- Standard deviation : - Characteristics of standard deviation

The analysis of the deviation on feeder pipe ultrasonic ...25DL + probe A at 25℃ & 35℃ 25DL +...

Transcript of The analysis of the deviation on feeder pipe ultrasonic ...25DL + probe A at 25℃ & 35℃ 25DL +...

The analysis of the deviation on feeder pipe ultrasonic thickness measurement of Qinshan NPP3

Shang Junmin / Yuan JianzhongJune,2014

Manual Measurement (before 2013)

feeder bend measure Template

the operator

1. Overview

� OT103, Unit 1’s first in-service Feeder ultrasonic thickness measurement was conducted by AECL ,the measuring result complied with FAC principle .

� OT203, Unit 2’s first in-service Feeder ultrasonic thickness measurement was conducted by a Chinese NDT company ,the measuring result deviate from FAC principle. After analysis, it was believed that data was incredible .

Overview

1. Overview

2. Analysis for deviation

Fishbone Diagram

People

AECL personnel�Canada NDT certificate

�Rich experience on Feeder inspection

Domestic NDT personnel�China NDT certificate

�Rich experience on nuclear component

No Reason

2. Analysis for deviation

People (AECL)

2. Analysis for deviation

Method

AECL�《In-Service Measurement of Qinshan Fuel Channel Feeder Pipe Wall Thickness 》9801-97000-PRO-001

Domestic NDT Company�Translate the AECL procedure

No Reason

2. Analysis for deviation

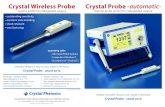

Machine

AECL�Instrument (PANAMETRICS-NDT 25DL Plu

s)

�Template (AECL)

�Block (AECL)

Domestic NDT Company�Instrument (PANAMETRICS-NDT 25DL Plus)

�Template (AECL)

�Block (AECL)

No Reason

2. Analysis for deviation

Machine (instrument)

�PANAMETRICS-NDT 25DL Plus

2. Analysis for deviation

Machine (template)

2. Analysis for deviation

Machine (block)

2. Analysis for deviation

Machine (Probe)

AECL�Probe A (PANAMETRICS-M2055 )

Domestic NDT Company�Probe A (PANAMETRICS-M2055 )

�Probe B (homemade )

Maybe

Reason

2. Analysis for deviation

� Before use probe B, conducted performance test on the calibration specimen .

� Test of probe B met the procedure requirement.

Machine (Probe)

2. Analysis for deviation

Environment

Temperature�The temperature of onsite Feeder pipe was 10℃ or so higher than that of the calibration specimen

Surface roughness�Feeder pipe with rough inner surface .

�the calibration specimen with a smooth inner surface.

Maybe

Reason

2. Analysis for deviation

� 25DL + probe A at 25℃ & 35℃� 25DL + probe B at 25℃ & 35℃

� No obvious deviation was found for probe A and B during the test at 25℃ and 35℃.

� No obvious deviation was found for probe A and probe B measuring data.

� Conclusion: the temperature difference of 10℃ would have no obvious influence on test result.

Temperature test

3. Test verification

� With FAC effect, the Feeder pipe inner surface would be eroded and the corrosion, which is called overlapped horseshoe pits .

Roughness test

3. Test verification

� 4 test pieces with shot peening on the inner surface .

� 2 with roughness of 25μm 2 inches and 2.5 inches .

� 2 with roughness of 50μm 2 inches and 2.5 inches.

Roughness test

3. Test verification

� measured with probe A and probe B respectively of 4 test pieces, total 288 points respectively .

� probe B, data for 4 measuring points were unstable and fluctuating.

� probe A, data for measuring points were almost stable and unchanged.

Roughness test

3. Test verification

� Ultrasonic wave diagram for unstable thickness-measuring data from probe A and from probe B Fig (for the same point)

Roughness test

3. Test verification

� high-damping and narrow-pulse, there are fewer pulse periods and large difference between the heights of wave amplitude of each wave crest.

� value from probe A is between the pulse which first reached 80% in the transmitted waveform and the pulse which first reached 80% in the echo waveform.

Roughness test (probe A)

3. Test verification

� The signal attenuates slowly and there are many pulse periods (more than 4) and the difference is small for the height of wave amplitude between neighbouring cycles.

� It could be the first pulse or second pulse of echo waveform reaches 80% first, resulting in the deviation in measurement .

Roughness test (probe B)

3. Test verification

The first pulse of echo waveform reaches 80% first

Roughness test (probe B)

3. Test verification

The second pulse of echo waveform reaches 80% first

Derivation =0.2mm~0.3mm

� OT104, 5 Feeder pipes were selected for testing and verification.

� The measuring result for the first bend of Feeder pipes D05 is taken as an example below .

� The wall thinning rate at each measuring point is calculated with the measured value from OT104 minus the measured value from outage 103 which is then divided by operation duration.

� Statistical analysis is then carried out for wall thinning rate at each measuring point.

Site verification

4. Site verification

� Wall thinning rate discretization graph measured with probe A with stable data.

� The standard deviation being 0.014mm. � The average deviation is -0.017mm .� Wall thinning rate meets FAC principle .

Site verification

-0.08

-0.07

-0.06

-0.05

-0.04

-0.03

-0.02

-0.01

0.00

0.01

0.02

0.03

1 3 5 7 9 11 13 15 17 19 21

4. Site verification

� Wall thinning rate discretization graph measured with probe B with stable data.

� The standard deviation being 0.216mm. � The average deviation is 0.014mm .� Obviously, the positive deviation does not comply with the

FAC principle.

Site verification

-0.20

-0.10

0.00

0.10

0.20

0.30

0.40

1 3 5 7 9 11 13 15 17 19 21 23

4. Site verification

� Wall thinning rate discretization graph measured with probe B with stable data.

� The standard deviation being 0.216mm. � The average deviation is 0.014mm .� Obviously, the positive deviation does not comply with the

FAC principle.

Site verification

-0.20

-0.10

0.00

0.10

0.20

0.30

0.40

1 3 5 7 9 11 13 15 17 19 21 23

4. Site verification

Site verification

4. Site verification

Root reason resulting in derivation high

1. Low-damping and wide-pulse probe

2. Rough inner surface of feeder pipe

� A high-damping and narrow-pulse probe is necessary during ultrasonic thickness measurement for thin-wall carbon steel pipes with rough inner surface and the probe quality could affect the accuracy of thickness measurement .

� When a performance test is carried out for ultrasonic inspection system, the inner and outer surface of the calibration specimen shall be consistent with that of the components to be tested as much as possible

Conclusion

5. Conclusion

Thanks!