Technical Memorandum Scholefield Tailings and McCleary … · 2019-12-14 · Storage Area and Dry...

Transcript of Technical Memorandum Scholefield Tailings and McCleary … · 2019-12-14 · Storage Area and Dry...

Tucson Office 3031 West Ina Road

Tucson, AZ 85741 Tel 520.297.7723 Fax 520.297.7724

www.tetratech.com

Technical Memorandum

Scholefield Tailings and McCleary Waste Alternative Noise Analysis

To: Kathy Arnold From: Robert Sculley

Company: Rosemont Copper Company Date: January 15, 2010

CC: Jamie Sturgess (Rosemont); David Krizek; Michael Dieckhaus (Tt)

Doc #: 024/10-320871-5.3

1.0 Introduction This Technical Memorandum was prepared by Tetra Tech and presents a Noise Analysis for the Scholefield Tailings and McCleary Waste Alternative being considered in the US Forest Service Environmental Impact Statement (EIS) for the proposed Rosemont Copper Project (Project). This analysis assesses the potential impacts that the Scholefield Tailings and McCleary Waste Alternative would have on noise conditions.

Tetra Tech published a comprehensive Supplemental Noise Study Report in April of 2009 that was based on the facility layouts in the Mine Plan of Operations (MPO). The Noise Study provided data on existing noise levels in the vicinity of the Project and noise levels measured at an active copper mine such as blasting and other operational activities. Modeling of the blasting vibrations was also performed. Noise effect contouring in the April 2009 study was based on the MPO facility layouts.

The following provides a comparison between the MPO and the Scholefield Tailings and McCleary Waste Alternative facility layouts:

The top surface of the Dry Stack Tailings Facility would be about 5,250 feet above mean sea level (amsl) for the MPO, and about 5,400 feet amsl for the Scholefield Tailings and McCleary Waste Alternative. The Dry Stack Tailings Facility for Scholefield Tailings and McCleary Waste Alternative would have a footprint of about 1,215 acres compared to 870 acres under the MPO.

The top surface of the Waste Rock Storage Facility would be about 5,450 feet amsl for the MPO. The Scholefield Tailings and McCleary Waste Alternative would have a Waste Rock Storage Area with a top elevation of 5,500 feet amsl. The footprint of the

Transmittal of Technical Memoranda and Pit Lake Report

February 8, 2010

To: Beverly Everson

Cc: Tom Furgason

From: Kathy

Doc #: 003/

Subject:

Date:

OSEMONT COPPER A Bridge to a Sustainable Future.

Memorandum

Rosemont Copper is pleased to transmit the following twenty technical memoranda and one report:

1. Rosemont Hydrology Method Justification, a Tetra Tech memo dated January 7, 2010; 2. Barrel Only alternative —

a. Noise Analysis, a Tetra Tech memo dated January 15, 2010 b. Traffic Analysis, a Tetra Tech memo dated January 8, 2010

c. Geochemical Characterization 'of Facilities, a Tetra Tech memo dated January 10, 2010 d. Lighting, an M3 memo dated December 2009

3. Barrel and McCleary alternative —

a. Noise Analysis, a Tetra Tech memo dated January 9, 2010 b. Traffic Analysis, a Tetra Tech memo dated December 15, 2009

c. Geochemical Characterization of Facilities, a Tetra Tech memo dated December 16, 2009

d. Lighting, an M3 memo dated December 2009

4. Scholefield Tailings and McCleary Waste alternative —

a. Noise Analysis, a Tetra Tech memo dated January 15, 2010

b. Traffic Analysis, a Tetra Tech memo dated January 12, 2010

c. Geochemical Characterization of Facilities, a Tetra Tech memo dated January 10, 2010

d. Lighting, an M3 memo dated January 2010

5. Sycamore Tailings and Barrel Waste alternative —

a. Noise Analysis, a Tetra Tech memo dated January 15, 2010

b. Traffic Analysis, a Tetra Tech memo dated January 9, 2010

c. Geochemical Characterization of Facilities, a Tetra Tech memo dated January 10, 2010

d. Lighting, an M3 memo dated January 2010

6. Partial Backfill alternative —

a. Noise Analysis, a Tetra Tech memo dated January 23, 2010

b. Traffic Analysis, a Tetra Tech memo dated January 9, 2010

c. Geochemical Characterization of Facilities, a Tetra Tech memo dated January 10, 2010

7. Geochemical Pit Lake Predictive Model, prepared by Tetra Tech and dated February 2010

As per your request, I am transmitting three hardcopies and two disks (disks contain tech memos only) directly to the Forest Service and two copies and one disk directly to SWCA. The Pit Lake report includes

a copy of the report on a CD on the inside of the back cover of each report.

2

Waste Rock Storage Area would be about 1,300 acres under the Scholefield Tailings and McCleary Waste Alternative, compared to 2,000 acres for the MPO.

The Heap Leach Pad for the MPO would be constructed in two (2) phases. The leach pad for the Scholefield Tailings and McCleary Waste Alternative would be constructed in a single phase and would have a smaller total footprint than under the MPO. Under the MPO, the closed heaps would eventually be covered with waste rock within the Waste Rock Storage Area. Under the Scholefield Tailings and McCleary Waste Alternative, the heap is a stand-a-lone facility. Closure of the heap would include regrading prior to placement of a closure cover.

Under the Scholefield Tailings and McCleary Waste Alternative the combined footprints of the Waste Rock Storage Area and Dry Stack Tailings Facility (about 2,515 acres) would be somewhat smaller than the combined footprints under the MPO (about 2,870 acres). The location and shape of the combined Waste Rock Storage Area and Dry Stack Tailings Facility, under the Scholefield Tailings and McCleary Waste Alternative, would be quite different from the combined footprint under the MPO. Under this alternative, the Waste Rock Storage Area and the Dry Stack Tailings Facility would both be located northeast of the Plant Site.

The location and size of the Open Pit would be the same under both the MPO and the Scholefield Tailings and McCleary Waste Alternative.

Under the Scholefield Tailings and McCleary Waste Alternative, the Plant Site facilities would have a slightly different configuration and footprint than under the MPO.

The Scholefield Tailings and McCleary Waste Alternative would have a different Primary Access Road alignment than that proposed in the MPO. The Primary Access Road for the Scholefield Tailings and McCleary Waste Alternative would join State Route 83 (SR 83) about one (1) mile south of the location proposed for the MPO.

The differences between the Scholefield Tailings and McCleary Waste Alternative and the MPO are primarily differences in the location and shape of the Waste Rock Storage Area and the Dry Stack Tailings Facility. Other features of this alternative are similar to those proposed for the MPO. Consequently, most of the noise and vibration impact discussions, and the associated noise contour figures in the April 2009 Noise Study, are applicable to the Scholefield Tailings and McCleary Waste Alternative. Differences in the location and shape of the combined Waste Rock Storage Area and Dry Stack Tailings Facility would, however, result in changes in the potential locations for equipment operations under this alternative.

The following sections of this Technical Memorandum explain which results of the April 2009 Noise Study are still applicable to the Scholefield Tailings and McCleary Waste Alternative, including which results would change under this alternative.

3

2.0 Blast Noise and Blast Vibration Impacts The Open Pit would be in the same location and operated in the same manner under both the MPO and the Scholefield Tailings and McCleary Waste Alternative. Blasting events would be limited to one (1) event per day. Daily explosives usage is also expected to be the same under both scenarios.

In addition, differences in the location, maximum height, and shape of the combined footprints of the Waste Rock Storage Area and the Dry Stack Tailings Facility would produce only minor localized shielding differences for blast noise under the MPO and the Scholefield Tailings and McCleary Waste Alternative. For in-pit blasting in particular, the pit walls would provide much more effective terrain shielding than would the Waste Rock Storage Area and Dry Stack Tailing Facility. Blast noise effects at the closest noise-sensitive receptor locations would not be significantly affected by differences in the location, shape, or height of the combined footprints of the Waste Rock Storage Area and the Dry Stack Tailings Facility under the MPO and the Scholefield Tailings and McCleary Waste Alternative.

Because blasting events would be similar under both the MPO and the Scholefield Tailings and McCleary Waste Alternative, groundborne vibrations would also be the same. Thus, the discussions and associated noise contour figures for blast noise and blast-related vibrations, as presented in the April 2009 Noise Study, would be applicable to the Scholefield Tailings and McCleary Waste Alternative.

3.0 Construction Noise Impacts Although the Plant Site would still be in the same general area, under the Scholefield Tailings and McCleary Waste Alternative, the Plant Site facilities would have a slightly different configuration and footprint than that of the MPO. However, there would be little if any difference in the construction activity noise levels between the MPO and the Scholefield Tailings and McCleary Waste Alternative. As noted in the April 2009 Noise Study, construction noise levels would attenuate to background noise levels over a relatively short distance and would not create any noise impacts at the nearest existing residences. Therefore, the discussions and associated noise contour figure for construction noise impacts presented in the April 2009 Noise Study would be applicable to the Scholefield Tailings and McCleary Waste Alternative.

4.0 Equipment Operation Noise Impacts As discussed in the April 2009 Noise Study, operational noise levels from the Plant Site area would be similar to the maximum construction noise levels. Operational noise levels are expected to attenuate to background noise levels over a distance of about two (2) miles and would therefore not create any noise impacts at the nearest existing residences or along SR 83.

As indicated in Section 1.0, the combined footprints of the Waste Rock Storage Area and Dry Stack Tailings Facility under the Scholefield Tailings and McCleary Waste Alternative (about 2,515 acres) would be somewhat smaller than the combined footprints under the MPO (about 2,870 acres). Maximum elevations of these facilities would be somewhat higher under the

4

Scholefield Tailings and McCleary Waste Alternative than under the MPO. The most important differences between the MPO and the Scholefield Tailings and McCleary Waste Alternative would be the location and shape of the combined Waste Rock Storage Area and Dry Stack Tailings footprints. In addition, the Heap Leach Facility would be separated from the Waste Rock Storage Area and Dry Stack Tailings Facility under the Scholefield Tailings and McCleary Waste Alternative.

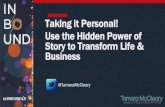

Figure 1 presents operational equipment noise contours for the Scholefield Tailings and McCleary Waste Alternative. Actual noise generation by equipment working on the Waste Rock Storage Area and the Dry Stack Tailings Facility would be the same as for the MPO, but potential equipment locations would be different due to differences in the facility footprint.

Haul trucks and other equipment working at the southern end of the Waste Rock Storage Area would be in a location about 2.75 miles further north than under the MPO. Compared to the MPO, the Waste Rock Storage Area under the Scholefield Tailings and McCleary Waste Alternative would be further from homes along Singing Valley Road, but somewhat closer to homes along State Route 83 (SR 83) to the northeast of the Project area. Figure 1 shows the noise contours for equipment operating at the south end of the Waste Rock Storage Area. As noted in the April 2009 Noise Study, existing minimum noise levels in the Project area are estimated to be about 30 to 40 dBA, and average noise levels were generally 37 to 45 dBA. Noise levels from intermittent equipment operations at the southern end of the Waste Rock Storage Area would be reduced to levels that are less than existing background noise levels at the closest residences along Singing Valley Road.

Equipment working at the north end of the Dry Stack Tailings Facility would be closer to homes located along SR 83 northeast of the Project site than would be the case under the MPO. Figure 1 shows noise contours for equipment operating at the north end of the Dry Stack Tailings Facility. Noise from such equipment operations would not result in any significant noise impacts at the nearest noise-sensitive locations.

The Scholefield Tailings and McCleary Waste Alternative would have a conveyor and stacker system along the eastern side of the Dry Stack Tailings Facility. Noise levels from such equipment are typically about 60 dBA at a distance of 50 feet, much lower than the noise levels generated by haul trucks, graders, loaders, and other heavy equipment. Noise levels from the conveyor system would be reduced to less than 40 dBA at a distance of about 940 feet, and would be below minimum background noise levels at distances beyond 2,000 feet. Because the conveyor system would have minimal noise impacts, Figure 1 does not include noise contours for the conveyor system.

The Heap Leach Facility for this alternative would be separated from the Waste Rock Storage Area and the Dry Stack Tailings Facility. Equipment operations would occur only during the earlier years of mine operation. Figure 1 shows noise contours for equipment operating at the Heap Leach Facility. Noise from such equipment operations would be reduced to about 30 dBA at the closest residences along Singing Valley Road, a level that would generally be less than existing background noise levels.

Compared to the MPO, maximum equipment operation noise levels at the closest residences along Singing Valley Road would drop from about 39 dBA to 30 dBA or less, and maximum

5

equipment operation noise levels at the closest residences near SR 83 northeast of the Project would remain below existing minimum background noise levels.

5.0 Traffic Noise Impacts The Scholefield Tailings and McCleary Waste Alternative would not alter the basic employment level or operating material requirements for the Project as described in the MPO. Consequently, the MPO and the Scholefield Tailings and McCleary Waste Alternative would be expected to have the same traffic generation. This alternative would, however, alter the routing of the proposed Primary Access Road. The Primary Access Road under the Scholefield Tailings and McCleary Waste Alternative would join SR 83 at a location about one (1) mile south of the location proposed in the MPO, and would follow a different alignment to the Plant Site. Truck traffic serving the Project would travel about one (1) mile further south on SR 83 under this alternative than would be the case under the MPO. Because there are no noise-sensitive receptor locations along this section of SR 83, and no noise-sensitive receptor locations along either alignment for the Primary Access Road, the change in the access road location would not result in significant changes in traffic noise effects. Therefore, the discussions and noise contour figures, as presented in the April 2009 Noise Study, would be applicable to this alternative.

6.0 Conclusion A review of operational and facility changes was performed between the MPO and the Scholefield Tailings and McCleary Waste Alternative being considered in the EIS process. Because the facilities, operations, and anticipated traffic patterns are generally the same for both scenarios, most of the discussions, noise contour figures, and analysis results presented in the April 2009 Noise Study are applicable to the Scholefield Tailings and McCleary Waste Alternative. Revised noise contours (Figure 1) were prepared to illustrate maximum equipment operation noise conditions under the Scholefield Tailings and McCleary Waste Alternative. Equipment operation noise levels under this alternative generally would be less than existing background noise levels at the closest residences along Singing Valley Road and at the closest residences northeast of the Project. Consequently, intermittent equipment operation noise levels under the Scholefield Tailings and McCleary Waste Alternative would not be audible at the closest residences northeast or southeast of the Project. In addition, the change in Primary Access Road location under this alternative would not significantly change the traffic noise impacts as presented in the April 2009 Noise Study.

6

REFERENCES Tetra Tech (2009) Supplemental Noise Study, Rosemont Copper Project. Prepared for

Rosemont Copper Company. Report Dated April, 2009 WestLand (2007) Rosemont Project Mine Plan of Operations. Prepared for Rosemont Copper

Company. Report Dated June, 2007

FIGURE

!(

!(

l

l

×

×

×

× ×

×

×

×× ××××

×

×××× ×

×

×

×

×

î

T 18 S

T 18 ST 19 S

T 17 S

T 18 S

T 18 ST 19 S

R 1

6

R 1

5

R 1

6 E

R 1

7 E

R 1

6 E

R 1

5 E

R 1

6 E

R 1

7 E

!(83

!(83

40 d

BA

50 d

BA

30 d

BA

80 dBA

70 dBA

60 dBA

40 d

BA

50 d

BA

30 d

BA

SINGING VALLEY RD

E GREATERVILLE RD

OLD

SO

NO

ITA

HW

Y

BIG

THU

ND

ER R

D

BIG THUNDER RD

GHOST DANCE RD MES

QU

ITE M

ESA P

L

35 dB

A

55 dBA45 dBA

55 dBA

45 dBA

35 dBA

80 dBA

70 dBA

60 dBA

!(

North End of Dry Stack Tailings Facility

40 d

BA

50 d

BA

30 d

BA80 dBA

70 dBA

60 dBA

SON

OITA H

Y

S HELVETIA RD

GR

EAT

ERVI

LLE

RD

E FISH CANYON RD

E EMPIRE RANCH RD

BOX C

ANYO

N R

D

S H

OU

GH

TON

RD

E YUCCA ASH FARM RD

E SINGING HILLS TR

S O

LD S

ON

OIT

A H

Y

HILTON RANCH RD

E BEATTY RANCH RD

W CAMINO AURELIA

YON EDG

E TR

E GARDNER CANYON RD

HIDDEN VALLEY RD

T 17 S

House Y

House X

House W

House V

House UHouse T

House S

House R

House Q

House P

House OHouse N

House L

House K

House JHouse I

House H

House D

House C

House B

House A

House E

Building F

Building G

Center of Open Pit

Plant SiteLocation

Santa Rita Abbey

South End of Waste Rock Storage

Area

South End of Heap Leach Pad

!(

!(

!(

!(

l

l

×

×

×

× ×

×

×

×× ××××

×

×××× ×

×

×

×

×

î

4100

4500

4400

4200

4700

4300

4000

4600

4800

4900

5000

5100

39003800

5200

5300

5400

5500

5600

3700

3600

5700

5800

3500

5900

6000

3400

6100

6300

6200

4300

4800

6000

5800

4600

4800

5300

4300

4100

5500

4900

4800

4700

5000

5100

5500

6200

4400

520056

00

5400

5300

4500

6000

6100

4500

4900

4900

5200

4200

4600

5600

4900

4900

4300

4000

4500

4000

4700

5300

4300

4800

4400

5900

5900

4900

5100

4600

5100

4400

4600

4500

4100

4500

5400

4600

4200

4600

4600

4600

5000

5500

61006200

5100

5200

5200

4400

5200

4400

5900

5900

4200

4400

50004900

46004000

5300

4600

5400

6100

4800

4700

4000

4600

5300

4400

5300

4300

5000

4200

5500

4600

5200

4500

4000

4900

5400

5600

5300

5300

5000

5800

4200

5100

4600

4900

4700

4000

4700

5200

5400

5500

4600

4700

4600

5700

5200

5300

5500

4300

5200

5400

4900

4200

5800

4100

5000

5700

6000

4700

5900

4600

4200

6100

5800

4400

5900

4000

4800

5300

4300

52005200

4800

5900

5200

4300

5000

5700

4800

5300

6200

4600

4400

5000

4300

5600

4100

5500

4700

4400

4700

50006000

4800

6000

5000

4700

5500

4800

4500

4500

5300

5100

4000

4700

4600 4000

4300

4500

5400

5200

4700

6000

4600

4800

4500

4300

4000

4200

5800

4200

4300

5900

4200

5000

5400

4500

5400

5700

4700

4600

4900

5700

4600

4500

5100

5800

4900

4700

4700

5000

4600

6000

4400

5100

4200

4600

4400

4600

5900

5000

5500

4600

5300

5400

5400

5300

4600

4900

4800

4500

4300

4500

4500

4500

5300

4600

4100

5600

4900

4600 4700

4900

4100

5400

5700

4800

5200

4100

4400

4600

4500

5000

4300

5400

5300

5400

5100

5600

4800

4500

4600

5900

5000

5300

4600

4200

4000

6200

5500

4000

4600

4500

4200

4600

4000

4300

5000

5000

5200

5300

4700

4000

4800

5000

5000

4800

4100

4600

5200

5800

5000

5900

5800

5800

5000

4900

5700 4600

5400

5000

4400

4900

4900

4600

4600

5500

4200

5000

4400

5400

4600

5400

4300

4300

5100

4500

4100

4800

5700

5100

6100

5100

4700

4100

4200

5700

5500

4600

5400

4500

4700

4900

5300

4700

4800

5300

5700

11

11 11

11

07

01

14 18

17

12

30

04

26

16

29

08

27

32

14

19

35

28

25

26

15

10

09

21

33 3432

22

27

27

31

29

14

05

23

35

20

26

10

33

2223

12

23

15

26

13

20

03

28

13

09

24

29

28

29

20

31

16

31

0602 02

30

14

24

29

35

26 25

21

08

32

2024

1713 18

30

17

34

12

31

07

32

30

25

23

19

18

19

17

36

30

08

02

35

01

07

0503

29

18

26

06

0606

25

04

19

36

0102 05

07

08

30

05

13

36

01

24

25

36

25

12

36 3635

32

31

3532 343331

20

19

2221

2323

2024 19 24

09

16

04

21

33

28

28

33

09

04

16

21

27

34

28

34

27

15

22

10

22

27

15

03

03

10

3334

2122

±

JANUARY 2010

FIGURE 1SCHOLEFIELD TAILINGS AND McCLEARY WASTE ALTERNATIVE

ROSEMONT COPPER PROJECT NOISE ANALYSIS

4,000 0 4,000 8,0002,000Feet

Note: Equipment operationnoise contours are shown forthe north end of the Dry StackTailings Facility, the south endof the Waste Rock StorageArea, and the south end of theHeap Leach Pad. Thesecontours represent intermittentequipment operation noiselevels when equipment isoperating in these areas.Traffic noise contours are24-hour Ldn noise levels forYear 20 traffic conditions.

LegendMain Facility Outline

RoadwayAZ State Highway 83

Township/Range Line

Section Lines

Ground Contour

55+ dBA Ldn Zone

45-55 dBA Ldn Zone

35-45 dBA Ldn Zone

Equipment Noise Contour (XX dBA)

Traffic Noise Contour Designations