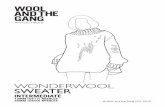

Sweater production process

-

Upload

shahadat-hossain -

Category

Education

-

view

348 -

download

9

Transcript of Sweater production process

1

Shahadat HossainShahadat HossainExecutiveExecutive

Quality Assurance DepartmentQuality Assurance Department

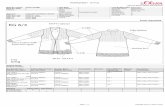

1. Making a knitted Panels (Front, back, sleeve)

1. Computerized Knitting Machine (Stoll & Shima)2. Hand Knit Machine (yarn Section)

2. Winding (lubrication) Yarn before knitting3. Dyeing Yarn before knitting4. Inspection5. Washing and Drying6. Linking operation7. Inspection, Pressing8. Packing

2

Sweater Production Process

Hand Knitting (Swatch making for

yarn approval)

3

The yarn before knitting needs to be dyed with

different colour. It can be done either by hank dyeing or cone

dyeing.

4

Hank dyeing

Hank Dyeing

5

Hank Dyeing

6

Different color and dyestuff must be prepared

carefully from the dye lab. Receipt will be formed for dyeing process.

7

Colour Formulationlab dip In SQ Hues

Lab Dip Preparation

8

Cone Dyeing(Package dyeing)

9

Dyed cone

10

Cone dyeing machine(sample machine)

11

One of the important step before panel

making is cone winding & lubrication. The cone winding is to remove dust, dirt or

fault on the yarn before knitting. The lubrication is to reduce the yarn friction

before knitting. It is important the wax should be free of

dust and rotated freely during the winding process.

12

Cone winding & lubrication

13

Cone winding and waxing

Cone Winding & Lubricating

before knitting

14Waxing yarn during winding process

Waxing

Winding process

15

The first step is to make the panel knitting

either by Computer Knitting machine or hand machine.

The decision to make by computer or hand machine is depended on the complexity of the design.

The panel making includes front, back and sleeve , placket.

Sometimes, intarsia design will be done.

16

Panel Making

Panel Knitting Computer Stoll Machine

17

Panel KnittingFully Fashion Knitting

18

First inspection on fabric panel

19Draw thread is removed manually

Knitting Panel AQL

20

Linking is to connect different panels (front, back

and sleeve) together to form a garment. Loop to loop connection is done manually for high

quality garment. For lower quality, a simple sewing can be done.

21

Linking process

Linking

22

Linking

23

Light Check

24

Trimming & Mending

25

After the linking process (front, back and

sleeve are joined together), 2nd fabric inspection will be carried out.

The inspected garment will go to washing and finishing.

This will improve the softness and hand free of the sweater before final inspection and packing.

26

Washing & Drying

Washing & Finishing

27

Tumble Dry Hydro extractor

Washing & Finishing

28

After Wash Light check

29

Garments distribution after wash

30

Sewing

31

FQC Check

32

Ironing

33

Get up Check

34

Hang tag attached

35

Metal Pass

36

Folding

37

Packing

38

Hourly Audit

39

Warehouse Goods keeping

40

Yarn storage

41

Panel making for front, back and sleeve

First inspection and remove draw thread Linking process to make a garment

Second inspection before washing Washing and finishing

Final inspection and pressing Packing for shipment.

42

Summary (1)

Additional processes are needed. Waxing the yarn before knitting Hank dyeing or cone dyeing before knitting. Make decision if the panel is to be knitted

by computer machine. Sample preparation is normally done by

hand machine but here use Computerized machine.

it will be develop gradually when I collect picture from floor.

The end 43

Summary (2)