Template for Electronic Submission to ACS Journals · Web viewKEYWORDS: protein crystallization,...

Transcript of Template for Electronic Submission to ACS Journals · Web viewKEYWORDS: protein crystallization,...

Hydrophobic Interface-assisted Protein Crystalliza-tion: Theory and Experiment

Christo N. Nanev,†,‡ Emmanuel Saridakis,§,‡ Lata Govada,⊥ Sean C. Kassen,⊥ Hodaya V. Solomon,⊥ and Naomi E. Chayen*,⊥ †Rostislaw Kaischew Institute of Physical Chemistry, Bulgarian Academy of Sciences, Acad. G. Bonchev Str. Bl. 11, 1113 Sofia, Bulgaria.§Structural and Supramolecular Chemistry Laboratory, Institute of Nanoscience and Nanotechnol-ogy, National Centre for Scientific Research “Demokritos”, Athens 15310, Greece.⊥Computational and Systems Medicine, Department of Surgery and Cancer, Faculty of Medicine, Imperial College London, London SW7 2AZ, UK.

KEYWORDS: protein crystallization, crystal nucleation, protein adsorption, hydrophobic liquid, hy-drophobic interface

ABSTRACT: Macromolecular crystallization is crucially important to a large number of scientific fields, including structural biology, drug design, formulation and delivery, the manufacture of biomaterials, and the preparation of foodstuffs. The purpose of this study is to facilitate control of crystallization, by inves-tigating hydrophobic interface-assisted protein crystallization both theoretically and experimentally. The application of hydrophobic liquids as nucleation promoters or suppressors has rarely been investigated, and provides an underused avenue to explore in protein crystallization. Theoretically, crystal nucleation is regarded as a two-step process, the first step being a local increase in protein concentration due to its adsorption on the hydrophobic surface. Subsequently, the protein is ordered in a crystal lattice. The en-ergetic aspect of crystal nucleation on water/hydrophobic substance interfaces is approached by calcu-lating the balance between the cohesive energy maintaining integrity of the 2D-crystal nucleus and the sum of destructive energies tending to tear up the crystal. This is achieved by comparing the number of bonds shared by the units forming the crystal and the number of unshared (dangling) bonds on the crys-tal surface pointing toward the solution. The same approach is extended to 3D protein crystal nucleation at water/hydrophobic liquid interfaces. Experimentally, we studied protein crystallization over oils and other hydrophobic liquids (paraffin oil, FC-70 Fluorinert fluorinated oil, and three chlorinated hydrocar-bons). Crystallization of α-lactalbumin and lysozyme are compared, and additional information is ac-quired by studying α-crustacyanin, trypsin, an insulin analogue and protein Lpg2936. Depending on the protein type, concentration, and the interface aging time, the proteins exhibit different crystallization propensities depending on the hydrophobic liquid used. Some hydrophobic liquids provoke an increase in the effective supersaturation, which translates to enhancement of crystal nucleation at their interface with the crystallization solution leading to formation of crystals.

1. INTRODUCTIONProtein X-ray crystallography is the most wide-spread method for the elucidation of the three-di-mensional structures of proteins and their com-plexes with other proteins, nucleic acids, ligands or effectors/inhibitors. Some of its major advan-tages are that there are no a priori limitations as

to the size of the macromolecule or complex that can be studied and that ultra-high (atomic) reso-lution can be reached in the most successful in-stances. The method, however, relies on the availability of well-diffracting crystals of the macromolecule under study, and obtaining such crystals is the most uncertain part of the crystal-lographic procedure.

1

The utilization of oil for protein crystallization was originally initiated to enable the dispensing and incubation of micro/nanoscale crystallization sam-ples using the microbatch method in which crys-tals are grown under a layer of oil.1 The primary role of the oil was to act as an inert sealant to prevent evaporation of the trials, however, exper-imental evidence has revealed that oil itself can play an important part in the outcome of a crys-tallization experiment by affecting the nucleation and growth stages of crystallization. Paraffin was selected after testing a variety of oils, as being the most inert.Crystallization of proteins using the microbatch under-oil technique is widely used in studies of protein crystallogenesis as well as in crystalliza-tion screening. Most recently, its application was extended for use in salt screening of organic cations, which is an essential but demanding step when identifying the most appropriate active pharmaceutical ingredients. As compared to the vapor diffusion method, the under-oil method was found to be much more effective in generating single crystals2. Thus, under-oil crystallization is an attractive alternative to the standard salt screenings, which are time, material and labor intensive. The increase in the use of under-oil crystallization begs for a deeper understanding of nucleation mechanisms of protein crystals under oils.Crystallization is not a smooth process. According to the classical nucleation theory (CNT)3,4, a free energy barrier must be overcome for sponta-neous crystallization to initiate. Formation of the smallest sized stable crystalline particles possible under the conditions present, known as ‘nuclei’, is the prerequisite for crystal growth to proceed. But due to the molecular-scale processes involved, the earliest stages of protein crystal nucleation remain not well understood and are still debated. A novel approach to the initiation of protein crys-tallization consists in establishing the balance between the cohesive energy (that maintains the integrity of a new phase cluster) and the surface energy (that tends to tear up this cluster). The crystal nucleation process is governed by this balance5.Various observations have already been made, relevant to the role of oils and other hydrophobic surfaces in protein crystal nucleation. Silver et al.6,7 compared the crystallization of lysozyme at air/solution and at oil/solution interfaces. He and his co-authors found that certain oil/water inter-faces enhance nucleation whilst others do not. For instance, nucleation and the extent of lysozyme crystallization at the chloroform/water interface are enhanced in comparison to the cor-responding air/water interfaces. Also, hydropho-bic interactions of proteins with solid surfaces are known to affect protein crystallization. A consider-

able acceleration of protein crystal nucleation was observed in the case of a hydrophobic hex-amethyl-disilazane coverage used as a template on glass.8 Furthermore, two-dimensional lysozyme5,6, ferritin11 and streptavidin12 crystals have been grown at an air/solution interface, which is the most typical hydrophobic substrate for proteins. To further elucidate the crystalliza-tion under oil, it is needed to focus on the protein adsorption at the oil-water interfaces.

Protein adsorption at the oil-water and air/water interfaces is a well-established and widely studied phenomenon, e.g.13-15. The reason is that globular protein adsorption at oil-water interfaces is of importance in many applications, such as phar-maceutics, cosmetics and food emulsions. Pro-teins adsorb at liquid/liquid interfaces due to their amphiphilic nature. Non-polar residues, most of which are hidden in the interior of the protein in its native state, are exposed towards the hy-drophobic phase during adsorption. As a result, proteins tend to unfold. Also, adsorption of lysozyme and protein–surfactant mixtures at the air–water interface have been studied using bub-ble and drop profile analysis tensiometry and ellipsometry16. However, the hydrophobic proper-ties of the oils, which decisively affect protein adsorption, are commonly neglected. It turns out that hydrophobicity, polarity and chain length of oils govern the adsorption kinetics. For instance, polar oils are acting as softening agents on the interfacial β-lactoglobulin network17. Therefore, the impact of different oils on protein crystalliza-tion is worth studying.Formation of an interface with broken hydrogen bonds, such as that between water and its vapor, is needed to assemble hydrophobic substances and units, e.g. to nucleate protein crystals. Simul-taneously, the removal of water from regions be-tween the two hydrophobic structures is obliga-tory18. Importantly, long-range attractive forces are needed to bring water-coated hydrophobic surfaces in direct contact. The problem was con-sidered by Despa and Berry19.Regarding protein crystallization in contact with hydrophobic liquids and oils, we must first con-sider that, depending on the protein type, con-centration, and the hydrophobic interface aging time (i.e. trial incubation time), proteins tend to exhibit irreversible adsorption at such interfaces. Beverung et al.13 studied the adsorption dynamics of a set of several different proteins (lysozyme, ovalbumin, β-casein, bovine serum albumin, li-pases) encompassing a representative sample of molecular structures and their stabilizing forces. As one example, the authors did not directly ob-serve any denaturation of lysozyme at low con-centration at the water/heptane interface, al-

2

though it was found to unfold at the water/decane interface (see also 20). Later, Postel et al.9 noted that whilst only partial denaturation/unfolding of lysozyme occurs at the air/water interface, the same cannot be said of lysozyme adsorption to a hydrophobic oil/water interface, where larger un-folding and conformational rearrangement in the interfacial region is known to occur (see also 21).Freer et al.22 elucidated the adsorption mecha-nism of lysozyme at the oil/water interface. They noted that despite being under diffusion control, protein adsorption is relatively rapid at early times. At the initial stage, the adsorbed protein molecules remain close to their native structure and interact very little with each other. Especially for hard globular proteins, like lysozyme, intra-protein interactions dominate at this stage, and intrinsically stabilize the native protein conforma-tion. However, with increased exposure time and amount of adsorption, the protein molecules on the interface begin to slowly reconfigure. In doing so, they partially unfold and expose some hy-drophobic residues. The latter interact with the oil to form interfacial protein containing “skins” (i.e. viscoelastic films). Visualized from pendant drop (bubble) and thin-film studies, these skins are ascribed to gel-like networks at the fluid/fluid interfaces. At this point the adsorption becomes irreversible and even lysozyme loses its rigidity. Aggregated multilayers may also form, which, subsequently rearrange and order in crystalline lattices.Abundant data for protein unfolding by adsorption at interfaces are available in the literature. A Re-view by Yano23 distinguishes three categories of proteins: “soft”, of intermediate structural hard-ness and “hard” (highly stable) structures, e.g. lysozyme. More rigorous determination of the protein molecule stability is given by the thermal unfolding ("melting") temperature (Tm), the tem-perature at which 50% of the protein is unfolded. Specific information about the degree of protein unfolding (induced by hydrophobic interactions between the oil and surface hydrophobic protein residues) is available for ovalbumin, β-casein, lysozyme, bovine serum albumin and lipases.13

Remarkably, a positively charged protein can ad-sorb onto a like-charged interface. This appar-ently anomalous behavior is attributed to a distri-bution of amino acid residues on the protein sur-face that results in patches of charge opposite to the net charge of the surface. The net charge of the protein does not therefore always play a de-termining role in the adsorption.24

In this study we investigate the way in which dif-ferent oils can affect the nucleation of protein crystals when they form an interface with the crystallization drop. Hydrophobic interface-as-sisted protein crystallization is studied both theo-retically and experimentally. Theoretically, crystal

nucleation is regarded as a two-step process, the first step being a local increase in protein concen-tration due to its adsorption on the hydrophobic surface (air or oil), the second being the ordering of protein molecules in a crystal lattice. Experi-mentally, we studied protein crystallization in contact with oils and other hydrophobic liquids (paraffin oil, Fluorinert FC-70 oil and three chlori-nated hydrocarbons: chloroform, dichloromethane and dichloroethane). Crystallization characteris-tics of several proteins are compared.2. THERMODYNAMIC CONSIDERATIONSClassical thermodynamics describes the change in free energy (or Gibbs thermodynamic potential, ΔG) required for the new phase formation as a sum of two terms: (1) the free energy gain result-ing from the transfer of n molecules from the su-persaturated phase to the new phase cluster, and (2) the free energy penalty, imposed due to the formation of the new interface. In other words, the cohesive energy (ΔGv) that maintains the in-tegrity of a new phase cluster is proportional to its volume, while the sum of energies (ΔGs) that tend to tear up the cluster is proportional to its surface:ΔG = − ΔGv + ΔGs (1)

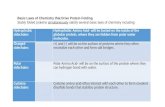

Considering the energy balance between ΔGv and ΔGs (i.e., − ΔGv + ΔGs = 0) which is needed for stability of the homogeneous critical nucleus, and using the simplest model of the so-called Kossel-crystal (simple cubic symmetry with 6 cohesive bonds per molecule, Figure 1), the total numbers of cohesive and destructive energy interactions can be counted. If it is assumed that cohesive (which will be denoted here as ψb) and destructive (ψd) interaction energies are equal, ψb/ψd = 1,25,26

a critical nucleus edge length of 3 molecules can be calculated (Figure 1).

Figure 1. Nucleus following the model of a Kossel-crystal (Reproduced with permission from reference 25, Copyright 2003 Elsevier Science).

The Kossel crystal model provides a reliable basis for general semi-quantitative considerations of crystallization processes, including crystal nucle-ation. Being the simplest model, it works well for

3

homopolar crystals. To widen the theoretical scope, heterogeneous (on hydrophobic inter-faces) nucleation of closest packed crystals is considered here.Nucleation is easier on foreign surfaces, as the crystal-solution interface is reduced. It is the en-ergy barrier that makes heterogeneous nucle-ation the preferred nucleation process - the het-erogeneous nucleation energy barrier is only a fraction of the energy barrier of homogenous nu-cleation. To predict whether nucleation is favored at the interface, the cluster/solution, solution/in-terface and interface/solution surface energies have to be considered. However, when dealing with very small crystals, the surface tension is strongly influenced by the entropic contributions (configurational and vibrational). When consider-ing protein crystallization, these contributions are of special importance. Using nucleation rate data obtained from in situ grazing incidence small-angle X-ray scattering (GISAXS) measurements, and the CNT expression for nucleation of spherical particles, Jun et al.27

calculate the effective interfacial free energy gov-erning the heterogeneous nucleation of CaCO3 (calcite, an inorganic substance) on quartz sur-faces. The authors also note that “the physico-chemical properties of both the nuclei and sur-faces significantly and dynamically change with time and aqueous chemistry”. Unfortunately, in-terfacial free energy data for the proteins and oils studied by us are unavailable.

3. RESULTS AND DISCUSSION3.1. Two-dimensional crystal nucleation at water/hydrophobic interfaces Hydrophobicity assisted protein crystal nucleation is regarded here as a two-step process.28 The first step is protein accumulation due to its adsorption on the hydrophobic surface (there is some simi-larity with protein accumulation in pores, where adsorption also plays a central role).29 Already at this step, being (partially) immobilized, the molecules lose some entropy due to the constrained (restricted to two dimensions only, parallel to the solution surface) translational and rotational degrees of freedom. Trapping and rearrangement of water also affect adsorption thermodynamics. Nevertheless, all entropy losses are compensated by the strong hydrophobic in-teraction and, as a result, adsorption is a sponta-neous process (which implies negative ΔGads). The second step in the nucleation process is ordering of the protein molecules, i.e. formation of crystal nuclei. It is stimulated by an entropy gain, which is due to the new vibrational degrees of freedom arising upon molecule attachment to the crystal (and to an enthalpic gain arising from saturation of some dangling bonds). The release of water

molecules attached to the contacting patches when the crystalline bonds are formed, is another reason for the system's entropy rise.30,31 These effects lead to the negative ΔGcryst values that are required for spontaneous crystallization.31 In this paper, we extend the above approach to also encompass heterogeneous nucleation of closest-packed crystals.We start our investigation with the most convinc-ing manifestation of hydrophobicity assisted pro-tein crystal nucleation, which is crystal nucleation at air/solution interfaces: air is a hydrophobic in-terface assisting crystal nucleation. The hy-drophobic patches situated on the protein mole-cule surface are pushed out of the water, towards the air. If these patches have different degrees of hydrophobicity, the most hydrophobic patch is pushed out of the solution most strongly. In other words, the protein molecules are “anchored” at the air/solution interface, the “anchor” being the strongest hydrophobicity patch. Thus, by causing accumulation of protein at the air/solution inter-face, protein adsorption stimulates 2D crystal nucleation there. This effect can be generalized to crystal nucleation at a protein solution/hydropho-bic liquid interface. In contrast to protein crystal-lization at air/solution however, such interfaces can have different interaction strengths - depend-ing on the combination of protein and hydropho-bic liquid (see Section 3.3). Importantly, our ex-perimental studies have shown that there is prac-tically no water evaporation (no permeability of the oils for water molecules). This excludes con-centration of the solution by slow evaporation through the oil being itself, a factor influencing the crystallization.To study the supersaturation dependence of the size of closest packed 2D heterogeneous crystal nuclei (which initiate growth of mono-molecular ferritin crystal layers upon the surface of a ferritin solution),11 we modify the approach used in 25. To establish the energy balance between ΔGv and ΔGs (i.e., − ΔGv + ΔGs = 0), we assume that the number ratio of the hydrophobic and destructiveforces, which act against each other, does not depend on the total number (n) of protein mole-cules constituting the 2D cluster; this ratio is con-stant, equal to 1:1. It is only the periphery of the 2D-cluster that can be torn up. Thus, the corre-sponding ΔGs are determined from the numbers of molecules at the periphery only. (Note that the equilibration of the 2D crystal with the mother phase is achieved via the adsorbed protein mole-cules: it doesn’t matter whether these are intact or partially unfolded).To consider 2D closest packed nuclei constituted by n ≤ 5 molecules (Figure 2), which are formed heterogeneously at the air/solution interface, like in 11, we adapt the above approach by assuming ψb/ψd ≠ 1 (see also 32). The idea behind this con-

4

sideration is simple: while ψb is independent of the supersaturation, ψd does depend on it. Evi-dently, at undersaturation conditions the “affin-ity” of the protein to the water molecules prevails highly over the crystallization tendency (ψd >> ψb), and no crystallization is possible. To induce crystallization, it is necessary to decrease the protein-water affinity. This is done by reaching supersaturation: the higher the latter, the lower the affinity between protein and solution. Hence, the energy that tends to tear up the crystal is lowered with increasing supersaturation, the en-ergy penalty for nucleus formation diminishes, and the critical nucleus becomes smaller in size (and vice versa, larger ψd means lower supersatu-ration, see Tables 1 and 2).To clarify the loosely defined “affinity” of the pro-tein to the water molecules, it is necessary to consider the enthalpic and entropic contributions to the energy of crystal nucleation. By definition, under constant temperature and pressure (where protein crystallization is typically carried out), ΔGcryst is expressed by process enthalpy (ΔHcrys) and entropy (ΔScrys) per molecule:

Figure 2. Differently sized clusters of (globular) pro-tein molecules represented by balls. a. dimer; b. trimer; c. tetramer; d. pentamer.

ΔGcryst = ΔHcrys – TΔScrys (2)

The entropy and enthalpy of protein crystalliza-tion have been determined from exact solubility data by means of van´t Hoff’s equation.33 The authors concluded that the negative entropic effect is compensated mainly by the large en-thalpic change (so that crystallization is an exothermic process). To account for the entropy, we define ψd in such a way that it also includes the sum of all nucleation disfavoring entropic contributions; and it is equally feasible to include all entropy increasing components (which favor crystal nucleation) within ψb.We infer that the smallest crystalline cluster, con-stituted of two molecules only, can be a critical nucleus under extremely high supersaturation, at which ψd = ψb/2. With decreasing supersaturation, only larger clusters become critical nuclei. Thus,

the crystal cluster constituted by 3 molecules is stable when ψd = ψb; the crystal cluster consti-tuted by 4 molecules is stable when ψd = 1.25ψb, etc. (see Table 1).However, incomplete crystalline clusters would have sites for subsequent attachment and forma-tion of minimum surface free energy clusters. Therefore, 2D clusters with complete hexagonal shapes (for which n ≥ 7) are also considered. The ΔGv of such clusters are obtained by considering the total disintegration of the crystal into its con-stituent molecules. This procedure can be con-ceived in different equivalent ways. During the disintegration process, the molecules remain nev-ertheless adsorbed on the hydrophobic surface: this means that the hydrophobic and destructive forces continue to equilibrate mutually.An algorithm for successive one-by-one detach-ment of all the molecules of a cluster is presented in the Supporting Information. Denoting the num-ber of the molecules in the corresponding hexagon’s edge by L, this algorithm provides a general equation for ΔGv of completed hexagon-shaped crystalline clusters of edges L ≥ 2:

ΔGv = 6ψb

∑L−1L

+ f(L)ψb + (4L - 2)ψb (3)

where:

for L = 2, ∑L−1L

= (L - 1) and f(L) = 0;

for L = 3, ∑L−1L

= (L - 1) + L and f(L) = 2;

for L = 4, ∑L−1L

= (L - 1) + L + (L + 1) and f(L) = 4;

for L = 5, ∑L−1L

= (L - 1) + L + (L + 1) + (L + 2) and f(L) = 6, etc.

In the case under consideration, ΔGs = 6X, where: X = 1, 2, 3, 4 … for L = 2, 3, 4, 5 … respectively, so that the energy balance needed for nucleus formation is:

− 6ψb

∑L−1L

+ f(L)ψb + (4L - 2)ψb + 6X = 0 (4)

The results for L = 2 till L = 5 are shown in Table 2.

5

b c da

Table 1. Heterogeneous nucleation of clos-est packed 2D crystals at an air/solution interface, or at a protein solution/hydropho-bic liquid interface, n ≤ 5.

n = 2 3 4 5ψd =a ψb/2 ψb 1.25ψb 1.4ψb

ain order of decreasing supersaturation

Table 2. Heterogeneous nucleation of clos-est packed 2D crystals having shapes of completed hexagons at an air/solution inter-face, or at a protein solution/hydrophobic liquid interface, L ≥ 2

L = 2 3 4 5ψd =a 2 ψb 3.33ψb 4.78ψb 6.25ψb

ain order of decreasing supersaturation

3.2. Three-dimensional nucleation of closest-packed crystalsBecause only 3D protein crystals are seen micro-scopically and are generally useful for structural studies, their nucleation is worth considering. Formation of a second (upper) crystalline layer (B) upon the already formed monolayer (A), which consists of n ≤ 5 molecules, will be considered first. There are two ways to form such a layer B:(1) A protein molecule that arrives from the solu-tion bulk may start forming layer B rather than attaching to the periphery of the already formed layer A because, sitting in the hole between three molecules of layer A (Figure 2b), the incoming molecule will be bonded with three molecules underneath it, i.e. by 3ψb. By comparison, to con-tinue layer A, i.e. be added to its periphery, the same molecule would acquire two protein-protein bonds and one bond with the hydrophobic sur-face. Under these circumstances, the condition for forming the crystalline layer B is that the hy-drophobic binding energy must be smaller than the intra-crystalline connection ψb. This allows a quantitative consideration of the 3D-nucleus size supersaturation dependence by applying the same approach used above for the 2D crystal nucleation. Starting formation of a second clos-est-packed crystalline layer B by adding a fourth molecule in the hole between the 3 molecules in monolayer A, Figure 2b (situation marked as 3+1 in Table 3), stabilizes the structure by increasing the number of the crystalline bonds to 6ψb; thus, ψd = 1.5ψb (instead of ψd = 1.25ψb for the 4-mole-cule cluster in Table 1). Similarly, adding a mole-cule in one of the holes between the 4 molecules in Figure 2c (situation marked as “4+1” in Table 3), increases the number of crystalline bonds to 8ψb, i.e. ψd = 1.6ψb (instead of ψd = 1.4ψb for the

5-molecule cluster in Table 1, Figure 2d). Thus, though constituted by the same number of mole-cules (n = 5), the 3D crystal nucleus is more sta-ble than the 2D nucleus. This consideration indi-cates why a second layer can be formed, rather than an ever-extending first monolayer A. Note that hard and soft proteins may differ in this re-spect, because the latter can be easily denatured after being adsorbed. Additional hydrophobic patches may appear on the soft protein molecule at its contact with the oil, as a result of such a molecule’s structural transformation. This will increase the protein-to-oil bond energy, possibly even to such a degree as to prohibit 3D crystal nucleation.

Table 3. Formation of a second crystal layer B in a 3D crystal nucleus.

n = 3+1 4+1 5+2ψd =a 1.5ψb 1.6ψb 2ψb

ain order of decreasing supersaturation

(2) A protein molecule from an already formed layer A (Figures 2c and 2d), or attached to the edge of a complete-hexagon monolayer, may jump into layer B. The jump may be feasible at high concentrations (above 10-3 wt%), as a multi-layer lysozyme adsorption settles under such conditions.34 Similarly to case (1), a jump into layer B depends on the ratio of hydrophobic bind-ing energy (which can differ for hard and soft proteins) to crystalline connection energy, ψb.Also bi- and tri-layered crystal nuclei forming on a complete hexagonal layer A with L = 3 (Figure 3) are worth considering. Although possible from an energetic point of view, crystal nuclei with L ≥ 4 become less and less likely due to kinetic rea-sons; bringing together a vast number of mole-cules requires very large fluctuations, which ne-cessitate an infeasibly long waiting time.According to eq. (3), ΔGv in layer A is equal to 42ψb. The bonds between layers A and B in the two-layered crystalline cluster (Figure 3) are 36 and those within layer B itself are 24. Thus, ΔGv = 102ψb, while ΔGs = 24ψd. This gives ψd = 4.25ψb, which means that the two-layered crystalline cluster is preferred to the corresponding 2D clus-ter (as the latter has ψd = 3.5ψb).Even more stable are the three-layered crystalline clusters in Figure 3:- The bonds in layer C of the FCC crystal have energy 9ψb, while the bonds between the layers B and C, 18ψb. Thus, ΔGv = 129ψb, while ΔGs = 27ψd; and ψd ≈ 4.8ψb.- The bonds in layer C of the HCP crystal have energy 12ψb and the bonds between the layers B

6

and C, 21ψb. Thus, ΔGv = 135ψb, while ΔGs = 28ψd; and ψd ≈ 4.82ψb.The examples considered above show an in-creased stability of the 3D crystals as compared with the 2D crystals. This conclusion is valid only under the implicit assumption that all crystal con-tacts are of equal bond energy, ψb. Especially for proteins, this is not always the case. As already mentioned, 2D ferritin crystals have been observed at the air/solution interface11 (re-call that the latter differs from an oil/solution in-terface). Evidently, in this particular case, the hydrophobic binding energy plus the energy of the two crystalline connections in monolayer A, exceeds the binding energy of the three bonds in layer B. In the absence of hydrophobic surfaces however, 3D raft-like apoferritin crystal nucleus shapes have been observed by Yau and Vekilov.35

All the above considerations indicate that both equal and different bond strengths may exist, as has also been recently experimentally observed by Van Driessche et al.,36 pointing to the diversity of hydrophobicity assisted protein crystal nucle-ation. In conclusion, a hydrophobic surface should assist nucleation of 3D protein crystals, but only on the condition that the interactions of the pro-tein molecules with the hydrophobic interface are weaker than the protein-protein intra-crystalline connections. Note that the latter result from inter-actions of some amino acid residues with polar and charged side chains (but are not hydropho-bic). It is therefore important to investigate exper-imentally whether different hydrophobic inter-faces lead indeed to different nucleation or pre-cipitation behavior of proteins at and near crystal-lization conditions. To check this, we carried out a series of experiments (see Section 3.3).

Figure 3. 3D crystalline clusters formed on a 2D clus-ter having the shape of a completed hexagon with L = 3, reprinted with modifications from reference 5 under a Creative Commons Attribution License, 2018.

Concerning the quality of the grown crystals, our assumption is that if the predominantly polar intermolecular contact patches are not disturbed much by the exposure of the hydrophobic oil-contacting patches, then a crystal with a single partly unfolded layer sitting on the oil-solution interface can form, while all the overlaying layers can be constituted of well-folded proteins. And if this single layer does not create spreading structural defects, it should not affect the crystal’s diffraction properties.

3.3. Experimental investigations of protein crys-tallization at oil/solution interfacesExperiments on oil-assisted crystallization with different hydrophobic liquids were compared. Two proteins, characterized by highly different molec-ular stabilities according to Yano,23 lysozyme (pos-sessing a “hard molecule” structure) and α-lactal-bumin (possessing a “soft molecule” structure) were tested. Their melting temperatures (Tm) cor-roborate this classification, lysozyme having an about 10° C higher Tm. Additional information was acquired by studying proteins such as trypsin, an insulin analogue, α-crustacyanin and Lpg2936 from Legionella pneumophila . Paraffin oil and three chlorinated hydrocarbons (chloroform, C H Cl 3; dichloromethane, C H 2Cl2, DCM; dichloroethane, C2H2Cl2, DCE) were chosen as hydrophobic liquids. Trials at higher and lower supersaturations were conducted, at and around known crystallization conditions for each of the proteins (see Methods). Another oil which is occasionally used in macro-molecular crystallization was subsequently also tested, at several of the above conditions (Table 4). Use of fluorinated (FC-70) oil has been re-ported in crystallization experiments performed with droplet-based microfluidic setups.37 Although it is used as an inert and water-impermeable oil that keeps the droplets separate from each other in the microfluidic channel, lysozyme and QR2 crystals have been observed at the oil-solution interface.37 Our intention was to see if and how the crystal-lization behavior of the above proteins varies in the presence of the different hydrophobic liquids. More specifically, if some of these proteins crys-tallize in the presence of one or more of the oils at conditions that are metastable for crystalliza-tion of that protein, or if they tend to precipitate or conversely remain clear at conditions that would result in crystallization in the absence of hydrophobic liquids. Our observations were com-pared to crystallization under paraffin oil, which is the standard more or less inert oil used in the microbatch under oil crystallization method1.

7

The hydrophobic liquids that have been used give different results from each other with the different proteins; in some cases they enhance, while in others they suppress crystallization. This observa-tion is in unison with the conclusions of Bergfre-und et al.17 that depending on oil polarity, globu-lar proteins adsorb distinctively. As theoretically expected, their effect is much more complex than that of air. Using the first four hydrophobic liquids mentioned above, no lysozyme crystals were ob-served after 4 weeks, neither with 20 mg/ml pro-tein and 0.25 M NaCl, nor with 25 mg/ml protein and 0.1 M NaCl. Lysozyme crystals appeared after 3 weeks in more supersaturated solutions of 25 mg/ml protein and 0.15 M NaCl, using chloroform and DCM, but not with paraffin oil or DCE. Further increasing the supersaturation by using 25 mg/ml lysozyme and 0.25 M NaCl, we observed phase separation with DCM after one week, and many small crystals in the same time using chloroform, with paraffin oil and DCE trials again remaining clear for at least 6 weeks. In the most supersatu-rated lysozyme solutions, containing 25 mg/ml protein and 0.35 M NaCl, crystal showers were observed after 24 hours with chloroform and DCE, while merely a couple of larger crystals were ob-served after 1 week with paraffin oil. DCM caused appearance of heavy precipitate already after 24 hours under these conditions. In conclusion, paraffin oil is the most reluctant to assist crystal-lization of the hard molecule-structured lysozyme, while chloroform and DCE increase crystal hits. In accordance with our theoretical proposal, the inertness of paraffin oil may be explained by our observation in Section 3.2, that for forming a 3D crystal, the hydrophobic binding energy must be smaller than the intra-crystalline connection ψb. If the hydrophobicity of the protein-paraffin oil pair is extremely high (as it can be for the highly hy-drophobic paraffin oil), the binding energy may indeed become stronger than ψb, and thus only invisible 2D crystalline or amorphous layers may grow on the interface.The situation with α-lactalbumin is somewhat different. Paraffin oil is completely ineffectual, even after 10 weeks, with 5 mg/ml, 7.5 mg/ml and 10 mg/ml protein and 0.5-1 M ammonium sulphate. At the lowest tested concentrations of 5 mg/ml protein and 0.5 M ammonium sulphate, DCE also remained clear, whereas chloroform and DCM yielded microcrystalline suspensions after 24 hours. At 5 mg/ml protein and 0.75 M ammo-nium sulphate, sizeable crystals appear with DCE and microcrystalline suspension with chloroform, after 48 hours (Figure 4). DCM produced amor-phous precipitates, indicating an even more dras-tic effective local supersaturation increase. At the two highest tested concentrations of 7.5 and 10 mg/ml protein and 1 M ammonium sulphate, all three chlorinated hydrocarbons yielded precipi-

tates. It appears therefore that the order of effec-tiveness of the different hydrophobic liquids for 3D crystal nucleation is the same for both pro-teins, lysozyme and α-lactalbumin. However, the chlorinated hydrocarbons appear to affect the crystallization ability of the soft structured α-lac-talbumin molecule more strongly than that of the hard molecule-structured lysozyme.In the case of the insulin analogue, at higher su-persaturation paraffin oil yielded crystals, whereas DCE yielded light phase separation and the other two chlorinated hydrocarbons gave phase separation together with precipitation. At lower supersaturation, paraffin oil always gave clear drops, whereas DCE and DCM gave crystals, and chloroform induced light phase separation. Paraffin oil induces trypsin crystallization, while the three chlorinated hydrocarbons induced only phase separation. Paraffin oil induces the forma-tion of showers of α-crustacyanin microcrystals at high supersaturation, where the other hydropho-bic liquids give heavy precipitation. At lower su-persaturation, trials under paraffin oil remain clear, DCE yields microcrystals and the other two chlorinated hydrocarbons give heavy precipita-tion. Paraffin oil is completely ineffective, even after 10 weeks, for protein Lpg2936 crystalliza-tion, while phase separation and heavy amor-phous precipitates are observed with the three chlorinated hydrocarbons.

a b c

Figure 4. α-lactalbumin trials: (a) Crystals under DCE. (b) Microcrystalline suspension under chloroform. (c)

8

Precipitation under DCM. Typical size of crystals in (a) is 200 x 150 x 50 µm.

The FC-70 fluorinated oil acts like paraffin oil, except for protein Lpg2936 for which it induced phase separation at conditions that had remained clear under paraffin oil. In that single case, its behavior was like that of the ‘intermediate’ DCE.In order to verify whether interfacial heteroge-neous nucleation is likely to influence the quality and/or properties of the grown crystals, we indica-tively collected data from three lysozyme crystals grown under DCM, at our laboratory X-ray source using Cu Kα radiation, at 100K. All the crystals diffracted to ca. 1.7 Å. A full 4.1-fold redundant dataset of one of them was collected to 1.85 Å (due to the detector geometry, although it did diffract usefully to 1.63 Å). The crystal belonged to tetragonal space group P43212, with unit cell dimensions a = b = 78.78 Å, c = 37.11 Å, as is typical for lysozyme crystals grown conventionally at similar conditions to ours. Molecular replacement was carried out using the HEWL structure with PDB code 1HEL. Re-

strained refinement gave a near-identical structure with final R and Rfree of 19.6% and 26.8% respectively, a very similar sol-vent structure and no extra density that would indicate bound organic solvent.To summarize, our experiments show that paraffin and FC-70 fluorinated oil are reluctant to assist 3D crystal nucleation, with dichloroethane being more effective in this respect, followed in order of effectiveness by the even more drastic chloro-form and dichloromethane. So, if the objective is to avoid heterogeneous 3D crystal nucleation as far as possible, paraffin oil is indeed a good choice, but if it is to harness the surface to help induce nucleation of crystals suitable for X-ray diffraction studies, a choice of intermediate effec-tiveness such as dichloroethane may prove opti-mal. Chloroform and, even more so, dichloro-methane, generally lead to precipitation, which seems to indicate an effect that is far too strong for the desired purposes. Furthermore, within the limitations imposed by our data, we have some corroboration of the theoretical view that for a “soft”protein, the hydrophobic interface effect should be much stronger.

Table 4. Overview of the crystallization trials results under hydrophobic liquids.

lysozyme α-lactalbu-min

trypsin Lpg2936 α-crustacy-anin

Insulinanalogue

Low high Low high

low high low high low high low high

paraffin 0 X 0 0 0 X 0 0 0 µX 0 XDCE 0 µX X ptt 0 ps ps ps µX ppt X ps

(light)DCM X ptt ptt ptt ps ps ptt ptt ppt ppt X ps+pt

t chloro-form

X µX µX ptt ps ps ptt ptt ppt ppt ps ps+ptt

FC-70 oil

0 X 0 - 0 - - ps - µX 0 X

X: crystals; µX: microcrystals/ microcrystalline suspension; ps: phase separation; ppt: amorphous precipi-tate. Results of trials at low and high supersaturations are shown.

4. CONCLUSIONS

Our approach takes into account the ordered structure of the protein crystal nuclei. By broad-ening the definitions of protein-to-water-affinity

(ψd) and crystal bonding energy (ψb), we consider heterogeneously formed two- and three-dimen-sional close packed crystal nuclei, which arise at an air/water solution interface and at water/hy-drophobic liquid interfaces, are considered. The main advantage of the present consideration is

9

its simplicity and adaptability. It operates solely with the ratio ψb/ψd, but not with their absolute values, which allows inclusion of the entropic con-tributions as well. Also, secondary effects, such as the "mechanical" segregation of protein and water molecules (like polyethylene glycols do), which is an effective reduction of the available water molecules but doesn't affect the affinity per se, or the reduction of the dielectric constant of water by some organic solvents, can be included in the ratio ψb/ψd.The theoretical consideration reveals the condi-tion for 2D crystal nucleation on hydrophobic in-terfaces, which is that the interaction between protein molecules and the interface must be somewhat weaker than the interactions in the protein crystal itself (see Section 3.2) - but not so weak as to exclude protein adsorption, i.e. ren-dering the surface ineffective for nucleation. A criterion showing whether the protein crystal nu-cleation at hydrophobic surfaces will be restricted to 2D (a monolayer of protein) or 3D nuclei is elaborated. The supersaturation dependences of the crystal nuclei sizes are derived.Hydrophobicity assisted protein crystal nucleation is regarded here as a two-step process. Simulta-neously, basic assumptions of classical nucleation theory (CNT) are used. Although frequently con-tested, CNT was confirmed by Yau and Vekilov,35

who observed that the pre-nucleation clusters were also crystalline and had the same molecular arrangement as the one found in mature crystals. Using cryo-TEM to image vitrified (at various time intervals) samples, Van Driessche et al. 36 investi-gated the earliest stages of glucose isomerase crystal nucleation, which in some cases proceeds according to CNT (also see 38). Moreover, al-though intuitively acceptable, the current formu-lation of the alternative two-step nucleation the-ory encounters experimental challenges (no inter-mediate condensed liquid droplets are ob-served).39 Our experimental results parallel some of our theoretical conclusions regarding the specificity of hydrophobicity assisted crystal nucleation. For instance, we observe that the hydrophobic liquids tested in this study increase either crystal hits or precipitation/ phase separation selectively, de-pending on the protein under investigation. For instance, lysozyme crystals appear at lower su-persaturations with the three chlorinated hydro-carbons that were used, than with paraffin oil. Also, precipitation or phase separation of the other proteins (α-lactalbumin, trypsin, insulin ana-logue and protein Lpg2936) appear most fre-quently by using the chlorinated hydrocarbons, meaning that they have a drastic effect, very different from that of paraffin oil.

To decide whether precipitation requires a differ-ent kind of nucleation, competing with the crystal nucleation phenomenon, we may recall the Ost-wald rule of stages, according to which the phase that nucleates first need not be the one that is thermodynamically most stable. Frequently, a metastable phase (namely the precipitate in the case under consideration) appears first, and it may then undergo a polymorphic form transition toward (another metastable phase and/or directly to) the stable phase.40,41 Amorphous precipitation, which is due to very strong hydrophobic protein-protein interactions, requires extremely high su-persaturation. Our theoretical model suggests that hydrophobic protein-to-oil interactions are strong enough to lead to protein adsorption. Then the growth of 2D or 3D protein crystals on the hydrophobic protein-to-oil interface depends on the degree of subsequent denaturation, itself depending on the hardness or softness of the protein molecule structure.The direct application of the reported results for growing crystals of newly expressed proteins, is to probe a range of hydrophobic liquids as auxil-iary crystallization agents that can work in one of two ways: either to promote nucleation of crystals where they would not normally grow, or to sup-press excessive nucleation leading to higher qual-ity crystals for structure determination. In the first instance, when an initial crystallization screen (microbatch under paraffin oil, or any other technique) yields no crystalline material or yields material that cannot be subsequently opti-mized, the screen can be repeated in microbatch using, instead of paraffin oil, a nucleation-promot-ing hydrophobic liquid. This will ‘reveal’ metastable screen conditions that would have otherwise remained clear and be ignored. In the second instance, optimization trials can be set up at lower supersaturation (metastable) conditions, relying on the oil interface to induce nucleation. Analogous ideas have been successfully applied before, using heterogeneous nucleants instead of oil interfaces (e.g. 42). Furthermore, we observe that hydrophobic surfaces can also lead to the quick production of large numbers (‘showers’) of microcrystals (Section 3.3, Table 4 and Figure 5). A steady and uniform supply of micro- or nanocrystals is required for free-electron X-ray laser (XFEL) time-resolved crystallography, and growing such crystals is often not trivial. Although the use of hydrophobic surfaces has not here been targeted or optimized for such use and does not at present meet the stringent requirements of XFEL, it may prove an avenue to be explored in the future.

5. METHODS

10

Proteins. Hen egg-white lysozyme (MW 14.3 kDa, Sigma L7651) was prepared in 50 mM so-dium acetate pH 4.5. Trypsin (MW 23.8 kDa, Sigma T9201) from bovine pancreas was pre-pared in 10 mg/ml benzamidine hydrochloride, 10 mM calcium chloride and 20 mM HEPES pH 7.0. α-lactalbumin (MW 14.2 kDa, Sigma L5385) was prepared in 10 mM Tris-HCl pH 8.5. The above commercially available proteins were used without additional purification. α-crustacyanin (MW 320kDa) was provided by Dr Peter Zagalsky of Royal Holloway University of London, and pre-pared in 0.1 M Tris-HCl pH 7.0, 1 mM EDTA and 10 mM sodium chloride. The insulin analogue (MW 5.8 kDa) was provided by the research group of Dr Gary Adams, University of Nottingham in Bis-Tris pH 5.5, protein Lpg2936 (MW 27.3 kDa) was provided by Dr Nikos Pinotsis, in 25mM Tris pH 8.0 and 150mM NaCl. The above proteins were provided already purified to a degree suitable for crystallographic work. Purification of Lpg2936 is detailed in 43.Reagents. All reagents were of analytical grade. Chloroform (372978), dichloromethane (66742) and dichloroethane (284505) were obtained from Sigma Aldrich, and paraffin oil (294365 H) from BDH, UK. Polyethylene glycol (PEG) 8000 was purchased from Sigma-Aldrich UK, and PEG 5000 monomethyl ether (MME) from Fluka Chemicals Ltd. The Alcohols Mix and MES/Imidazole buffer system were purchased from Molecular Dimen-sions Ltd. All solutions were freshly prepared, using Milli-Q water (Barnstead Nanopure, Thermo Scientific). PEG 8000, PEG 5000 MME and all pro-tein stock solutions were kept at 4° C. Salt and buffer stock solutions as well as the hydrophobic liquids were kept at room temperature for the duration of the study. Experimental setup. Drops of protein solutions containing the corresponding precipitating agents for their crystallization were dispensed under the hydrophobic liquids. The drops always remained under the oil layer, thus never coming into direct contact with air after their dispensing. 2.5 µl of each protein stock solution was mixed with 2.5 µl of buffer plus precipitating agent to their final concentrations, and the resulting drops were in-cubated under 50µl of hydrophobic liquid at 20 ° C in Chromacol 300µl fixed insert vials (Thermo Scientific, Figure 5a). All trials were observed ev-ery 24 hours for a two-week period and subse-quently once every week for up to 10 weeks. Each experiment was set up at least in triplicates, and was highly reproducible. A “clear drop” result is reported only if all trials at the given condition resulted in clear drops within the timescale of the experiment. Where crystals did appear, the final size and number of crystals and the time of ap-pearance of the first crystals slightly varied between trials at the same condition, but gener-

ally not the final outcome (clear drop, crystals, phase separation, precipitation). Therefore, whenever a time of appearance of crystals (or precipitate) is given in Section 3.3, it refers to the time when crystals (precipitate) became visible in the earliest drop at that condition that yielded crystals (precipitate). Thanks to the high overall reproducibility however, the general outcomes given in Table 4 represent not a statistical aver-age, but the result in all the drops incubated at the corresponding condition. To check that the reported observations were indeed due to interfacial hydrophobic effects, rather than to different permeabilities of the oils for the aqueous crystallization solutions and therefore different rates of concentration of the drops via slow evaporation through the oils, we performed the following checks. First, the dia-meter of the drops under the various oils (one drop per protein/oil combination), as seen through a standard stereoscope, was monitored for six weeks after setup. Each of the monitored drops kept the same diameter throughout that period to the attainable accuracy of the stereo-scopic observation, even after crystals or precipit-ate appeared in the drop (Supporting Information Table S1). Second, drops yielding crystals were carefully observed through the stereoscope in order to assess whether the crystals appeared at the oil/solution interface or in the solution bulk. We could observe that crystals were localised at the oil/solution interface, as opposed to controls set up without oil. In the latter, crystals were vis-ible throughout the drop, with a clear tendency to sediment at its bottom. In the cases where phase separation or amorphous precipitation occurred, these were also observed to form at the oil/solu-tion interface. All these trials were difficult to pho-tograph due to the geometry of the crystallization vial and the small volumes of liquid involved (Fig-ure 5b and c).Crystallization conditions. Conditions for the model proteins used in this study are widely re-ported in the literature. Not only are there many published X-ray structures for these proteins, but several laboratories, including ours, consistently use these proteins for systematic work on crystal nucleation, and have therefore identified not only crystallisation but also undersaturated, meta-stable and amorphous precipitation condi-tions.44,45 As reproducibility, even between com-mercially produced protein samples (but also buffers, incubation temperatures etc), is never perfect, working crystallization phase diagrams46

of these proteins, as well as for the insulin ana-logue and Lpg2936 (based on initial crystal ‘hits’ and on 30), were established at the outset of this study. Different supersaturation levels were tested against the various oils. “Low supersatura-tion” refers to conditions that always gave clear

11

drops in the controls (under paraffin oil), but higher supersaturations were also tested to provide a more complete picure of the effects of the oils. The selected tested conditions are as follows: Lysozyme: 0.15 M NaCl (low supersatura-tion) to 0.35 M NaCl (high supersaturation), 25 mg/ml protein, 75 mM sodium acetate pH 4.5. α-lactalbumin: 0.5 M ammonium sulphate, 5 mg/ml protein, 50 mM Bis Tris pH 6.5 (low supersatura-tion) to 1.0 M ammonium sulphate, 10 mg/ml protein, 50 mM Bis Tris pH 6.5 (high supersatura-tion). Trypsin: 6 % PEG 8000 (low supersatura-tion) to 8.5 % PEG 8000 (high supersaturation), 50 mg/ml protein, 50 mM Tris pH 7.5. Protein Lpg2936: 6 % PEG 8000 and 12 % ethylene glycol (low), to 12 % PEG 8000 and 24 % ethylene glycol (high), 0.07 M each of a mixture of alcohols (1,6-Hexanediol; 1-Butanol; 1,2-Propanediol; 2-Pro-panol; 1,4-Butanediol; 1,3-Propanediol) and 50 mM MES/Imidazole at pH 6.5. α-crustacyanin: 7.5 % PEG 5000 MME, 5 mg/ml protein, 0.1 M ammo-nium sulphate, 50 mM MES pH 6.5 (low supersat-uration) to 15 % PEG 5000 MME, 19 mg/ml pro-tein, 0.1 M ammonium sulphate, 50 mM MES pH 6.5 (high supersaturation).X-ray diffraction. Diffraction data from crystals were collected at the laboratory Rigaku Micromax 007HF-M X-ray source, equipped with a Rigaku Saturn 944+ CCD detector and an Oxford Cryosystems 700 cryostream. The collected dataset (120 images, 0.5°/image) was processed with Mosflm and scaled with Scala. The lysozyme structure was solved, for comparison with the already published structures, using Molrep and refined with Refmac5. All the software used was from the CCP4 suite 47.

a b c

Figure 5: a. The experimental setup, showing a Chromacol vial with protein solution (blue α-crus-tacyanin) under a layer of hydrophobic liquid. b. Lysozyme crystals in the bulk of a solution without an oil layer. c. Lysozyme crystals at the DCE oil-solu-tion interface. The crystallization conditions in b and c were identical high supersaturation conditions.

ASSOCIATED CONTENT Supporting Information. Appendix: Algorithm for successive detachment of molecules from a cluster (PDF).This material is available free of charge via the Inter-net at http://pubs.acs.org.

AUTHOR INFORMATIONCorresponding Author* [email protected]

ORCID Christo Nanev 0000-0003-0678-737XEmmanuel Saridakis: 0000-0003-0724-5425Lata Govada: 0000-0002-8077-0480Sean Kassen: 0000-0003-2218-2397Hodaya Solomon: 0000-0002-0122-6744Naomi Chayen: 0000-0003-2861-2458

Author ContributionsC.N.N. contributed the theoretical part of the work with input from E.S. and N.E.C., L.G. performed the bulk of the experi-ments, S.C.K. and H.V.S. performed some experiments. N.E.C. and E.S. analyzed the results. C.N.N., E.S. and N.E.C. wrote the manuscript. ‡ C.N.N and E.S. contributed equally.

12

NotesThe authors declare no competing financial interest.

ACKNOWLEDGMENTS The authors thank Dr Peter Zagalsky, Dr Nikos Pinto-sis and the research group of Dr Gary Adams, Uni-versity of Nottingham for providing proteins and acknowledge networking support by the COST Ac-tion CM1402 Crystallize. C.N.N. acknowledges co-fi-nancing by the National Science Fund of the Bulgar-ian Ministry of Science and Education, contract DCOST 01/22.

REFERENCES1. Chayen, N. E. The Role of Oil in Macromolecular

Crystallization. Structure 1997, 5, 1269-1274.2. Babor, M.; Nievergelt, P. P.; Čejka, J.; Zvoníček, V.;

Spingler, B. Microbatch Under-Oil Salt Screening of Organic Cations: Single-crystal Growth of Active Phar-maceutical Ingredients. IUCrJ 2019, 6, 145–151.

3. Kashchiev, D. Nucleation, Basic Theory with Applic-ations. Butterworth-Heinemann, 2000.

4. Kelton, K. F.; Greer, A. L. Nucleation in Condensed Matter, Applications in Materials and Biology. Elsevier, 2010.

5. Nanev, C. N. Recent Insights into Protein Crystal Nucleation. Crystals 2018, 8, 219.

6. Silver, B. R.; Fülöp, V.; Unwin, P. R. Protein Crystal-lization at Oil/water Interfaces. New J. Chem. 2011, 35, 602–606.

7. Silver, B.R. New Approaches to Protein Crystalliza-tion. Ph.D. Thesis [Online], University of Warwick, 2013. http://go.warwick.ac.uk/wrap/55616.

8. Tsekova, D.; Dimitrova, S.; Nanev, C. N. Heterogeneous Nucleation (and Adhesion) of Lysozyme Crystals. J. Crystal Growth 1999, 196, 226-233.

9. Postel, C.; Abillon O.; Desbat, B. Structure and Denaturation of Adsorbed Lysozyme at the Air–water Interface. J. Colloid Interface Sci. 2003, 266, 74-81.

10. Jia, Y.; Liu, X.-Y. From Surface Self-Assembly to Crystallization: Prediction of Protein Crystallization Con-ditions. J. Phys. Chem. B 2006, 110, 6949-6955.

11. Yoshimura, H. Protein-assisted Nanoparticle Syn-thesis. Colloids Surf. A: Physicochem. Eng. Aspects 2006, 282-283, 464-470.

12. Azadani, A. N.; Lopez, J. M.; Hirsa, A. H. Protein Crystallization at the Air/Water Interface Induced by Shearing Bulk Flow. Langmuir 2007, 23, 5227-5230.

13. Beverung, C. J.; Radke C. J.; Blanch, H. W. Protein Adsorption at the Oil/water Interface: Characterization of Adsorption Kinetics by Dynamic Interfacial Tension Measurements. Biophys. Chem. 1999, 81, 59-80.

14. Hunter, J. R.; Kilpatrick, P. K.; Carbonell, R. G. Lysozyme Adsorption at the Air/Water Interface. J. Col-loid Interf. Sci. 1990, 137, 462- 482.

15. Walstra P.; De Roos, A. L. Proteins at Air-Water and Oil-Water Interfaces: Static and Dynamic Aspects. Food Rev. Int. 1993, 9, 503-525.

16. Alahverdjieva, V. S.; Fainerman, V. B.; Aksenenko, E. V.; Leser. M. E.; Miller, R. Adsorption of Hen Egg-White Lysozyme at the Air–Water Interface in Presence of Sodium Dodecyl Sulphate. Colloids Surf. A: Physic-ochem. Eng. Aspects 2008, 317, 610–617.

17. Bergfreund, J.; Bertsch, P.; Kuster, S.; Fischer, P. Effect of Oil Hydrophobicity on the Adsorption and Rhe-

ology of β-Lactoglobulin at Oil–Water Interfaces. Lang-muir 2018, 34, 4929–4936.

18. Chandler, D. Hydrophobicity: Two Faces of Water. Nature 2002, 417, 491.

19. Despa, F.; Berry, R. S. The Origin of Long-Range Attraction between Hydrophobes in Water, Biophys. J. 2007, 92, 373-378.

20. Graham D. E.; Phillips, M. C. Proteins at Liquid Interfaces: II. Adsorption Isotherms. J. Colloid Interface Sci. 1979, 70, 415-426.

21. Rao C. S.; Damodaran, S. Is Surface Pressure a Measure of Interfacial Water Activity? Evidence from Protein Adsorption Behavior at Interfaces. Langmuir 2000, 16, 9468-9477.

22. Freer, E. M.; Yim, K. S.; Fuller, G. G.; Radke, C. J. Interfacial Rheology of Globular and Flexible Proteins at the Hexadecane/Water Interface: Comparison of Shear and Dilatation Deformation. J. Phys. Chem. B 2004, 108, 3835-3844.

23. Yano, Y. F. Kinetics of Protein Unfolding at Inter-faces. J. Phys.: Condens. Matter 2012, 24, 503101.

24. Ravichandran, S. Madura, J. D. Talbot, J. A Brown-ian Dynamics Study of the Initial Stages of Hen Egg-White Lysozyme Adsorption at a Solid Interface. J. Phys. Chem. B 2001, 105, 3610–3613.

25. Garcia-Ruiz, J. M. Nucleation of Protein Crystals. J. Struct. Biol. 2003, 142, 22–31.

26. Although the supersaturation dependence of nucleus size is here intentionally ignored, this approach nevertheless accounts for the most basic fact that, depending on their surface positions, the crystal build-ing blocks are connected with different strengths to the crystal. The building blocks at the crystal corners are connected most loosely; they are pulled by water mole-cules towards the solution from three (perpendicular) directions. The crystal building blocks at the crystal edges are connected intermediately; they are pulled away from two directions. The strongest connection is that of the crystal building blocks on the crystal face; those are pulled away from one direction only.

27. Jun, Y.-S.; Kim, D.; Neil, C. W. Heterogeneous Nuc-leation and Growth of Nanoparticles at Environmental Interfaces. Acc. Chem. Res. 2016, 49, 1681−1690.

28. As is well known, the change of the Gibbs free energy of crystallization, ΔGcryst does not depend on the process path, i.e. on whether classical nucleation the-ory or the two-stage mechanism applies; it depends on the initial and final stage of the system only.

29. Nanev, C. N. Saridakis, E. Chayen, N. E. Protein Crystal Nucleation in Pores. Sci. Rep. 2017, 7, 35821; doi: 10.1038/ srep35821.

30. Vekilov P. G.; Chernov, A. A. The Physics of Protein Crystallization. Solid State Physics 2003, 57, 1-147.

31. Vekilov, P. G. What Determines the Rate of Growth of Crystals from Solution? Cryst. Growth Des. 2007, 7, 2796–2810.

32. Nanev, C. N. On Some Aspects of Crystallization Process Energetics, Logistic New Phase Nucleation Ki-netics, Crystal Size Distribution and Ostwald Ripening. J. Appl. Cryst. 2017, 50, 1021-1027.

33. Sleutel, M.; Maes, D.; Van Driessche, A. What Can Mesoscopic Level IN SITU Observations Teach us About Kinetics and Thermodynamics of Protein Crystallization? In Kinetics and Thermodynamics of Multistep Nucleation and Self-Assembly in Nanoscale Materials : Advances in Chemical Physics Vol. 151; Nicolis, G.; Maes, D., Ed.; John Wiley, 2012; pp 223-276.

13

34. Hunter, J. R.; Kilpatrick, P. K.; Carbonell, R. G. Lysozyme Adsorption at the Air/Water Interface. J. Col-loid Interface Sci. 1990, 137, 462-482.

35. Yau, S.-T.; Vekilov, P. G. Quasi-planar Nucleus Structure in Apoferritin Crystallization. Nature 2000, 406, 494-497.

36. Van Driessche, A. E. S.; Van Gerven, N.; Bomans, P. H. H.; Joosten, R. R. M.; Friedrich, H.; Gil-Carton, D.; Sommerdijk, N. A. J. M.; Sleutel, M. Molecular Nucleation Mechanisms and Control Strategies for Crystal Poly-morph Selection. Nature 2018, 556, 89-94.

37. Gerard, C. J. J.; Ferry, G.; Vuillard, L. M.; Boutin, J. A.; Ferte, N.; Grossier, R.; Candoni, N.; Veesler, S. A Chemical Library to Screen Protein and Protein-ligand Crystallization Using a Versatile Microfluidic Platform. Cryst. Growth Des. 2018, 18, 5130-5137.

38. Sleutel. M; Van Driessche, A. E. S. Nucleation of Protein Crystals - A Nanoscopic Perspective, Nanoscale 2018, Advance Article; DOI: 10.1039/C8NR02867B.

39. Yamazaki, T.; Kimura, Y.; Vekilov, P. G.; Furukawa, E.; Shirai, M.; Matsumoto, H.; Van Driessche, A. E. S.; Tsukamoto, K. Two Types of Amorphous Protein Particles Facilitate Crystal Nucleation. Proc. Natl. Acad. Sci. USA 2017, 114, 2154–2159.

40. Ostwald, W. Studien über die Bildung und Umwandlung fester Körper. Z. Phys. Chem. 1897, 22, 289-330.

41. Nývlt, J. The Ostwald Rule of Stages. Cryst. Res. Technol. 1995, 30, 443–449.

42. Saridakis, E.; Khurshid, S.; Govada, L.; Phanc, Q.;, Hawkins, D.; Crichlow, G.V.; Lolis, E.; Reddy, S.M.; Chayen, N.E. Protein Crystallization Facilitated by Molecularly Imprinted Polymers. Proc. Natl. Acad. Sci. USA 2011, 108, 11081-11086.

43. Pinotsis, N.; Waxsman, G. Crystal Structure of the Legionella pneumophila Lpg2936 in Complex with the Cofactor S-adenosyl-L-methionine Reveals Novel In-sights into the Mechanism of RsmE Family Methyltrans-ferases. Protein Sci. 2017, 26, 2381-2391.

44. Chayen, N. E.; Saridakis, E; El-Bahar, R.; Ne-mirovsky, Y. Porous Silicon: an Effective Nucleation-in-ducing Material for Protein Crystallization. J. Mol. Biol. 2001, 312, 591-595.

45. Chayen, N. E.; Saridakis, E.; Sear, R. P. Experi-ment and Theory for Heterogeneous Nucleation of Pro-tein Crystals in a Porous Medium. Proc. Natl. Acad. Sci. USA 2006, 103, 597-601.

46. Saridakis, E.; Chayen, N. E. Systematic Improve-ment of Protein Crystals by Determining the Supersolu-bility Curves of Phase Diagrams. Biophys. J. 2003, 84, 1218-1222. 47. Winn, M. D.; Ballard, C. C.; Cowtan, K. D.; Dodson, E. J.; Emsley, P.; Evans, P. R.; Keegan, R. M.; Krissinel, E. B.; Leslie, A. G.; McCoy, A.; McNicholas, S. J.; Murshu-dov, G. N.; Pannu, N. S.; Potterton, E. A.; Powell, H. R.; Read, R. J.; Vagin, A.; Wilson, K. S. Overview of the CCP4 Suite and Current Developments. Acta. Crystal-logr. 2011, D67, 235-242.

14

SYNOPSIS TOC

15