System 5000 Specifications - WordPress.com · superior feeding system The high-speed System 5000...

Transcript of System 5000 Specifications - WordPress.com · superior feeding system The high-speed System 5000...

fully automated bookletmaking systemsuperior feeding systemnon-stop productivityunparalleled versatility5000 booklets per hour10000 collated sets per hour

System 5000realise the potential of print

Duplo presents the first truly automatic finishing machine that delivers cutting edge technology and speeds of up to 5,000 booklets and 10,000 collated sets per hour. The heavy-duty System 5000 demonstrates superbversatility with its ability to feed up to 300gsm covers and a variety of sheet sizes. Fully loaded with a wide range of first-rate features, the System 5000 will turn any novice into a finishing expert.

Duplo DC-10/60 Collator

Duplo DSF-2000 Sheet Feeder

In-line digital printer

Duplo DBM-500

Duplo International Ltd, Sandown Industrial Park,Mill Road, Esher, Surrey, KT10 8BL, England

t +44 (0)1372 468131f +44 (0)1372 460252

email: [email protected]: www.duplointernational.com

realise the potential of print

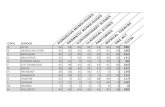

DC-10/60 CollatorNumber of Bins 10, 20, 30, 40, 50, 60Paper Size (Min./Max.) 120mm x 148mm to 350mm x 500mmPaper Weight 40 – 300gsmBin Capacity 60mmDetection Double-feed, misfeed, paper jam, paper,

transport jam, bin emptySpeed Bookletmaking - up to 5,000 sets per hour*

Collating - up to 10,000 sets per hour*Feed System Vacuum belt with air sheet separationOther Features 5-digit display; twin conveyor vertical paper

transport; left or right exit selection; automatic bin selection; 4-step overlap controls; multi-stepspeed adjustment; block mode; interleaving sheet insertion; reject tray (right and left); hand-marry unit

Connecting Devices DBM-500 BookletmakerDC-12JR Rear JoggerDBM-300 Bookletmaker DBM-400 STR Right StackerDBM-400 STL Left Stacker

Options Document Integrity System (Barcode Scanners), Intelligent Multi-bin Feeding System

Dimensions (LxWxH) 630mm x 750mm x 1972mm when connectedto the lift unit

Power Consumption 230V 50Hz 4.5AWeight 320kg

DSF-2000 Sheet FeederCapacity:Main (Upper) Tray 2000 x 80gsm sheetsSecondary (Lower) Tray 600 x 80gsm sheetsPaper WeightsMain (Upper) Tray 60 - 130gsm Secondary (Lower) Tray 60 - 250gsm (160gsm for art / coated stock)

Sheet Size (Min./Max.) 210mm x 297mm to 457mm x 320mm*Speed (A4) Max. 150 sheets /min

Max. 60 books /min(A3) Max. 52 books /min

*Set Thickness Max. 25 sheets (80gsm)Detection Miss feed; double feed; Optical Mark

Recognition (Standard) upper & lower side of sheet; count and check function; search for last sheet function

Options Bar Code Reading Upper side of sheet; verify correct sequence;

complete set; no doubles; insert from tray BJob Tracking Auto set up from job ticket; reporting of books

competedDCM Kit Air knives for main and secondary feed trays,

active anti-static barDimensions (LxWxH) 1100mm x 750mm x 1020mmPower Requirements 230V 50Hz 0.9AWeight 136kg

DBM-500 Bookletmaker

Saddlestitching and FoldingSheet Size (Min./Max.) 120mm x 170mm to 350mm x 500mmPaper Capacity Up to 25 sheets**Speed Up to 5,000 sets per hour*Detection Wire draw detectionNumber of Stitcher Heads 1-4 (2 standard) Hohner headsStitch Positions Saddle, corner, side, none (fold only)Programmable Memory Settings 12

Corner/Side/Top Stitching ApplicationSheet Size (Min./Max.) 170mm x 250mm to 250mm x 350mmPaper Capacity Up to 30 sheets**Dimensions (LxWxH) 1610mm x 700mm x 1005mmPower Requirements 230V 50Hz 3.8AWeight 412kg

Other Features LCD touch panel and ten-key pad; DBM-500T settings adjustable from DBM-500 control panel;accepts set-by-set and sheet-by-sheet; jam clearance accessibility; side and corner stitchcatch tray; attachment for inserting loose sheets into booklets; external fold skew adjustment

Connecting Devices DC-10/60 Collator, DBM-500T Trimmer,DSF-2000 Sheet Feeder

System 5000 Calendar Kit for DBM-500Size A4 / Cover: A3 A5 / Cover: A4Sheet Weight 105gsm - 157gsm 157gsm - 250gsmNumber of Sheets Per Set 3 - 12 sheets Cover 1 sheet

DBM-500T TrimmerTrimming Mechanism Upper and lower shearing actionBooklet Sizes (Min./Max.) 85mm x 120mm to 250mm x 350mm Trimmed Booklet Sizes (Min./Max.) 75mm x 120mm to 250mm x 350mmTrim Margin 1 to 25mmSpeed Up to 5,000 sets per hour*Other Features Jam detectors; inter-locking safety covers;

automatic setting exit rollers; bypass for documents that do not need a face trim; trim/no trim; trim scrap-box-full sensor; spine compression

Connecting Devices Extended conveyor; batch kicker, short stackerDimensions (LxWxH) 584mm x 700mm x 1094mmPower Consumption 230V 50Hz 3.3AWeight 241kg

DBM-2KT Knife TrimmerSpeed up to 4,000 A5 books/hr**Max trim 25mm on each edgeMin trim 2mm on each edgeMax thickness 50sheets (80gsm)

Book sizesMax book size from DBM500 356 x 250mmMin book size from DBM500 124 x 75mmMax book size using bypass (untrimmed) 356 x 250mmMin book size using bypass (untrimmed) 120 x 75mmTrimming not possible for books less than 124mm in lengthDimensions 2540mm (W) x 758mm(D) x 1100mm(H)Power requirements 200V, 5.4AWeight 365kg

DBM-400 STR/L StackerSheet Capacity (Min./Max.) 140mm x 210mm to 350mm x 500mmPaper Capacity 430mmSpeed Up to 10,000 sets per hour*Other Features Automatic size change; 12 programmable

memory settings; straight or offset stacking; jam and door open detectors

Dimensions (LxWxH) 750mm x 880mm x 890mmPower Consumption Supplied by collatorWeight 148kg

System 5000 Specifications

*Dependent upon connected devices and number of bins in use **Dependent upon paperweight and size

Ref: E-S5000BR/05

Production rates are based on optimal operating conditions and may vary depending on stock and environmentalconditions. As part of our continuous product improvement program, specifications are subject to change without notice.

Duplo is a trade mark of the Duplo Corporation Duplo has a policy of continuous improvement

and reserves the right to amend the above specifications without prior notice

System 5000

A modular approachDuplo has designed print finishing systems with modular components, which communicate with one another. Changes between jobs,even between sheet-by-sheet and set-by-set input, is at the touch of a button. The modular system means printers can invest inequipment to meet current demands, and scale up the system as those demands change. Our newest module, the DBM-2KT, provides anindependent modular approach to trimming all open sides of a booklet, removing the need to pre-guillotine printed pages before collating,saving both time and money.

DBM-2KT Knife Trimmer

superior feeding system

The high-speed System 5000 collators, connectable up to 60bins, deliver superior performance while maintaining completeaccuracy

• Each bin has two individual, adjustable fans to deliver variable amounts of air and vaccum per bin, to suit different stocks.

• Vacuum belt feed system with 260cm square of contact area for accurate and consistent feeding.

• Fast and accurate double sheet and misfeed detection.

Duplo presents the first truly automatic finishing machine that delivers cutting edge technology and speeds of up to 5,000 booklets and 10,000 collated sets per hour. The heavy-duty System 5000 demonstrates superbversatility with its ability to feed up to 300gsm covers and a variety of sheet sizes. Fully loaded with a wide range of first-rate features, the System 5000 will turn any novice into a finishing expert.

non-stop productivity

• Each tower is equipped to operate independently, allowing two jobs to run at the same time in two different output directionseg booklets and stacked sets

• The special block mode function allows continuous, on the fly reloading while the towers are in operation.

• Downtime is dramatically reduced as doubles and misfeeds are diverted into a unique reject tray without stopping or interrupting production.

• Having the largest bin capacity in its class means more print can be loaded into each bin, increasing machine running time between loading.

a sound investment

Among the multitude of features that set the System 5000 aboveand beyond its competition, the bookletmaker also boasts a re-designed fold unit that provides a flatter, crisper fold. Engineeredto meet your every demand, this revolutionary machine is thefastest, easiest, most economical and accurate method availablefor turning printed material into quality finished documents.

not just a collator - an intelligent feeder

With an optional touch-screen PC controller and custom designed Duplo software, the towers transform into the IMBF (IntelligentMulti-bin Feeder), enabling the operator to select the bin fromwhich to feed from and the feeding sequence. The IMBF fulfilsa variety of applications in the digital printing environment

• One-to-one marketing material based on a pre-determined database.

• Mailing applications with optional folder/inserter unit.

• Inserting selected pre—printed material into black and white and colour merging jobs.

three knife trimming

The 2KT unit provides a unique, scalable and modular solution tothe requirement for three-knife trimming of saddle-stitched andfolded booklets. Benefits include:

• Fully automatic set-up

• The U-shaped configuration takes up very little additional space at the end of the machine.

• Oversized full-bleed booklets will not require additional finishing since all three open edges are trimmed in one pass.

truly automatic finishing

Push-button setup and changeover make the System 5000bookletmaker the world’s easiest to use stitcher/folder.

• Go from 350mm x 500mm to a CD size book job without anyadditional parts or manual intervention. The stitcher heads, side guides, back joggers, stitch and fold stoppers, and even the foldroller gap automatically adjust in only 25 seconds.

• The bookletmaker’s LCD touch panel enables all functions of the trimmer to be controlled from the main unit.

• Easy changeover is achieved by diverting corner or side-stitchedjobs to a separate catch-tray, while other jobs continue to passthrough the trimmer onto the belt-stacker.

• The memory stores up to 12 frequently used jobs for effortless changeover.

unparalleled versatility

Incorporating significant technical upgrades, the fully automaticDBM-500 bookletmaker is exceptionally user-friendly, versatile,and includes a revolutionary offering that sets itself apart from competitors:

• A state-of-the-art set accumulation system offers complete flexibility by accepting both set-by-set of the traditional offset press and sheet-by-sheet pre-collated output of digital printers.

• Developed to meet UP3I standardization, set to becomethe graphic arts industry standard for machine language,the DBM-500 bookletmaker will be connectable in-line to all UP3I compatible digital printers.

the duetto system

The Duetto bookletmaking and collating solution incorporates upto three DC-10/60 collating towers, a DSF-2000 dynamic sheetfeeder, DBM-500 bookletmaker and DBM-500T trimmer.

The Duetto system is the first of its kind to address both digital and offset print finishing requirements. The ability ofthe DBM-500 to handle set-by-set and sheet-by-sheet output with equal ease makes the system ideal for printers making thetransition from offset to digital, allowing the incorporation ofcolour content and variable data into their finishing solutions.

Printers once had to purchase two separate finishing lines foreither offset or digital print. The Duetto is the first system to offer a combined offset and digital print finishing solution.

Duplo has designed print finishing systems with modularcomponents, which communicate to one another. Changesbetween jobs, even between sheet-by-sheet and set-by-setinput, is at the touch of a button.

The modular system means printers can invest in equipment to meet current demands, and scale up the system as thosedemands change.

The main control panel automaticallyadjusts all functions of the trimmer.

Corner and side-stitched jobs arediverted into a separate catch tray forfaster production.

The reject tray collects doubles andmisfeeds ensuring non-stop productivity.

DC-10/60 collator Class leading 60mm feed bin capacity

The simple to use touch-screen, keypad, and LED display allows for easy navigation and programming.

System 5000realise the potential of print

![Portable LED Luminaire - Candilux GmbH · 2016. 2. 25. · 6600 6600 9400 9400 28200 39600 122 105 122 101 109 97 Correlated Colour Temperature [K] 5000 5000 5000 5000 5000 5000 Rated](https://static.fdocuments.in/doc/165x107/611b2b29098d3326ef3bd61d/portable-led-luminaire-candilux-gmbh-2016-2-25-6600-6600-9400-9400-28200.jpg)