Tensile Strength of Fibers

-

Upload

sandip-bakshi -

Category

Documents

-

view

231 -

download

1

Transcript of Tensile Strength of Fibers

-

7/24/2019 Tensile Strength of Fibers

1/26

Delhi Public School

VaranasiChemistry Investigatory Project

Topic: Study the efect o acids and bases ontensile strength o bers.

Yash Kesharwani

-

7/24/2019 Tensile Strength of Fibers

2/26

Inde

!c"no#ledgement

Certicate Introduction

$aterials re%uired

Procedure

&bservation table

'esult

Precautions

(ibliography

-

7/24/2019 Tensile Strength of Fibers

3/26

!c"no#ledgement

I have taken efforts in this project. However, it

would not have been possible without the kind support

and help of many individuals. I would like to extend

my sincere thanks to all of them.

I am highly indebted to Anju maam and ilanjana

maam for their guidance and constant supervision as

well as for providing necessary information regarding

the project and also for their support in completingthe project. I would like to express my gratitude

towards my parents for their kind co!operation and

encouragement which help me in completion of this

project.

"y thanks and appreciations also go to my friends in

developing the project and people who have willingly

helped me out with their abilities.

-

7/24/2019 Tensile Strength of Fibers

4/26

CerticateThis is to certiy that )ash *eshar#ani oclass +II,- o -elhi Public School /aranasi

or academic session 012,0134 has

prepared his chemistry investigatory project

on the topic allotted to him properly.I hereby certiy that this project is prepared

by the above mentioned student.

$rs. !nju Singh-epartment o Chemistry

-elhi Public School /aranasi

5iber

#iber is a natural or synthetic string used as a

component of composite materials, or, when matted

into sheets, used to make products such as paper,

papyrus, or felt.

-

7/24/2019 Tensile Strength of Fibers

5/26

$ynthetic fibers can often be produced very cheaply

and in large amounts compared to natural fibers, but

for clothing natural fibers can give some benefits,

such as comfort, over their synthetic counterparts.

6atural 5ibers

atural fibers include those produced by plants,

animals, and geological processes and can be

classified according to their origin%

-

7/24/2019 Tensile Strength of Fibers

6/26

&egetable fibersare generally based on

arrangements of cellulose, often with lignin%

examples

include cotton, hemp,jute, flax, ramie,sisal, bag

asse, and banana. 'lant fibers are employed inthe manufacture of paperand textile(cloth),

and dietary fiberis an important component of

human nutrition.

*ood fiber, distinguished from vegetable

fiber, is from tree sources. #ormsinclude ground wood, lacebark, thermo

mechanical pulp (+"'), and bleached or

unbleached kraftor sulfite pulps. raft and

sulfite (also called sulphite) refer to the type

of pulping process used to remove the ligninbonding the original wood structure, thus

freeing the fibers for use in paper

and engineered woodproducts such

as fiberboard.

Animal fibersconsist largely of particularproteins. Instances are silkwormsilk, spider

silk, sinew, catgut, wool, sea silkand hair such

as cashmere, mohairand angora, fur such as

sheepskin, rabbit, mink, fox, beaver, etc.

https://en.wikipedia.org/wiki/Fiber_crophttps://en.wikipedia.org/wiki/Cellulosehttps://en.wikipedia.org/wiki/Ligninhttps://en.wikipedia.org/wiki/Cottonhttps://en.wikipedia.org/wiki/Cannabis_sativahttps://en.wikipedia.org/wiki/Jutehttps://en.wikipedia.org/wiki/Flaxhttps://en.wikipedia.org/wiki/Ramiehttps://en.wikipedia.org/wiki/Sisalhttps://en.wikipedia.org/wiki/Bagassehttps://en.wikipedia.org/wiki/Bagassehttps://en.wikipedia.org/wiki/Banana#Fiberhttps://en.wikipedia.org/wiki/Paperhttps://en.wikipedia.org/wiki/Textilehttps://en.wikipedia.org/wiki/Dietary_fiberhttps://en.wikipedia.org/wiki/Wood_fibrehttps://en.wikipedia.org/w/index.php?title=Groundwood&action=edit&redlink=1https://en.wikipedia.org/wiki/Lagetta_lagettohttps://en.wikipedia.org/wiki/Kraft_processhttps://en.wikipedia.org/wiki/Engineered_woodhttps://en.wikipedia.org/wiki/Fiberboardhttps://en.wikipedia.org/wiki/Animal_fiberhttps://en.wikipedia.org/wiki/Silkwormhttps://en.wikipedia.org/wiki/Silkhttps://en.wikipedia.org/wiki/Spider_silkhttps://en.wikipedia.org/wiki/Spider_silkhttps://en.wikipedia.org/wiki/Sinewhttps://en.wikipedia.org/wiki/Catguthttps://en.wikipedia.org/wiki/Woolhttps://en.wikipedia.org/wiki/Sea_silkhttps://en.wikipedia.org/wiki/Mohairhttps://en.wikipedia.org/wiki/Angora_woolhttps://en.wikipedia.org/wiki/Cellulosehttps://en.wikipedia.org/wiki/Ligninhttps://en.wikipedia.org/wiki/Cottonhttps://en.wikipedia.org/wiki/Cannabis_sativahttps://en.wikipedia.org/wiki/Jutehttps://en.wikipedia.org/wiki/Flaxhttps://en.wikipedia.org/wiki/Ramiehttps://en.wikipedia.org/wiki/Sisalhttps://en.wikipedia.org/wiki/Bagassehttps://en.wikipedia.org/wiki/Bagassehttps://en.wikipedia.org/wiki/Banana#Fiberhttps://en.wikipedia.org/wiki/Paperhttps://en.wikipedia.org/wiki/Textilehttps://en.wikipedia.org/wiki/Dietary_fiberhttps://en.wikipedia.org/wiki/Wood_fibrehttps://en.wikipedia.org/w/index.php?title=Groundwood&action=edit&redlink=1https://en.wikipedia.org/wiki/Lagetta_lagettohttps://en.wikipedia.org/wiki/Kraft_processhttps://en.wikipedia.org/wiki/Engineered_woodhttps://en.wikipedia.org/wiki/Fiberboardhttps://en.wikipedia.org/wiki/Animal_fiberhttps://en.wikipedia.org/wiki/Silkwormhttps://en.wikipedia.org/wiki/Silkhttps://en.wikipedia.org/wiki/Spider_silkhttps://en.wikipedia.org/wiki/Spider_silkhttps://en.wikipedia.org/wiki/Sinewhttps://en.wikipedia.org/wiki/Catguthttps://en.wikipedia.org/wiki/Woolhttps://en.wikipedia.org/wiki/Sea_silkhttps://en.wikipedia.org/wiki/Mohairhttps://en.wikipedia.org/wiki/Angora_woolhttps://en.wikipedia.org/wiki/Fiber_crop -

7/24/2019 Tensile Strength of Fibers

7/26

"ineral fibersinclude the asbestosgroup.

Asbestos is the only naturally occurring

long mineralfiber. $ix minerals have been

classified as -asbestos- including chrysotileof

the serpentineclass and those belonging tothe amphiboleclass% amosite, crocidolite, tremo

lite, anthophylliteand actinolite. $hort, fiber!

like minerals

include wollastoniteand palygorskite.

iological fibersalso known as fibrousproteinsor protein filamentsconsist largely of

biologically relevant and biologically very

important proteins, mutations or other genetic

defects can lead to severe diseases. Instances

are collagenfamily of proteins, tendon, muscleproteinslike actin, cell proteins

like microtubulesand many others, spider silk,

sinewand hairetc.

$an,made 5ibers"an!made fibers or chemical fibers are fibers

whose chemical composition, structure, and

properties are significantly modified during the

https://en.wikipedia.org/wiki/Mineral_fiberhttps://en.wikipedia.org/wiki/Asbestoshttps://en.wikipedia.org/wiki/Mineralhttps://en.wikipedia.org/wiki/Chrysotilehttps://en.wikipedia.org/wiki/Serpentine_grouphttps://en.wikipedia.org/wiki/Amphibolehttps://en.wikipedia.org/wiki/Amositehttps://en.wikipedia.org/wiki/Crocidolitehttps://en.wikipedia.org/wiki/Tremolitehttps://en.wikipedia.org/wiki/Tremolitehttps://en.wikipedia.org/wiki/Anthophyllitehttps://en.wikipedia.org/wiki/Actinolitehttps://en.wikipedia.org/wiki/Wollastonitehttps://en.wikipedia.org/wiki/Palygorskitehttps://en.wikipedia.org/w/index.php?title=Biological_fiber&action=edit&redlink=1https://en.wikipedia.org/w/index.php?title=Fibrous_proteins&action=edit&redlink=1https://en.wikipedia.org/w/index.php?title=Fibrous_proteins&action=edit&redlink=1https://en.wikipedia.org/wiki/Protein_filamenthttps://en.wikipedia.org/wiki/Collagen#Diseaseshttps://en.wikipedia.org/wiki/Collagenhttps://en.wikipedia.org/wiki/Tendonhttps://en.wikipedia.org/wiki/Muscle_proteinshttps://en.wikipedia.org/wiki/Muscle_proteinshttps://en.wikipedia.org/wiki/Actinhttps://en.wikipedia.org/wiki/Microtubulehttps://en.wikipedia.org/wiki/Spider_silkhttps://en.wikipedia.org/wiki/Sinewhttps://en.wikipedia.org/wiki/Hairhttps://en.wikipedia.org/wiki/Mineral_fiberhttps://en.wikipedia.org/wiki/Asbestoshttps://en.wikipedia.org/wiki/Mineralhttps://en.wikipedia.org/wiki/Chrysotilehttps://en.wikipedia.org/wiki/Serpentine_grouphttps://en.wikipedia.org/wiki/Amphibolehttps://en.wikipedia.org/wiki/Amositehttps://en.wikipedia.org/wiki/Crocidolitehttps://en.wikipedia.org/wiki/Tremolitehttps://en.wikipedia.org/wiki/Tremolitehttps://en.wikipedia.org/wiki/Anthophyllitehttps://en.wikipedia.org/wiki/Actinolitehttps://en.wikipedia.org/wiki/Wollastonitehttps://en.wikipedia.org/wiki/Palygorskitehttps://en.wikipedia.org/w/index.php?title=Biological_fiber&action=edit&redlink=1https://en.wikipedia.org/w/index.php?title=Fibrous_proteins&action=edit&redlink=1https://en.wikipedia.org/w/index.php?title=Fibrous_proteins&action=edit&redlink=1https://en.wikipedia.org/wiki/Protein_filamenthttps://en.wikipedia.org/wiki/Collagen#Diseaseshttps://en.wikipedia.org/wiki/Collagenhttps://en.wikipedia.org/wiki/Tendonhttps://en.wikipedia.org/wiki/Muscle_proteinshttps://en.wikipedia.org/wiki/Muscle_proteinshttps://en.wikipedia.org/wiki/Actinhttps://en.wikipedia.org/wiki/Microtubulehttps://en.wikipedia.org/wiki/Spider_silkhttps://en.wikipedia.org/wiki/Sinewhttps://en.wikipedia.org/wiki/Hair -

7/24/2019 Tensile Strength of Fibers

8/26

manufacturing process. "an!made fibers consist

of regenerated fibers and synthetic fibers.

Semi-synthetic fibers

$emi!synthetic fibers are made from raw

materials with naturally long!chain polymer

structure and are only modified and partially

degraded by chemical processes, in contrast to

completely synthetic fibers such

as nylon(polyamide) or dacron(polyester), whichthe chemist synthesi/es from low!molecular

weight compounds by polymeri/ation (chain!

building) reactions. +he earliest semi!synthetic

fiber is the cellulose regenerated

fiber, rayon. "ost semi!synthetic fibers arecellulose regenerated fibers.

Cellulose regenerated fibers

0ellulose fibersare a subset of man!made fibers,regenerated from natural cellulose. +he cellulose

comes from various sources% rayon from tree

wood fiber, "odalfrom beech trees, bamboo

fiberfrom bamboo, seacellfrom seaweed, etc. In

the production of these fibers, the cellulose is

https://en.wikipedia.org/wiki/Nylonhttps://en.wikipedia.org/wiki/Dacronhttps://en.wikipedia.org/wiki/Rayonhttps://en.wikipedia.org/wiki/Cellulose_fiberhttps://en.wikipedia.org/wiki/Cellulosehttps://en.wikipedia.org/wiki/Modal_(textile)https://en.wikipedia.org/wiki/Bamboo_fiberhttps://en.wikipedia.org/wiki/Bamboo_fiberhttps://en.wikipedia.org/w/index.php?title=Seacell&action=edit&redlink=1https://en.wikipedia.org/wiki/Seaweedhttps://en.wikipedia.org/wiki/Nylonhttps://en.wikipedia.org/wiki/Dacronhttps://en.wikipedia.org/wiki/Rayonhttps://en.wikipedia.org/wiki/Cellulose_fiberhttps://en.wikipedia.org/wiki/Cellulosehttps://en.wikipedia.org/wiki/Modal_(textile)https://en.wikipedia.org/wiki/Bamboo_fiberhttps://en.wikipedia.org/wiki/Bamboo_fiberhttps://en.wikipedia.org/w/index.php?title=Seacell&action=edit&redlink=1https://en.wikipedia.org/wiki/Seaweed -

7/24/2019 Tensile Strength of Fibers

9/26

reduced to a fairly pure form as a viscous mass

and formed into fibers by extrusion through

spinnerets. +herefore, the manufacturing process

leaves few characteristics distinctive of the

natural source material in the finished product.$ome examples are%

rayon

bamboo fiber

1yocell, a brand of rayon

"odal, using beech trees as input

diacetate fiber

triacetate fiber.

Historically, cellulose diacetate and !triacetate

were classified under the term rayon, but are now

considered distinct materials.

Synthetic fibers

$yntheticcome entirely from synthetic materials

such as petrochemicals, unlike those man!made

fibers derived from such natural substances as

cellulose or protein.

https://en.wikipedia.org/wiki/Rayonhttps://en.wikipedia.org/wiki/Bamboo_textileshttps://en.wikipedia.org/wiki/Lyocellhttps://en.wikipedia.org/wiki/Modal_(textile)https://en.wikipedia.org/wiki/Cellulose_diacetatehttps://en.wikipedia.org/wiki/Cellulose_triacetatehttps://en.wikipedia.org/wiki/Synthetic_fiberhttps://en.wikipedia.org/wiki/Petrochemicalhttps://en.wikipedia.org/wiki/Rayonhttps://en.wikipedia.org/wiki/Bamboo_textileshttps://en.wikipedia.org/wiki/Lyocellhttps://en.wikipedia.org/wiki/Modal_(textile)https://en.wikipedia.org/wiki/Cellulose_diacetatehttps://en.wikipedia.org/wiki/Cellulose_triacetatehttps://en.wikipedia.org/wiki/Synthetic_fiberhttps://en.wikipedia.org/wiki/Petrochemical -

7/24/2019 Tensile Strength of Fibers

10/26

#iber classification in reinforced plastics falls

into two classes% (i) short fibers, also known as

discontinuous fibers, with a general aspect ratio

(defined as the ratio of fiber length to diameter)

between 23 to 43, and (ii) long fibers, also knownas continuous fibers5 the general aspect ratio is

between 233 to 633.

Metallic fibers

"etallic fiberscan be drawn from ductile metalssuch as copper, gold or silver and extruded or

deposited from more brittle ones, such as nickel,

aluminum or iron. $ee also $tainless steel fibers.

Carbon fiber0arbon fibersare often based on oxydi/ed and

via pyrolysiscarboni/ed polymers like 'A, but

the end product is almost pure carbon.

Silicon carbide fiber

$ilicon carbidefibers, where the basic polymers

are not hydrocarbonsbut polymers, where about

637 of the carbon atoms are replaced by silicon

atoms, so!called poly!carbo!silanes. +he pyrolysis

https://en.wikipedia.org/wiki/Metallic_fiberhttps://en.wikipedia.org/wiki/Stainless_steel_fiberhttps://en.wikipedia.org/wiki/Carbon_(fiber)https://en.wikipedia.org/wiki/Pyrolysishttps://en.wikipedia.org/wiki/Polyacrylonitrilehttps://en.wikipedia.org/wiki/Silicon_carbidehttps://en.wikipedia.org/wiki/Hydrocarbonhttps://en.wikipedia.org/wiki/Silanehttps://en.wikipedia.org/wiki/Metallic_fiberhttps://en.wikipedia.org/wiki/Stainless_steel_fiberhttps://en.wikipedia.org/wiki/Carbon_(fiber)https://en.wikipedia.org/wiki/Pyrolysishttps://en.wikipedia.org/wiki/Polyacrylonitrilehttps://en.wikipedia.org/wiki/Silicon_carbidehttps://en.wikipedia.org/wiki/Hydrocarbonhttps://en.wikipedia.org/wiki/Silane -

7/24/2019 Tensile Strength of Fibers

11/26

yields an amorphous silicon carbide, including

mostly other elements like oxygen, titanium, or

aluminium, but with mechanical properties very

similar to those of carbon fibers.

Fiberglass

#iberglass, made from specific glass, and optical

fiber, made from purified natural 8uart/, are also

man!made fibers that come from natural raw

materials, silica fiber, made fromsodiumsilicate(water glass) and basalt fibermade from

melted basalt.

Mineral fibers

"ineral fibers can be particularly strong becausethey are formed with a low number of surface

defects, asbestosis a common one.9:;

Polymer fibers

'olymer fibers are a subset of man!made

fibers, which are based on synthetic chemicals

(often from petrochemicalsources) rather than

https://en.wikipedia.org/wiki/Fiberglasshttps://en.wikipedia.org/wiki/Optical_fiberhttps://en.wikipedia.org/wiki/Optical_fiberhttps://en.wikipedia.org/wiki/Quartzhttps://en.wikipedia.org/wiki/Silica_fiberhttps://en.wikipedia.org/wiki/Sodium_silicatehttps://en.wikipedia.org/wiki/Sodium_silicatehttps://en.wikipedia.org/wiki/Basalt_fiberhttps://en.wikipedia.org/wiki/Asbestoshttps://en.wikipedia.org/wiki/Fiber#cite_note-8https://en.wikipedia.org/wiki/Petrochemicalhttps://en.wikipedia.org/wiki/Fiberglasshttps://en.wikipedia.org/wiki/Optical_fiberhttps://en.wikipedia.org/wiki/Optical_fiberhttps://en.wikipedia.org/wiki/Quartzhttps://en.wikipedia.org/wiki/Silica_fiberhttps://en.wikipedia.org/wiki/Sodium_silicatehttps://en.wikipedia.org/wiki/Sodium_silicatehttps://en.wikipedia.org/wiki/Basalt_fiberhttps://en.wikipedia.org/wiki/Asbestoshttps://en.wikipedia.org/wiki/Fiber#cite_note-8https://en.wikipedia.org/wiki/Petrochemical -

7/24/2019 Tensile Strength of Fibers

12/26

arising from natural materials by a purely

physical process. +hese fibers are made from%

polyamide nylon

'

-

7/24/2019 Tensile Strength of Fibers

13/26

'olyethylene('

-

7/24/2019 Tensile Strength of Fibers

14/26

denier). >enierand >texare two measurements

of fiber yield based on weight and length. If the

fiber density is known, you also have a fiber

diameter, otherwise it is simpler to measure

diameters in micrometers. "icrofibers intechnical fibers refer to ultra!fine fibers (glass

or meltblown thermoplastics) often used in

filtration. ewer fiber designs include extruding

fiber that splits into multiple finer fibers. "ost

synthetic fibers are round in cross!section, butspecial designs can be hollow, oval, star!shaped or

trilobal. +he latter design provides more optically

reflective properties. $ynthetic textile fibers

are often crimped to provide bulk in a woven, non!

woven or knitted structure. #iber surfaces can

also be dull or bright. >ull surfaces reflect morelight while bright tends to transmit light and

make the fiber more transparent.

&ery short and=or irregular fibers have been

called fibrils. atural cellulose, such as cotton or

bleached kraft, show smaller fibrils jutting outand away from the main fiber structure.

https://en.wikipedia.org/wiki/Units_of_textile_measurement#Denierhttps://en.wikipedia.org/wiki/Units_of_textile_measurement#Texhttps://en.wikipedia.org/wiki/Units_of_textile_measurement#Denierhttps://en.wikipedia.org/wiki/Units_of_textile_measurement#Tex -

7/24/2019 Tensile Strength of Fibers

15/26

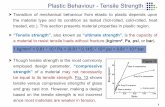

Tensile Strength &5ibers

>epending upon the sources, the various types of

fibers can be classified into the following main three

categories%

Animal #ibers

&egetable #ibers

$ynthetic fibers

-

7/24/2019 Tensile Strength of Fibers

16/26

esides their chemical composition and properties,

most important property of these fibers is their

tensile strength, meaning the extent to which a fiber

can be stretched without breaking and it is measured

in terms of minimum weight

re8uired to break the fiber. +o

determine the tensile strength

of nay fiber, it is tied to a hook

at one end and weights areslowly added to the other end until the fiber breaks.

$ince peptide bonds are more

easily hydroly/ed by bases

than by acids, therefore wool

and silk are affected by basesand not by acids.

It is because of this reason

that wool and silk threads breakup into fragments

and ultimately dissolves in alkalines.

In other words, alkalines decrease the tensilestrength of animal fibers (wool and silk), vegetable

fibers (cotton and linen), on the other hand, consist

of long polysaccharide chains in which the various

glucose units are joined by ethers linkage. $ince

-

7/24/2019 Tensile Strength of Fibers

17/26

ethers are hydroly/ed by

acids and not by bases,

therefore vegetable fibers

are affected by acids but

not by bases. In other words,

acids decrease the tensile

strength of vegetable fibers. In contrast, synthetic

fibers such as nylon and

polyester practically remainunaffected by both acids and

bases.

$ynthetic

fibers owe some of their

chemical resistance to theirmore @crystalline@ structure,

i.e., there is greater regularity

in the molecular structure, and this regularity

reduces the ability of bases or acids to approach the

amide bonds to initiate a hydrolytic reaction.

-

7/24/2019 Tensile Strength of Fibers

18/26

-

7/24/2019 Tensile Strength of Fibers

19/26

Procedure 0ut out e8ual lengths of a cotton fiber, nylon

fiber and silk fiber from the given sample. +ie one end of cotton fiber to a hook which has

been fixed in a vertical plane. +ie a weight hanger

to the other end. 1et the thread get straight.

'ut a weight to the hanger and observe the

thread stretch. +hen, increase the weightsgradually on the hanger until the breaking point is

reached. +hen note the minimum weight needed

for breaking the cotton fiber.

?epeat the above experiment by tying nylon and

silk fibers to the hook separately and determinethe tensile strength of each fiber.

$oak the woolen thread in a dilute solution of

sodium hydroxide for five minutes. +ake it out

from hydroxide solution and wash it thoroughly

with water and then dry by keeping it in the sun.>etermine the tensile strength again.

ow take another piece of woolen thread of the

same si/e and diameter and soak it in a diluter

solution of hydrochloric acid for five minutes.

-

7/24/2019 Tensile Strength of Fibers

20/26

+ake it out, wash thoroughly with water, dry and

determine the tensile strength agin.

?epeat the above procedure for the samples of

cotton and nylon fiber.

&bservation Table

-

7/24/2019 Tensile Strength of Fibers

21/26

$.o. +ype

f

#ibre

*t. ?e8uired

+o reak +he

Bntreated #iber

*t. ?e8uired +o

reak +he #iber

After $oaking In

>il. H0l

*t. ?e8uired +o

reak +he #iber

After $oaking In

aH $olution

C. *ool

2. 0otton

D. ylon

'esult

+he tensile strength of woolen fiber decreases in

alkalies but practically remains unaffected on

soaking in acids.

-

7/24/2019 Tensile Strength of Fibers

22/26

+he tensile strength of cotton fiber decreases on

soaking in acids but remains practically

unaffected on soaking in alkalies.

+he tensile strength of nylon fibers remain

practically unaffected on soaking either in acids

or in alikalies.

Precautions

+he threads must be of identical diameters.

+he length of the threads should always be same.

-

7/24/2019 Tensile Strength of Fibers

23/26

+he weights should be added in small amounts

very slowly.

+he chemicals should be handled very carefully.

(ibliography

Eoogle

*ikipedia

ritannica

-

7/24/2019 Tensile Strength of Fibers

24/26

-

7/24/2019 Tensile Strength of Fibers

25/26

$aterials 7

Chemicals 'e%uired

Weight Hanger &

Weights

Hook

Sodium

HydroxideSolution

Dilute Hydrochloric

cid

-

7/24/2019 Tensile Strength of Fibers

26/26

!ylon

CottonSilk