Emulsion Polymerization: Effects of Polymerization Variables on

Synthesis of poly(diiodophenyleneoxide)s through atom transfer radical rearrangement polymerization...

Click here to load reader

Transcript of Synthesis of poly(diiodophenyleneoxide)s through atom transfer radical rearrangement polymerization...

Reactive & Functional Polymers 68 (2008) 1594–1600

Contents lists available at ScienceDirect

Reactive & Functional Polymers

journal homepage: www.elsevier .com/locate / react

Synthesis of poly(diiodophenyleneoxide)s through atom transferradical rearrangement polymerization of variouscopper complexes – Effect of ligand

Oya S�anlı a,*, Fatma Zerrin Görgün a, Pinar Camurlu b

a Gazi Üniversitesi, Fen Edebiyat Fakültesi, Kimya Bölümü, Ankara 06500, Turkeyb Akdeniz Üniversitesi, Fen Edebiyat Fakültesi, Kimya Bölümü, Antalya 07058, Turkey

a r t i c l e i n f o

Article history:Received 19 February 2008Received in revised form 11 August 2008Accepted 24 August 2008Available online 31 August 2008

Keywords:Poly(diiodophenyleneoxide)Transition metal complexesAtom transfer radical rearrangementpolymerizationSolution polymerization

1381-5148/$ - see front matter � 2008 Elsevier Ltddoi:10.1016/j.reactfunctpolym.2008.08.012

* Corresponding author.E-mail address: [email protected] (O. S�anlı).

a b s t r a c t

Although extensive work has been devoted to explore the synthesis of poly(dichlorophen-yleneoxide)s and poly(dibromophenyleneoxide)s, in the literature synthesis of poly(diiod-ophenyleneoxide)s has been scarcely investigated. Hence, this study efforts to investigatethe synthesis of poly(diiodophenyleneoxide)s via atom transfer radical rearrangementpolymerization through decomposition of triiodophenoxy copper complexes withN,N,N0 ,N0-tetramethyl ethylenediamine, ethylenediamine, N,N0-dimethylformamide anddimethylsulfoxide ligands. Polymerizations were carried out to investigate the effect oftype of ligand and polymerization time on percent conversion, polymer structure andintrinsic viscosities of the polymers. Characterizations of the polymers were performedby FT-IR, DSC, 1H NMR and viscometric measurements. Among the synthesized polymers,the highest percent conversion was achieved by the decomposition of TMEN–Cu(TIP)2

complex and all the synthesized poly(diiodophenyleneoxide)s displayed selectivity in thefavor of 1–4 additions having linear structure and high Tg values.

� 2008 Elsevier Ltd. All rights reserved.

1. Introduction

The discovery of oxidative polymerization of the phe-nols to poly(phenyleneoxide)s has permitted the develop-ment of an entirely new family of engineering plastics. Thelargest commercial usage of this resin is in Noryl (regis-tered trademark, General Engineering Co.) engineering re-sin which are alloys of poly(2,6-dimethyl-1,4-phenyleneether) and polystyrene [1]. The halogenated poly(phenyl-eneoxide)s also have the outstanding mechanical, chemi-cal, thermal properties and can find use in applicationsrequiring fire resistance [2]. The original synthesis wasachieved by Hunter and his colleagues through the ethyliodide-induced decomposition of anhydrous silver2,4,6-trihalophenoxide [3]. Later Harrod et al. [5–9] andKısakürek et al. [6,8,10–14] revealed much progress in

. All rights reserved.

understanding the factors affecting the percent conversion,polymer structure and the mechanism of the reactionwhere the mechanism (Scheme 1) was concluded to beatom transfer radical rearrangement polymerization[13,14].

Up to date synthesis of poly(dihalophenyleneoxide)shave been surveyed through several transition and innertransition metal complexes with various amine ligandsthrough techniques like, electroinitiation in solution[15–18], thermal decomposition in solid state [19–24]and in solution [25–28]. Results of the intensive studies re-vealed that the polymers with lowest molecular weightwere obtained via electro-initiated polymerization andthe highest via thermal decomposition in solution. It wasobserved that as the amine ligand increases the oxidizingpower of metal, the thermal stability of the complexeswas decreased. The phenoxo complexes with chelatingligand were found to be exceptionally resistant to thermaldecomposition compared to non-chelating ligand along

O

POLYMER+ X.O OX

X

XX X

XX

III

O

X

X

X

Ligand / M Ligand / M

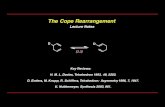

Scheme 1. The reaction mechanism of atom transfer radical rearrangement polymerization.

O. S�anlı et al. / Reactive & Functional Polymers 68 (2008) 1594–1600 1595

with the increase in the induction periods of polymer for-mation [25–27,29].

Although extensive work has been devoted to investigatethe effect of type of transition metal, ligand and polymeri-zation technique on the synthesis of poly(dichlorophenylene-oxide)s and poly(dibromophenyleneoxide)s, current study isthe pioneer to investigate the effect of type of ligand on struc-ture, induction period, percent conversion and Tg’s of poly(diiodophenyleneoxide) synthesised through atom transferradical rearrangement polymerization of bis(2,4,6-triiodo-phenolato) N,N,N0,N0-tetramethyl ethylenediamine copper(II)(TMEN–Cu(TIP)2), bis(2,4,6-triiodophenolato) ethylenedia-mine copper(II) (EN–Cu(TIP)2), bis(2,4,6-triiodophenolato)N,N0-dimethylformamide copper(II) (DMF–Cu(TIP)2) and bis(2,4,6-triiodophenolato) dimethylsulfoxide copper(II) (DMSO–Cu(TIP)2) complexes.

2. Experimental

2.1. Materials

Analytical grade 2,4,6-triiodophenol (Sigma ChemicalCo. Ltd.) was used without further purification. Reagentgrade tetramethyl ethylenediamine (TMEN, Merck), ethy-lenediamine (EN, Sigma), dimethylformamide (DMF,Merck) and dimethylsulfoxide (DMSO, Merck) were usedas the ligands in the preparation of complexes. Commer-cially available reagent grade copper sulfate pentahydrate;(CuSO4 � 5H2O, Merck) was used for preparation of com-plexes. Toluene (Merck) was used as the solvent duringpolymerization.

2.2. Instrumentation

Viscosity of the polymers measured in toluene at 30 �Cby using Schott Gerate AVS 400 model automatic viscome-ter equipped with Schott Gerate CT 1150 model thermo-stat. The glass transition temperatures of the polymerswere recorded by Pelkin–Elmer DSC-4 model differentialscanning calorimeter with 20 �C/min for 7-mg sample,where the treatment of the polymer samples was per-formed under nitrogen. The thermal analyses of the com-plexes were preformed by Dupont thermal analyst 2000DSC 910 S with 10 �C/min under nitrogen. Infrared spectraof the complexes and the polymers were recorded on aPelkin–Elmer 7500 FT-IR spectrometer by dispersing thesample in KBr pellets. Thermo gravimetric analyses of thecomplexes were performed in Perkin–Elmer Pyris 1 TGAcoupled with Spectrum 1 FT-IR Spectrometer. 1H NMR

spectra of samples were recorded by using Bruker Spectro-spin Avance DPX-400 Spectrometer. CDCl3 and TMS wereused as the solvent and the internal reference, respectively.Elemental analysis of the complexes was performed withHewlett–Packard 185 CHN elemental analyzer.

2.3. Syntheses of TMEN–Cu(TIP)2 and EN–Cu(TIP)2

complexes

Triiodophenol (0.04 mol) was dissolved in 100 ml dis-tilled water containing 0.04 mol sodium hydroxide (solu-tion 1). CuSO4 � 5H2O (0.02 mol) and 0.02 mol tetramethylethylenediamine (TMEN) or ethylenediamine (EN) weredissolved in 100 ml distilled water (solution 2). Solution1 was added to solution 2 dropwise while vigorous stirringat room temperature. The slurry solution formed was stir-red for 2 h. The resulting purple (TMEN–Cu(TIP)2) and darkbrown (EN–Cu(TIP)2) complexes were recovered by filtra-tion, washed with distilled water, and dried in a vacuumoven till to constant weight. Elemental analysis results ofthe complexes are given in Table 1.

2.4. Syntheses of Cu(TIP)2, DMF–Cu(TIP)2 andDMSO–Cu(TIP)2 complexes

2,4,6-Triiodophenol (0.02 mol) was dissolved in 100 mldistilled water containing 0.02 mol sodium hydroxide(solution 1). CuSO4 � 5H2O (0.01 mol) was dissolved in100 ml distilled water (solution 2). Solution 1 was addedto solution 2 dropwise while vigorous stirring at roomtemperature. The slurry solution formed was stirred for2 h. The resulting dark brown Cu(TIP)2 complex was recov-ered by filtration, washed with methanol and dried. Cu(-TIP)2 (0.02 mol) complex was dissolved in 100 ml DMF orDMSO and stirred for 1 h. Then, the solution was slowlyadded to distilled water and the DMF–Cu(TIP)2 or DMSO–Cu(TIP)2 complex as recovered as in previous procedure.Elemental analysis results of the complexes are given inTable 1.

2.5. Polymer synthesis

The atom transfer radical rearrangement polymeriza-tion of the complexes was performed at constant decom-position temperature of 70 �C where the effect of timewas investigated by variation of the decomposition periodbetween 6 and 48 h. During the synthesis of polymers 3.3 gof the complex was dissolved in 50 ml toluene and 1 mlCCl4 mixture and was placed into a round bottom three

Table 1Elemental analysis results of the complexes

Complex % C % H % N Molecularweight(g/mol)

Cal. Exp. Cal. Exp. Cal. Exp.

TMEN–Cu(TIP)2 19.28 21.09 1.98 2.71 2.49 2.49 1121.16EN–Cu(TIP)2 15.78 15.84 1.13 1.97 2.62 2.50 1065.12DMF–Cu(TIP)2 16.71 15.15 1.03 1.05 1.29 0.60 1071.14DMSO–Cu(TIP)2 15.42 15.35 0.93 1.21. – – 1083.18

The experimental errors ± 0.3.

1596 O. S�anlı et al. / Reactive & Functional Polymers 68 (2008) 1594–1600

neck balloon that was inserted in oil bath. The decomposedcomplex was precipitated, after the removal of the insolu-ble by-products by filtration, in large amount of ethanolcontaining a few drops of concentrated HCl. The precipi-tated polymer was recovered by filtration, washed withethanol and dried till to constant weight under vacuum.The calculated yields for the polymerizations were basedon the initial weight of the complexes; since the ligandand metal do not incorporate into the polymer, the resultsmay appear to be low in value. For all syntheses, the per-cent conversions were calculated as follows:

% Conversion ¼Weight of the polymeric productInitial weight of the complex

� 100

Fig. 1. FT-IR Spectrum of the (a) TMEN–Cu(TIP)2, (b) EN–Cu(TIP)2, (c)DMSO–Cu(TIP)2, (d) DMF–Cu(TIP)2 complexes and (e) poly(diiodophenyl-eneoxide)s.

3. Results and discussion

Synthesized amorphous complexes were subjected toelemental analysis to characterize the complexes. Resultsimplied the presence of one mole of ligand and two molesof phenolate coordinated to the copper ion in all the cases.FT-IR spectra of the complexes are similar to those of com-plexes given in literature [30], where phenol ligands werecharacterized by aromatic CAH stretching at 3000–3100 cm�1, C@C ring stretching at 1410–1610 cm�1 andCAO stretching at 1140–1300 cm�1, CAH out of planebending at 810–890 cm�1 (Fig. 1a–d). Amine ligands werecharacterized by aliphatic CAH stretching at 2800–3000 cm�1 and CAN stretching at 1000–1250 cm�1 alongwith the presence of intense C@O stretching (amide I band)at 1640 cm�1 incase of DMF (Fig. 1d). Presence of DMSO asligand was clearly signified via S@O stretching centered at1056 cm�1 (Fig. 1c). For all the complexes the polymer for-mation was followed by the FTIR through the appearanceof the new peaks around 1040 cm�1 due to formation ofthe etheric bonds during the polymerization. Hence, thepolymers were characterized by the C@C stretching at1421, 1578 and 1601 cm�1, CAOAC stretching at 1039,1008 and 995 cm�1, CAO stretching at 1100–1226 cm�1,out of plane CAH bending at 859 and 890 cm�1, CAHstretching at 3070 cm�1 and C@C out of plane bending at718 cm�1 of benzene ring. The peak around 3500 cm�1 sig-nified the phenolic end group of the polymer (Fig. 1e).Thermal behaviors of the complexes were investigated byDSC measurements under nitrogen atmosphere (Fig. 2).TMEN–Cu(TIP)2, DMSO–Cu(TIP)2 and DMF–Cu(TIP)2 com-plexes revealed a single sharp exothermic peak at 161.2,130.1 and 114.4 �C, respectively. The exothermic peaks

are attributed to the new bond formation during polymer-ization which previously supported by DSC-IR study [22].

Table 2 depicts the polymerization induction periodswhich were followed by the formation of turbidity during

Fig. 2. DSC thermograms of (a) DMF–Cu(TIP)2, (b) DMSO–Cu(TIP)2 and (c)TMEN–Cu(TIP)2.

0 10 20 30 40 502

4

6

8

10

12

14

16

18 TIP COMPLEXES

% C

onve

rsio

n

Time (h)

TMENEN DMSO DMF

Fig. 3. Percent conversion vs. time graph of TMEN–Cu(TIP)2, EN–Cu(TIP)2,DMSO–Cu(TIP)2 and DMF–Cu(TIP)2 complexes at polymerization temper-ature of 70 �C.

O. S�anlı et al. / Reactive & Functional Polymers 68 (2008) 1594–1600 1597

the initial stage of polymerization. As reflected, the induc-tion periods are in the order of DMSO > DMF > EN > TMENligand functionalized complexes, where the order is con-sidered to be related with the stability of the initial com-plex [9,4]. Previous studies have also implied thisdependency where the phenoxo complexes with chelatingligands were found to be highly resistant to thermaldecomposition as compared to non-chelating ligands[5,26]. Similar trend was shown to be relevant withpoly(diiodophenyleneoxide)s. The decline in the inductionperiods were considered to be due to pronounced leavinggroup properties of I atom in comparison to Br and Cl.

The atom transfer radical rearrangement polymeriza-tion of copper triiodophenolate complexes were achievedin toluene at constant temperature of 70 �C with variationin polymerization period (Fig. 3). As a general trend, thepercent conversion increased with the polymerization per-iod and followed the TMEN > EN > DMF > DMSO orderwhich is in the reverse sequence in terms of induction peri-ods. Table 3 presents the relevant data that provides theopportunity to investigate the effect of type of phenol onpercent conversion. As a general trend, irrespective of thetype of the ligand used, percent conversion increased asthe size of the halogen decreased (TCP > TBP > TIP). Theunderlying reasons could be (1) the atomic weight differ-

Table 2Induction periods of poly(dihalophenyleneoxide)s synthesized throughvarious copper complexes in solution

Type of ligand Type of phenol Induction period

TMENa TIP 10ENa TIP 20DMSOa TIP 27DMFa TIP 30TMEN [26] TCP 45EN [26] TCP 56DMSO [27] TCP 160DMF [27] TCP 120

a Current study.

ences between the halogens that would lead to a decreasein percent conversion and (2) the steric effect that preventsthe head-to-tail but rather enhances the tail-to-tail typecoupling.

The effect of the thermal decomposition (loss of ligand,phenol, etc.) of the complexes on polymerization wasinvestigated via TGA-FT-IR study (Fig. 4). For this purposecomplexes were subjected to thermogravimetric analysisat temperatures between 30 and 250 �C and evolved gas-eous products were investigated by FT-IR. The thermo-gravimetry scan of the TMEN–Cu(TIP)2 complex showedsingle type weight loss starting from 120 �C and reachedits maximum at 180 �C. At 265 �C remaining residue ofcomplex was less than 55.07%. This behavior was drasti-cally altered in case of DMF–Cu(TIP)2 and DMSO–Cu(TIP)2

complexes, where both of the complexes stable only upto 95 �C. Decomposition of the DMF–Cu(TIP)2 complexreached its maxima at 120 �C with a the remaining residueof 78.1% at 265 �C. TGA thermogram of DMSO–Cu(TIP)2

complex revealed a multi-step decomposition profile thatwas maximized at 123 �C, 176 �C, 203 �C having 74.8% res-idue at 265 �C. As seen from both the DSC and TGA studiesthe complex with chelating ligand (TMEN) was found to bemore resistant to thermal decomposition compared tonon-chelating ligands such as DMF and DMSO.

Fig. 5 represents the FT-IR spectrum of the gaseousproducts evolved during the TGA scan of the complexesat the temperatures of maximum weight loss. DMF–Cu(TIP)2 complex revealed a well defined spectrum of thegaseous product that has the characteristic peaks at 1051and 1349 cm�1 (CAN stretching), 1691 cm�1 (C@O stretch-ing), 2847–2934 cm�1 (aliphatic CAH stretching), indicat-ing the ligand, DMF, evolution. Similarly, the gaseousproduct of TMEN–Cu(TIP)2 complex also disclosed thecharacteristic peaks of the amine ligand which were cen-tered at 1012, 1283, 1471 and 3072 cm�1. However,DMSO–Cu(TIP)2 complex showed an ill-defined FT-IR spec-trum where evolution of DMSO considered to be signifiedby the S@O stretching at 1093 cm�1, aliphatic CAH stretch-

Table 3Percent convertions of poly(dihalophenyleneoxide)s synthesized throughvarious copper complexes in solution

Type ofligand

Polymerizationperiod

% Conversion

TIPa TBP TCP

TMEN 3 – 6.5 19.56 4.8 10 31.812 7.8 10.9 37.024 8.5 11.4 38.948 17.9 – –

EN 3 – 12 22.56 6.4 19.8 35.512 7.2 21 50.924 8 22.2 57.548 8.6 – –

DMSO 3 – 41.7 17.16 4.0 52.2 21.412 6.2 – –18 – 63.4 37.924 7.6 66.1 48.348 8.0 – –

DMF 3 48.7 21.36 3.2 60.9 44.812 5.6 – –18 69.6 63.824 6.2 76.5 68.948 7.9 – –

a Current study; TMEN/TCP, TMEN/TBP, EN/TCP, EN/TBP [26]; DMSO/TCP, DMSO/TBP, DMF/TCP, DMF/TBP [27].

1598 O. S�anlı et al. / Reactive & Functional Polymers 68 (2008) 1594–1600

ing at 2940 cm�1. According to TGA-FT-IR study all of thecomplexes were found to be stable at the polymerizationtemperature of 70 �C. However, prolonged polymerizationperiods could be affected by the loss of ligands duringpolymerization.

1H NMR was utilized to enlighten the structural proper-ties of the resultant poly(diiodophenyleneoxide)s (Fig. 6).The signals at d = 8.2, 7.05 ppm and d = 7.2 ppm were attrib-uted to the 3,5 protons of 2,4-diiodo-1,6-phenyleneoxideunits (1,2-addition) and to the 3 protons of 2,6-dibromo-1,4-phenyleneoxide units (1,4-addition), respectively.According to the integration results, for all of the synthe-

Fig. 4. TGA thermogram of the complexes with a scan rate of 5 �C/min.

sized polymers irrespective of the type of the ligand of thecomplex, the polymerizations were considered to proceedmainly through 1,4-addition rather than 1,2-addition, lead-ing to linear structure (Fig. 7). Table 4 represents the struc-ture of the some of the poly(dihalophenyleneoxide)s inliterature among which poly(dichlorophenyleneoxide)ssynthesised through copper complexes were found to bebranched irrespective of the type of ligand present in initialcomplex. With the exception of EN as the amine ligand,poly(dibromophenyleneoxide)s generally were confirmedto be mainly in linear form.

It has been previously shown that the polymers synthe-sized through ATRRP of trihalophenoxide–metal com-plexes have anomalously low intrinsic viscosities whichwere correlated with the high degree of branching of thepolymer. In general the polymers synthesized throughthe ATRRP of triiodophenoxo complexes yielded the high-est intrinsic viscosities among the halogenated phenols.All these are in concurrence with the previous works[31,32], where the results implied superior reactivity ofthe para-position than ortho-position and halogen selectiv-ity of the displaced phenols as in the order of I > Br > Cl.Hence, the easy access of para-position relative to ortho-po-sition and selectivity of the iodine led to a linear polymerwith the minor amount of monomeric branches. Synthe-sized poly(diiodophenyleneoxide)s revealed rather highTgs where the ligand dependency seem to be insignificantwith respect to the other poly(dihalophenyleneoxide)s. Insome cases results of the viscosity and Tg measurementsmay appear as if they are inconsistent. Structures of the

Fig. 5. Simultaneous FT-IR spectrum of the evolved gases during TGAscan.

Fig. 6. 1H NMR Spectrum of the polymer obtained from the ATRRP of (a) TMEN–Cu(TIP)2 and (b) EN–Cu(TIP)2.

I

O

O O O

O

n

O

O

O

n

OO

O

On

I

I

I

I

I

I

II

I

I

II

I

I

I

I

I

I

I

I

I

I

I

I

a

b

c

I

O

O

Fig. 7. Possible structures of poly(diiodophenyleneoxide)s, (a) 1,4-addition, (b) 1,2-addition and (c) both 1,4- and 1,2-addition.

Table 4Structure, intrinsic viscosities and glass transition temperatures ofpoly(dihalophenyleneoxide)s synthesized through various copper com-plexes in solution

Type of ligand Type of phenol Structure [g] (dl/g) Tg (�C)

TCP [26] Branched 0.022 283TMEN TBP [26] Linear 0.096 270

TIP a Linear 0.181 240

TCP [26] Branched 0.026 280

EN TBP [26] Branched 0.056 278TIPa Linear 0.130 240

TCP [27] Branched – 125

DMSO TBP [27] Linear – 150TIPa Linear 0.354 220

TCP [27] Branched – 152

DMF TBP [27] Linear – 110TIPa Linear 0.149 250

a Current study.

O. S�anlı et al. / Reactive & Functional Polymers 68 (2008) 1594–1600 1599

all polymers are considered to be mainly linear. However,it is obvious that almost all of the polymers contain somebranched parts with in their structure. Hence, this situa-tion could be due to relative increase in the number ofbranched units with in the polymer that may lead to thisinconsistency.

4. Conclusion

In this study poly(diiodophenyleneoxide)s were syn-thesised through atom transfer radical rearrangementpolymerization of bis(2,4,6-triiodophenolato) N,N,N0,N0-tetramethyl ethylenediamine copper(II) (TMEN–Cu-(TIP)_2), bis(2,4,6-triiodophenolato) ethylenediaminecopper(II) (EN–Cu(TIP)_2), bis(2,4,6-triiodophenolato)N,N0-dimethylformamide copper(II) (DMF–Cu(TIP)_2) andbis(2,4,6-triiodophenolato) dimethylsulfoxide copper(II)(DMSO–Cu(TIP)_2) complexes for the first time. The atomtransfer radical rearrangement polymerization of coppertriiodophenolate complexes were achieved in toluene at

1600 O. S�anlı et al. / Reactive & Functional Polymers 68 (2008) 1594–1600

constant temperature of 70 �C with variation in polymeri-zation period where the percent conversion increased withthe polymerization period and followed the TME-N > EN > DMF > DMSO order. This order is in the reverse se-quence in terms of induction periods which wasconsidered to be related with the stability of the initialcomplex. As a general trend, irrespective of the type ofthe ligand used, poly(diiodophenyleneoxide)s revealedlower percent conversion than other poly(dihalophenyl-eneoxide)s. This fact could be both due to the atomicweight differences of the halogens and to the steric effectthat might prevent the head-to-tail type coupling. Poly(dii-odophenyleneoxide)s were found to be linear structurewith higher intrinsic viscosities than the halogenatedpoly(phenyleneoxide)s. All the polymers had high Tg val-ues indicating that they are rigid polymers.

Acknowledgments

Authors gratefully thank Gazi and Akdeniz UniversityResearch Funds for their support.

References

[1] I.K. Jacqueline, Concise Encyclopedia of Polymer Science andEngineering, John Wiley and Sons, New York, 1990.

[2] G. Gündüz, D. Kısakürek, S. Kayadan, Polym. Degrad. Stabil. 64(1999) 501.

[3] W.H. Hunter, A.O. Olson, E.A. Daniels, J. Am. Chem. Soc. 38 (1916)1761.

[4] H.S. Blanchard, H.L. Finkbeiner, G.A. Russell, J. Polym. Sci. 58 (1962)469.

[5] B. Carr, J.F. Harrod, J. Am. Chem. Soc. 95 (1973) 5707.[6] J.F. Harrod, P. Van Gheluwe, D. Kısakürek, A. Shaver, Macromolecules

14 (1981) 565.[7] J.F. Harrod, A. Shaver, Macromolecules 15 (1982) 676.[8] D. Kısakürek, N. Binboga, J.F. Harrod, Polymer 28 (1987) 767.[9] J.F. Harrod, Can. J. Chem. 47 (1969) 637.

[10] M. Saçak, U. Akbulut, D. Kısakürek, L. Türker, L. Toppare, J. Polym. Sci.Polym. Chem. 27 (1989) 1599.

[11] L.M. Karabey, D. Kısakürek, Macromol. Chem. Phys. 202 (2001) 2999.[12] L. Türker, D. Kısakürek, Brit. Polym. J. 20 (1988) 131.[13] G.B. Celik, D. Kısakürek, Des. Mon. Polym. 9 (2006) 663.[14] G.B. Celik, W. Sultan, D. Kısakürek, e-Polymers 73 (2006).[15] S�. S�en, D. Kısakürek, Polymer 34 (1993) 4146.[16] L. Aras, S�. S�en, D. Kısakürek, Polymer 36 (1995) 3013.[17] S�. S�en, D. Kısakürek, L. Toppare, J. Macromol. Sci. Pure A30 (1993)

481.[18] M. Saçak, U. Akbulut, D. Kısakürek, L. Türker, L. Toppare, J. Polym. Sci.

Polym. Chem. 27 (1989) 1599.[19] M. Bas�türkmen, D. Kısakürek, Polymer 34 (1993) 625.[20] O. S�anlı, M. Pulat, D. Kısakürek, Eur. Polym. J. 31 (1995) 255.[21] N. Kesici, D. Kısakürek, Polym. Int. 50 (2001) 1061.[22] M. Bas�türkmen, D. Kısakürek, J. Macmol. Sci. Part A 41 (2004) 1071.[23] D. Kısakürek, A. Aslan, Polymer 41 (2000) 5149.[24] M. Pulat, O. S�anlı, Macromol. Chem. Phys. 197 (1996) 811.[25] O. S�anlı, D. Kısakürek, Makromol. Chem. 193 (1992) 619.[26] H._I. Ünal, O. S�anlı, D. Kısakürek, Polymer 30 (1989) 344.[27] D. Kısakürek, O. S�anlı, Makromol. Chem. 190 (1989) 843.[28] L.K. Molu, D. Kısakürek, J. Appl. Polym. Sci. 86 (2002) 2232.[29] D. Kısakürek, L. Aras, O. S�anlı, METU J. Pure Appl. Sci. 23 (1990) 9.[30] A.R. West, Basic Solid State Chemistry, John Wiley and Sons, New

York, 1988.[31] D. Kısakürek, in: J.C. Salamone (Ed.), Poly(dichlorophenylene oxide)s

(by Pyridine/Copper Complex) Polymeric Materials Encyclopedia,CRC Press, 1996, p. 5731.

[32] W. Hunter, M.A. Dahlen, J. Am. Chem. Soc. 54 (1932) 2456.