the algae house - · PDF filehydrogen produced by the algae necessitated its housing in some...

Transcript of the algae house - · PDF filehydrogen produced by the algae necessitated its housing in some...

the

alga

e ho

use

- alg

aete

ctur

e K

arug

a K

oina

nge

- Chr

is B

owle

r - D

anie

la K

rug

In c

olla

bora

tion

with

Cam

brid

ge R

esea

rche

rs &

Eng

inee

rs

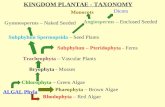

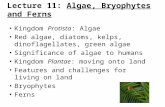

algae?! Algae is fast becoming the preferred source of bio-mass for use in the production of bio-diesel. Unlike conventional means of processing biomass crops however, a far cleaner, greener method is possible by way of hydrogen production. In the absence of sulphur they will switch from the production otf oxygen as in normal photosynthesis, to the production of hydrogen. Capture of hydrogen, used in conjunction with a fuel cell, opens up the potential for a totally CO2 free route to end-use consumption of energy.

The team set out to investigate the potential for the micro-generation of algae within a domestic context through a process of experimental design.

urban-rural algaetecture

why tubed algae?

...energy flows

What are the benefits of cultivating algae in a closed-system, closely integegrated with the architectural form of a house, as opposed to a natural pond based open system?

The geometries and solar system developed in AlgaeHouse are adaptable to an increased urban density and scale.

Retractable privacy blind

Structural column

Louvre support cable

Roof construction:zinccompressed insulationboardingtimber structure

High performance UV triple glazing

Insulation &Damp proof membrane

Adjustable ventillationopening

reflective pool

White painted surface coating

drainage cover

waste water &biomass

under floor heating

Algae tubes

Hydrogen

Nutrients (sewage)Recycled WaterCarbon dioxideAlgae solution

Louvre system

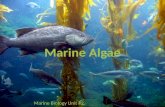

the algae house From early on in the design development it became clear that certain environmental constraints on successful cultivation were analogous to those required by humans. Specifically, these concerned issues to do with light and heat. Like people, algae thrive on exposure to high levels of solar insolation. However, the capture of gaseous hydrogen produced by the algae necessitated its housing in some form of sealed, transparent tank. Such tanks are highly prone to over-heating, killing the algae if rising to a temperature much above 30ºC. It became clear therefore

that there existed the potential for the algae and domestic spaces of our ‘Algae House’ to enter a symbiotic relationship, whereby the one promoted the optimum environmental conditions for the other and vice versa. (This close relationship is even evident in the waste water recycling system whereby filtered brown water provides vital nutrients for the algae to grow). The form of the façade was developed to achieve maximum solar insulation from the sun, whilst maintaining a stable temperature, so optimising the production of hydrogen. Through careful consideration of the algae tubes’ altitude and azimuth orientation to the sun, and working in combination with a fixed louvre system, direct solar heat gain is allowed only during winter months and on spring and autumn mornings and evenings. The shallow pool of water, or ‘moat’, located adjacent to the façade is intended to perform two functions. Firstly, the pool reflects low angle sun up to the overhanging algae façade, whilst absorbing more of the higher energy high angle mid-day summer sun. Secondly, as the major component of heat energy is transferred in the infrared band of the spectrum of light, the water usefully absorbs much of the heat from direct sunlight before reflecting it up to the algae. Calculating an estimate for the total amount of energy produced through the AlgaeHouse system was achieved through consultation with algae biochemical engineer and Cambridge PhD candidate Ben Taylor. Through this collaboration a tripartite energy extraction strategy was identified as realising the optimal potential from the algae. Indeed, algae are in fact unable to produce hydrogen for sustained periods of time and so, in the AlgaeHouse system, energy is also released through the extraction of lipids (oils) and bio-gas (through the processing of algae bio-mass in an anaerobic digester). To convert these oils and gas to useful electricity, rather than utilising the traditional ‘dirty’ technology of conversion through combustion, instead a catalytic-reactor based fuel processor converts the oils to hydrogen. This hydrogen, combined with that produced directly from the algae, is converted to electricity and heat in a hydrogen fuel cell. Based on the assumption that current trends in the genetic modification of algae continue towards the anticipated level of 15% efficiency in the conversion of light energy to hydrogen and given a volume of 2545 litres of algae solution, the house is estimated to produce 4100kWh per annum – enough to cover all energy demands of the occupants.

Algae and people may not present themselves as obvious bedfellows, but through this project we hope to have shown that the integration of algae as an energy generator within a house is not only feasible, but that co-habitation can result in a self-sustainable symbiotic system and open up many exciting architectural possibilities for ‘green living’.in

Algae Photo-bio-reactor

A total of 4059 kWh/ annum produced by the Algae facade

+ SUPPLY - DEMAND

Breakdown of energy

Hydrogen or Biodiesel Car

Fuel Processor

Electric Appliances

Underfloor Heating

Fuel Cell

Biomass

Algae

Anaerobic Digester

Algae OilPress

Biodiesel

Biogas

Electricity

Electricity

Hydrogen

Waste Heat from Fuel Cell

Waste Heat from Fuel Cell

Hydrogen

Cool climate

Algae strain used;

Chlamydomonas f-9Marine (saltwater) tolerant

100 dwellings per hectare

= approx. 300000 kWh per annum per hectare

‘AlgaeTower’

‘AlgaeCourtyard’

Hot, arid climate

Algae Strain used;

Scenedesmus obliquusTolerant of hot, arid conditions

25 dwellings per hectare

= approx. 65000 kWh per annum per hectare

‘AlgaeHouse’

Moderate climate

Algae strain used;

Chlamydomonas reinhardtiiFavour moderate conditions

6 dwellings per hectare

= approx. 24600 kWh per an-num per hectare

summer

winter

ratio of sides

+40+20

-200

-40

1:51:31:13:15:1

summersummer

winterwinter

ratio of sides

heat loss/ gain in kWh /day

+12

+6

-6

0

-12

1:51:31:11:1.6

Optimal

Optimal

3:15:1

summersummerwinterwinter

ratio of sides

heat loss/ gain in kWh /day

+12

+6

-6

0

-12

1:51:31:13:15:1 1:1.3

[Academic use only]

summer

winter

ratio of sides

+40+20

-200

-40

1:51:31:13:15:1

summersummer

winterwinter

ratio of sides

heat loss/ gain in kWh /day

+12

+6

-6

0

-12

1:51:31:11:1.6

Optimal

Optimal

3:15:1

summersummerwinterwinter

ratio of sides

heat loss/ gain in kWh /day

+12

+6

-6

0

-12

1:51:31:13:15:1 1:1.3

[Academic use only]

[Academic use only]

summer

winter

ratio of sides

heat loss/ gain in kWh /day

+12

+6

-6

0

-12

1:51:31:1.13:15:1

Optimal

[Academic use only]

Space heating 20%

Computer control4%

Bio-reactor pumps14%

Heat recovery ventilation fan

0.5%TV3% Washing

machine2%

Lighting 13%

Laptop 1%

Fridge/ freezer5%

Kettle 2%

Gas oven 6%

Hot water2%

Showers28%

Hydrogen11%

Biogas from anaerobic digestion

43%

Algal biodiesel46%

Algae TubesWC

Lipid extraction press

Fuel processor

Anaerobic digester

Fuel Cell

Inverter/ transformer

House Power Sensors

Appliances

Control Computer

Filtration System

Algae Remnants Nutrients

CO2

biodiesel

biomass

hydrogen

hydrogen

(hydrogen car)

hydrogen store

nutrient water

nutrient water & algae remnants

biomass

space heating

pumps and valves not shown

biogas

mains water

mains water

hot water

electricity

air

air

brown water

Credits:

Ben Taylor (Cambridge University, Department of Chemical Engineering & Biotechnology)Phd researcher specialising in Algae based energy sources.

Ben Sheppard (Cambridge University, Department of Engineering)David Valinsky (Cambridge University, Department of Architecture)Oliver Hudson (Cambridge University, Department of Engineering)

integrated algaetecture

the algae house - algaetecture Karuga Koinange - Chris Bowler - Daniela Krug

In collaboration with Cambridge Researchers & Engineers

Mitigating solar energyThe physical properties of water have been utilised in the design of AlgaeHouse and play a fundemental part in mitigating the strength of solar radiation reaching the algae tubes.

High angle, summer sun; Mitigation of sunlight desirable. As the incident angle of light becomes steeper, a higher proportion passes below the surface of the water. As it passes through infra-red heat energy is absorbed. The reflective coating on the floor of the pool reflects the reduced energy light back up to the algae tubes.

Low angle, winter sun; Maximum solar insolation desirable. As the incident angle of light becomes shallower, a higher proportion of light is reflected off the surface of the water.

[Academic use only] [Academic use only]

1

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

1.5

0.5

1.0

0

500250 1000 1500 2000 2500

Wavelength (nm)

Solar Radiation vs Water Absorption Spectrum

Surface Reflectivity of Water

Visable InfraredUV

Spe

ctra

l Irr

adia

nce

(W/m

2 /nm

)S

pect

ral I

rrad

ianc

e (W

/m2 /n

m)

Abs

orpp

tion

co-e

ffici

ent o

f Wat

erA

bsor

pptio

n co

-effi

cien

t of W

ater

0.1

00 10 20 30 40 50 60 70 80 90

Ref

lect

ivity

Incident Angle From Normal, Deg

Approximately 50% of total solar radiation energy is absorbed in the heat carrying infra-red waveband by the water pool.

The physical properties of water have been utilised in the design of AlgaeHouse and play a fundemental part in mitigating the strength of solar radiation reaching the algae tubes.

High angle, summer sun;Mitigation of sunlight desirable.As the incident angle of light becomes steeper, a higher proportion passes below the surface of the water. As it passes through infra-red heat energy is absorbed. The reflective coating on the floor of the pool reflects the reduced energy light back up to the algae tubes.

Low angle, winter sun;Maximum solar insolation desirable.As the incident angle of light becomes shallower, a higher proportion of light is reflected off the surface of the water.

Mitigating solar energy

[Academic use only] [Academic use only]

1

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

1.5

0.5

1.0

0

500250 1000 1500 2000 2500

Wavelength (nm)

Solar Radiation vs Water Absorption Spectrum

Surface Reflectivity of Water

Visable InfraredUV

Spe

ctra

l Irr

adia

nce

(W/m

2 /nm

)S

pect

ral I

rrad

ianc

e (W

/m2 /n

m)

Abs

orpp

tion

co-e

ffici

ent o

f Wat

erA

bsor

pptio

n co

-effi

cien

t of W

ater

0.1

00 10 20 30 40 50 60 70 80 90

Ref

lect

ivity

Incident Angle From Normal, Deg

Approximately 50% of total solar radiation energy is absorbed in the heat carrying infra-red waveband by the water pool.

The physical properties of water have been utilised in the design of AlgaeHouse and play a fundemental part in mitigating the strength of solar radiation reaching the algae tubes.

High angle, summer sun;Mitigation of sunlight desirable.As the incident angle of light becomes steeper, a higher proportion passes below the surface of the water. As it passes through infra-red heat energy is absorbed. The reflective coating on the floor of the pool reflects the reduced energy light back up to the algae tubes.

Low angle, winter sun;Maximum solar insolation desirable.As the incident angle of light becomes shallower, a higher proportion of light is reflected off the surface of the water.

Mitigating solar energy

winter sun

summer sun

equinox sun

bedroom

...closing the

biological cycle.

Algae microscopic reproductionprocess...

Sunpath diagramCambridge, UK

Lat: 51°31’12”N

kitchen area

reflection pool

louvre line (above)

work area

living area

ALGAE

HUMANS

CO2

O2

kWh RECYCLE

Fossil Fuel Power PlantPollution

Waste H20Cleaner H20

WasteLandfill

Pollution

Other benefits to using this system include natural scrubbing of CO2 emissions from household systems and household wastewater treat-ment using renewable algae.

Continuous production system for the generation of hydrogen and biomass from algae

Algae reproduce by cell division. The flow rate within the system is such that the algal cell count

doubles before it reaches the filter. Then half of the algae are

removed while the remainder are recycled, along with the water,

back into the growth system.

The concentrated algal biomass can be processed to extract

the lipids for transformation to biodiesel, with the remaining dry

algal mass fed to an anaerobic digester for production of biogas

for household water heating. The solids from the digester unit can then be used as plant fertiliser, animal feed, or as feed for the

algae.

Algae initially release clean oxygen as they grow in size and number.

Once sulphur is depleted algae produce hydrogen instead of oxygen.

After hydrogen production algae are fed more sulphur to encourage lipid and biomass growth.

Sulphur-limited nutrients from pre-treated wastewater and CO2 from

anaerobic digester

Concentrated algae biomass

Some algae +

most water recycled

Direction of flow

Tangential flow filter