Water and Wastewater Market

2

Paul Keough is Chesterton’s Marketing Development Manager for the Water and Wastewater Industry. He has been with the company for 17 years and has been in the fluid sealing industry for 37 years. Prior to his current position, Paul was the Business Development Manager for Chesterton, responsible for North American engineering firms in the Mining and Wastewater Industries. He has done sealing presentations to firms such as Fluor, AMEC, Tetra Tech, CDM Smith, Arcadis, AECOM to name a few.

Steve Bowditch is the Global Market Development Manager for ARC Efficiency and Protective Coatings. He has been with the company for 27 years and is a NACE Level III CIP Inspector and SSPC Corrosion Specialist with over 35 years’ experience in the areas of protective coatings development and applications. He is an active contributing member of numerous NACE Technical Committees associated with corrosion prevention and protection and has presented papers on corrosion and associated control technologies.

Host

Presenter

3

What will we cover

What is corrosion’s impact to water and wastewater infrastructure

What mechanisms are responsible What are available options to address How protective coatings can protect infrastructure What coatings technologies are available Pro’s and con’s

How to implement a sound coatings program Performance based versus product based specifications Manufacturer’s qualified applicators Installation QA/QC Testing

4

Infrastructure at risk

5

Annual Cost of Corrosion in Water and Wastewater

$27$28$29$30$31$32$33$34$35$36$37

AWWA FHWA EPA

Billion

• Blocked or broken pipes release as much as 10 billion gallons of raw sewage every year. • US EPA estimates that over $330B needs to be spent over the next 20 years to upgrade existing water/wastewater infrastructures

6

Life Expectancy of Buried Cast Iron Pipe

12 22 32 42 52 62 72 82 92 102% Life Remaining 100% 96% 90% 85% 75% 63% 51% 40% 22% 12%

0%

20%

40%

60%

80%

100%

% Life Remaining vs Years in Service

“More than a million miles of pipes are nearing the end of its useful life and approaching the age at which it needs to be replaced.”

(AWWA 2012)

7

Increased US Population Shift to Urban Locales

0%10%20%30%40%50%60%70%80%90%

100%

1900 1925 1950 1975 2000 2025

Rural Population Urban Population“Over 75 percent of the nation’s population is served by centralized wastewater collection and treatment systems. “

EPA 2004

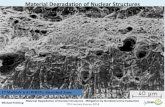

Common Mechanism’s of Attack

9

Mechanisms Biogenic corrosion: SRB, SOB, H2SO4 (vapor phase) Acidic attack – manufactured acids (liquid phase) Sulfate attack (vapor phase) Carbonation in water (liquid phase) Abrasive erosion / cavitation (liquid phase) Chloride induced corrosion (vapor phase)

10

Changing Environment is More Corrosive

Corrosivity of wastewater in USA has changed dramatically in past 35 years

1980 1985 1990 19950

5

10

15

DI

SSO

LVED

SUL

FIDE

CO

NCEN

TRAT

ION

(mg/

l)

Corrosion Threshold

Sulfides

1980 1990 2000 2010 2020

11

11

Relationship between pH and Corrosivity to Concrete

12

Mechanism of Attack – Biogenic Corrosion

Partial Listing of micro-organisms

known to be present in and deleterious to

concrete water and waste

water systems

Secrete 40% H2SO4

13

Mechanism of Attack - Biogenic Corrosion

Other bacteria present in the water convert sulfates to sulfides. This causes the rotten egg smell, hydrogen sulfide gas (H2S).

When the dissolved oxygen concentration falls below 0.1 mg/l, the environment becomes anaerobic becomes septic.

H2S Gas H2S Gas H2S Gas H2S Gas

pH ~ 7 D.O.<0.1 mg/l

Bacteria in the wastewater consume oxygen.

O2 O2 O2

Sewer

Wastewater

Bacteria

14

Conditions Favorable for Producing Sulfides

Low dissolved oxygen content High-strength wastewater (in terms of biological oxygen

demand) Low flow velocity and long detention times Turbulence/extensive pumping Elevated wastewater temperatures.

15

Mechanism of Attack - Biogenic Corrosion

SO42- HS- H2S

H2S Gas H2S Gas

H2S Gas

H2S H2S H2S

In water at pH 7, about 50% of the dissolved sulfide converts to H2S gas.

0.00

1.00

2.00

3.00

4.00

5.00

6.00

0

200

400

600

800

1000

1200

3 4 5 6 7 8 9 10

H2S

(aq)

and

HS-

in s

olut

ion

(mg/

L)

H2 S

(g) in air (ppm)

pH

H2S(g)

H2S(aq)

HS-

16

Mechanism of Attack - Biogenic Corrosion

On the surfaces above the water, H2S gas is converted to strong sulfuric acid by Thiobacillus bacteria.

This acid corrosion, not “aging”, then dissolves the infrastructure. SO4

2- HS- H2S

H2S

Thiobacillus

+ O2 = H2SO4

Acid Attacks Concrete

And virtually nothing is being done to stop it from happening.

17

Mechanism of Attack - Biogenic Corrosion

Where to look Influent pump stations Manways Head works Bar screen chambers Primary clarifiers Grit chambers

18

Mechanisms of Attack - Manufactured Acids

Primarily seen in industrial wastewater systems Attack can occur in liquid & vapor phase Rate of attack dependent on concentration, solubility & flow

pH below 12.5 – potassium and sodium depletion pH below 10.0 – calcium hydroxide depletion pH below 8.0 – calcium-silicate-hydroxide gel depletion

Acid – Base reaction Caused by the reaction of an acid and the calcium hydroxide portion of

the cement paste Soluble calcium salt which produces a highly soluble calcium salt

Ca(SO)4 by product. These soluble salts are easily removed from the cement paste

weakening the paste’s structure as a whole.

19

Manufactured Acids - pH Effect on Concrete

Source L.A.County San District

0.001 0.01 0.1 1.0 Corrosion Rate (in./year)

7

6

5

1

0

pH

Cor

rosi

on

Ran

ge

4

3

2

0.25

200 yr

100 yr

50 yr 20 yr

8 yr

The life cycle of concrete with a pH of 2 compared to a pH of 4 is 85% shorter

20

Mechanisms of Attack – Sulfate Attack SO4 ions react with Ca(OH)2

Na2SO4 + Ca(OH)2 => CaSO4 CaSO4 + C3A => CaO-Al2O3-31H2O

Gypsum(CaSO4) & Tri-calcium sulfoaluminate (CaO-Al2O3-31H2O) are much larger compounds.

Resulting expansive forces cause micro-cracking, exposure of structural steel & disintegration

Where to look • Splash zones (wet/dry) • Wherever H2SO4 attack occurs

21

Mechanisms of Attack – Carbonation

Ca(OH2) + CO2 Ca(CO3) + H2O

Forms carbonic acid which causes slow acidic attack of cement paste due to lowered pH

Pore blocking characteristics

Where to look • Secondary clarifiers • Aeration basins – O2 reactors • Chlorine contact basins • Outfalls

22

Mechanisms of Attack – Abrasive Attack

Suspended solids in flowing wastewater

Wears cement paste – then aggregate can be dislodged

Influenced by size, quantity of suspended solids plus velocity

Prevalent in collection systems or plant inlet structures

Where to look • Collection systems • Plant inlet

23

Mechanisms of Attack – Chloride Intrusion

Chloride ions (Cl-) are found in coastal regions and industrial flows.

Soluble Cl- are transmitted into concrete structure by capillary transport.

Cl- disturb passive oxide film on rebar initiating active corrosion cells.

Rate of reinforcement corrosion increases by over 1000%

Where to look • Coastal Regions • Pipes • Manholes • Chambers • Treatment plant

What Technologies are Available

25

Methods to Address

Protective linings material selection Design and fabrication details Evaluation programs Periodic inspections Process changes (wherever possible) Reduce slime layers by removing debris (grit and sand) Control dissolved sulfide through chemical addition Reduce H2S gas release by reducing turbulent flow Protect sensitive surfaces from the effect of acid generation

26

Vinyl sheet liners Polyurethane/Polyurea Bag systems Cementitious

Calcium aluminate

Concrete additives Epoxies

Solvent cut/coal tar 100% solids reinforced

27

What Coatings Technologies Are Available?

Anchored or adhered thermoplastic (vinyls) Spray applied elastomeric polyurethanes

Polyureas

Mat reinforced linings Polyester/Vinylester

Trowel applied aggregate filled lining Calcium aluminates Epoxies

Spray applied high solids -amine cured epoxies

Bottom Line They ALL can fail and they ALL have limitations

28

Vinyl Liners

In use for >40 years 60-180 mil thick vinyl sheet Adherent surface must be

flush and flat Adhesive mounted and hot

gas sealed joints More difficult to use in rehab Primary mode of failure is

joint failure, leakage, blistering and delamination

28

29

Spray Applied Polyureas/Polyurethanes

Elastomeric urethane technology Aliphatic or aromatic based Typically 100% solids Good elastic modulus for flexing

applications Good chemical resistance. Rapid cure provides shorter

return to service times Isocyanates create hazardous

exposures Prone to sheet delamination due

to low wet out properties during application

30

Mat reinforced linings

Fiberglass saturated sock, mat or chopped strand reinforced.

Typically used with polyester or vinyl ester resins

Excellent chemical resistance Good chemical resistance

Poor elastic modulus for flexing applications

Creates explosive/flammable environment during application

Moisture sensitive Prone to sheet delamination due

to wicking along glass strand

31

Trowel applied aggregate reinforced epoxies

Silica/quartz reinforced, typically used with BisA/F or epoxies

Excellent chemical resistance Low permeability High wet adhesion High tensile strength High abrasion resistance High wet adhesion High elastic modulus for flexing

applications

32

Spray applied reinforced epoxies

Silicate reinforced, typically used with BisA/F or epoxies

Excellent chemical resistance Low permeability High wet adhesion High tensile strength High flexural strength Moderate abrasion resistance Low elastic modulus for flexing

applications Corrosive hazards

33

Critical Properties to Consider

Thickness Smooth concrete (<36 grit finish appearance) allows for 30-60 mil dry film

thicknesses If concrete roughness is> than a 36 grit finish sandpaper increase to 60-120

mil dry film thickness

Flexural strength Necessary for flexing and vertical misalignment which can commonly occur

buried wastewater treatment and collection systems. Values of 4,000 psi or greater for flexural strength and 5 x 106 psi or less for

flexural modulus are good.

Tensile strength Necessary to calculate overburden-bearing capacity and is of paramount

importance to resistance to ground water infiltration. Tensile strengths of 1,800 psi are considered excellent

34

Critical Properties to Consider

Bond Strength The bond of the coating to the substrate is perhaps the key element to

achieving a long service life. Bond strength to wet concrete should exceed the cohesive strength of the

concrete, usually above 400 psi.

Permeability Permeability is the property that controls passage of corrodents through the

coating to the substrate. If all other properties and chemistry are equivalent, the coating exhibiting

the highest permeability will typically fail first. A permeability of 10-6 perm inches is typically acceptable.

Chemical resistance Resistant to acidic immersion Resistant to bacterial organisms

35

Qualified Applicators

Utilize applicators experienced with specified manufacturers products

Request 3+ years of experience with 5 or more projects completed

Other endorsements such as SSPC QP or ICATS, NACE pre-qualify experience and knowledge but not necessarily with your specified products

Should have a staff person certified to a coatings inspection program such as NACE CIP, SSPC MCI, FROSIO, ICORR.

Certified for confined space, handling hazardous chemicals, PPE, low OSHA EMR

36

QA/QC Inspection

Shift from product based to performance based specifications “What you want it to accomplish not how you want it built”

All specifications need standardized tests to describe how a product may be qualified to a approved material ASTM, NACE, ICRI, ACI etc.

QA/QC logs and inspection hold points

Sole source “turnkey supply/apply” Regular inspections

Surface decontamination Surface cleanliness Ambient environmentals

Surface profile/roughness Material log Wet film thickness

Dry film thickness Holiday Test

37

? QUESTIONS ?