Leader Orientation, Leader Behavior, Group Effectiveness ...

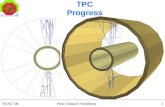

TB 19.4.06 Peter Glässel, Heidelberg1 TPC Progress Project leader: Peter Braun-Munzinger, GSI...

-

Upload

claire-grant -

Category

Documents

-

view

218 -

download

4

Transcript of TB 19.4.06 Peter Glässel, Heidelberg1 TPC Progress Project leader: Peter Braun-Munzinger, GSI...

TB 19.4.06 Peter Glässel, Heidelberg 1

TPC Progress

Project leader: Peter Braun-Munzinger, GSI DarmstadtProject leader: Peter Braun-Munzinger, GSI DarmstadtDeputy project leader: Deputy project leader: Johanna Stachel, HeidelbergJohanna Stachel, HeidelbergTechnical coordinator: Technical coordinator: Peter GlPeter Gläässel, Heidelbergssel, Heidelberg

TB 19.4.06 Peter Glässel, Heidelberg 2

Main Activities

Front End Electronics

‘Dry’ testing of sectors w/o HV started

Laser system

Shipped today, to arrive 24.4.

About 1 week (incl weekend) to install and align A-side

Cabling

Gas system

Accorde

Drift HV 100 kV (Heinzinger) installed, test with DCS

ELMB pt1000 sensor system:

Sensors cabled up 90%

TB 19.4.06 Peter Glässel, Heidelberg 4

Accorde is

in place

Next: complete cabling, setting up trigger

TB 19.4.06 Peter Glässel, Heidelberg 5

Gas system

Gas commissioning started Re-commissioning complete functionality (after software upgrade)

With new gas lines (modifications on plug) and dummy volume

Improvements on filling cycle: try to speed up filling cycle by using higher pressure, lower temperature on CO2 absorber

TPC gas lines prepared for switch to gas system

Start gas system with TPC end of week, filling next week (expected to take 2 to 3 weeks)

→ mid MayClean room part of system

TB 19.4.06 Peter Glässel, Heidelberg 6

TRD/TPC heat screenDesign done

0.5 mm Al panels with Al water lines (avg 1% X0)Fixed to SF from TPC side with bolts welded to SFWater manifolds along axial SF beams

Bidding ongoingInstallation before TRD installation (June)

TB 19.4.06 Peter Glässel, Heidelberg 7

Summary

Commissioning started

A lot to do before we see the first tracks

TB 19.4.06 Peter Glässel, Heidelberg 9

Pre-Commissioning plans, SLXL2

Commissioning of gas system from 20.3. to ~19.4.Commissioning of Field cage, FEE and ROCs

DCS systemDrift HV Laser ROC HVGatingReadout chainTrigger for cosmics, laserOnline monitoringVerify each sector, at least with laser tracks

Tracks (laser, cosmics) with 2 sectors (joining, opposite, …)Commissioning of temperature sensors

Move to UX25: 4.9.06

TB 19.4.06 Peter Glässel, Heidelberg 10

Gas system

Previously commissioned with dummy volumes

Pre-commissioning with TPC in SXL2 with final gas mixture

Control Backup Mixer Purifier CO2 Distr Analys Pump