TECAPRES TPA / TPG SERIEStecapres.com/images/catalogo/series/13_Series TPA-TPG.pdf · TPA / TPG...

Transcript of TECAPRES TPA / TPG SERIEStecapres.com/images/catalogo/series/13_Series TPA-TPG.pdf · TPA / TPG...

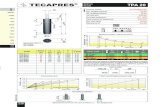

TPA / TPG SERIES

Manufactured by TÉCNICAS APLICADAS DE PRESIÓN, S.L. · WWW.tecapres.com

Manufactured by TÉCNICAS APLICADAS DE PRESIÓN S L · WWW tecapres com

Code ØBodymm

Strokesmm

FadaN

ACTIVE SAFETYTPA 20 20 13 - 80 90TPA 25 25 10 - 50 200TPG 22 22 12 - 160 90TPG 25 25 12 - 100 200TPG 26 26 12 - 160 200TPG 32 32 12 - 100 300TPGP 32 32 12 - 100 450TPG 500 45 12 - 100 500

!

Small gas springs for reduced forces

229

PED2014/68/UE

TPATPG

TPSR

TPSRS

TPNS

STOPCYLINDERHOTFORMING

TPHT

TPSL

TECAPRES®

1,00

1,05

1,10

1,15

1,20

1,25

1,30

1,35

0 15 25 38 50 63 8012,7

Color code FadaN

FcdaN

PBar

GR (Green) 25 (±5%) 50BL (Blue) 50 (±5%) 100RD (Red) 75 (±5%) 150YW (Yellow) (±5%) 175(Other forces)

Assembly possibilities

Code Smaxmm

Lamm

Lcmm

Vl Kg

TPA 20x13 12,7 0,11TPA 20x15 15 71 0,005 0,12TPA 20x25 25 0,007TPA 20x38 0,15TPA 20x50 50 0,012TPA 20x63 180 117 0,18TPA 20x80 80 0,017 0,20

TPA 20Pressure medium Gas Nitrógeno (N2)

Max. charging pressure 175 Bar

Min. charging pressure 25 Bar

Rod seal area 0,50 cm2

Operating temperature 0ºC - 80ºC

Force increase by temperature 0,33 %/ºC

Max. stem speed 1,6 m/s

Maintenance kit Kit A20

Manufactured by TÉCNICAS APLICADAS DE PRESIÓN, S.L. · WWW.tecapres.com

Force

(daN

)

Pressure (Bar)

Force

(daN

)

Stroke (mm)

Initial force/charging pressure ratio

Ø20mm90daN

Force/stroke ratio

Stroke (mm)

Maximum strokes / minute (at 20ºC)

i

The black color code denotes a different pressure from that which the customer could choose when ordering between the minimum charging pressure (25Bar)

gas spring will be supplied in the yellow code version.

How to order

Model Stroke Color code

0102030405060708090

100

25 50 75 100 125 150 175

7975

60

4840

3429

102030405060708090

15 25 38 50 63 8012,7

Ø20+1.0+0.5 FP 20

TPA 20 GR15x

3.5

3

Ø15

Ø20

Color

code

max

LcS

La

Ø8

17

r 1

±0.2

5

1

±0.1

Gas charging M6(8mm)TPFV3 valveM6-C adapter

230

PED2014/68/UE

Maximum recommended 90% stroke

TPGA

S 07

01-

2018

Stro

kes/m

in (sp

m)

V D I S A F E T Y

iMICRO

TITAN

TPH

TPS

TPSP

TPF

TPK

TPC

TPCT

TPB

TPR

TPATPG

TECAPRES®

1,00

1,05

1,10

1,15

1,20

1,25

1,30

1,35

1,40

0 10 12,7 16 25 38 50

Color code FadaN

FcdaN

PBar

GR (Green) 50 (±5%) 45BL (Blue) 100 (±5%) 90RD (Red) 150 (±5%) 135YW (Yellow) (±5%)(Other forces)

Assembly possibilities

Code Smaxmm

Lamm

Lcmm

Vl Kg

TPA 25x10 10 65 55 0,006 0,14TPA 25x13 0,14TPA 25x16 16 61 0,15TPA 25x25 95TPA 25x38 0,19TPA 25x50 50 145 95

TPA 25Pressure medium Gas Nitrógeno (N2)

Max. charging pressure 175 Bar

Min. charging pressure 25 Bar

Rod seal area 1,13 cm2

Operating temperature 0ºC - 80ºC

Force increase by temperature 0,33 %/ºC

Max. stem speed 1,6 m/s

Maintenance kit Kit A25

Manufactured by TÉCNICAS APLICADAS DE PRESIÓN, S.L. · WWW.tecapres.com

Force

(daN

)

Pressure (Bar)

Force

(daN

)

Stroke (mm)

Initial force/charging pressure ratio

Ø25mm200daN

Force/stroke ratio

Stroke (mm)

i

The black color code denotes a different pressure from that which the customer

gas spring will be supplied in the yellow code version.

How to order

Model Stroke

0

50

100

150

200

250

25 50 75 100 125 150 175

10799

91

75

6050

405060708090

100110120

10 16 25 38 5012,7

n

+1.0+0.5

16

TPA 25 BL25x

S±0

.25ma

x

1Lc

La

Ø12

10.5

r 1

Ø25±0

.1r 1

5

Gas charging M6 (5,5mm)TPFV3 valveM6-C adapter

Color

code

M6

231

PED2014/68/UE

Maximum recommended 90% stroke

TPGA

S 07

01-

2018

Stro

kes/m

in (sp

m)

V D I S A F E T Y

TPATPG

TPSR

TPSRS

TPNS

STOP

HOTFORMING

TPHT

TECAPRES®

1,00

1,05

1,10

1,15

1,20

1,25

1,30

1,35

0 15 25 38 50 63 80 125 16010012

Color code FadaN

FcdaN

PBar

GR (Green) 30 (±5%) 60*BL (Blue) 50 (±5%) 100*RD (Red) 70 (±5%) 140*YW (Yellow) (±5%) 175*(Other forces) 50 - 175

Assembly possibilities

Code Smaxmm

Lamm

Lcmm

Ødmm

Vl Kg

TPG 22x12 12 72 0,005 0,23TPG 22x15 15 75 0,006 0,24TPG 22x25 25 110 0,27TPG 22x38 136 0,010TPG 22x50 50 160 110 0,013 0,32TPG 22x63 63 123 0,015 0,36TPG 22x80 220 140TPG 22x100 100 260 160 0,023 0,44TPG 22x125 125 310 0,46TPG 22x160 160 220 10 0,035 0,52

TPG 22Pressure medium Gas Nitrógeno (N2)

Max. charging pressure 175 Bar

Min. charging pressure 50 Bar

Rod seal area Ø8mm - 0,50 cm2

Ø10mm - 0,78 cm2

Operating temperature 0ºC - 80ºC

Force increase by temperature 0,33 %/ºC

Max. stem speed 1,6 m/s

Maintenance kit Kit G22

Manufactured by TÉCNICAS APLICADAS DE PRESIÓN, S.L. · WWW.tecapres.com

Force

(daN

)

Pressure (Bar)

Force

(daN

)

Stroke (mm)

Initial force/charging pressure ratio

Ø22mm90daN

Force/stroke ratio

Stroke (mm)

Maximum strokes / minute (at 20ºC)

i

The black color code denotes a different pressure from that which the customer could choose when ordering between the minimum charging pressure (50Bar)

gas spring will be supplied in the yellow code version.How to order

Model Stroke Color code

8175

60

4840

3429

24 20 16

10

20

30

40

50

60

70

80

90

1215 25 38 50 63 80 100 125 160

020406080

100120140160180

50 75 100 150 175125 130

Ø22

2/3 Lc

min

+1.0+0.5

TPG 22 YW100x

Ø10mm

Ø22

Color

code

max

LcS

La

16

r 1

±0.25

1

Gas charging M6(8mm)TPFV3 valveM6-C adapter

Ød

±0.1

232

PED2014/68/UE

V D I S A F E T Y

Maximum recommended 90% stroke

TPGA

S 07

01-

2018

Stro

kes/m

in (sp

m)

iMICRO

TITAN

TPH

TPS

TPSP

TPF

TPK

TPC

TPCT

TPB

TPR

TPATPG

TECAPRES®

1,001,051,101,151,201,251,301,351,40

0 1215 25 38 50 63 80 100

Color code FadaN

FcdaN

PBar

GR (Green) 50 (±5%) 45BL (Blue) 100 (±5%) 90RD (Red) 150 (±5%) 135YW (Yellow) (±5%)(Other forces)

Assembly possibilities

Code Smaxmm

Lamm

Lcmm

Vl Kg

TPG 25x12 66 0,009 0,16TPG 25x15 15 69 0,010TPG 25x25 104 0,014TPG 25x38 130 0,019TPG 25x50 50 154 104TPG 25x63 63TPG 25x80 134 0,035TPG 25x100 100 154 0,043

TPG 25Pressure medium Gas Nitrógeno (N2)

Max. charging pressure 175 Bar

Min. charging pressure 25 Bar

Rod seal area 1,13 cm2

Operating temperature 0ºC - 80ºC

Force increase by temperature 0,33 %/ºC

Max. stem speed 1,6 m/s

Maintenance kit Kit G25

Manufactured by TÉCNICAS APLICADAS DE PRESIÓN, S.L. · WWW.tecapres.com

Force

(daN

)

Pressure (Bar)

Force

(daN

)

Stroke (mm)

Initial force/charging pressure ratio

Ø25mm200daN

Force/stroke ratio

Stroke (mm)

i

The black color code denotes a different pressure from that which the customer

gas spring will be supplied in the yellow code version.

How to order

Model Stroke

10194

75

6050

4336

30

20

40

60

80

100

120

15 25 38 50 63 80 10012

0

50

100

150

200

250

25 50 75 100 125 150 175

+1.0+0.55

16

TPG 25 RD63x

S±0

.25ma

x

1Lc

La

Ø12

16 10.5

r 1

Ø25±0

.1r 1

5

Gas charging M6 (5.5mm)TPFV3 valveM6-C adapter

Color

code

M6

233

PED2014/68/UE

Maximum recommended 90% stroke

TPGA

S 07

01-

2018

Stro

kes/m

in (sp

m)

V D I S A F E T Y

TPATPG

TPSR

TPSRS

TPNS

STOP

HOTFORMING

TPHT

TECAPRES®

1,001,051,101,151,201,251,301,351,401,45

0 25 38 50 63 80 100 125 16012

Color code FadaN

FcdaN

PBar

GR (Green) 50 (±5%) 45BL (Blue) 100 (±5%) 90RD (Red) 150 (±5%) 135YW (Yellow) (±5%)(Other forces)

Assembly possibilities

Code Smaxmm

Lamm

Lcmm

Vl Kg

TPG 26x12 93 0,009 0,16TPG 26x25 119 94 0,014TPG 26x38 145 0,019TPG 26x50 50 169 119TPG 26x63 63 195TPG 26x80 149 0,035 0,30TPG 26x100 100 169 0,039 0,33TPG 26x125 319 194 0,049 0,39TPG 26x160 160

TPG 26Pressure medium Gas Nitrógeno (N2)

Max. charging pressure 175 Bar

Min. charging pressure 25 Bar

Rod seal area 1,13 cm2

Operating temperature 0ºC - 80ºC

Force increase by temperature 0,33 %/ºC

Max. stem speed 1,6 m/s

Maintenance kit Kit G26

Manufactured by TÉCNICAS APLICADAS DE PRESIÓN, S.L. · WWW.tecapres.com

Force

(daN

)

Pressure (Bar)

Force

(daN

)

Stroke (mm)

Initial force/charging pressure ratio

Ø26mm200daN

Force/stroke ratio

Stroke (mm)

i

The black color code denotes a different pressure that the customer could

spring will be supplied in the yellow code version.

How to order

Model Stroke

0

50

100

150

200

250

25 50 75 100 125 150 175

101

75

6050

4336

30 25 20

10

30

50

70

90

110

12 25 38 50 63 80 100 125 160

n

+1.0+0.5

TPG 26 RD100x

2.53

Ø26

Ø20

S±0

.25ma

x

1Lc

La

Ø12

M6(10mm)

±0.3

Gas charging M6TPFV1 valveM6-A adapter

234

PED2014/68/UE

V D I S A F E T Y

Maximum recommended 90% stroke

TPGA

S 07

01-

2018

Stro

kes/m

in (sp

m)

iTITAN

TPH

TPS

TPSP

TPF

TPK

TPB

TPR

TPATPG

TECAPRES®

1,001,051,101,151,201,251,301,351,401,45

0 12 25 38 50 63 80 100

Color code FadaN

FcdaN

PBar

GR (Green) 100 (±10)BL (Blue) 200 100RD (Red) (±20)YW (Yellow) (±20)(Other forces)

Assembly possibilities

Code Smaxmm

Lamm

Lcmm

Vl Kg

TPG 32x12 12TPG 32x25 110TPG 32x38 98TPG 32x50 110TPG 32x63TPG 32x80 80 220TPG 32x100 100

TPG 32Pressure medium Gas Nitrógeno (N2)

Max. charging pressure 150 Bar

Min. charging pressure 25 Bar

Rod seal area 2,01 cm2

Operating temperature 0ºC - 80ºC

Force increase by temperature 0,33 %/ºC

Max. stem speed 1,6 m/s

Maintenance kit Kit G32

Manufactured by TÉCNICAS APLICADAS DE PRESIÓN, S.L. · WWW.tecapres.com

Force

(daN

)

Pressure (Bar)

Force

(daN

)

Stroke (mm)

Initial force/charging pressure ratio

Ø32mm300daN

Force/stroke ratio

Stroke (mm)

Maximum strokes / minute (at 20ºC)

i

The black color code denotes a different pressure from that which the customer

gas spring will be supplied in the yellow code version.

How to order

Model Stroke Color code

108

80

6353

4538

32

20

40

60

80

100

120

12 25 38 50 63 80 100

0

50

100

150

200

250

300

350

25 50 75 100 125 150

TPG 32 YW50x

n

+1.0

Color

code

LcLa

±0.25

1S

max

11.5

r 1

43.5

Ø32±0

.1

M6(10mm)

Ø27

Ø16Gas charging M6TPFV1 valveM6-A adapter

235

V D I S A F E T Y

PED2014/68/UE

Maximum recommended 90% stroke

TPGA

S 07

01-

2018

Stro

kes/m

in (sp

m)

TPATPG

TPSR

TPSRS

TPNS

STOP

HOTFORMING

TPHT

TECAPRES®

Color code FadaN

FcdaN

PBar

GR (Green) 100 (±10) 40BL (Blue) 200 80RD (Red) (±20) 120YW (Yellow) (±20)(Other forces)

Assembly possibilities

Code Smaxmm

Lamm

Lcmm

Vl Kg

TPGP 32x12 12 84 0,008TPGP 32x25 110TPGP 32x38 98 0,41TPGP 32x50 110 0,48TPGP 32x63 0,041 0,49TPGP 32x80 80 220 140TPGP 32x100 100

TPGP 32Pressure medium Gas Nitrógeno (N2)

Max. charging pressure 175 Bar

Min. charging pressure 25 Bar

Rod seal area 2,54 cm2

Operating temperature 0ºC - 80ºC

Force increase by temperature 0,33 %/ºC

Max. stem speed 1,2 m/s

Maintenance kit Kit GP32

Manufactured by TÉCNICAS APLICADAS DE PRESIÓN, S.L. · WWW.tecapres.com

Force

(daN

)

Pressure (Bar)

Initial force/charging pressure ratio

Ø32mm450daN

Force/stroke ratio

Stroke (mm)

Maximum strokes / minute (at 20ºC)

i

The black color code denotes a different pressure from that which the customer

gas spring will be supplied in the yellow code version.

How to order

Model Stroke Color code

0

100

200

300

400

500

25 50 75 100 125 150 175

95

70

5647

4033

28

2030405060708090

100

12 25 38 50 63 80 100

n

+1.0

TPGP 32 GR25x

M6(10mm)

Ø32

±0.1

4

Ø27

S±0

.25ma

x

1Lc

La

Ø18

11.5

r 1

3.5

Gas charging M6TPFV3 valveM6-A adapter

Color

code

236

V D I S A F E T Y

PED2014/68/UE

TPGA

S 07

01-

2018

Stro

kes/m

in (sp

m)

1,00

1,10

1,20

1,30

1,40

1,50

1,60

1,70

0 806350382512 100

Force

(daN

)

Stroke (mm)

Maximum recommended 90% stroke

iMICRO

TITAN

TPH

TPS

TPSP

TPF

TPK

TPC

TPCT

TPB

TPR

TPATPG

TECAPRES®

500

550

600

650

700

750

800

0 12 25 38 50 63 80 100

Assembly possibilities

Code Smaxmm

Lamm

Lcmm

FadaN

FdaN

FcdaN

PBar

Vl Kg

TPG 500x12 12 84 72

500 ±5%(20ºC)

590 600

132 (20ºC)

0,028 0,70TPG 500x25 25 110 85 635 655 0,041 0,78TPG 500x38 38 136 98 660 685 0,054 0,88TPG 500x50 50 160 110 675 705 0,066 0,97TPG 500x63 63 186 123 690 720 0,079 1,07TPG 500x80 80 220 140 700 735 0,096 1,20TPG 500x100 100 260 160 710 745 0,117 1,38

TPG 500Pressure medium Gas Nitrógeno (N2)

Max. charging pressure 155 Bar

Min. charging pressure 35 Bar

Rod seal area 3,80 cm2

Operating temperature 0ºC - 80ºC

Force increase by temperature 0,33 %/ºC

Max. stem speed 1,6 m/s

Maintenance kit Kit G500

Manufactured by TÉCNICAS APLICADAS DE PRESIÓN, S.L. · WWW.tecapres.com

Force

(daN

)

Pressure (Bar)

Force

(daN

)

Stroke (mm)

Initial force/charging pressure ratio

Ø45mm500daN

Force/stroke ratio

Stroke (mm)

Maximum strokes / minute (at 20ºC)

100%90%

i

95

70

5647

4033

28

2030405060708090

100

12 25 38 50 63 80 100

0

100

200

300

400

500

600

700

35 50 75 100 125132

150155

2xM6(10mm)

±0.1

Ø22

Ø38

Ø45

14.5

r 1

44

Gas charging M6TPFV3 valveM6-A adapter

S±0

.25ma

x

1Lc

La

20

FS 45 · FSC 45 FB 45FP 45 · FPR 45 FI 45 · FI 45/1+1.0+0.5

2/3 Lc

min

Ø45

22

237

PED2014/68/UE

RE-2

2-32

Maximum recommended 90% stroke

TPGA

S 07

01-

2018

Stro

kes/m

in (sp

m)

V D I S A F E T Y

TPATPG

TPSR

TPSRS

TPNS

STOPCYLINDERHOTFORMING

TPHT

TPSL

TECAPRES®