Surface Engineering of Powders and Particles by ALD and PVD · Surface Engineering of Powders and...

Transcript of Surface Engineering of Powders and Particles by ALD and PVD · Surface Engineering of Powders and...

Surface Engineering of Powders and Particles by

ALD and PVD

Geert Rampelberg

Surface Technology 2018, Stuttgart

DEPARTMENT OF SOLID STATE SCIENCESRESEARCH GROUP COCOON

Surface engineering of 3D materials

Surface Engineering of Powders and Particles by ALD & PVD 2

3D materials require various kinds of surface functionalities:

electrical insulation/conduction, protective coatings, hydrophobic/hydrophilic, catalytic activity,...

Sol-gel PVD CVD ALD

Solution: add a thin,

conformal coating

Surface Technology 2018, Stuttgart

Surface engineering of 3D materials

Surface Engineering of Powders and Particles by ALD & PVD 3

3D materials require various kinds of surface functionalities:

electrical insulation/conduction, protective coatings, hydrophobic/hydrophilic, catalytic activity,...

Sol-gel PVD CVD ALD

Solution: add a thin,

conformal coating

Surface Technology 2018, Stuttgart

Coating research at CoCooN

Gas-phase thin-film coating techniques:

Physical Vapor Deposition mostly 2D materials

Atomic Layer Deposition 2D and 3D materials

Surface Engineering of Powders and Particles by ALD & PVD Surface Technology 2018, Stuttgart 4

Physical Vapor Deposition

(Magnetron sputtering)Atomic Layer Deposition

Outline

Surface Engineering of Powders and Particles by ALD & PVD Surface Technology 2018, Stuttgart 5

Atomic Layer Deposition (ALD)

Description of the technique

Advantages and limitations

Plasma-Enhanced Atomic Layer Deposition

Coating library

ALD & PE-ALD on powders and particles

Equipment

Examples and applications

PVD on particles

Summary

Atomic layer deposition (ALD)

Gas-phase thin film deposition technique

Cyclic process of self-limiting surface

reactions

layer-by-layer growth

Example :

ALD growth of Al2O3 from trimethylaluminum

(TMA) and H2O

6Surface Engineering of Powders and Particles by ALD & PVD Surface Technology 2018, Stuttgart

TMA pulse Self-saturated

chemisorption

One layer of Al2O3 H2O pulse

Advantages and limitations of ALD

Advantages:

+ Stoichiometry determined by chemistry

+ Precise control of thickness

+ Excellent uniformity

suitable for large batches

+ Highest degree of conformality

Major limitations:

- Slow: ~1Å/cycle

- Sometimes expensive chemicals

Surface Engineering of Powders and Particles by ALD & PVD Surface Technology 2018, Stuttgart 7

ALD = ideal technique for 3D surface

engineering

Sol-gel PVD CVD ALD

Plasma-enhanced atomic layer deposition (PE-ALD)

Surface Engineering of Powders and Particles by ALD & PVD Surface Technology 2018, Stuttgart 8

TMA pulse Self-saturated

chemisorption

One layer of Al2O3 O2 plasma

Plasma-enhanced ALD:

Highly energetic plasma species facilitate

surface reactions “combustion-like

reactions”

Example Al2O3:

H2O can be replaced by O2 plasma

Plasma is also used for pre-cleaning the

substrateAdvantages: cost reduction, lower deposition

temperatures, higher purity, enlarged coating library,

coating of hard-to-treat materials (e.g. Teflon),…

Coating library

ALD/PE-ALD expertise at UGent-CoCooN: Al2O3, AlN*, SiO2*, TiO2, TiN*,M, VO2, V2O5*, VN*,M,

MnO*, Mn3O4*, MnO2*, FeOx, CoOx, ZnO, ZnS, Ga2O3,* ZrO2, RuM, RuO2M, Ag*,M, In2O3*,

SnO2, HfO2, Ta2O5, TaNM, PtM, Pt alloysM, Au*,...

World-leading expertise in ALD of phosphates*: Al*, Ti*, Fe*, Zn*,...

Pure, mixed or as multilayers

*: only using plasma-enhanced ALD

M: metallic / electrically conductive

Reported processes include metal oxides,

nitrides, sulfides, selenides, carbides,

and some pure metals

Surface Engineering of Powders and Particles by ALD & PVD 9Surface Technology 2018, Stuttgart

Outline

Surface Engineering of Powders and Particles by ALD & PVD Surface Technology 2018, Stuttgart 10

Atomic Layer Deposition (ALD)

Description of the technique

Advantages and limitations

Plasma-Enhanced Atomic Layer Deposition

Coating library

ALD & PE-ALD on powders and particles

Equipment

Examples and applications

PVD on particles

Summary

Rotary reactor for ALD on particles and small components

Patented system and

method for ALD on particles,

including plasma-enhanced

ALD

Surface Engineering of Powders and Particles by ALD & PVD Surface Technology 2018, Stuttgart 11

Rotary reactor for ALD on particles and small components

Patented system and

method for ALD on particles,

including plasma-enhanced

ALD

Surface Engineering of Powders and Particles by ALD & PVD Surface Technology 2018, Stuttgart 12

Pump system

Furnace +

sample container

Plasma source

Precursors

Capabilities

Demonstrated nanocoatings on nano-, micro- and millimeter sized particles

Conformal coatings into porous particles

Recent upscaling: liter-scale reactor available since 2017

Surface Engineering of Powders and Particles by ALD & PVD Surface Technology 2018, Stuttgart 13

Conductive PE-ALD TiN coating on non-conducting

nano-ZnO powder.

x 100

10 ml 1000 ml

Opportunities for ALD in particle technology

Surface Engineering of Powders and Particles by ALD & PVD 14

Broad range of

potential applications:

• Metal particles

• Porous particles

• Polymer particles

• Catalysts

• LED phosphors

• Li-ion batteries

• Pharma

• ...

Surface Technology 2018, Stuttgart

Opportunities for ALD in particle technology

Surface Engineering of Powders and Particles by ALD & PVD 15

Broad range of

potential applications:

• Metal particles

• Porous particles

• Polymer particles

• Catalysts

• LED phosphors

• Li-ion batteries

• Pharma

• ...

Oxidation barriers for copper particles

HAADF-STEM measurements show a conformal,

uniform and pinhole free Al2O3 coating on the Cu

micron sized powder.

TGA measurements in air show

how the oxidation resistance

increases with the thickness of the

Al2O3 ALD coating. The oxidation

temperature was increased with

400°C.

Cu

CuO

Surface Technology 2018, Stuttgart

Opportunities for ALD in particle technology

Surface Engineering of Powders and Particles by ALD & PVD 16

Broad range of

potential applications:

• Metal particles

• Porous particles

• Polymer particles

• Catalysts

• LED phosphors

• Li-ion batteries

• Pharma

• ...

Tailoring porous particles

OAl Ti C

Uniform, conformal TiO2 coating of the outer layer of the porous Al2O3 particles.

Surface Technology 2018, Stuttgart

Opportunities for ALD in particle technology

Surface Engineering of Powders and Particles by ALD & PVD 17

Broad range of

potential applications:

• Metal particles

• Catalysts

• Polymer particles

• Catalysts

• LED phosphors

• Li-ion batteries

• Pharma

• ...

Fluoropolymers – making Teflon hydrophilic WO 2014/111492 A1

0 200 400 600 8000

20

40

60

80

100

120

Wa

ter

co

nta

ct

an

gle

(d

eg

ree

)

Number of Cycles

Plasma treatment

Thermal ALD

Plasma enhanced ALD

200 cycles only O2

plasma exposurePTFE untreated

Hydrophobic Teflon particles

200 cycles

PE-ALD Al2O3

200 cycles

PE-ALD TiO2

Hydrophilic Teflon particles

Surface Technology 2018, Stuttgart

Coating small parts

Coating of metal parts for corrosion protection

Surface Engineering of Powders and Particles by ALD & PVD Surface Technology 2018, Stuttgart 18

ALD coated

Uncoated

ALD coated

Uncoated

No oxidizing treatment Air 600°C, 1 hour

Air 600°C, 1 hourNo oxidizing treatment

Corrosion

No corrosion

Outline

Surface Engineering of Powders and Particles by ALD & PVD Surface Technology 2018, Stuttgart 19

Atomic Layer Deposition (ALD)

Description of the technique

Advantages and limitations

Plasma-Enhanced Atomic Layer Deposition

Coating library

ALD & PE-ALD on powders and particles

Equipment

Examples and applications

PVD on particles

Summary

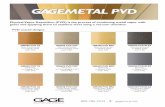

PVD on particles

Magnetron sputtering

Vibrating system for particle agitation

allows for conformal coating

Coating materials:

Almost any metal

Also metal nitrides and metal oxides

Example: metallization of glass beads

Surface Engineering of Powders and Particles by ALD & PVD Surface Technology 2018, Stuttgart 20

Outline

Surface Engineering of Powders and Particles by ALD & PVD Surface Technology 2018, Stuttgart 21

Atomic Layer Deposition (ALD)

Description of the technique

Advantages and limitations

Plasma-Enhanced Atomic Layer Deposition

Coating library

ALD & PE-ALD on powders and particles

Equipment

Examples and applications

PVD on particles

Summary

Summary

Surface Engineering of Powders and Particles by ALD & PVD Surface Technology 2018, Stuttgart 22

Nanometer thin coatings

Conformal coatings onto porous and 3D materials

Highly uniform and scalable

Metal oxides: Al2O3, SiO2, TiO2, ZrO2, ZnO,…

Metal nitrides: AlN, TiN, SiN,…

(Noble) metals: Pt, Au, Ru, Ni,…

> 10 persons working on process- & application

development

Nano- & micrometer thin coatings

Directional coatings for non-porous materials

Conformal coatings on non-porous particles

Uniform and scalable

Metals: almost any metal

Metal nitrides: TiN, ZrN,…

Metal oxides: optional

> 30 years PVD expertise

First commercial system built

ALD & PE-ALD on particles PVD on particles

Applications: barriers/encapsulation, metallization, flow enhancement, modification of hydrophobicity, catalysts,…

Team

Surface Engineering of Powders and Particles by ALD & PVD 23

CoCooNConformal Coating of Nanomaterials

Prof. Dr. Christophe

Detavernier

TT / IOF

Dr. Bart

Hommez

Dr. Geert Rampelberg Véronique

Cremers

Ir. Hugo

Lievens

Consultant

Surface Technology 2018, Stuttgart

Geert RampelbergPhD

COCOON RESEARCH GROUP

T +32 9 264 43 55

M +32 485 46 37 92

www.cocoon.ugent.be

Ghent University

@ugent

Ghent University