Technical Specification Airslide Analyzer · Page 1 of 5 Technical Specification 1. SpectraFlow...

Transcript of Technical Specification Airslide Analyzer · Page 1 of 5 Technical Specification 1. SpectraFlow...

Page 1 of 5

Technical Specification

1. SpectraFlow Airslide Analyzer for raw meal behind the raw mill

The SpectraFlow Airslide Analyzer is an online measurement system for the cement and minerals industries. When used on an airslide behind the raw mill in the cement plant, it provides the chemical analysis of the raw meal. This analysis is the base to control in real-time the additives to the raw material, which is fed into the raw mill.

The SpectraFlow system consists of two major hardware components:

a. The illumination head including the spectrometer, and b. the control unit containing the industrial PC, heating and cooling system,

and the power supply.

Requirements of the airslide: a. The width of the airslide has to be in minimum 300mm. b. During normal operation the condition inside the airslide has to be in low-

pressure.

2. Near Infrared Technology

Near Infrared (NIR) technology utilizes the full wide range of infrared spectra which are provided by light lamps. Their emitted NIR radiation hits the target raw meal to be analyzed as it passes through the airslide. This NIR radiation excites vibrational oscillations of the molecular bonds in the monitored material, which results in reflection and absorption spectra that are characteristic for the analyzed constituents. Figure 1 shows a typical set of absorbance spectra, received from limestone after the raw mill.

Figure 1: A typical wide range infrared spectrum

Page 2 of 5

3. SpectraFlow Illumination Head

The complete NIR spectrum, which is needed to perform the online chemical analysis, is supplied by a set of light sources. These lights emit the NIR radiation, which is used for the analysis. The infrared light reflected by the moving bulk material gets collected by a Fourier Transform Infrared (FTIR) Spectrometer in the center of the illumination system (Figure 2).

Figure 2: Basic principle of the SpectraFlow illumination system

The FTIR spectrometer is used to generate the absorbance spectra output because it defines each single spectrum in one step. This also means it is extremely stable and calibration models can be easily transferred from one spectrometer to the other in case of spectrometer maintenance.

The FTIR spectrometer used can utilize much more of the reflected NIR radiation than a standard dispersive NIR Spectrometer and it is mechanically extremely robust. The FTIR spectrometer does not need any electric motor. A periodically excited electromagnet is sufficient. This feature ascertains an extremely stable measurement performance.

A frequent alignment to a white reference is also no necessary. As the environmental conditions inside the airslide are extremely stable the performance of an external white reference once a year during the annual maintenance stop is sufficient.

The analyzer is placed above a rectangular opening in the airslide. The light and dust shield of the analyzer covers completely the airslide. The dust shield makes it impossible for the raw meal to exhaust the entry providing that the airslide is operated properly and overpressure does not create a backdraft. If the airslide stops working, a feed dog automatically closes the entrance to the airslide. Figure 2 and 3 show the dust and light shield for the airslide application.

Raw Meal

Lamps

Light and dust shield

FTIR Spectrometer

Page 3 of 5

Figure 3: Picture of the opened SpectraFlow illumination head

4. SpectraFlow Calibration Model

In order to run properly the SpectraFlow analyzer and getting the accurate measurement results about the chemical composition of the analyzed bulk raw meal, a calibration model is needed, which performs the transformation of the received spectra into chemical concentrations (see Figure 4).

Figure 4 Example of a Calibration Model for CaO

Spectrometer entry

Lamps

Box with FTIR Spectrometer

Light and dust shield

Control cabinet

Page 4 of 5

The SpectraFlow analyzer system is delivered with a customized calibration models for the appropriate application. To build the calibration model well analyzed samples have to be provided to SpectraFlow Analytics approximately 8 weeks before the intended shipping date.

A detailed description on how to prepare the samples is given in document “E. Procedure to Prepare the Calibration Samples”

After the calibration of the FTIR spectrometer SpectraFlow Analytics provides a final dynamic performance guarantee for the SpectraFlow analyzer. A semi-dynamic factory acceptance test can be done at that stage described in document “D. Guarantees Airslide Analyzer”

After the installation of the SpectraFlow analyzer system the online results are compared with the laboratory XRF results and the calibration model is optimized for the specific customer ranges. This crosschecks and improves the accuracy of the reported analyzed components.

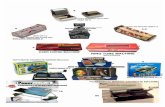

5. Control Unit

Inside the control unit, a dual core Industrial PC (IPC) is running: On one core runs a soft PLC, which controls and supervises the complete analyzer. On the other core runs the basic spectral data handling software. The SpectraFlow Client Software with the Graphical User Interface (GUI) is installed on a second PC either in the control room or in the laboratory that is connected to the same network. On this PC the concentration of the constituents is actually determined. Figure 5 shows some the SpectraFlow GUI screenshots.

Figure 5 Examples of SpectraFlow GUI screenshots

A maximum benefit of a SpectraFlow analyzer can be gained when the analyzer is used together with a Raw Mix Proportioning (RMP) control software. The software package can be provided from any supplier as long as this control software is installed either on the same network, in this case the analysis results are transferred as ASCII text files via TCP/IP, or the SpectraFlow Analyzer is connected to the Profibus-DP bus of the plant and the control software has access to these values over e.g. OPC.

Page 5 of 5

Light and dust shield

Airslide PLC/IPC

DC power supply for the lamps

Spectrometer box Control cabinet

Complete installation Control cabinet opened

6. Installation

The installation of the SpectraFlow analyzer system is quick and easy. Figure 6 shows a typical arrangement of the SpectraFlow airslide analyzer installation (see document “B. Scope of Supply”). The dust and light protection is mounted to the actual airslide diameter and the height of the analyzer above. A heating and cooling system provides the right working ambient of the measurement components.

The SpectraFlow illumination head does not need to be installed perfectly horizontal. In case the airslide is slanted, the SpectraFlow head can be installed directly on the airslide and its exact position (see left-side pictures of figure 6). For the operation of the SpectraFlow analyzer, the supplies is listed in document scope of supply must be provided by customer (see document “B. Scope of Supply: Supply needed from others”).

A separate frame support or wall is needed to mount the control cabinet containing the power supply, the communication electronics and the IPC. The total weight including all components is approximately 180 kg.

Figure 6 Typical SpectraFlow Airslide installation

Total installation time, testing of the integrated system, and communication verification require only a few days, if everything for erection is well prepared by customer. After the successful installation, the SpectraFlow analyzer system is ready to use.

![Application Example 09/2016 Exchange of large data volumes ...€¦ · Raw[3] Raw[4] GetTagRawWait Tag Raw R_ID Raw[0] Raw[1] Raw[2] Raw[3] Raw[4] SetTagRawWait. 3 Basic information](https://static.fdocuments.in/doc/165x107/5f1fce0444607025af2e69fc/application-example-092016-exchange-of-large-data-volumes-raw3-raw4-gettagrawwait.jpg)