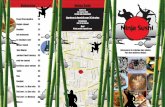

Team Ninja

-

Upload

kadeem-hansen -

Category

Documents

-

view

85 -

download

7

description

Transcript of Team Ninja

Introduction/OverviewIntroduction/OverviewImplementation of Subsystems

– MCU board– Chassis/Motor/Motor Driver– Sensor

Parts ListScheduleDivision of Labor

MC68711K4 MicroprocessorMC68711K4 Microprocessor

Features– 8-bit opcodes and data– 16-bit addressing– 8 A/D Converters– 4 PWM signal

generators– Non-multiplexed

address and data lines

XC95108 CPLDXC95108 CPLD

Implementation– Chip select device– All other on board

logic CPLD vs FPGA

– Simpler

AT29C256 EPROMAT29C256 EPROM

Features– Fast read access

time –70ns– Fast program time

64 byte program time –10 ms

Chip erase time – 10 ms

– Typical Endurance > 10,000 cycles

Power SystemPower System

MC7805 Voltage Regulator– Outputs Steady 5V– Large Input Voltage

Range (7.5V – 18V)

Power Busses Bypass Capacitors

(0.1uF)

Infrared SensorsInfrared Sensors

Using Sharp GP2D120 IR sensors– Max of 8 sensors (high cost)

Above, below, and forward sensors

– Analog Output Consistent voltage curve vs distance

– Low power consumption 150 mW / sensor max

IR Sensor limitationsIR Sensor limitations

High Cost per unit ($15)– Unfeasible to be covered on all sides

Need to ensure unit always “looks forward” before driving– Up to 8 sensors on front side

Positioned to see:– Directly forward– 45 deg angle upward of directly forward– 45 deg angle below directly forward

Infrared SensorsInfrared SensorsOutput CharacteristicOutput Characteristic

Device 1 and 2 averages and spec sheet

0

0.5

1

1.5

2

2.5

3

3.5

0 5 10 15 20 25 30 35 40 45 50

Distance to reflected object (cm)

Anal

og o

utp

ut vo

ltag

e (V

)

Datasheet spec

Device2avg

Device1avg

Device 1 and 2 averages and spec sheet

0.5

1

1.5

2

2.5

3

0 2 4 6 8 10 12 14

Distance to reflected object (cm)

Analo

g o

utp

ut voltage (V

)

Datasheet spec

Device2avg

Device1avg

0-15 cm to right

0-50cm below

A/D ConversionA/D Conversion

HC711K4 provides 8 multiplexed inputs to an A/D converter

Continuously sample inputsIR sensor directly connected to multiplexed

MCU input

A/D Conversion A/D Conversion

Provides 8 bits of resolution Output of A/D converter is $00-$FF stored in register

– VRH controls maximum voltage seen Will use VRH = 3.0 V Sampled Voltage > VRH

– Data stored = $FF

– VRL controls minimum voltage seen Will use VRL = 0.8 V Sampled Voltage < VRL

– Data stored = $00– Linearly scaled in between $00 - $FF

– 8.5 mV resolution using above VRH and VRL

A/D ReconstructionA/D Reconstruction

Convert Voltage-Distance table to $00-$FF format for easy lookup– $00 = 15 cm…$01 = 15 cm…$FE = 3cm…$FF = 3cm

Constraint: Need to know how close to wall start position is

Fix: always start more than 5cm away from wallDevice 1 and 2 averages and spec sheet

0.5

1

1.5

2

2.5

3

0 2 4 6 8 10 12 14

Distance to reflected object (cm)

Analo

g o

utp

ut voltage (V) Datasheet spec

Device2avg

Device1avg

A/D ReconstructionA/D Reconstruction7-Segment LED7-Segment LED

7-segment LED displays current position– 1 display per sensor

Hex display – 3-9 cm displayed as 3-9

– 10-15 cm displayed as A – F

Assistance in debugging movement– Why did it turn when it

wasn’t even near a wall?

A/D ReconstructionA/D Reconstruction7-Segment LED Implementation7-Segment LED Implementation

Encode distance measurement into signal displayable by 7-segment LED

Write result to $2000-$2FFF– Reserved for LED latches by CS CPLD

Latch this data using 8-bit latch– Connect to display with pull-up resistors

3-F displayed on 7-segment LED

Battery PowerBattery PowerConstraintsConstraints

MCU board requirements:– 8V - 30V

Voltage regulator limits to 5V, 1A Max of 1000mAh

Motor requirements:– 2000mAh / motor

Step-up voltage to ~10V Monitor battery charge to prevent going below

10% charge

Battery PowerBattery PowerSolution: TetherSolution: Tether

5000mAh batteries expensive, heavy, and/or difficult to recharge

Tethered approach 1 or 2 cables attached to exterior power supply

Too complicated to complete on time

Focus of project: intelligent movement of device

Programming:Programming:OverviewOverview

Move Forward IR Check

Turn, ChangeDirection

Always

No objects detected

Objectdetected

Check for obstacle

Programming:Programming:Moving ForwardMoving Forward

Set internalLatch

PWM~200Hz

BothMotorDriverCount Steps

N/S

Count StepsE/W

NoObjectDetected

MoveForwardMoving N/S

Moving E/W

TurnOnPWM

SteptheMotor

Always

Programming: IR CheckProgramming: IR Check

InitializeA/D

IR sensor’sA/D conversionResult register

Compare to Voltage-Distance table

DistanceEstimationCalculation

7-seg LEDlatch

7-segLED

Objected Detected?

Always

Thresholdi.e. 4 cm

ObjectDetected No Object Detected

Programming:Programming:TurningTurning

(Always Turn Left)(Always Turn Left)

SetR wheellatch

ClearL wheellatch

PWM~200 Hz

R WheelMotorDriver

L WheelMotorDriver

RotateDirection 45deg

Done Turning

Object detected(straight ahead)

R wheel forward

L wheel backward

Check for obstacle

STP-MTR-17048 Bipolar STP-MTR-17048 Bipolar MotorMotor

Stepper Motor 1.8 degrees/step Lightweight 6.0 lbs Maximum Load 2.0A Rated Current 0.59Nm Maximum

Holding Torque Motor/Driver Works Best

Above 200Hz Motor Needs at Least 16W

of Power

Bipolar Stepper Motor Bipolar Stepper Motor DriverDriver

One Driver for Each Stepper Motor

Powered at 8-30VDirectionStepOptoisolationDual H-Bridge

Parts ListParts List

STP-MTR-17048 Bipolar Motors (2)

Quasar 3158 Bipolar Stepper Motor Driver (2)

3”x13/16” Wheels (2) Swivel Wheels (2) Sensors (8) Plexiglas Chassis HC711K4 Microprocessor XC95108 CPLD

ECS-2200B ClockAT29C256 ROMSamsung K6x0808C1D-DF70 RAMMC7805 Voltage Regulator7-Segment LEDs (8)Vacuum (Black and Decker Cyclone)

StatusStatus

Connects Motor With U-BoltsDone With Chassis AssemblyDone With SensorsMCU Board connected and runningCPLD ProgrammedProcessor Resetting CorrectlyROM connected

Plan of AttackPlan of Attack

Milestone 1– MCU board completely done– Sensor input to MCU– MCU output to motor drivers– Basic vehicle movement

Milestone 2– Intelligent movement based on sensor input– Integration of vacuum– User interface

Division of LaborDivision of Labor Kevin

– Microcontroller Programming– MCU board– Communication Between Devices

Tim – Peripheral Sensors– MCU board– Sensor Logic

Simone – Mobility Functions– Chassis– Mobility Logic– Track Distance/Make Internal Map– Vacuum Integration

ConclusionConclusionImplementation of Subsystems

– MCU board– Chassis/Motor/Motor Driver– Sensor

Parts ListScheduleDivision of Labor