Synthesis and Characterization of Silica Nanotube by...

Transcript of Synthesis and Characterization of Silica Nanotube by...

-

Communications to the Editor Bull. Korean Chem. Soc. 2010, Vol. 31, No. 12 3519DOI 10.5012/bkcs.2010.31.12.3519

Synthesis and Characterization of Silica Nanotube by Glycyldodecylamide as a Template†

Sang-Cheol Hana and Sang-Eon Park*

Laboratory of Nano-Green Catalysis and Nano Center for Fine Chemicals Fusion Technology, Department of Chemistry, Inha University, Incheon 402-751, Korea. *E-mail: [email protected]

Received December 14, 2009, Accepted October 19, 2010

Key Words: Silica nanotube, Glycyldodecylamide, Bio-silication, Self-assembly

NH

H2N

OHNN

H2

O

NH

H2N

OHNN

H2

O

HN

NH2

ONH

H2N

O

HN

NH2

ONH

H2N

O

NH

H2N

OHNN

H2

O

NH

H2N

OHNN

H2

O

HN

NH2

ONH

H2N

O

HN

NH2

ONH

H2N

O

NH

H2N

OHNN

H2

O

NH

H2N

OHNN

H2

O

HN

NH2

ONH

H2N

O

HN

NH2

ONH

H2N

O

Cool down for re-assembly of GDA at R.T. in water

GDA amphiphiles lamellar crystal

N

N

ON

N

O

HH HH

HHN

N

ON

N

O

HH HH

HHN

NO

N

NO

HH HH

HHN

NO

N

NO

HH HH

HH

N

NO

H H

HN

N

O

H H

HN

NO

H H

HN

NO

H H

H N

N

O

H H

H N

N

O

H H

H N

N

O

H H

HN

NO

H H

H

N

NO

HH

HN

NO

HH

HN

NO

HH

H

N

N

O

H H

H

3~4nm

N

ON

H

H H

NO

NHH H

NO

NHH

H

NO

NHH

HNO

NHH

H NO

NH H

H NO

NH H

HN

ON

H H

HN

ONH

H

H

N

O NH

H

H

N

O NHH

H

N

ON

H

HH

NO

N HHH

NO

N HH

H

N O

N HH

HN O

N HH

HNO

NHH

HNO

NHH

HN

ONHH

H

N

ONH

H

H

N

ONH

H

H

N

ONH

H

H TEOS (Silication)

Extractionin EtOHand Dry

40~45nm

Dissolving water at 60°Cusing ultrasonification

Cool down for re-assembly of GDA at ice temp in ice bath

SNT-1 SNT-2

N

NOH

H

H

NNOH

H H

NNOHH

H

NNO

HH

H

NNOHH

H

NN

OH

HH

NNO

HH H

NNO

HH

H

N

NO

H H

H

NH

H2N

OHNN

H2

O

NH

H2N

OHNN

H2

O

HN

NH2

ONH

H2N

O

HN

NH2

ONH

H2N

O

NH

H2N

OHNN

H2

O

NH

H2N

OHNN

H2

O

HN

NH2

ONH

H2N

O

HN

NH2

ONH

H2N

O

NH

H2N

OHNN

H2

O

NH

H2N

OHNN

H2

O

HN

NH2

ONH

H2N

O

HN

NH2

ONH

H2N

O

NH

H2N

OHNN

H2

O

NH

H2N

OHNN

H2

O

HN

NH2

ONH

H2N

O

HN

NH2

ONH

H2N

O

NH

H2N

OHNN

H2

O

NH

H2N

OHNN

H2

O

HN

NH2

ONH

H2N

O

HN

NH2

ONH

H2N

O

NH

H2N

OHNN

H2

O

NH

H2N

OHNN

H2

O

HN

NH2

ONH

H2N

O

HN

NH2

ONH

H2N

O

NH

H2N

OHNN

H2

O

NH

H2N

OHNN

H2

O

HN

NH2

ONH

H2N

O

HN

NH2

ONH

H2N

O

NH

H2N

OHNN

H2

O

NH

H2N

OHNN

H2

O

HN

NH2

ONH

H2N

O

HN

NH2

ONH

H2N

O

NH

H2N

OHNN

H2

O

NH

H2N

OHNN

H2

O

HN

NH2

ONH

H2N

O

HN

NH2

ONH

H2N

O

Cool down for re-assembly of GDA at R.T. in water

GDA amphiphiles lamellar crystal

N

N

ON

N

O

HH HH

HHN

N

ON

N

O

HH HH

HHN

NO

N

NO

HH HH

HHN

NO

N

NO

HH HH

HH

N

NO

H H

HN

N

O

H H

HN

NO

H H

HN

NO

H H

H N

N

O

H H

H N

N

O

H H

H N

N

O

H H

HN

NO

H H

H

N

NO

HH

HN

NO

HH

HN

NO

HH

H

N

N

O

H H

H

N

N

ON

N

O

HH HH

HHN

N

ON

N

O

HH HH

HHN

NO

N

NO

HH HH

HHN

NO

N

NO

HH

N

N

ON

N

O

HH HH

HHN

N

ON

N

O

HH HH

HHN

NO

N

NO

HH HH

HHN

NO

N

NO

HH HH

HH

N

NO

H H

HN

N

O

H H

HN

NO

H H

HN

NO

H H

H N

N

O

H H

H N

N

O

H H

H N

N

O

H H

H

HH

HH

N

NO

H H

HN

N

O

H H

HN

NO

H H

HN

NO

H H

H N

N

O

H H

H N

N

O

H H

H N

N

O

H H

HN

NO

H H

H

N

NO

HH

HN

NO

HH

HN

NO

HH

H

N

N

O

H H

H

3~4nm

N

ON

H

H H

NO

NHH H

NO

NHH

H

NO

NHH

HNO

NHH

H NO

NH H

H NO

NH H

HN

ON

H H

HN

ONH

H

H

N

O NH

H

H

N

O NHH

H

N

ON

H

HH

NO

N HHH

NO

N HH

H

N O

N HH

HN O

N HH

HNO

NHH

HNO

NHH

HN

ONHH

H

N

ONH

H

H

N

ONH

H

H

N

ONH

H

H

N

ON

H

H H

NO

NHH H

NO

NHH

H

N

N

ON

H

H H

NO

NHH H

NO

NHH

H

NO

NHH

HNO

NHH

H NO

NH H

H N

O

NHH

HNO

NHH

H NO

NH H

H NO

NH H

HN

ON

H H

HN

ONH

H

H

N

O NH

O

NH H

HN

ON

H H

HN

ONH

H

H

N

O NH

H

H

N

O NHH

H

N

ON

H

HH

NO

N HH

H

H

N

O NHH

H

N

ON

H

HH

NO

N HHH

NO

N HH

H

N O

N HH

HN O

N HH

H

NO

N HH

H

N O

N HH

HN O

N HH

HNO

NHH

HNO

NHH

HN

ONHH

HNO

NHH

HNO

NHH

HN

ONHH

H

N

ONH

H

H

N

ONH

H

H

N

ONH

H

H

N

ONH

H

H

N

ONH

H

H

N

ONH

H

H TEOS (Silication)

Extractionin EtOHand Dry

40~45nm

Dissolving water at 60°Cusing ultrasonification

Cool down for re-assembly of GDA at ice temp in ice bath

SNT-1 SNT-2

N

NOH

H

H

NNOH

H H

NNOHH

H

NNO

HH

H

NNOHH

H

NN

OH

HH

NNO

HH H

NNO

HH

H

N

NO

H H

H

N

NOH

H

H

NNOH

H H

NNOHH

H

NNO

HH

H

NNOHH

H

NN

OH

HH

NNO

HH H

NNO

N

NOH

H

H

NNOH

H H

NNOHH

H

NNO

HH

H

NNOHH

H

NN

OH

HH

NNO

HH H

NNO

HH

H

N

NO

H H

H

Cool down for re-assemblyof GDA at room temp in water

Dissolving water at 60 oCusing ultrasonification

Cool down for re-assemblyof GDA at ice temp in ice bath

GDA amphiphileslamellar crystal

TEOS(Silication)

Extractionin EtOHand Dry

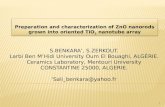

Scheme 1. Schematic representation of tubular nanostructure by self assembled GDA amphiphilic templating process (left: SNT-1, right SNT-2)

Many efforts have been devoted to synthesize various kind of inorganic nanotubes1 due to their numerous significant appli-cations.2-4 Among them hollow silica nanotubes (SNTs) have drawn considerable interest because of their advantages such as biocompatiblity, controllable size, and accessible for the modification of surfaces5-7 increasing its utility in areas of nano-fluidic, drug delivery, adsorption, catalysis, hydrogen storage, and bioseparation.8-11

Several methods have been developed for synthesizing hol-low silica nanotube. However, normal synthetic methods of silica nanotube are mainly through the sol-gel transcription pro-cess using various kinds of templates. These methods relied on severe conditions such as extreme pH, difficult template pre-paration and high pressure. For synthesizing silica nanotube, an organic templates including biomolecules and lipids which leads to gelation through the self-assembly of amphiphiles is required.12-19 Nowadays, research has increasingly focused on finding new templates for producing well-defined structures in terms of pore diameters, wall thickness, and aspect ratios etc. But several difficulties lie on the high orderness and creation of well-defined morphology.

One of attractive method for synthesizing silica nanotube is via neutral templating route20-24 due to formation of mesoporous structures with neutral amine and neutral silica precursors.21 Moreover this method is simple, based on ambient conditions facilitate easy recovery of the surfactant, yielding a thick silica wall and hydrothermally stable materials. This finding inspired us to develop a new glycyldodecylamide (GDA) surfactant as template for synthesis of silica nanotube.

The aim of our study was to undertake bio-silication through assembly in an aqueous solution using glycyldodecylamide surfactant. Two types of silica nanostructure (SNT-1 and SNT-2) were synthesized with narrow (3 - 4 nm) and wide (45 nm) dia-meters, respectively by temperature dependent self assembly (Scheme 1). The silica nanotubes were synthesized by the hydro-lysis of TEOS as a silica source after dissolving the surfactant in a water/ethanol (10: 1) solution.21

The XRD pattern of SNT-1 showed the broad band at the small-angle scattering regime (2θ < 2o), which could indexed as a lattice constant, a = 4.1 nm (Figure S1 red line). The self- assembled GDA gel in a dry form also shows the periodical diffraction peaks, indicating its assembled structure as a lamellar organization (Figure S1 black line). The d-spacing of the aggre-gates were approximately 4.1, 2.06, 1.38, 1.05 nm and corres-ponded to the twice of the extended molecular length of GDA aPresent address: Department of Nano-Fusion Technology Thermolon Korea, Co. Ltd, Jung-gu, Busan

(2.05 nm, by the Chemdraw 3D molecular modeling) that is quite similar to the length of two molecules of GDA surfactant.25 These results indicated that a gelation material maintained a bilayered structure with a 4.1 nm of bimolecular sheet which was corresponded to the (100) plane (Figure S1A). The SEM image strongly supported the lamellar structure, which could be explained due to the hydrogen bonded bilayered assembly of GDA dimeric amphiphile (Figure 1A). The measured diameter of 48 nm of GDA gel in D2O solution at 4 oC from SANS (Small Angle Neutron Scattering) was corresponded to the 45 nm of diameter of SNT-2 (Figure S1B).

Moreover, it was confirmed that GDA surfactant could be easily extracted by simple extraction with hot ethanol. After extraction of the GDA surfactant the obtained SNT-1 was in-vestigated with FE-SEM and FE-TEM (Figure 1B, 1C). This mesoporous silica displays a wormhole structure with an inner diameters ca. around 3 nm. This result was similarly to the typi-cal HMS typed mesoporous silica from long chain alkylamine surfactant.21 However, SNT-2 that had an around 45 nm of inner porosity and 85 nm of outer diameter was prepared after gelation (Figure 1E, 1F). Also SNT-2 had pretty long ranged straight- channeled structure having a high aspect ratio with one dimen-

-

3520 Bull. Korean Chem. Soc. 2010, Vol. 31, No. 12 Communications to the Editor

FBA

1μm

(A)

1 μm 1μm

B(B)

1 μm

AAC(C)

50 nm

D

1μm

(D)

1 μm

E

100 nm

(E)

100 nm

F(F)

100 nm

Figure 1. (A) SEM image of GDA gelator (B) SEM image of SNT-1 (C) High resolution transmission electron micrograph (FE-TEM, JEOL, JEM 2100F) of SNT-1 (D) SEM image of SNT-2 bundles (E) Enlarger SEM image of SNT-2 (F) TEM image of SNT-2.

sionality (Figure 1D). The preformed GDA structures in aqueous solution into the rigid and large-sized nanotubes were accurately transcribed into the relatively large pore silica nanotube.

The mesoporosity of the samples were analyzed by using nitrogen sorption study. The SNT-1 showed type IV isotherm with narrow mesopore distributions at 2.8 nm. However, this pore size of SNT-1 did not match with the linear length of GDA molecule. We assumed that the GDA micelles were densely packed in the aqueous solution cause by hydrophobic inter-action of long tails of amphiphiles. Whereas in the case of SNT-2 showed the presence of big sized mesopore tubes. The ethanol extracted SNT-1 and SNT-2 materials had a BET (Brunauer- Emmett-Teller) surface area of 685 m2/g and 395 m2/g and pore volumes of 0.85 cm3/g and 1.12 cm3/g, respectively. The pore size distribution clearly confirmed that the pore volume corres-ponding to the 2.8 nm pore diameter decreased with increasing pore volume around 45 nm (Figure S2).

The FT-IR shows the stretching modes of the GDA amphi-phile at 1638 and 1674 cm‒1 assigned to hydrogen bonded amide stretch and amide stretch induced by non-hydrogen bond, res-pectively26 inferring β-sheet like character. In the as-synthesized SNT-1 material, the hydrogen bonding peak (named as Amide Band I) was strongly observed at 1655 cm‒1 indicate that the peptide region also adopts significant α-helix or random coil hydrogen bonding conformations. However, the as-synthesized SNT-2 material shows similar peaks as those of amide peaks of GDA. So, it revealed that the bilayered structured GDA am-phiphiles easily converted to GDA dimer structure under drying condition (Figure S3).

In summary, controlled diameters and morphology of the mesoporous silica nanotubes were formed at neutral conditions by temperature dependent self-assembly of GDA amphiphile and moreover surfactant recyclability. The hydrogen bonded self-assembly of the GDA crystal in a polar solvent gave a well- ordered GDA lamellar structure. This seemed to be due to the primary amine group in GDA, which gave stronger hydrogen bonded moiety with oxygen from the carbonyl group than with amide proton during the drying process. In an aqueous solution the micelle of GDA amphiphile formed at before gelation, showed 3 - 4 nm diameter wormhole like structure (SNT-1). In contrast, at 0 oC GDA formed was bilayered large tubular structure after gelation having around 45 nm (SNT-2).27 These findings might open a great opportunity for appropriate use of such materials for molecules storage and as nanoreactor.

Acknowledgments. This work was supported by National Research Foundation of Korea (NRF) grant funded by the Korea government (MEST) (2009-0083073), Inha University. MKE (Ministry of Knowledge Economy) for Nano centre for Fine Chemicals Fusion Technology.

Reference

1. lijima, S. Nature 1991, 56. 2. Xia, Y.; Yang, P.; Sun, Y.; Wu, Y.; Mayer, B.; Gates, B.; Yin, Y.;

Kim, F.; Yan, H. Adv. Mater. 2003, 15, 353. 3. Wang, Z. L. Adv. Mater. 2000, 12, 1295. 4. Jang, J.; Lim, B. K.; Lee, J.; Hyeon, T. Chem. Commun. 2001, 83. 5. Van Brommel, K. J. C.; Friggeri, A.; Shinkai, S. Angew. Chem.

Int. Ed. 2003, 42, 980. 6. Nishikawa, H.; Shiroyama, T.; Nakamura, R.; Ohki, Y. Phys. Rev.

B 1992, 45, 586. 7. Jang, J.; Lim, B. Adv. Mater. 2002, 14, 1390. 8. Mitchell, D. T.; Lee, S. B.; Trofin, L.; Li, N.; Nevanen, T. K.; So-

derlund, H.; Martin, C. R. J. Am. Chem. Soc. 2002, 124, 11864. 9. Zhang, Y.; Suenaga, K.; Colloex, C.; Lijima, S. Science 1998, 281,

973.10. Hu, J. Q.; Bando, Y.; Wada, K.; Cheng, L. L.; Pirouz, P. Appl. Phys.

Lett. 2002, 80, 491.11. Goldberger, J.; Fan, R.; Yang, P. Acc. Chem. Res. 2006, 39, 239.12. Ji, Q.; Iwaura, R.; Kogiso, M.; Jung, J. H.; Yoshida, K.; Shimizu,

T. Chem. Mater. 2004, 16, 250.13. Gao, P.; Zhan, C.; Liu, M. Langmuir 2006, 22, 775. 14. Meegan, J. E.; Aggeli, A.; Boden, N.; Brydson, R.; Brown, A. P.;

Carrick, L.; Brough, A. R.; Hussain, A. R.; Ansell, J. Adv. Funct. Mater. 2004, 14, 31.

15. Jung, J. H.; Shinkai, S.; Shimizu, T. Nano Lett. 2002, 2, 17. 16. Yuwono, V. M. J.; Hartgerink, D. Langmuir 2007, 23, 5033. 17. Zollfrank, C.; Scheel, H.; Greil, P. Adv. Mater. 2007, 19, 984. 18. Wu, X.; Ruan, J.; Ohsuna, T.; Terasaki, O.; Che, S. Chem. Mater.

2007, 19, 1577.19. Pouget, E.; Dujardin, E.; Cavalier, A.; Moreac, A.; Valéry, C.;

Marchi-Artzner, V.; Weiss, T.; Renault, A.; Paternostre, M.; Artz-ner, F. Nat. Mater. 2007, 6, 435.

20. Kresge, C. T.; Leonowicz, M. E.; Roth, W. J.; Vartuli, J. C.; Beck, J. S. Nature 1992, 359, 710.

21. Tanev, P. T.; Pinnavaia, T. J. Science 1995, 267, 865.22. Kim, S. S.; Zhang, W.; Pinnavaia, T. J. Science 1998, 282, 1302. 23. Che, S.; Garcia-Bennett, A. E.; Yokoi, T.; Sakamoto, K.; Kunieda,

H.; Terasaki, O.; Tatsumi, T. Nat. Mater. 2003, 2, 801.24. Choi, M.; Cho, H. S.; Srivastava, R. ; Venkatesan, C.; Choi, D.-H.;

Ryoo, R. Nat. Mater. 2006, 5, 718.25. Jung, J. H.; John, G.; Masuda, M.; Yoshida, K.; Shinkai, S.; Shi-

mizu, T. Langmuir 2001, 17, 7229.26. Mandal, H. S.; Kraatz, H.-B. J. Am. Chem. Soc. 2007, 129, 6356.27. Shimizu, T.; Masuda, M.; Minamikawa, H. Chem. Rev. 2005, 105,

1401.

/ColorImageDict > /JPEG2000ColorACSImageDict > /JPEG2000ColorImageDict > /AntiAliasGrayImages false /CropGrayImages true /GrayImageMinResolution 300 /GrayImageMinResolutionPolicy /OK /DownsampleGrayImages true /GrayImageDownsampleType /Bicubic /GrayImageResolution 300 /GrayImageDepth -1 /GrayImageMinDownsampleDepth 2 /GrayImageDownsampleThreshold 1.50000 /EncodeGrayImages true /GrayImageFilter /DCTEncode /AutoFilterGrayImages true /GrayImageAutoFilterStrategy /JPEG /GrayACSImageDict > /GrayImageDict > /JPEG2000GrayACSImageDict > /JPEG2000GrayImageDict > /AntiAliasMonoImages false /CropMonoImages true /MonoImageMinResolution 1200 /MonoImageMinResolutionPolicy /OK /DownsampleMonoImages true /MonoImageDownsampleType /Bicubic /MonoImageResolution 1200 /MonoImageDepth -1 /MonoImageDownsampleThreshold 1.50000 /EncodeMonoImages true /MonoImageFilter /CCITTFaxEncode /MonoImageDict > /AllowPSXObjects false /CheckCompliance [ /None ] /PDFX1aCheck false /PDFX3Check false /PDFXCompliantPDFOnly false /PDFXNoTrimBoxError true /PDFXTrimBoxToMediaBoxOffset [ 0.00000 0.00000 0.00000 0.00000 ] /PDFXSetBleedBoxToMediaBox true /PDFXBleedBoxToTrimBoxOffset [ 0.00000 0.00000 0.00000 0.00000 ] /PDFXOutputIntentProfile () /PDFXOutputConditionIdentifier () /PDFXOutputCondition () /PDFXRegistryName () /PDFXTrapped /False

/Description > /Namespace [ (Adobe) (Common) (1.0) ] /OtherNamespaces [ > /FormElements false /GenerateStructure true /IncludeBookmarks false /IncludeHyperlinks false /IncludeInteractive false /IncludeLayers false /IncludeProfiles true /MultimediaHandling /UseObjectSettings /Namespace [ (Adobe) (CreativeSuite) (2.0) ] /PDFXOutputIntentProfileSelector /NA /PreserveEditing true /UntaggedCMYKHandling /LeaveUntagged /UntaggedRGBHandling /LeaveUntagged /UseDocumentBleed false >> ]>> setdistillerparams> setpagedevice