Task 4 HTS material characterization & dipole insert conceptual design

description

Transcript of Task 4 HTS material characterization & dipole insert conceptual design

CEA DSM Irfu

i r f u

yalcas

i r f u

yalcas

- J-M Rey - EUCARD Meeting - UNIGE 08/06/2010 1

Task 4HTS material

characterization &dipole insert conceptual

designMélanie Bruchon, Maria Durante, Thibault

Lécrevisse, Jean-Marc Gheller, Olivier Louchart, Jean-Michel Rey

CEA/IRFU/SACM

CEA DSM Irfu

i r f u

yalcas

i r f u

yalcas

- J-M Rey - EUCARD Meeting - UNIGE 08/06/2010 2

HTS characterization

Superpower

AMSC

CEA DSM Irfu

i r f u

yalcas

i r f u

yalcas

- J-M Rey - EUCARD Meeting - UNIGE 08/06/2010 3

HTS characterizationSuperpower (with insulation)

CEA DSM Irfu

i r f u

yalcas

i r f u

yalcas

- J-M Rey - EUCARD Meeting - UNIGE 08/06/2010 4

HTS characterizationSuperpower (without insulation)

CEA DSM Irfu

i r f u

yalcas

i r f u

yalcas

- J-M Rey - EUCARD Meeting - UNIGE 08/06/2010 5

HTS characterizationAMSC

CEA DSM Irfu

i r f u

yalcas

i r f u

yalcas

- J-M Rey - EUCARD Meeting - UNIGE 08/06/2010 6

HTS characterizationWhat next ?

Cooling influence: what happens if we remove insulation?

Quench propagation: next study using compact solenoids. MPZ and MQE determination versus temperature.

CEA DSM Irfu

i r f u

yalcas

i r f u

yalcas

- J-M Rey - EUCARD Meeting - UNIGE 08/06/2010 7

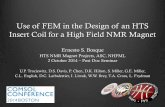

Dipole design

20 mm beam tube

3 double pancakes

2 flat one

1 with bent end, each pancake symetrical / mid plane (only one tooling needed)

External winding diameter: 98 mm

Bloc 2

Bloc 1

Bloc 3

X

Y

CEA DSM Irfu

i r f u

yalcas

i r f u

yalcas

- J-M Rey - EUCARD Meeting - UNIGE 08/06/2010 8

Dipole designInner bore diameter: 20 mm

254 A/mm² needed to reach 6T

Peak field 6,1T

Fx = 47,8 kdaNFy = 78,5 kdaN

No Nb3Sn contribution

Bloc 2

Bloc 1

Bloc 3

X

Y

CEA DSM Irfu

i r f u

yalcas

i r f u

yalcas

- J-M Rey - EUCARD Meeting - UNIGE 08/06/2010 9

Dipole designConductor extrapolation

Using Superpower SCS 4050 @ 20 T and 10 K extrapolation: 520 A for a 4 mm wide.

Assuming 2 12 mm wide ribbons and 60% efficiency on one of them the critical current may be 2496 A.

Assuming 12 mm wide conductor of 0,4 mm thickness corresponding to 0,2 mm conductor + 0,1 mm tin + 0,1 mm kapton insulation the critical current density is 520 A/mm².

Bloc 2

Bloc 1

Bloc 3

X

Y

CEA DSM Irfu

i r f u

yalcas

i r f u

yalcas

- J-M Rey - EUCARD Meeting - UNIGE 08/06/2010 10

Dipole designConductor length needed

With a straight length of 500 mmBlock 1: 69 mBlock 2: 105 mBlock 3: 142 mOnly block 3 needs « flare dance » end.

Or 1260 m of 12 mm wide ribbons needed (or 202 k$)

Bloc 2

Bloc 1

Bloc 3

X

Y

We may be able to discuss this number!

CEA DSM Irfu

i r f u

yalcas

i r f u

yalcas

- J-M Rey - EUCARD Meeting - UNIGE 08/06/2010 11

Dipole design

Junctions

Main conductor: SC face to face

Mid point and end connections: SC back to back

Bloc 2

Bloc 1

Bloc 3

X

Y

CEA DSM Irfu

i r f u

yalcas

i r f u

yalcas

- J-M Rey - EUCARD Meeting - UNIGE 08/06/2010 12

Thank you for your attention

12

CEA DSM Irfu

i r f u

yalcas

i r f u

yalcas

- J-M Rey - EUCARD Meeting - UNIGE 08/06/2010 13

CEA DSM Irfu

i r f u

yalcas

i r f u

yalcas

- J-M Rey - EUCARD Meeting - UNIGE 08/06/2010 14

CEA DSM Irfu

i r f u

yalcas

i r f u

yalcas

- J-M Rey - EUCARD Meeting - UNIGE 08/06/2010 15

Which HTS will fit?

Bi2212

YBCO

Bloc 4

Bloc 2

Bloc 1

Bloc 3

X

CEA DSM Irfu

i r f u

yalcas

i r f u

yalcas

- J-M Rey - EUCARD Meeting - UNIGE 08/06/2010 16

Bi 2212

Assume we can make a Rutherford cable using a round wire with 25% SC material

Ic @ 4.2K & 20T = 82A

Winding with 20% insulation

No cabling degradation

Good head treatment

Je = 130 A/mm²

We may expect B = 2.72T

Bloc 4

Bloc 2

Bloc 1

Bloc 3

X

CEA DSM Irfu

i r f u

yalcas

i r f u

yalcas

- J-M Rey - EUCARD Meeting - UNIGE 08/06/2010 17

YBCO

Using AMSC 344 Cu (made for magnets)4.55 x 0.22 = 1 mm²Ic @ 4.2K & 10T = 325AIc @ 4.2K & 15T = 245AExtrapolation : Ic @ 4.2K & 20T = 165AWinding with 20% insulationNo winding degradation

Je = 130 A/mm²We may expect B = 2.72T

Bloc 4

Bloc 2

Bloc 1

Bloc 3

X

Measured values

17

CEA DSM Irfu

i r f u

yalcas

i r f u

yalcas

- J-M Rey - EUCARD Meeting - UNIGE 08/06/2010 18

YBCO

Using AMSC 344 S (with stainless steel, not made for magnets)

1.41 mm²Ic @ 4.2K & 15T = 580AExtrapolation : Ic @ 4.2K & 20T = 500AWinding with 20% insulationNo winding degradation

Je = 285 A/mm²We may expect B = 5.96T

Bloc 4

Bloc 2

Bloc 1

Bloc 3

X

Measured value

18

CEA DSM Irfu

i r f u

yalcas

i r f u

yalcas

- J-M Rey - EUCARD Meeting - UNIGE 08/06/2010 19

YBCOUsing Super Power SCS 4050i

(with kapton insulation)

19

Unit Ribbon Insulated

Width mm 4 4.2

Thickness mm 0.1 0.3

Cross section mm² 0.4

SC cross section mm² 0.004

Cu Cross section mm² 0.016

SC / Non SC ratio % 1%

19

CEA DSM Irfu

i r f u

yalcas

i r f u

yalcas

- J-M Rey - EUCARD Meeting - UNIGE 08/06/2010

YBCO ribbon characterization

16 mars 2010 20

Results (with 0.1 µV/cm criterion) :

Je = 275 A/mm² @ 20K & 13T

We may reach what we need !

(287 A/mm² @ 4.2K & 18T)

Worrying concern: this tape blew up after 8 critical current measurement under 15T at 4.2K and 30K

20

CEA DSM Irfu

i r f u

yalcas

i r f u

yalcas

- J-M Rey - EUCARD Meeting - UNIGE 08/06/2010

YBCO ribbon characterization

Test “as purchased”

16 mars 2010 21

Test after “damaging quench”

21

CEA DSM Irfu

i r f u

yalcas

i r f u

yalcas

- J-M Rey - EUCARD Meeting - UNIGE 08/06/2010

YBCO ribbon characterization•Some measurements problems :

To much heat power generated in the sample-current leads junctions : Uneasy to regulate the température.

The problem is corrected but we haven’t done the tests again yet.

•It’s very difficult to limit the heat generation next to the sample when high current (> 500A) flows through the sample over long period of time (> 20s).

A new measurement setup is needed for high current under low field

16 mars 2010 2222

CEA DSM Irfu

i r f u

yalcas

i r f u

yalcas

- J-M Rey - EUCARD Meeting - UNIGE 08/06/2010 23

A rough mechanical approach - Forces Blo

c 4

Bloc 2

Bloc 1

Bloc 3

X

1040 tonnes

50 tonnes

CEA DSM Irfu

i r f u

yalcas

i r f u

yalcas

- J-M Rey - EUCARD Meeting - UNIGE 08/06/2010 24

A rough mechanical approach - Stresses

Bloc 4

Bloc 2

Bloc 1

Bloc 3

X

Stress 270 MPa20 mm

Mid plane Stress 17 MPa

Interbloc Stress 9 MPa

CEA DSM Irfu

i r f u

yalcas

i r f u

yalcas

- J-M Rey - EUCARD Meeting - UNIGE 08/06/2010 25

Bloc 4

Bloc 2

Bloc 1

Bloc 3

X

StructureWhy should we keep the insert in a

circular bore?

25

CEA DSM Irfu

i r f u

yalcas

i r f u

yalcas

- J-M Rey - EUCARD Meeting - UNIGE 08/06/2010 26

Winding

Bloc 4

Bloc 2

Bloc 1

Bloc 3

X

How to use ribons for the mid plane pancake ?

Can we assemble ribbons to increase Ic ?

Can we mix Bi2212 and YBCO in the same insert ?

26

CEA DSM Irfu

i r f u

yalcas

i r f u

yalcas

- J-M Rey - EUCARD Meeting - UNIGE 08/06/2010

Winding

27

Winding developments can be inspired from the INNOVAC project (Danish Technical Institute/Danfysik/ Siemens)

From an IOP presentation by Nikolaj Zangenberg, Danish Technological Institute

CEA DSM Irfu

i r f u

yalcas

i r f u

yalcas

- J-M Rey - EUCARD Meeting - UNIGE 08/06/2010 28

ProtectionBloc 4

Bloc 2

Bloc 1

Bloc 3

X

Can we allow HTS to quench ?HTS material degradation often observed after

quench

Where could we have copper ?The need of high current density does not

leave place for stabilizer

28

CEA DSM Irfu

i r f u

yalcas

i r f u

yalcas

- J-M Rey - EUCARD Meeting - UNIGE 08/06/2010 29

It may be wise to add a contribution of the HTS fringe field on the Nb3Sn

winding.

A sub task with T3 and T4 people for the interface definition is strongly

needed !

29