TB 291 Keystone Colorants for Wood Coatings (2!16!12)

Transcript of TB 291 Keystone Colorants for Wood Coatings (2!16!12)

P I G M E N T S & D Y E S S I N C E 1 9 2 0

Innovation in Color Solutions

TM

GLOBAL COLOr INTELLIGENCE

fOr COATINGSChanging the way you think about color

WOOD COATINGS fOIL COATINGS | INDUSTrIAL COATINGS | CONCrETE COATINGS

TA B L E O F C O N T E N T S

PIGMENTS AND DYES SINCE 1920 | PAGE 1

WOOD COATINGS OvervIeW ............................... 1-3

TeCHNICAL DATA GUIDeS

NerosolTM Liquid Dyes......................................... 4-5 KeyfastTM Spirit Solvent-Soluble Powder Dyes ....... 6-7 KeysperseTM WPN Pigment Dispersions ............... 8-9 NeroTintTM Pigment Dispersions .............................. 9

KeYSTONe LIqUID DYe, PIGMeNT & DISPerSION PLANT — SPeCIAL OvervIeW ............................. 10

Color Solutions For Wood Coatings

A MOrE INNOvATIvE COLOr PALETTE In the global marketplace of wood coatings, color is what makes a product stand out and be noticed. Color delivers a message of vitality, functionality and individuality all in one glance.

At KeystoneTM, we help you achieve maximum success — and profit — through the use of color. Our palette includes over 150 dyes and pigments for all types of coatings applications. You benefit from the expertise of the industry’s premier technical laboratory, with application and color specialists and other professionals who consistently formulate new ideas and solutions.

Let our application expertise help you meet your most critical demands. Whether you need wood coating stains and dispersions, or direct to metal coatings, you can count on Keystone for the colorants, dyes and pigments — and the specialized intelligence — to bring your products to their full potential.

Keystone has engineered

and debuted an exciting new

environmentally friendly

zero-VOC line of pigment

dispersions called NeroTintTM.

This enables our customers

to achieve great exterior

lightfastness in wood

coatings while incorporating

incredible wood penetration

from this innovative

submicron stain technology.

GF

E

A

BC

D

Color Solutions For Wood Coatings

A MOrE INNOvATIvE INfrASTrUCTUrE The global requirements for utilizing dyes and pigments in wood coatings go beyond the understanding of proper selection and application. They also include the need for regulatory compliance and supply chain support in both domestic and international markets.

Keystone has a worldwide framework in place to ensure that all products meet the complex compliance regulations of reACH, eINeCS, FDA and more. And we maintain distribution channels and warehouses in the U.S., europe, Asia and Latin America, so products are readily available wherever and whenever needed.

Our global technical sales support team not only provides local and regional access to information and products, but also a worldwide communication network for fast response to questions and changes in market demand.

PIGMENTS AND DYES SINCE 1920 | PAGE 3PAGE 2 | PIGMENTS AND DYES SINCE 1920

Keystone can help you

coordinate your regulatory,

technical and commercial

needs by utilizing our global

databases and international

management team.

DY E S F O R W O O D C O AT I N G S

PIGMENTS AND DYES SINCE 1920 | PAGE 5PAGE 4 | PIGMENTS AND DYES SINCE 1920

N E r O S O L TM L I Q U I D D Y E S

N E R O S O L

Nerosol Yellow 2GN* 830-540-43 Lightfastness 5-6

Nerosol Yellow R 830-502-43 Lightfastness 6-7

Nerosol Orange GX 530-503-41 Lightfastness 6-7

Nerosol Red GX 630-501-44 Lightfastness 6-7

Nerosol Red B 630-502-44 Lightfastness 6-7

Nerosol Bordeaux V 630-452-44 Lightfastness 5-6

Nerosol Violet B 730-409-43 Lightfastness 5

Nerosol Royal Blue R* 230-501-42 Lightfastness 4-5

Nerosol Navy N 230-502-43 Lightfastness 6-7

Nerosol Sap Green D* 430-450-43 Lightfastness 5

Nerosol Golden Brown Y 330-451-42 Lightfastness 6-7

Nerosol Brown 4GLM 330-506-41 Lightfastness 6-7

Nerosol Brown 4RM 330-504-45 Lightfastness 6-7

Nerosol Dark Brown 2R 330-503-43 Lightfastness 6-7

Nerosol Brown MM 330-502-43 Lightfastness 6-7

Nerosol Dark Brown Y 330-452-42 Lightfastness 6-7

Nerosol Black J 130-502-43 Lightfastness 7

N E R O S O L C R N

Nerosol Yellow CRN 830-502-48 Lightfastness 6-7

Nerosol Orange CRN 530-501-48 Lightfastness 6-7

Nerosol Red CRN 630-502-48 Lightfastness 6-7

Nerosol Bordeaux CRN 630-452-48 Lightfastness 5-6

Nerosol Brown CRN 330-503-48 Lightfastness 6-7

Nerosol Black CRN 130-502-48 Lightfastness 7

N E R O S O L U S

Nerosol Yellow US 830-502-49 Lightfastness 6-7

Nerosol Orange US 530-501-49 Lightfastness 6-7

Nerosol Red US 630-502-49 Lightfastness 6-7

Nerosol Bordeaux US 630-452-49 Lightfastness 5-6

Nerosol Brown US 330-503-49 Lightfastness 6-7

Nerosol Black US 130-502-49 Lightfastness 7

Dye Concentration: 20 g/L; 5-1/3 oz./gal.* Lightfastness — Most Nerosol dyes are made with a metal-complex group

reacted to the dye molecule. The exceptions are noted with an asterisk.

NerosolTM concentrates are specially selected dyes formulated into a solution with glycol ether solvents. They are particularly well suited for the coloration of wood and wood-related finishes and coatings due to the following properties:

LIGHTFASTNESS* Most Nerosol dyes are made with a metal-complex group reacted to the dye molecule. The exceptions are noted with an asterisk. The metal-complex group significantly improves the lightfastness or resistance to fade of the product as compared to other dyes. The fastness ratings are included on the Nerosol shade card.

Although Nerosols have excellent lightfastness relative to dyes, they generally do not possess the fastness properties of pigments and therefore are not recommended for exterior paint and coatings applications. Also, variation in wood, over-coats such as lacquers and varnishes, and the use of UV absorbers and inhibitors can significantly alter actual lightfastness performance. The lightfastness ratings are intended to serve as a guide for relative analysis only.

COLOR STRENGTH Nerosol dyes are true solutions, not dispersions, and therefore have very little or no filterable solid matter. However, they are high-strength concentrates with typical dye content of 20–35% relative to “pure” powder. The actual dye content may vary, as the product is quality controlled for color strength and not for solids content.

EASE OF USE / LOW VISCOSITY Nerosol dyes are readily pourable, easily pumped liquid concentrates that quickly and completely dissolve in the intended solvent systems.

SOLVENT COMPATIBILITY All Nerosol dyes have good compatibility with a wide variety of solvents. They have complete solubility with alcohols, glycols, glycol ethers and water. Additionally, they can be used in conjunction with formulations containing ketone, ester and aromatic solvents.

When using ketone and ester solvents, some alcohol or glycol ether should be incorporated into the formulation to help stabilize the dye solution. We recommend a minimum of 15-20% alcohol or glycol ether in this case.

In solvent recipes containing aromatic or aliphatic solvents, an alcohol or glycol ether solvent must be present in the formulation in higher concentrations than any combination of aromatic or aliphatic solvent. Ideally, there should be a 2:1 ratio of alcohol or glycol ether solvent in the formulation relative to the amount of aliphatic or aromatic solvent in order to maintain the dye in solution and prevent precipitation, seeding or color loss.

Wood stained with Nerosol dyes generally will not bleed when over-coated with most water-free finishes. In some cases, however, the dye may be attacked by particularly acidic or alkaline components of a finish, potentially resulting in color shift or color loss. This applies also in the case of peroxide containing finishes (polyesters). It is therefore always recommended that tests be conducted in the laboratory to determine suitability of the dye / stain recipes with particular resin over-coat.

FAST DRYING / FLASH POINT Nerosol dyes are relatively fast drying, yet they have been formulated with flash points that allow them to be shipped as non-flammable in accordance with IATA and U.S. DOT regulations.

Nerosol US (Universal System) dyes are formulated in lower-flash solvent and glycol ether systems for added flexibility in final coating and finishes recipes. They are labeled as flammable.

Nerosol CRN dyes are high-flash formulations developed for global requirements. They can be shipped and labeled as non-flammable, and they are the same shade and strength as the Nerosol US Series.

STORAGE STABILITY At room temperature and when kept sealed in original containers, Nerosol dyes should remain stable for a minimum of one year. If the dyes are exposed to prolonged cold or freezing conditions, some gelling or precipitation of the dye may occur. This can generally be reversed by heating the dye to approximately 100˚F (38˚C) and applying agitation.

> Excellent dye lightfastness*

> High color strength

> Easy to use

> Low viscosity

> Compatibility in a wide range of solvents

> Fast drying

The information provided above regarding the application of Nerosol dyes is of a general nature. The data are not intended as specifications and, as mentioned previously, laboratory tests should always be conducted to determine compatibility and suitability of the dyes in the user’s particular formulation. Wide variations of recipes, application methods and wood used from customer to customer mean that the information is intended as a guide only.Generally, however, Nerosol dyes are suitable for all types of softwood and hardwood commonly used in the furniture and flooring industry. They are effective in coloring difficult hardwoods, such as beech, evenly. Wood stains produced using Nerosol dyes may be applied in a variety of ways, including by spray, roller, wiping and dip processes typically used.

DY E S F O R W O O D C O AT I N G S

Product Code /Product Color IndexName Name

Met

hyl E

thyl

Ket

one

(MEK

)

Met

hyl I

so B

utyl

Ket

one

(MIB

K)

Ace

tone

Ethy

l Ace

tate

Dia

ceto

ne A

lcoh

ol

Ethy

l Cel

loso

lve

Etha

nol

Tolu

ene

Cycl

ohex

anon

e

Ligh

tfast

ness

Caus

tic S

oda

Ace

tic A

cid

But

ter /

Mar

gari

ne

Soap

Wat

er 8

0˚C

30 M

in.

Coco

nut O

il

Chee

se

Resistance to Chemicals and FoodstuffsSolubility (Grams / Liter)*

PIGMENTS AND DYES SINCE 1920 | PAGE 7PAGE 6 | PIGMENTS AND DYES SINCE 1920

Keyfast Spirit Red BL 606-122-52B/S SR 122

250 200 200 50 200 300 100 Trace 60 6 5 5 4 4 3 5 4

Keyfast Spirit Magenta RBS

606-127-50SR 127

20 20 25 20 100 100 100 Trace 75 3-4 4-5 5 3-4 4-5 3 4-5 3

Keyfast Spirit Black X-51

106-027-50SB 27

250 200 250 100 350 400 140 Trace 100 6 5 5 5 5 5 5 4

Keyfast Spirit Black KR

106-029-55SB 29

200 150 250 50 300 350 200 Trace 50 5-6 5 5 5 5 5 5 4

Keyfast Spirit Black RBL

106-034-50SB 34

200 150 250 60 350 350 100 Trace 150 6 5 5 5 5 5 5 4

Keyfast Spirit Blue 6G-SS

206-070-50SB 70

120 75 150 30 250 150 200 Trace 50 6 5 3-4 3-4 3-4 5 3-4 5

Keyfast Spirit Blue 3R 206-412-50Proprietary Blend

200 50-70 25 10 </=199 20 10 <10 200 2-3 4-5 4-5 4 5 4 5 4-5

Keyfast Spirit Royal Blue

206-403-50Proprietary Blend

100 50 120 20 200 150 200 Trace 50 5-6 5 3-4 3-4 3 4 3-4 4-5

Keyfast Spirit Brown 2RM

306-401-50Proprietary Blend

240 175 250 50 300 250 100 Trace 75 6 5 5 4 2-3 4 4 4-5

Keyfast Spirit Dark Brown 5R

306-402-51Proprietary Blend

250 175 250 50 300 250 100 Trace 75 6 4-5 4-5 4-5 2-3 4-5 3-4 5

Keyfast Spirit Green GL 406-402-50Proprietary Blend

175 100 125 100 250 150 100 Trace 75 5-6 5 4 4-5 2-3 5 5 5

Keyfast Spirit Green BL 406-406-50Proprietary Blend

175 100 125 100 250 150 100 Trace 75 5-6 5 4 4-5 2-3 5 5 5

K E Y fA S T TM S P I r I T S O Lv E N T- S O L U B L E P O W D E r D Y E S

KeyfastTM Spirit dyes are brilliant, organic metal-complex dyes with good solubility in cellosolve and many other solvents. They are particularly suitable for the production of transparent and relatively lightfast shades in foil coatings, wood stains, general coatings and printing ink applications.

Keyfast Spirit Yellow 4G

806-042-50SY 42

30 20 50 100 250 100 190 220 50 3-4 5 5 5 4-5 5 5 5

Keyfast Spirit Yellow 2RLS

806-062-50SY 62

50 50 100 25 300 250 50 Trace 125 6 5 5 5 4-5 5 5 5

Keyfast Spirit Yellow 2GN

806-082-50SY 82

50 200 250 150 400 400 100 50 100 6-7 5 5 5 4-5 5 5 5

Keyfast Spirit Golden Yellow 3R

806-404-50Proprietary Blend

50 200 250 150 400 400 100 30 175 6 5 5 5 4 5 5 5

Keyfast Spirit Orange RSE

506-062-50SO 62

75 50 150 20 150 150 50 Trace 50 6 5 5 4 3 3 5 5

Keyfast Spirit Orange RLN

506-438-50SO 99

250 200 275 50 300 425 75 Trace 75 6 5 5 4 3 3 5 5

Keyfast Spirit Red 2BK 606-008-50SR 8

200 200 200 50 200 300 100 Trace 75 6 5 4 5 4 3 5 3-4

Keyfast Spirit Fire Red GLS

606-089-50SR 89

150 50 400 20 400 350 20 Trace 200 5 5 4 2 2-3 5 5 4

Keyfast Spirit Fire Red G

606-119-50SR 119

100 50 200 20 200 200 20 Trace 150 6 5 4 3 3 5 5 4

Keyfast Spirit Red KL 606-122-50Y/S SR 122

300 250 200 50 200 300 100 Trace 75 6 5 4 5 4 3 5 5

Product Code /Product Color IndexName Name

Met

hyl E

thyl

Ket

one

(MEK

)

Met

hyl I

so B

utyl

Ket

one

(MIB

K)

Ace

tone

Ethy

l Ace

tate

Dia

ceto

ne A

lcoh

ol

Ethy

l Cel

loso

lve

Etha

nol

Tolu

ene

Cycl

ohex

anon

e

Ligh

tfast

ness

Caus

tic S

oda

Ace

tic A

cid

But

ter /

Mar

gari

ne

Soap

Wat

er 8

0˚C

30 M

in.

Coco

nut O

il

Chee

se

Resistance to Chemicals and FoodstuffsSolubility (Grams / Liter)*

* These gram / liter solubility figures are certainly best case statistics and depending on your specific solvent quality, solvent mix formulation and powder dye moisture conditions, these numbers may vary. Please consult your Keystone technical representative with questions regarding your specific applications and needs.

* These gram / liter solubility figures are certainly best case statistics and depending on your specific solvent quality, solvent mix formulation and powder dye moisture conditions, these numbers may vary. Please consult your Keystone technical representative with questions regarding your specific applications and needs.

D I S P E R S I O N S F O R W O O D C O AT I N G S

D I S P E R S I O N S F O R W O O D C O AT I N G S

Typical Properties*Product Product Name Code Pigment Total Solids Wt. / Gallon pH Pigment %

PIGMENTS AND DYES SINCE 1920 | PAGE 9PAGE 8 | PIGMENTS AND DYES SINCE 1920

K E Y S P E r S E TM W P N P I G M E N T D I S P E r S I O N S

N E r O T I N T TM P I G M E N T D I S P E r S I O N S

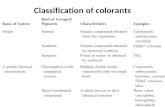

KeysperseTM WPN pigment dispersions are aqueous, resin-based dispersions designed for use in wood coatings and other surface-coloring industrial applications. These products are formulated for both spray and wiping applications. Keysperse WPN dispersions are:

Keystone NeroTintTM products are aqueous, non-vOC (U.S. compliant), high-performance pigment dispersions engineered for wood coatings. The NeroTint line has been formulated to provide excellent transparency, high gloss, and uniform color in both spray and wiping applications. These products are formulated with high-performance pigments, milled to very fine standards for ease of wood penetration, and are exceptionally clean and transparent, as well as very miscible in water systems.

Keysperse Black WPN 110-207-44 Black 7 30.6% 9.1 8.0-10.0 ~23%

Keysperse Blue WPN 210-415-44 Blue 15:3 34.7% 9.36 8.0-10.0 ~23%

Keysperse Brown WPN

310-223-44 Brown 23 31.0% 8.97 8.0-10.0 ~10%

Keysperse Raw Sienna WPN

310-507-44 Pigment Yellow 43 44.7% 10.2 8.0-10.0 ~35%

Keysperse Oxide Brown WPN

310-517-44 Iron Oxide Mixture 44.7% 10.16 8.0-10.0 ~35%

Keysperse Burnt Sienna WPN

310-527-44 Red 102 44.7% 11.02 8.0-10.0 ~35%

Keysperse Green WPN 410-207-44 Green 7 33.2% 9.58 8.0-10.0 ~26%

Keysperse Red BS-WPN

610-223-44 Red 23 31.4% 8.91 8.0-10.0 ~24%

Keysperse Red YS-WPN

610-321-44 Red 214 24.4% 8.93 8.0-10.0 ~13%

Typical Properties*Product Product Name Code Pigment Total Solids Wt. / Gallon pH Pigment %

> VOC free

> Transparent

> Sprayable or rollable

> Formulated for great penetration into multiple species of wood without raising the grain

> Acrylic resin based

> Compatible with acetone

> Designed with high-performance pigments

NeroTint Y/S Red 610-421-22 Pigment Red 221

Azo Red

NeroTint B/S Red 610-423-22 Pigment Red 23

Naphthol Red

NeroTint Oxide Brown 310-417-22 Pigment Brown 6

Oxide Van Dyke Brown

NeroTint Brown 310-423-22 Pigment Brown 23

Naphthalene-carboxamide

NeroTint Raw Sienna 310-507-22 Pigment Yellow 43

Oxide Pigment

NeroTint Burnt Sienna

310-527-22 Pigment Burnt Sienna Brown 7

Oxide Pigment

NeroTint R/S Yellow 810-483-22 Pigment Yellow 83

Azo Yellow

NeroTint G/S Yellow 810-493-22 Pigment Yellow 93

Azo Yellow

NeroTint White 910-406-22 Pigment White 6

Titanium White

NeroTint Black 110-407-22 Pigment Black 7

Carbon Black

Product Product Name Code Pigment Chemistry

Product Product Name Code Pigment Chemistry

Keysperse Yellow GS-WPN

810-293-44 Yellow 93 25.3% 8.89 8.0-10.0 ~14%

Keysperse Yellow RS-WPN

810-483-44 Yellow 83 29.1% 8.98 8.0-10.0 ~22%

Keysperse White WPN

910-206-44 White 6 44.9% 10.8 8.0-10.0 ~27%

*Not to be considered as exact measurements.

*Not to be considered as exact measurements.

I N M A N , S C , P L A N T P R O D U C T L I N E S

PAGE 10 | PIGMENTS AND DYES SINCE 1920

K E Y S T O N E L I Q U I D D Y E , P I G M E N T & D I S P E r S I O N P L A N T

In 2002, Keystone opened operations at a new liquid dye and pigment dispersion plant in Inman, SC, to expand our product line portfolio for inks, coatings and other markets. Since 2002, the plant has added new milling and grinding capacity for submicron dispersion production and upgraded the laboratory and office facilities in response to the needs of customers in these industry segments. We produce a wide range of both aqueous and solvent-based pigment dispersions and work closely with customers in developing unique and custom-made products for specific application requirements.

The Keystone PIGMeNT DISPerSIONS LINeS produced at Inman include:

> Keyvinyl — vinyl solvent dispersions

> Keygloss RF — acrylic solvent dispersions

> Keygloss RS / SS — nitro dispersions

> Keysperse HP — water acrylic organic colors and oxide dispersions

> Keysperse WPN — water acrylic dispersions

> Keyfine UFD — submicron water surfactant dispersions

> NeroTint — zero-vOC and submicron-based surfactant dispersions

The Keystone LIqUID DYe LINeS produced at Inman include:

> Nerosol — aqueous-based metal-complex concentrates

> Keyazine — basic dyes

> Keyfast Spirit — custom liquid solvent-soluble dyes

PIGMENTS AND DYES SINCE 1920 | PAGE 11

Color Solutions For Wood Coatings

A MOrE INNOvATIvE KEYSTONE Keystone understands color. Color and color application is our only business, and we have more than 90 years of experience we can share. Dyes and pigments are complex raw materials, and we excel at making them work in many varied applications, plus providing the support to deliver your color message and product to markets around the world.

Take advantage of our world-class expertise in the world of color. Contact us today and let us know how we can help meet your challenges.

PAGE 12 | PIGMENTS AND DYES SINCE 1920

Keystone’s laboratory carries

more than 90 years of

collective color knowledge.

We pride ourselves on

utilizing this knowledge in

a collaborative partnership

with our customers’ own

expertise, thus bringing the

performance level of our

customers’ final product to

the next generation.www.dyes.com

Huddersfield, U.K.

Shanghai, China

Singapore

Sao Paulo, Brazil

Buenos Aires, Argentina

Chicago, ILInman, SCPhoenix, AZ

Innovation in Color Solutions

TM

U.S. CORPORATE OFFICE KEYSTONE

2501 West Fulton Street Chicago, IL 60612

(800) 522-4393 (312) 666-2015

U.S. SOUTH CAROLINA PLANT KEYSTONE

2165 Highway 292Inman, SC 29349

(864) 473-1601

EUROPEAN OFFICE KEYSTONE EUROPE

Units 1-2 Beckview Business Parks Bradley Junction Industrial Estate

Leeds Road Huddersfield, UK HD2 1UR

+44 1484 341466

www.dyes.com

DISCLAIMER: These data were obtained by testing according to our methods, with any necessary test deviations. Other test methods may give different results. Incoming evaluations by the customer are therefore unconditionally recommended. The use and application of our colorants and information included is without any warranty, whether expressed or implied, verbal or written. No statements of recommendation contained in this product literature are to be construed as inducement to infringe on any relevant patent now or hereafter in existence.

Suggested testing of products must include testing to determine suitability from a technical as well as health, safety, workplace and environmental standpoints. Such testing has not necessarily been done by Keystone Aniline Corporation. Keystone Aniline Corporation disclaims any liability, in negligence or otherwise, incurred in connection with the use of our products and information. Keystone Aniline Corporation neither assumes nor authorizes any representative or other person to assume for it any obligation or liability.

The shades illustrated in this brochure are designed to impart a general idea of the color characteristics of each dye, not a guarantee of how the dye will look in a particular formulation. Variations in formulations and application will affect the dye performance properties. Samples of our dyes are available upon request for testing and approval. © Copyright 2012 Keystone Aniline Corporation

D

YES AND

PIG

M E N T S

1920since

TB 291 | rEvISION 02/16/12

> As a Keystone customer, you will have direct access to professionals who can answer technical questions and provide timely assistance, as well as samples of our dyes, technical specifications and formulating assistance.

> In addition to supplying a complete and comprehensive line of colorants, we are committed to providing you with the best technical information available.

For more information on custom solutions, contact your Keystone representative.