Sustainable Energy Solutions for reducing CO2 emissions | VigilantPlant

-

Upload

yokogawa-europe -

Category

Technology

-

view

321 -

download

0

description

Transcript of Sustainable Energy Solutions for reducing CO2 emissions | VigilantPlant

Subject to change without noticeAll Rights Reserved. Copyright © 2010, Yokogawa Electric Corporation

Represented by: YOKOGAWA ELECTRIC CORPORATIONWorld Headquarters9-32, Nakacho 2-chome, Musashino-shi, Tokyo 180-8750, Japanhttp://www.yokogawa.com/

YOKOGAWA CORPORATION OF AMERICA12530 West Airport Blvd, Sugar Land, Texas 77478, USAhttp://www.yokogawa.com/us/

YOKOGAWA EUROPE B.V. Euroweg 2, 3825 HD Amersfoort, The Netherlands http://www.yokogawa.com/eu/

YOKOGAWA ENGINEERING ASIA PTE. LTD.5 Bedok South Road, Singapore 469270, Singaporehttp://www.yokogawa.com/sg/

YOKOGAWA CHINA CO., LTD. 3F Tower D Cartelo Crocodile BuildingNo. 568 West Tianshan Road, Shanghai 200335, Chinahttp://www.yokogawa.com/cn/

YOKOGAWA MIDDLE EAST B.S.C.(c)P.O. Box 10070, ManamaBuilding 577, Road 2516, Busaiteen 225, Muharraq, Bahrainhttp://www.yokogawa.com/bh/

TrademarksAll brand or product names of Yokogawa Electric Corporation in this bulletin are trademarks or registered trademarks of Yokogawa ElectricCorporation. All other company brand or product names in this bulletin are trademarks or registered trademarks of their respective holders.

[Ed:03/b] Printed in Japan, 105(KP)

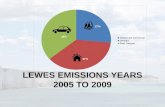

Fossil �red power plants

Gas turbine power plants

Renewable energy power plants

Plant services and/or plant simulators

Yokogawa service o�ces

Italy 400 MWcombined cycle

Romania4 x 330 MW�ue gas desulphurization

Turkey130 MWcombined cycle

China450 MWwind power

China 6 x 300 MW coal �red

India 2 x 600 MW 2 x 500 MW coal �red

India3 x 660 MWsupercriticalcoal �red

Algeria369 MWIWPP

Nigeria 530 MW & 2 x 450 MW simple cycle

Taiwan2 x 550 MWcoal �red

Korea9 x 100 MWcoal �red

Brazil 2 x 75 MW, oil & gas �red

Trinidad and Tobago720 MWcombined cycle

Bulgaria8 x 200 t/h�ue gas desulfurization

Korea800 MW supercriticaltraining simulator

Japan2 x 1,050 MWflue gas desulfurization

U.S480 MW, combined cycle

U.S100 MW, combined cycle

Canada120 MW, cogeneration

U.S3 x 70 MW, gas & oil �red

Brazil 460 MW, combined cycle

Vietnam2 x 300 MW, coal �redsimulator & training

Japan 375 MW & 350 MW gas �red

Brunei110 MWcombined cycleThailand

2 x 110 MWcombined cycle

Saudi Arabia360 MWIWPP

Australia4 x 500 MWcoal �red revamping

Indonesia110 MW & 95 MWgeothermalSingapore

2 x 600 MWoil �redsimulator & training

Australia4 x 720 MWcoal �red revampingsimulator & trainingturbine upgrading

Australia 4 x 550 MW brown coal �red revamping simulator & training

Mongolia8 x 420 t/hcoal �redrevamping & simulator

Spain800 MWcombined cyclew/ LNG terminal

Venezuela 460 MW combined cycle

UK37 MWwaste to energy

Kuwait90,000 t/ddesalination

Egypt750 MW750 MW750 MWcombined cycle

Australiasolar (CSP)

Vietnam2 x 600 MWcoal �red

Yokogawa Vigilance at your service worldwide - representative projects

Bulletin 53T01A01-02E

Sustainable energy solutions for reducing CO2 emissionsin the power industry

21

VigilantPlant: smart ideas for a sustainable future

Redefining VigilantPlant

For years, Yokogawa has used the word “VigilantPlant” as our vision for operational excellence. What this meant was bringing out the best in your plant and people through visibility of information, predictability of process, and agility of business.

We now believe VigilantPlant means much more than just what goes on in your plant.

Yokogawa is committed to sustaining your business, the environment, and the society that we all are a part of. We are doing this by developing more energy-efficient technology, helping operations produce a smaller carbon footprint, and building rock solid products that protect our environment from contaminants. Sustainability is not just a job for Yokogawa but for all industry.

Will you join in embracing a new VigilantPlant?

Sustainable energy solutions for a promising future

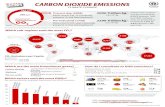

Carbon dioxide (CO2)

is one of the major greenhouse

gases causing climate change

and global warming.

In the power industry,

Yokogawa has taken the lead

in providing solutions to improve

power efficiencies by reducing

emissions.

Yokogawa has been providing

control solutions for generating

power from solar, wind, hydro,

biomass, geothermal, and other

renewable energy sources based�

on its extensive experience in

this field and technologies.

For a brighter future, Yokogawa

offers sustainable energy solutions�

that minimize the impact of CO2

emissions and achieve the

operational excellence that is the

hallmark of the VigilantPlant.

3 4

Control LAN ( Vnet/IP )

Boiler & BOPcontrols

Turbomachinerycontrol & protection

Field control station (FCS)

Geothermalpower

Biomasspower

Windpower

Solarpower

Hydropower

Fossilpower

Nuclearpower

Combinedcycle

power

Waste to energy

Renewable energy control solutionSTARDOM with FAST/TOOLS provides an innovative

web-based SCADA solution for renewable energy plants.

Efficiency improvement control solutionCENTUM VP is a core platform and a key component of our comprehensive control solutions that make it possible for power plants to operate more efficiently.

Multi-sensing digitaltechnology solution

DPharp series transmitters with multi-sensing digital technology offer unmatched performance and precision.

Combustion gas analysis solutionThe TruePeak TDLS200 analyzer utilizes powerful and highly sensitive lasers and can detect and analyze combustion gases under a wide variety of conditions.

The advanced technology, excellent product quality, and extensive application know-how that go into Yokogawa’s optimum solutions help you reduce your power plant’s CO2 emissions.

Leading-edge technology for reduc ing CO2 emissions

Susta inable energy solutions

DPharpISA100.11a

field wireless

DPharpOpen access

to field intelligence

5 6

fficiency improvement

missions reduction

conomic returns

E

E

E

Protecting the environment has become a pressing concern in many industries, and the power industry is no exception. Many new regulations are forcing businesses to reduce their emissions of CO2 and other greenhouse gases to prevent global warming.

CO2 emissions reduction is crucial at coal-fired power plants, which discharge much greater amounts of this gas into the atmosphere than other types of fossil-fired power plants. By bringing to bear its technologies and expertise, Yokogawa is focused on improving environmental control over the entire plant lifecycle and ensuring clean air for generations to come.

The 3Es of efficiency improvement, emissions reduction, and economic returns are a key part of Yokogawa’s control strategy for reducing CO2 emissions. Our unparalleled control schemes for coal-fired power plants help reduce CO2 emissions and create clean power.

Optimal combustion and soot blowing inside the boiler enhance the heat rate, reduce outages, and reduce fuel consumption.

Control strategies reduce emissions by optimizing combustion and improve emissions measurement.

Improved performance reduces fuel and operating costs.

Yokogawa’s control strategy to reduce CO2 emissions

7 8

Approx.

Approx.

Approx.

0.3 - 1%

CO 2 3 - 10kilotons/year

0.3 - 1.1million US$/year

fficiency improvement

missions reduction

conomic returns

E

E

E

Turbine & BOP efficiency

Plantoutput

Boilerefficiency

Improvements

Benefit estimation of CO2 emissions reduction and cost saving

Example of typical benefit estimation Annual returns from “3Es” for a 300 MW coal - fired unit

Coal-fired power plant

Coal yard

Coal bunker

PulverizerBurner

DrumFSH

Bottomash

Ash pond

Ambient air

FDF

AHHot air

PAFHot air

Waste water

RH

Reheated steamCondenser

Raw water

CP Demineralizer

LPheatersBFP

HPheaters

ECO

Feedwater

DeNOxFlue gas

EP IDF

FGD

BUF

Stack

Fly ash Gypsum

Superheated steam

Make up water

FOP

Fuel oil

PSH

LPHP IP

Condensatepolishers

DSH

Deaerator

9 10

G

Approx.

Approx.

Approx.

0.3 - 0.9%

CO 2 3 - 9kilotons/year

0.3 - 0.9million US$/year

fficiency improvement

missions reduction

conomic returns

E

E

E

Example of boiler efficiency improvement

Benefit estimation of CO2 emissions reduction and cost saving

Know-how & technology

Improves heat rate

Improves steam temperature control

Implements coordinated control

Minimizes opacity violations

Adapts to various fuel properties

Enables optimal use of fuel-air mixing

Optimizes closed-loop combustion

Quickly analyzes hotspots inside boiler

Performs multivariable predictive control

Enables smart automatic soot blowing

In a power generation unit, the

main conversion process takes place in

the boiler, where superheated steam is generated

to drive the turbine. The thermodynamics inside the

boiler are a complex, multivariable process, where

it is possible to both to improve the efficiency and

reduce emissions. Hence, the boiler model is

constantly updated based on the operating status,

and appropriate optimizing algorithms are used to

improve the heat rate and minimize fuel

consumption.

The resultant fuel saving is converted to an

equivalent emissions reduction. The economic

returns are calculated from both the optimal heat

rate and emission reduction initiatives.

Estimated 3Es

Overview

Coal-fired power plant

Coal yard

Coal bunker

PulverizerBurner

DrumFSH

Bottomash

Ash pond

Ambient airFDF

AHHot air

PAFHot air

RH

Reheated steam

Condenser Raw water

CP Demineralizer

LPheatersBFP

HPheaters

ECO

Feedwater

DeNOxFlue gas

EP IDF

FGD

BUF

Stack

Fly ash Gypsum

Superheated steam

Make up water

FOP

Fuel oil

PSH

LPHP IP

Condensatepolishers

DSH

Deaerator

Waste water

11 12

G

Approx.

Approx.

Approx.

Up to 0.1%

CO 2 up to 1kilotons/year

Up to 0.1million US$/year

fficiency improvement

missions reduction

conomic returns

E

E

E

Estimated 3Es

Example of turbine and BOP efficiency improvement

Benefit estimation of CO2 emissions reduction and cost saving

Efficiency can also be greatly

improved in the turbines and BOP. For the

turbines, the condenser back pressure loss, steam

pressure loss, and temperature loss can all be

minimized.

For BOP, which is vulnerable to variations in fuel

feed, improvements can be attained by closely

coordinating control strategies to optimize the

operation of the feed pump and minimize auxiliary

power consumption.

Know-how & technology

Minimizes condenser back pressure loss

Minimizes feed heater loss

Minimizes high/low-steam pressure loss

Minimizes low-steam temperature loss

Minimizes auxiliary power consumption

Optimizes feed pump operation

Reduces forced outages

Overview

Coal-fired power plant

Coal yard

Coal bunker

PulverizerBurner

DrumFSH

Bottomash

Ash pond

Ambient airFDF

AHHot air

PAFHot air

RH

Reheated steam

Condenser Raw water

CP Demineralizer

LPheatersBFP

HPheaters

ECO

Feedwater

DeNOxFlue gas

EP IDF

FGD

BUF

Stack

Fly ash Gypsum

Superheated steam

Make up water

FOP

Fuel oil

PSH

LPHP IP

Condensatepolishers

DSH

Deaerator

Waste water

G

13 14

Approx.

conomic returnsE

Example of plant output improvement

Benefit estimation of CO2 emissions reduction and cost saving

Highly reliable DCS & instruments for reduction in forced outages

Plant output can be improved

by carrying out proper operating and

maintenance procedures, having advance warning

of tube leaks, and optimizing soot blowing

operations.

The resulting benefits are calculable based on the

recovered megawatt-hours from the reduction in

forced outages, improvement of plant availability,

and reduction of start-up plant operation.

Know-how & technology

Improves plant availability

Improves operating procedures

Improves maintenance procedures

Improves ancillary plant performance

Smoothens plant operations

Recovers megawatts of power

Reduces oil usage for start-ups

Enables the creation of feasible maintenance schedules

Overview

Up to 0.1 million US$/year

15 16Coal-fired power plant

Coal yard

Coal bunker

PulverizerBurner

DrumFSH

Bottomash

Ash pond

Ambient airFDF

AHHot air

PAFHot air

RH

Reheated steam

Condenser Raw water

CP Demineralizer

LPheatersBFP

HPheaters

ECO

Feedwater

DeNOxFlue gas

EP IDF

FGD

BUF

Stack

Fly ash Gypsum

Superheated steam

Make up water

FOP

Fuel oil

PSH

LPHP IP

Condensatepolishers

DSH

Deaerator

Waste water

G

1

32

step

step

step

Auditing your plant performance

Improving plant efficiencyImproving plant availabilityReducing CO2 emissions

Improving operation skillsImproving asset managementReducing maintenance cost

Comprehensive solutions for your plant lifecycleFrom planning to project execution, operations, and maintenance, Yokogawa helps power plant users achieve operational excellence throughout their facility’s lifecycle with the following sophisticated solutions:

Long-term partnership for your businessDuring the relatively long life cycle of a power plant, there comes a time when the instrumentation and control systems must be renewed to maintain a competitive edge. Yokogawa supports power plants with expert services that maximize efficiency and minimize cost over the entire life cycle. From initial planning, design, engineering, construction, and operation to revamp and re-instrumentation, Yokogawa stands by your power plant. This long-term partnership ensures bottleneck-free performance and ongoing optimization that bring speed and flexibility to your business.

Envision a plant where people are watchful and attentive while your power generation business responds to changes quickly and efficiently. Now picture an operation that delivers non-stop power generation while confidently improving your plant efficiency and reducing CO2 emissions long into the future. Imagine no further. This is the reality attained by VigilantPlant, the clear path to operational excellence.

With the VigilantPlant vision, Yokogawa delivers comprehensive solutions to ensure that environmentally friendly plants run continuously at maximum efficiency and optimal profitability throughout their lifecycle.

Key services and products forreducing CO2 emissions

Plant audits

Plant simulators

Advanced management

Total power plant control

Renewable energy control

Combustion gas analyzers

Intelligent field devices

Building a lasting future

17 18

Audit your plant performance

Plant audits

Yokogawa delivers cost benefits through the refurbishment of power plant controls and instrumentation. This improves the performance of older plants and ensures that they can operate competitively in today’s open power markets, and also reduces their CO2 emissions.

Maximize your cost benefits and returns

Yokogawa assists power plant owners and operators to identify areas of plant operations that will benefit from modern controls running on the latest digital control system platform, with modern field instrumentation.

Our experts will visit your site to carry out field surveys and assess the status of your plant. We collect plant operating data and cost details, then prepare a plant survey report along with our recommendations on a control system and field instrumentation upgrade.

Based on this data and these recommendations, a cost-benefit report is drawn up. This report, along with pricing information for a control and instrumentation upgrade project, is provided to the plant owner for consideration, discussion, and action.

Key services and products for reducing CO2 emissions

Audit items

Plant availability, reliability, and efficiency

Operating regime (daily and seasonal load profiles)

Benchmarks against other facilities of similar age

Review of organizational structure

Review of maintenance management

Review of costs, routine, and capital

General plant condition and life expectancy

19 20

Full-replica power plant simulator Instructor systemSimulation computer Turbine running up system

Ethernet

Control LAN ( Vnet/IP )

20000 600

500

400

300

200

100

010 20 30 40 50 60

Time ( Min. )

18000

16000

14000

12000

10000

8000

6000

4000

2000

0

10

9

8

7

6

5

4

3

2

1

0

MW

,leve

l,tem

pera

ture

Stea

m p

ress

ure

Flue

gas

oxy

gen

Boiler / BOP control

Safety system

Turbine control

Human interface station

Performance-based operation

Plant resource management

Power plant DCS

Training scenariosMalfunctionsTrainee database

・・・

Plant logicsMathematical modelsExecutive process

・・・

Features

Benefits

Plant simulatorsKey services and products for reducing CO2 emissions

High fidelity

Freely devise any training scenario to improve and evaluate operator skills in the following areas:

• Executing routine operational procedures • Responding to plant malfunctions • Performing unusual operations such as forced cooling and cold start-ups

Flexible trainingand evaluation

• 99% accuracy (>99% steady state; >95% dynamic state)

Faster commissioning

The DCS is fully tested before it is installed, drastically reducing the number of modifications to logic, set points, and tuning parameters during the commissioning phase.

Smoother plant start-up

Before a DCS is installed at a power plant, it is fully tested using dynamic simulation. In this way, both operators and engineers become familiar with the DCS operation and controls.

Minimized risk of plant damage

By dynamically testing the safety interlocks prior to DCS installation, the simulator reduces the risk of major equipment damage occurring during the commissioning process.

You no longer have to ignore the complexity of real-life processes. No other simulators available today can match the accuracy of a Yokogawa power plant simulator. Flexible training scenarios can help your operators learn how to control the entire plant with complete confidence. Experience the reassurance that comes from having a Yokogawa power plant simulator.

Reassure supreme accuracy

•

•

•

21 22

Exapilot

Performance-based operation with Exaquantum

Operation efficiency improvement package

Exaplog Event analysis package

PRMPlant Resource Manager

Plant information at your fingertips

Our key performance indicator (KPI) monitoring solution makes KPIs visible and enables you to efficiently operate the production.

Performance-based operation

Exaquantum, a comprehensive plant information management package integrates and delivers operational information that helps enterprises meet complex business requirements.

Increase operational efficiency

Exapilot, an easy-to-use tool can be used to standardize operating methods by creating automatic sequences that incorporate the know-how of experienced operators.

Benchmark your operational efficiency

Exaplog is an easy-to-use suite of tools that analyze the historical logs of the DCS plant and the results on various graphs, allowing you to analyze and benchmark your operational and controllability performance.

Predict availability Plant Resource Manager (PRM) provides easy-to-use tools for asset management and intelligent diagnostics for field instrumentation, actuators, and rotating equipment to increase plant availability.

Advanced management

Making plant information fully visible is vital in preventing disruptions to your critical plant processes. Our knowledge-based tools and advanced management solutions help you steadily improve efficiency and attain operational excellence.

Secure the predictability of your critical process

Key services and products for reducing CO2 emissions

23 24

The ProSafe-RS SCS is a TÜV SIL3 certified safety system that incorporates Yokogawa’ s pair-and-spare technology.

Safety control station (SCS)

The FCS provides powerful control functions with a highly reliable dual redundantconfiguration that incorporates Yokogawa’s own pair-and-spare technology.

Field control station (FCS)

Performance-based operation

Coordinated control

Turbomachinery control

Boiler controlBalance of plant control

Coordinated control

Steam turbine area

Boiler control area

Plant resource management

20000 600

500

400

300

200

100

010

20 30 40 50 60Time ( Min. )

18000

16000

14000

12000

10000

8000

6000

4000

2000

0

10

9

8

7

6

5

4

3

2

1

0

MW

,leve

l,tem

pera

ture

Stea

m p

ress

ure

Flue

gas

oxy

gen

Human interface station/engineering station

Boiler & BOPcontrols

Plant safetysystem

Turbomachinerycontrol & protection

Steam turbine

Control LAN ( Vnet/IP )

Air and flue gas oveview

Coal yard

EP

FGD

Fuel

Total power plant control

With its state-of-the-art architecture, the highly reliable CENTUM VP platform is fully up to the challenge of monitoring and controlling an entire power plant’s turbines, boilers, and balance of plant (BOP) facilities.

Raise plant availability and performance

Key services and products for reducing CO2 emissions

25 26

Wind turbine view

Wind turbine details

Remotedevices

Wireless LANSTARDOM

engineering tool

Plant informationmanagement system

Plant resource manager

Modem

Modem

GSM/GPGR,Satellite,

RF,and more

GPS receiver,SNTP server

Process network

Safety instrumented system

PSTN. xDSL.and more

Field control node

Field control junction

Remote terminal unit

Optical fiber ring

Wind power

Solar power

Small hydro power

Geothermal power

Waste to energy

Biomass power

Renewable energy control

Shift to renewable energy

Key services and products for reducing CO2 emissions

R e n e w a b l e e n e r g y

STARDOM is a network-based control system that brings operational excellence to renewable energy plants that may be widely distributed. STARDOM autonomous controllers have remote management and stand-alone capability, and reduce running costs by making flexible use of e-mail, the web, and supervisory control and data acquisition (SCADA) technology. STARDOM is widely used in the renewable energy industry with the FAST/TOOLS distributed SCADA system. FAST/TOOLS is a scalable product to cover a wide range of very small up to large distributed applications. FAST/TOOLS supports remote web-based operations and maintenance.

27 28

O2

O2

CO2

H2O

H2O

CH4

CO

CO

O2

H2O

Measures gases directly in the process (no sampling system required)Powerful laser overcomes the effects of high particulate loading (fly ash and dust)Measures gases continuously, accurately, sensitively, and selectively with no lag time

Combustion gas analyzersKey services and products for reducing CO2 emissions

Coal bunker

Pulverizer

Burner

FSH

Bottomash

Hot air

PAFHot air

RH

ECO

Feedwater

DeNOx

Flue gas

Fuel oil

PSH

Reheated steam

TruePeakTDLS200

Superheated steam

DSH

Drum

Features

CO measurement for highest efficiency improvement

The TruePeak TDLS200 is a pioneering combustion gas analyzer with a powerful tunable diode laser that is ideal for making direct measurements in harsh process environments. It can be used to optimize the combustion process in boiler plants to reduce both CO2 and NOx emissions, and is a highly cost-effective solution that makes no compromise in speed, accuracy, or reliability.

Enhance combustion control

Continuous measurement of carbon monoxide (CO) and oxygen (O2) concentrations allows operators at fossil fuel power plants to fine tune the air-fuel ratio to boost combustion efficiency and reduce NOx emissions.

The TruePeak TDLS200 utilizes powerful lasers that are highly sensitive and selective for CO. In boilers it can directly measure CO, eliminating lag time in detecting CO breakthrough and producing no false low readings.

NH3 measurement for NOx reduction

Ammonia (NH3) gas is injected to remove NOx and thus reduce the NOx concentration in the stack flue gas, as well as to increase the dust collection efficiency of the electrostatic precipitator (EP) and prevent corrosion. However, excess ammonia injection increases running costs and residual NH3, resulting in foul odors. Therefore, the NH3 concentration in the stack flue gas is measured, controlled, and monitored.

With conventional ammonia analyzers that perform measurements indirectly, NH3 concentrations are obtained through a sampling system, causing problems with the maintenance and running costs of the sampling system, and time delays in measurement. The TruePeak TDLS200 solves all these problems.

NH3injection

29 30

Feed water flow

Ambient air

FDF

AH

DeNOx

Flue gas

Silicon resonant sensor

Intelligent field devicesKey services and products for reducing CO2 emissions

DPharp digital pressure transmitters are the first to use a revolutionary silicon resonant sensor technology that provides superior stability and repeatability in the most demanding process applications. They are ideal for use in highly critical power plant processes.

This intelligent field device a best-in-class and reliable digital solution that meets present and future needs in the power industry by being fully interoperable with an extensive range of open industrial protocols.

Take your plant into the digital era

Best-in-class performance

Precision and quick response time

Field - proven reliability

No-error-prone A/D converter: Full end-to-end digital communications from process to control system

Drift free, long-term stability Unparalleled stability guarantee

Full interoperabilityOpen industrial communications: Whether you choose BRAIN, HART, FOUNDATION™ fieldbus or Profibus, our transmitters will deliver their full benefits.

Multi-sensing Measurement of differential pressure and static pressures (DP and SP) by a single transmitter minimizes your instrumentation cost.

Multi-variable DP, SP, and inline temperature measurement in a single transmitter enables mass flow to be calculated by an on-board flow computer.

Coal bunker

Pulverizer

Burner

FSH

Bottomash

Hot air

PAFHot air

RH

ECO

Feedwater

Fuel oil

PSH

Reheated steam

Superheated steam

DSH

Drum

Drum level

PXFX

FX

FX

LX

Main steam flow and pressure

Spray flow

Air flow

FX

For all ultra critical processesBoiler drum level measurement

Very high static pressure

Varying pressure affecting density

Very small measurement span

Feed water flow measurement

Very high pressure surges (water hammer)

Varying flow for varying load

DPharpISA100.11a

field wireless

DPharpOpen access

to field intelligence

31 32

Plant information

Thermal Power Plant No. 4

Ulaanbaatar, Mongolia

Mongolian Ministry of Minerals and Power

8 x 420 t/h (including steam for town heating)

560 MW (4 x 100 MW and 2 x 80 MW)

Lignite coal

1980 - 1990

1997 - 2007

Boilers - 8 x 420 t/h, lignite-firedTurbines - 2 x 80 MW, 4 x 100 MW with town heating

Retrofit of control and safety systems, and replacement of field instruments and actuators

Plant name :

Location :

Owner :

Steam outputs (boilers) :

Electricity outputs (turbines) :

Fuel :

Construction :

Retrofit :

Output/fuel :

Scope of replacement :

Project background

A case study of CO2 emissions reduction

In Mongolia, temperatures fall as low as -40℃ in mid-winter. The heat and electricity generated by Thermal Power Plant No.4 (TES4) in the capital city of Ulaanbaatar is an important lifeline for the people living there.

TES4 is the largest coal-fired power plant in Mongolia and it generates 70% of the electricity for Mongolia’s central energy system and 65% of the heat energy used by Ulaanbaatar district heating system.

Retrofit of Mongolia’s largest thermal power plant

TES4 was built many years ago and has been severely affected by the scarcity of spare parts for its legacy systems. Plant shutdowns were a frequent occurrence due to equipment malfunctions and accidents, disrupting the supply of heat and power. In addition, the plant caused severe air pollution due to inefficient control of coal combustion. Efforts to correct these problems were also hampered by the loss of many of the plant’s original blueprints and other design related documents.

To solve these problems, the Mongolian government decided to execute a plant revamping project in two phases using an official development assistance (ODA) loan. Phase one for boilers one to four started in 1996 and was completed in 2000. Phase two for boilers five to eight started in 2002 and was completed in 2007. For this project, Yokogawa delivered control systems and field instrumentation for all eight boilers.

33 34

Design of fully automated control logic TES4 converted the existing indirect combustion system to the new direct combustion type. Yokogawa

performed a detailed investigation of the original boiler combustion control system and the direct

combustion control logic together with a new burner vendor and TES4’s engineers. Yokogawa

succeeded in designing a fully automated burner management system that replaced the old manually

operated system. Other major controls for the boilers and BOP facilities were also reviewed and

designed based on the new control strategy and Yokogawa’s expertise.

Full automation of boilers, burners, and balance of plant (BOP) facilities

A highly reliable and expandable distributed control system (DCS)

Replacement with state-of-art DCSThe control systems for all eight boilers at TES4 were changed over to a state-of-the-art Yokogawa

CENTUM CS 3000 DCS, which provides a highly reliable platform for the comprehensive control and

operation of the entire power generation plant. As a result, operation efficiency and safety were

dramatically improved. For interfacing with the existing I/O signals, a redundant remote fiber-optic

network was installed that reduced the cabling cost and improved both safety and reliability.

A power plant simulator for training DCS operators

Supply of power plant simulatorIn line with the replacement of the DCS, a power plant simulator was supplied for operator training,

allowing operators to get experience with plant operating procedures, gain familiarity with the DCS,

and improve their skills. As the result, they achieved a smooth transition from the conventional analog

control panels to an all -new graphical user interface.

The challengesThe existing combustion boilers employed an indirect firing system. This system stores pulverized coal in a silo and feeds it to the boilers as required. The indirect firing system caused frequent equipment troubles and there was a high risk of explosion.

The boilers and mill burners were manually controlled by operators except for feed water control. The combustion air was always sent by fans fully opened, thus the combustion efficiency was extremely low.The control operation system was a board operation type equipped with analog and discrete control logics. Only a few very old Russian documents for the control logic scheme were available.

TES4 plant control room before refit

Yokogawa’s solutionsCustomer’s requirements

A case study of CO2 emissions reduction

35 36

TES4 plant control room with CENTUM system

1998 1999 2000 2001 2002 2003 2004 2006

10,000

5,000

0

15,000

1997 2005 2007

tons

13,897

10,300

7,280

4,7934,757 4,755 4,012 3,852

2,8081,897 1,682

Total heavy oil consumption

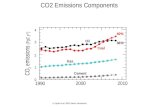

The new control system for TES4’s eight boilers was changed over one boiler at a time, starting at the end of 1998 and finishing in 2007. Fuel consumption was dramatically reduced thanks to improved boiler efficiency. This has enabled the power plant to provide a stable supply of electricity and district-heating steam to the city of Ulaanbaatar.

Improved boiler efficiency and reduced coal and heavy oil consumption have made it possible for this power plant to generate more electricity from the same amount of fuel, and has significantly reduced CO2 emissions.

Improved reliability and operation safety at TES4 have decreased the number of plant outages caused by boiler trips and accidents and reduced the amount of oil consumed for boiler start-ups. With the improved reliability of this plant, the Mongolian government no longer has to purchase as much electricity from other countries.

1998 1999 2000 2001 2002 2003 2004 2006

400

350

300

1997 2005 2007

g/kWh

409417

393

389 388 389

365 365

349

337

317

Coal consumption ratefor electricity generation

1998 1999 2000 2001 2002 2003 2004 2006

190

180

170

1997 2005 2007

kg/Gcal

188

186 186

184 184 184

182181

180

177

174

Coal consumption ratefor district-heating steam

1998 1999 2000 2001 2002 2003 2004 2006

3,000

2,500

2,000

1997 2005 2007

kilo tons

2,9302,957

2,8462,817 2,811 2,818

2,696 2,6902,614

2,537

2,426

Total CO2 emissions amountof electricity & district-heating steam

fficiency improvement

missions reduction

conomic returns

E

E

E

Note : Coal consumption and CO2 emissions are estimated based on coal consumption rate at 7,000 kcal in 1997 with the following values.Calorific value: 29.3 GJ/ton Emission coefficient: 0.0247 tC/GJ CO2 conversion coefficient: 3.6667

22% reductionfrom 1997 to 2007

7% reductionfrom 1997 to 2007

17% reductionfrom 1997 to 2007

88% reductionfrom 1997 to 2007

A case study of CO2 emissions reduction

Achievements

37 38