TFA Gold Etchant (diluted 9:1)

-

Upload

reed-zamora -

Category

Documents

-

view

21 -

download

0

description

Transcript of TFA Gold Etchant (diluted 9:1)

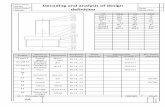

TFA Gold Etchant (diluted 9:1)

0

200

400

600

800

0 10 20 30

Low limitHigh limit

y = +24.3100x1 -11.9000

a=0.801686,

b=14.9982

y = +25.8800x1 -0.700000

a=0.172626,

b=3.22954

Etch time (sec.)

Etc

h de

pth

(Å

)

Au etch rate of 10x diluted TFA etchant

24-26 Å / sec.Conditions: 2 mL concentrated TFA in 18 mL of DI H2O. Room temp. Clean room. Sample was agitated continuously by hand. Rinsed in DI H2O afterwards. Profilometry done at CHANL.

Performed 12.05.09 – Dmitry

RIE etching (@ SMiF)Fe = 0 Å / sec. Nb = 9.25 - 15 Å / sec. Ge = 726 – 900 Å / sec. Conditions: 100 W, CF4 = 40 sccm, O2 = 4 sccm.

Performed 06.02.09 – Alex and/or Liang

AuNb

Fe

Ge (15mm*15mm)6

3

5

2

4

1

Each section is about3mm*7mm

0

0.5

1.0

1.5

2.0

0 40 80 120

20W, 80 m device25 W, 80 m device30 W, 80 m device

Ashing time (sec)

Am

oun

t re

mov

ed

(m

)

S1813 removal via ashing (CHANL plasma asher)

Plasma Asher (CHANL)S 1813 polymer. Non-linear.

Conditions: 1 sccm O2 flow, varied power. Etching profile of square device

Performed 12.03.09 – Dmitry

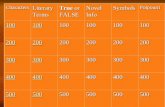

10 mM HCl

0

100

200

300

400

500

0 10 20 30 40

y = +11.8533x1 -22.1665, max dev:15.8999, r2=0.986500

a=0.980487,

b=26.8518

Time (sec)

Etc

h d

epth

(Å

)

Etch Rate of Pure Sputtered Fe (on Si) via 10 mM HCl

11-13 Å / sec.Conditions: 1mL of 3N (=3M) HCl diluted in ~ 300 mL of DI H2O. Continuously stirred with a magnetic stir bar. Washed with running DI H2O for 5+ min. Room temp., CHANL clean room. Profilometry done at CHANL. Mask – S1813.

Performed 02.03.10 – Dmitry

ICP – RIE Fe etch (SMiF)6-7 Å / sec.Conditions: SMiF Trion Minilock II. 300 W ICP, 125 W RIE. BCl3 = 5±1 sccm, Cl2 = 45±1 sccm. Manual runs to make sure flow is stabilized. Sample: Si substrate, Ti/Fe 60/1000 Å. Profilometry done at SMiF. Mask – S1813.

Performed 11.02.11 – Dmitry

0

100

200

300

400

0 20 40 60 80

y = +6.60000x1 -88.0000

a=0.264575,

b=14.8492

300 W ICP125 W RIEBCl

3 - 5 sccm

Cl2 - 45 sccm

Etch time (sec)

Etc

h de

pth

(Å

)

Fe etching [ICP-RIE, Trion Minilock II]

Note: although the rate was not measured, the etch does go through the Ti wetting layer and Si substrate, albeit at 500 W ICP.