Surface Finish for Flanges

-

Upload

vermaakash22 -

Category

Documents

-

view

23 -

download

2

description

Transcript of Surface Finish for Flanges

-

Doc.No. : GENL-PI-UZ-0142 Rev.2Group No. : 6.008

SURFACE FINISH FOR FLANGES Page No. : 1

SURFACE FINISH FOR FLANGES

2 13.10.2003 TNG Rud Rud Finish in m added 1 15.02.2001 Pki Rud Rud Issued for Reference (Change in

format only)0 14.07.1987 Rud Ke Ke Issued for Reference

Rev. Date Prepared Checked Approved Description

-

Doc.No. : GENL-PI-UZ-0142 Rev.2Group No. : 6.008

SURFACE FINISH FOR FLANGES Page No. : 2

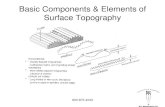

1.0 General :This specification gives the general guidelines for selecting the surface finish for flange facing

both for piping and nozzle flange of equipments.

2.0 Recommendation :2.1 In view of past experience of various projects, it is recommended to specify the following finishes

for flange facings, depending on the use of the common types of Gaskets :

TYPE OF GASKET FINISH IN ROUGHNESS AVERAGE Ra

in (Micro inches) m(Micro meters)

1. CAF 2 or 3 mm thk. 250 - 500 6.3 - 12.5

2. CAF 1 or 1.5mm thk. 125 - 250 3.2 - 6.3

3. CAF with PTFE Envelope 125 - 250 3.2 - 6.3

4. CAF with S.S. Insert 16 - 32 0.4 - 0.8

5. Spiral Wound metallic 125 - 200 3.2 - 5.1

6. Spiral Wound metallic Vac.duty 80 2.0

7. Metallic Ring Joint Gaskets 16 - 32 0.4 - 0.8

8. Reinforced graphite 125 - 250 3.2 - 6.3

2.2 It may be noted that in case of Ring Joint Gaskets, the finish specified is on the side wall

surfaces which are the seating surfaces.

3.0 Special instruction :3.1 It has been observed that the use of the word "concentric / spiral serration" in conjunction with Ra

finish has caused a considerable amount of confusion and hence the following note is to be

added whenever specifying the surface finish :

" This surface is to be obtained by cylindrical machining so that no radial

tool markings are created on the finish surface during machining."

4.0 Equipment Flange Finish :4.1 Nozzles for static and rotating equipment's :

In case of static or rotating equipment's it is decided that, in order to simplify the system and

avoid unnecessary confusions, only 125 Ra finish will be specified except in the case of SS

envelope or ring joint gaskets. In case of ring joint gaskets, 16-32 Ra finish shall be specified.

The note regarding the method of production of the surface finish will, of course, be specified as

given above.

Rev.2