Supply Post East Oct 2014

-

Upload

supply-post-newspaper -

Category

Documents

-

view

223 -

download

3

description

Transcript of Supply Post East Oct 2014

STRONGERSTRONGERGROWINGGROWING

STRONGERGROWING

STRONGER

publications mail Agreement #40070144

VOL.

7 NO.

10

Advertiser’s Index ........ 5

Front Page Story ........ 11

Classifieds ................. 13

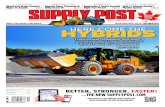

CANADA’s #1 HEAvy EQUIpmENT & TrUCK NEWspApEr · sUppLypOsT.COm

A G R I C U L T U R E

New Holland’s New CR Combine Series And New 16 Row Corn Head PAGE 4

E N V I R O N M E N T

50 Million Tree Program Grows Its Reach To Northern Ontario PAGE 8

E Q U I P M E N T

Sandvik’s New Prisec TM 3 C1531 & C1532 HSI Crushers PAGE 12

M I N I N G

Ontario Taking Steps To Improve Mining Safety PAGE 14

CONSTRUCTION: One might think the construction industry took a deep hit in recent years, but a closer look at the

numbers tells a different story. SEE PAGE 11

ceNtraL/eaSterNcaNaDaeDItIoN·october2014Family Owned Since 1971

didN’T fiNd WHaT YOU Need?find THOUsaNds of listings online at

sUPPlYPOsT.cOM

GreG

loc

ke

Lindsay Construction begins construction on a 30,000 sq. ft. 2-storey tilt-up concrete multi-tenant office building in St. John’s, Newfoundland.

Page 2 Supply Post Central/Eastern Canada Edition · supplypost.com October 2014

October 2014 Supply Post Central/Eastern Canada Edition · Our Readers Are Your Buyers Page 3

Trailering in a 59,300 pound excavator to de-molish a brick building will definitely draw no-tice – especially when the buildings on either side of the structure to be razed are literally just a couple feet away.

That’s the challenge that family-owned RoadEx Contracting Ltd, a three-generation owner op-erator construction com-pany located in Toronto, Canada, frequently faces. “We’ve had occupants of buildings sit and watch

our operators all day as we knock the structures down,” said Ernie Camp-oli, RoadEx owner. “Hav-ing the right equipment to operate smoothly in tight places provides the con-fidence we need to work quickly but safely.”

The machine of choice for this project is the Ko-belco SK260SR, a new addition to RoadEx’s stable of excavators. The SR stands for “short rear swing” and a unique abil-ity to perform continuous dig, 180-degree swing and dump operations within a working space as small as 12 feet 6 inches. “Ko-belco was the first manu-facturer to develop a SR-capable excavator in the industry,” said Bob Green,

founder and owner of Robert Green Equipment, an exclusive Kobelco dealer in Toronto Canada. “It’s just one of many in-novations the company has pioneered over the years.”

But despite their stel-lar history of building in-novative excavators, up to this year RoadEx had never operated a single Kobelco machine. “We’ve purchased and operated excavators from Cater-

pillar, Case, John Deere, Volvo and Komatsu,” said Ernie. “We’re always looking for an edge to compete against the big fleets around town. Paul Ambler, our salesman at Robert Green Equipment, finally convinced us to demo a Kobelco 350.”

That meant the patri-arch of the family, Ernie’s dad Joe, got first dibs dur-ing their test run. “The next day, Ernie gives me a call and tells me right off they don’t like the Ko-belco,” remembers Bob Green. “But before I could respond he adds ‘we love it’ and I knew we had a sale.”

There were three things that won Joe, Ernie and the other operators over as they put the 350 through its paces during the trial: smoothness of operation through every manoeuvre they attempted, overall operation comfort, and fuel economy that was up to 40% better than what they were used to seeing in the other excavation equipment they operated. “The combined benefits means greater productiv-ity on the job site for us,” summarized Ernie. “But

Toronto Owner Operator Finds Increased Productivity In The Tightest Of Places

Continued on page 5

“We’re always looking for an edge to compete against the

big fleets around town.”

Page 4 Supply Post Central/Eastern Canada Edition · supplypost.com October 2014

New Holland’s new CR Series combines raise harvesting to a whole new level: up to 15% more productivity, grain crack-age as low as 0.2%, and the ultimate comfort cab. The brand new Harvest Suite Ultra cab is larger and offers more glass than

previous models. The model series is topped by the CR10.90 Elevation, the most powerful CR model ever, with the highest power in the industry that delivers outstanding per-formance.CR Elevation Combine

“The new CR Series

is the culmination of 40 years of Twin Rotor tech-nology,” stated Dan Valen, New Holland North Amer-ica Cash Crop Equipment Segment Manager. “It of-fers the best of New Hol-land’s smart harvesting technologies: Twin Pitch rotors, Dynamic Feed

Roll, SmartTrax rubber tracks, Tier 4B ECOBlue Hi-eSCR engine technolo-gies - all working together to allow producers to har-vest in a new dimension. All this is coupled with the Harvest Suite Ultra cab that defines harvest-ing comfort. You couldn’t ask for more.”Proven technologies deliver more capacity than ever

New Holland continues to improve and refine its

proven Twin Rotor tech-nology, which is designed for high-capacity harvest-ing, delivering high out-puts and superior grain quality.

The Dynamic Feed Roll on-the-go mechani-cal stone protection sys-tem further raises the CR’s massive capacity by feeding the rotors faster and more smoothly while removing stones with no stopping or hesitation. The new serrated blades on the roll are gentle on the crop, resulting in high-quality grain.

CR Series combines work seamlessly in tough crop conditions with the Twin Pitch rotors, which can raise productivity by up to 10% in damp con-ditions. Switching be-tween small grain/corn configurations to harvest rice is easy. The rede-signed adjustable rotor vanes require less power in high-volume crops and consistently deliver high capacity.

The SmartTrax rub-ber tracks, optional on all models ensure excellent traction and low soil com-paction, while providing a silky, smooth ride.Massive power, extensive autonomy, vast grain tank: productivity reaches new heights, increasing by up to 15%

The CR Series combines offer more horsepower than ever: from 401 hp

of the CR6.90 to the mas-sive 653 hp of the flag-ship CR10.90 Elevation. The entire series features the Tier 4B ECOBlue Hi-eSCR technology (CR9.90 Elevation model features Tier4A ECOBlue SCR tech-nology), while the flag-ship CR10.90 Elevation is equipped with the Diesel Of The Year 2014 Cursor 16 engine which features Common Rail technology for precision fueling and outstandingly responsive performance, resulting in constant, high productiv-ity in all field conditions.

New Holland’s highly efficient ECOBlue technol-ogy delivers impressive fuel savings, reducing run-ning costs and extending further the already exten-sive autonomy given by the ample fuel tank - 340 gallons in the CR8.90 and CR9.90 models, CR9.90 Elevation and CR10.90 Elevation models. The extra-long 34-foot folding unloading auger on the larger models is a match for the widest heads.

The grain tank’s high capacity - ranging from 315 bushels in the, CR6.90 and CR7.90 to 410 bush-els in the CR8.90, CR9.90, CR9.90 Elevation and CR10.90 Elevation - com-bined with the lightning fast unloading speed of up to 4.0 bushels/second, and the extensive autono-my, mean that no second is wasted during the day; productivity soars by up to 15% and does not waiver until the job is done.Harvest Suite Ultra cab: designed for ultimate harvesting comfort

Designed in consulta-tion with customers, the new Harvest Suite Ultra cab defines harvesting comfort. The ample, 131 cu. ft. cab is larger than its predecessor, and the interior layout has been entirely redesigned to fur-ther improve ergonomics and comfort. The new force-based Command-Grip multifunction handle is intuitive to use and makes it easy to fine tune harvesting speed to op-timize performance. The new harvesting console is designed to become an extension of the operator.

The ultra-wide 10.4-inch IntelliView IV colour touchscreen monitor puts all key parameters at the operator’s fingertips and is fixed on rollers so that it can be moved to the most

VISIT US AT CANADIAN WASTE & RECYCLING EXPO - BOOTH #1118

Tel 1.800.668.5458 [email protected] www.flocomponents.com

For Total Lube Solutions,

GO WITH THE FLO!√ Autogreasers for Your Mobile Equipment√ Fluid Handling Equipment for Your Garage√ Our Mobile Workshops Come to You

New Holland raises Harvesting stakes With New Cr Combine series And New 16 row Corn Head

Continued on page 7

New Holland’s new CR Series combines raise harvesting to a whole new level: up to 15% more productivity, grain crackage as low as 0.2%, and the ultimate comfort cab.

October 2014 Supply Post Central/Eastern Canada Edition · Our Readers Are Your Buyers Page 5

the fuel savings alone al-lows us to now bid on and win projects we tradition-ally might not have got-ten.”

Choosing to purchase the smaller, more nimble Kobelco 260SR is a case in point for gaining profit-able new demolition and site prep work for Road-Ex. “Other short tail exca-vators have a tendency to be so neutrally balanced that they’re like a rock-ing horse to operate,” said RoadEx operator Jason Rorsion. “The 260SR is the first short rear swing machine I’ve operated where I don’t have to slow down in even the tightest of spaces.”

Demolishing the all-brick building was quick-work for the 260SR. The maximum digging height of 36’9” and digging reach of 32’4” combined with the compact swing ca-pability provided ample power and control for the RoadEx operators to topple the building safely and quickly. After a while, even the onlookers were convinced their structures weren’t going to be af-fected by the work being completed.

The full-size Kobelco cab was another welcome surprise for the RoadEx operators. “In other short tail machines, I’m lucky if I can fit a sandwich in the cab with me,” said Ja-son. “The Kobelco 260SR has the same full size cab as the 350 with plenty of room to store my lunch pail, construction hard hat, and a whole bunch of other stuff.”

But the greatest num-ber of comments Bob Green has heard from his newest customer has been the fuel-sipping technolo-gies Kobelco has included in their complete exca-vator line. “We received a call from one of the RoadEx operators saying he thought the fuel gauge was broken because it wasn’t going down fast enough,” recounted Ko-belco dealer Green. “We told him to check the li-ters per hour rating and he was amazed it showed 2.1.”

“With our new Kobel-cos, we’re saving thou-sands of dollars a week on fuel,” said Ernie. “Fuel use is consistently lower across all modes of opera-tion.” Fuel consumption boosts productivity, too.

“On the other excavators, as soon as the fuel gauge hits the one-quarter mark I have to call for a refu-eling truck,” said Jason. “With Kobelco excava-tors, I know I can finish out the day’s work with-out a worry.” Even when that day’s work is in the tightest of spaces.

RoadEx Contracting Ltd was established in 1977 to provide excava-tion and grading work for general contractors and design build firms in To-ronto. The three-genera-tion, family-owned owner operator company special-izes in earthworks, from site remediation to bulk excavation, and is also an expert in demolition ser-vices for the commercial and residential sectors. In the last year, the company has more than tripled the size of their business.

Robert Green Equip-ment started business in 1982 and became an au-thorized Kobelco dealer in 1991. He has served the Toronto metropolitan and surrounding area as an exclusive Kobelco dealer ever since, and averages selling between 35 and 40 Kobelco excavators each year. b

Axis Forestry .....................13

Brandt Value Parts........6, 13

Case .................................. 2

Drive Products ..................11

Eagle Equipment ..............13

FLO Components ................ 4

Gear Centre ......................14

HKX.................................... 7

Iron Planet .......................16

Kubota Engines .................. 3

Langley Excavator Parts ...... 5

Magnum Attachments .......10

Quadco ............................15

Tigercat .............................. 9

Toro Steel Buildings ..........12

Van Ed ............................... 8

NEXT DEADLINE: Friday, October 17th, 2014

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO CIRCULATION DEPT.: (Covers/Labels Only)

No. 105, 26730 - 56th Avenue, Langley, BC V4W 3X5

Managing Partner ...............................Gary Mazur

Sales Manager ................................... Jeff Watson

Regional Account Manager .............Jake Peterson

Classified Sales/Production Assistant ...Tanya Lee

Sales/IT ..............................................Gary Mazur

Marketing/Circulation Manager ... Christine Mazur

Controller ....................................... Debra Watson

Accounting Assistant ...................... Heather Egeto

Production Coordinator ................. Eleanor Klawer

Editorial Coordinator .............................Tanya Lee

Art Director ......................................... Linda Horn

Graphic Designer .............................Lisa Schmale

Graphic Designer ....................... Carol Van Muyen

CIRCULATIONMonthly Copies .................. 13,000+Please call our office for full details

#105, 26730 - 56th Avenue, Langley, B.C. V4W 3X5

www.supplypost.com � www.truckpost.caPHONE (604) 607-5577 � FAX (604) 607-0533 � TOLL FREE 1-800-663-4802

The Supply Post is a proud member of the following Trade Associations:

Here Today...Here Tomorrow.

www.postpublishers.com

Produced by:

Published Monthly - Printed in Canada

Publications Mail Agreement No. 40070144Reproduction of any material including photographs and/or

advertisements in whole or in part is forbidden.

A D V E R T I S E R S I N D E X

INTERIORLOGGING

ASSOCIATION

Continued from page 3

Components · Cylinders · Cabs · EnginesUndercarriage · Booms · Sticks · Linkage

www.langleyexcavator.com | [email protected]

Focused on Parts for John Deere & Hitachi Late Model Excavators

5425 Production Blvd., Surrey, BC, V3S 8P6Phone 604.530.5758Fax 604.530.3554

Toll Free 1.888.530.5444

ZX 330 DISMANTLED ZX 850-3 DISMANTLED

Page 6 Supply Post Central/Eastern Canada Edition · supplypost.com October 2014

Terex Washing Sys-tems (TWS) is pleased to report a successful “Open Day” in Australia which is the first of sev-eral planned events for 2014. The recent Open Day event took place at Dubbo Sands, Dubbo, NSW, Australia on July 30-31, 2014 to showcase the recently installed Terex Aggresand 165 washplant.

Niall Donaghy, Sales

Manager, MWS, com-mented, “We at MWS, were delighted to be able to showcase the first Terex Aggresand 165 washplant here in NSW, Australia, to current and prospective customers. The event was realized in partnership with our valued customer, Dubbo Sands and TWS, both of which played an integral part in delivering a suc-cessful event.”

Dubbo Sands’ will-ingness to showcase the plant, in collaboration with TWS Australian dis-tributor, Mineral Wash-ing Solutions (MWS), afforded TWS the oppor-tunity to host the event. An exceptional number of potential customers from leading material companies, throughout Australia, Queensland, NWS and Victoria, at-tended the event where

they saw for the first time a working Terex Ag-gresand 165 washplant.

Mardi and Graham Colbran, Owners of Dub-bo Sands, commented, “Dubbo Sands were so proud to be involved with TWS and MWS in hosting the very first Ag-gresand 165 washplant release in Australia. The Open Day was a huge success, with so many positive comments; we know we made the right decision. The knowledge and expertise has been proven on the ground, with the team sent from Ireland, working along-side Niall, we have ex-actly what our quarry required and more.”

E-mail: [email protected] Inventory: brandt.ca eBay Store: valueparts.ca

For more information call toll free

1-877-685-4886

John Deere330C LC330LC270D LC270LC230LC200LC2054992E892E790E790D690E693D

653G744H744E644G644E644C544H544G444E344H848G748G-III748G-II748G748E

648G710B410G310SE310D772CH770CH772BH770BH770A300D ADT750C-II280-II SL

hitachiEX330-5EX300-3EX270-5EX270L

We are currently wrecking a Deere 744H Wheel Loader s/n DW744HX580150+. Cab, Axles, Cylinders, Boom, Rims and Engine are all in good condition. Also has a 5.5 cu yd pin-on Craig bucket.

DismantleDcurrently Wrecking

Value Parts is your number one choice in North America for quality new, used and rebuilt industrial equipment parts. We specialize in John Deere and Hitachi, but also have access to parts inventories for Caterpillar, Timberjack, Bomag, Ditch Witch and many more makes.

Terex Welcomes prospective Customers To Australian Open Day

The plant is currently processing in excess of 200tph of natural sand and gravel feed material to produce a range of ag-gregates and concrete sands. Attendees were clearly impressed with the plant, which was evi-dent from some customer feedback. One customer commented, “very im-pressive and clearly an efficient unit”, another stated, “I was impressed by the modular system, with the quick set-up and ease of maintenance.” A third added, “ the Open Day was extremely in-formative, presented by staff who were knowl-edgeable and experi-enced.”

When asked about the best features of the Ag-gresand 165 washplant, one customer comment-ed, “the ability to blend feed two products before washing is impressive as well as the accessibility to the entire plant.” An-other customer added, “the small footprint, in-novative design and ease of maintenance are some of the best benefits to me as a customer”.

Sean Loughran, Direc-tor of TWS, commented, “TWS were delighted to host the first of a series of “Open Days” in Australia. With it being the first Ag-gresand 165 wash plant operating in this market, reaction and interest to the plant was phenomenal, which is testament to our commitment to providing enhanced and unique so-lutions to meet customers’ needs and demands. TWS and MWS had the oppor-tunity to meet with exist-ing and many potential new customers and we look forward to working with them in the future to provide similar cohesive washing solutions.”

Fergal McPhillips, TWS Sales Manager, comment-ed, “The Open Day proved to be another successful showcase for TWS. Reac-tion to the plant was ex-ceptional and we received immediate orders as a re-sult. The Aggresand 165 washplant is continually proving to set TWS apart from other providers in the market and is revolu-tionizing the washplant market by introducing innovative solutions and continuing to serve our customers’ needs and de-mands around the world.”

Donaghy went on to

comment, “Customers particularly liked the op-portunity to meet with Dubbo Sands’ owners, Mardi and Graham, who spent time with customers and shared their experi-ence of the ongoing suc-cess and benefits of the plant, namely the ease of set-up and installation, pre-wash system, access, remote operation and the efficient running and pro-duction of the plant.”

Mardi and Graham Colbran added, “The pro-fessionalism and dedica-tion from Niall and his team, starting with pur-chasing right through to commissioning, has been outstanding; we feel that there is noth-ing else currently on the market that even comes close. We chose the Ag-gresand 165 washplant for ease of setup. Having the ability to minimize disruption to our site was very important. Our Aggresand 165 wash-plant incorporates the Pre Wash system which enables us to bring our sand into spec in just one pass, whilst producing 3 aggregates, giving us a very cost effective opera-tion. The Quality of de-sign and construction of this plant is easily seen. A lot of thought has gone into access for servicing to pumps, screens, and the controls, including remote operation from the loader, all of which are user friendly. This plant demonstrates what washing sand should be, ‘Easy’. Everyone worked extremely hard to pull this together, and we are positive ours will be the first of many hitting Aus-tralian shores.”

TWS are hosting a se-ries of further Open Days in 2014 to showcase other products within their expansive portfo-lio, as well as another Aggresand plant, operat-ing in a different market. The events are scheduled for France in September, Canada in October and India in November.

If you are interested in attending one of the forthcoming events con-tact Elaine Donaghy, Marketing Manager – [email protected], to register your in-terest and find out more.

For More informa-tion on TWS full prod-uct portfolio visit www.terex.com/washing. b

Mineral Washing Solutions, in New South Wales, Australia, showcased the recently installed Terex Aggresand 165 washplant.

October 2014 Supply Post Central/Eastern Canada Edition · Our Readers Are Your Buyers Page 7

Two new Tier 4-com-pliant Doosan excava-tors are now available in the United States and Canada — the DX300LC-5 and DX350LC-5 — featur-ing improvements in fuel efficiency, productivity and durability. Replacing the DX300LC-3 and DX-350LC-3 models respec-tively, the new Doosan crawler excavators have new engine modifications and aftertreatment tech-nologies to meet Tier 4 emissions regulations.Tier 4 engine configuration

Doosan 271-horse-power DX300LC-5 and 318-horsepower DX-350LC-5 excavators are powered by Scania diesel

engines that have been configured with a High-Pressure Common-Rail (HPCR) fuel delivery sys-tem as well as Cooled Ex-haust Gas Recirculation (CEGR). Doosan also add-ed a Mass Airflow (MAF) sensor and exhaust brake to the engine to help meet Tier 4 emission standards. The mass airflow sen-sor allows the Electronic Control Unit (ECU) to im-prove the management of airflow provided by the Variable Geometry Tur-bocharger (VGT), and to optimize fuel delivery to the combustion chamber based on air intake vol-ume and rpm. The VGT is utilized to enhance boost pressure through-

out a wide rpm range of the engine, resulting in improved fuel efficiency at lower rpms. This also generates higher torque levels and faster engine response even at low rpm, and improves machine performance in the Stan-dard and Economy power modes while saving fuel.

The exhaust brake helps to maintain consis-tent engine temperatures at lower engine speeds to improve operating ef-ficiency. Consistent en-gine temperatures reduce harmful emission levels in the exhaust when the engine is running at lower rpms. Under normal oper-ation, with high rpms, the exhaust brake is inactive.

Aftertreatment technologies

New Tier 4 compliant Doosan excavators com-bine Selective Catalyst Reduction (SCR) with a Diesel Oxidation Catalyst (DOC) to reduce engine emission levels. Diesel Exhaust Fluid (DEF) is used with SCR technology and stored in a DEF tank near the front-left corner (opposite of the operator station) of Doosan crawl-er excavators. The DOC transform Particulate Mat-ter (PM) emissions into harmless water and car-bon dioxide. DEF is inject-ed into the exhaust system to transform the nitrogen oxides (NOx) produced during combustion into water and nitrogen.Productivity boost

Available for the DX-350LC-5, D-ECOPOWER optimizes hydraulic sys-tem output with engine

horsepower, improving machine efficiency, pro-ductivity and fuel con-sumption, as well as refin-ing machine control and enhancing operator com-fort. A pressure controlled pump, closed centre main control valve and various sensors in the excavator electronically detect and control the precise amount of hydraulic oil required to perform a task.Four power modes

Similar to previous Doosan excavators, op-erators can choose from four power modes for more control to better bal-ance fuel consumption and machine power to the working conditions. Power modes include the following:•Power+ mode: deliv-

ers the fastest work-group speeds for load-ing trucks, top digging performance and extra power for digging in

hard ground•Power mode: provides

exceptional power and performance for tough digging conditions and truck loading tasks

•Standard power mode: balances the excava-tor’s fuel consumption in everyday digging, grading and lifting tasks

•Economy mode: re-duces fuel consumption for low-demand appli-cations, slows down machine movement for conditions that require extra precisionTo further match Doo-

san excavators to the ap-plication at hand, opera-tors can choose from four work modes — Digging, Breaker, Shear and Lifting — to maximize efficiency and fuel economy in spe-cific applications. Op-erators can configure the work mode by adjusting a dial switch on the right-

comfortable position. An optional second IntelliV-iew display is available for operators requiring the maximum amount of in-formation.

The new cab also fea-tures more glass than previous models. With 68 sq. ft. of glassed area, and the floor slop-ing down into the front windscreen, the operator has excellent visibility all round and a clear view of the header.

For the long harvest-ing days, there is a choice of three types of seat, the standard wide cloth seat, the deluxe cloth seat and

the top of the range leath-er trimmed seat. Both the deluxe cloth trimmed and leather seats feature heating and active venti-lation.

When harvesting con-tinues into the night, the lighting package is pre-cision engineered to en-sure perfect visibility of the entire header and the field ahead. An unload-ing auger light for preci-sion unloading and four rear work lights mean farmers can continue to work long after dark just as efficiently, as during the day, in order to get the job done right. HID and LED packages are

Working with excavators isn’t all that glamorous, but attach an HKX hydraulic kit to one and their coolness factor goes off the charts!

Standard kits for a wide variety of attachments

Latest in attachment control technology

Kits ship within 1 - 5 days—ground or air

call +1 800.493.5487 or 360.805.8600www.HKX.com/SPP

G L A M O RO U S ? not so much

COOL FACTOR? of f the char ts

Continued from page 4 available. A perfect match: designed to deliver improved harvesting productivity and reliability

To match the capac-ity of the largest of the CR Series combines, New Holland launches a new 16- row version of the 980CR Series of corn heads. Available in a 30- inch row spacing configuration, this model includes all the perfor-mance and convenience features already recog-nized on the 980 Series corn heads. Redesigned dividers and points bet-ter follow ground con-

tours and actively feed laid crop to collect ev-ery kernel. Replaceable wear strips and self-sup-porting gas struts make adjustment and servicing easier.

“New Holland has been committed to equipping our customers with prod-uct advancements, new technology and solutions for well over a century,” says Valen. “The 16-row CR980CR corn head and the CR combine line are just some of the many new product innovations to be introduced in 2014. Dedicated. Uncompro-mised. Smart. That’s New Holland.” b

Doosan Introduces Two New Tier 4 Crawler Excavators — The DX300LC-5 And DX350LC-5

Continued on page 8

Two new Tier 4-compliant Doosan excavators are now available in the United States and Canada — the DX300LC-5 and DX350LC-5 — featuring improvements in fuel efficiency, productivity and durability.

Page 8 Supply Post Central/Eastern Canada Edition · supplypost.com October 2014

hand console. A work mode icon displays on the monitor after the operator presses the mode button.Fuel savings

New Tier 4 compliant Doosan excavators feature improved fuel efficiency to help owners reduce operating costs. For ex-ample, a Tier 4 compliant DX350LC-5 excavator has a 10 percent fuel savings from the equivalent Tier 3 model. For further fuel savings, auto shutdown helps owners save fuel during non-working con-ditions. When enabled, the feature will shut down the excavator’s engine after a preset idle time. For example, the opera-tor can configure the idle time from 3 to 60 minutes. For operators in Califor-nia, auto shutdown helps meet the state’s regula-tions of idling for only five minutes for off-highway machines.Display enhancements

An improved 7-inch LCD display panel allows operators to continue monitoring the excavator parameters while viewing the rearview and/or side view camera image. Criti-cal machine data appears next to the camera view. With an optional side camera, a split screen al-lows both camera displays to be viewed at once. New additions to the monitor include the DEF gauge and fuel efficiency.

New machine updatesIn addition to auto

shutdown and LCD dis-play panel updates, the new Doosan DX300LC-5 and DX350LC-5 crawler excavators have the fol-lowing updates:• Improved serviceability

for uptime protection•Auto belt tensioner: fan

and air conditioning•Anti-skid plates for bet-

ter traction on steps and other walking surfaces

•Enhanced access to the emergency engine stop

•Battery and alternator upgrades to minimize downtime

•For greater operator comfort, the floor ped-al angle has been im-proved by 10 degrees.

OptionsSome factory-installed

options for the new DX-300LC-5 and DX350LC-5 crawler excavators in-clude the following:•Additional work lamps•Cab guarding for special

applications•Diesel-powered coolant

heater for cold starts•Rotate circuit hydraulic

piping•Straight travel pedal,

which allows the opera-tor to travel in a straight line more easily

•Two-way auxiliary hy-draulic pedal (in addi-tion to joystick control)

DurabilityIn an effort to mini-

mize downtime, Doosan excavators have standard features that ensure their

durability, even when operating in harsh con-ditions. These features include a robust and reli-able track tensioning sys-tem. Improvements made during the launch of the Dash-3 models, such as larger bushings in track rollers and thicker sprock-et teeth, are evident in the Dash-5 models. Also carried over from Dash-3 models are added rein-forcement plates and in-creased plate thickness to the excavators’ boom and arm.Doosan Telematics

Doosan DX300LC-5 and DX350LC-5 crawler excavators come with a standard three-year subscription to telemat-ics, commonly known as “machine intelligence.” Telematics allows equip-ment owners to monitor machine location, hours, fuel usage, engine idle versus work time, error codes, and engine and hydraulic temperatures. Owners and fleet man-agers can monitor their machines remotely after they log in to a website account. Equipment deal-ers can also help custom-ers through telematics by responding to machine warning messages, pro-viding the proper parts and service after review-ing the website and di-agnosing an issue with a machine, and then send-ing a field service vehicle to make the repairs. b

ATTACHMENTS & MORE

Own or Rent • Hammers • Crushers

Crusher Buckets • Vibrorippers • Compactors • Blowers & Dust Suppression

1-877-255-9293 www.vanedequipment.com

Continued from page 7

Trees Ontario, the for-est restoration arm of For-ests Ontario, recently an-nounced the expansion of the Ontario government’s 50 Million Tree Program into northern Ontario. Un-til recently, the program focused its efforts on re-gions in southern Ontario with goals of re-greening settled landscapes and helping to fight climate change. Since the pro-gram’s inception in 2008, Trees Ontario has planted more than 15 million trees with an ultimate goal of planting 50 million trees by 2025.

The expansion kicked off on May 23rd with the first northern tree plant in Desbarats, Ontario at the Archibald Homestead. Led by Brent Attwell at REGEN Forestry with full support by the Kensington Conservancy, the plant saw volunteers, including elementary students from Johnson-Tarbutt Central

School in Debarats, plant 2,000 trees on the prop-erty. This event was fol-lowed by a larger planting effort over the following days that achieved a to-tal of 10,500 trees planted overall. The plant sought to restore abandoned agri-cultural land at the Home-stead to support conserva-tion and restoration efforts in regions maintained by the Conservancy.

“We are always excited to see so many come out to re-green their communi-ties,” said Rob Keen, Trees Ontario CEO. “Since the beginning of the 50 Million Tree program, we’ve had thousands of volunteers of all ages and backgrounds join us across dozens of communities. Now that the program has expanded its reach, we hope to bring to-gether more Ontarians, es-pecially our youth, in creat-ing a greener and healthier future for all of us.”

Among the planters

was Peter Gagnon, Trees Ontario’s newest Field Advisor supporting For-ests Ontario’s northern Ontario programs. Ga-gnon indicated that the program’s extended reach may take time to develop, but that growth will ulti-mately benefit the prov-ince, noting, “It is exciting to be able to implement the 50 Million Tree Pro-gram across the province and promote forest stew-ardship on a larger scale.”

The task ahead is to work with local forestry consultants to identify potential Planting Deliv-ery Agents (PDAs), such as conservation authori-ties, forestry consultants and local municipalities, to assist with project de-livery. The PDAs, in turn, will help to connect with potential landowners who qualify for planting subsi-dies under the program. Reception thus far has been very positive and

Gagnon confirms that new PDAs have already agreed to take part in areas such as Dryden and Timmins.

Many regions in north-ern Ontario have signifi-cant areas of under-utilized marginal farmland that may be suitable for restora-tion, including Manitoulin Island, New Liskeard, Fort Frances, Thunder Bay and Dryden. “Significant tree planting subsidies provided by the 50 Million Tree Pro-gram can help landowners increase property value, improve water quality, and enhance wildlife habi-tat, among other benefits,” says Gagnon.

Bill Mauro, Minister of Natural Resources and Forestry, welcomed the expansion of the 50 Mil-lion Tree Program into northern Ontario as a ma-jor step forward in achiev-ing the Ministry’s overall goals. Mauro remarked, “We are committed to

protecting and expand-ing Ontario’s rich biodi-versity. Our forests are crucial as they help fight climate change, clean the air, increase wildlife habi-tat and prevent floods. Our Government will con-tinue to work with Trees Ontario to help grow On-tario’s forests.”

Ultimately, the pro-gram’s growth will con-tribute to Trees Ontario’s ongoing efforts to promote forest stewardship and sup-port sound forest manage-

ment practices on private lands. Together with the government of Ontario, Trees Ontario will now administer the 50 Million Tree Program across the entire province with a goal to support healthy and sus-tainable forests.

For more information about the 50 Million Tree Program and other tree planting programs, as well as local tree planting work-shops, visit: www.treesontar io .ca/programs/#50MILL b

50 million Tree program Grows Its reach To Northern Ontario

Trees Ontario has planted more than 15 million trees with an ultimate goal of planting 50 million trees by 2025.

October 2014 Supply Post Central/Eastern Canada Edition · Our Readers Are Your Buyers Page 9

Mustang is proud to announce the all-new mid-frame R Series Ra-dial-Lift Skid Steer Load-ers. These include three new models: the 1350R (replacing the 2041), the 1500R (replacing the 2044), and the 1650R (re-placing the 2054). These skid loaders feature an all-new operator station with an integrated digital dis-play, new load arm design with increased visibility, Yanmar-powered Tier IV engines and several ser-viceability enhancements.

The 1350R, 1500R and 1650R radial-lift skid steer loaders fall into the mid-frame category, bringing unparalleled versatil-ity to the jobsite. When equipped with optional counterweights, the rated operating capacities range from 1,500 lbs. (680 kg) on the 1350R to 1,800 lbs. (816.5 kg) on the 1650R. Lift heights reach up to

119” (3023 mm) on the 1500R and 1650R.

These mid-size skid steer loaders come equipped with emissions compliant Tier IV Yanmar engines that incorporate DPF (Diesel Particulate Filter) technology. This engine technology is en-vironmentally sound and does not require fuel after-treatments, such as urea. With maximum torque rat-ings from 107.8 ft.-lbs. (146 Nm) on the 1350R and 1500R to 178 ft.-lbs. (241 Nm) on the 1650R, these machines are equipped with the power needed to tackle demanding jobs.

The new R Series skid steer loaders feature standard proportional auxiliary hydraulics for maximum precision and infinitely adjustable flow control. Achieve flow rates from 17 gpm (64.4 L/min) on the 1350R and 1500R to 18.9 gpm (71.4

L/min) on the 1650R. Im-pressive breakout forces deliver optimal digging and lifting performance. Faster cycle times further enhance productivity on the jobsite. Pressure-re-lieving hydraulic couplers make attachment changes simple and safe.

The state-of-the-art op-erator’s compartment on the new R Series skid steer loaders leaves little to be desired. A front-lifting re-straint bar and armrests with multiple adjustments enhance operator comfort and safety. The mechani-cal or air-ride suspension seat options deliver out-standing comfort. Crea-ture comforts - such as automatic dome light, cup holder, 12-volt outlet, storage tray and multiple air vents – come standard on these intuitive load-ers. A cab-forward design and lowered rear towers deliver unmatched vis-

ibility to the bucket edge and rear of the machine. The optional pressurized cab enclosure, with sound reduction material and a rear-mounted air filter, provides a cleaner, qui-eter, climate-controlled working environment.

Controllability and ease of use are part of the pack-age on the new R Series skid steer loaders. Cus-tomize your skid steer with three control options; hands only, hand/foot, and joystick (1650R only). Aux-iliary hydraulic controls are located on the joystick in all configurations for easy access. A fully-customiz-

able digital colour display provides coolant, fuel, bat-tery, environmental, en-gine regeneration informa-tion and other features in real time.

Excellent service ac-cess is achieved on the R Series models through the extra-wide rear door and engine hood. A swing out rear door and new swing out cooler provide unparalleled access to fil-ter, fluid reservoirs and the engine bay area. The level II FOPS structure tilts back with the aid of gas springs, providing easy internal access to the pumps, hydraulic valve

bank and drive motors. A safety restraint holds the ROPS/FOPS structure in the raised position. Release of the safety re-straint is made easy with a new pull cord. Plus, all high-rotation pins have grease points for ease of maintenance and quiet operation.

These exciting new R Series skid steer loaders also include many other features such as the manual Quick-a-Tach or hydraulic Power-a-Tach attachment systems, HydraGlide ride control and the Hydraloc safety system. A variety of

T H E R I G H T WAY T O D O R I G H T - O F - WAY.

T H E 4 8 0 M U L C H E R

With maximum horsepower to the ground, efficient hydraulics and excellent cooling capacity, the 480 is a high performance, high uptime machine for the most demanding and time-sensitive right-of-way projects.

Contact us to today to find out more about the 480 mulcher and Tigercat's other

off road industrial products.

off road industrial products519.753.2000

www.facebook.com/Tigercat

Mustang R Series Skid Loaders

Continued on page 11

1350R Dumping Gravel

Page 10 Supply Post Central/Eastern Canada Edition · supplypost.com October 2014

With its all-new Smart-Trax system, New Hol-land matches the overall versatility of a wheeled tractor with the high trac-tion and flotation of rubber

tracks. Although based on the established GENESIS T8 Series, SmartTrax trac-tors have detail design differences. These include purpose-developed high

torque axles that match large-diameter front wheels with the rear tracks. This enables full power to be delivered between the front wheels and rear tracks for

optimum performance.GENESIS T8 Tractor with SmartTrax

“SmartTrax-equipped T8 Series tractors have been developed to deliver the proven versatility of a wheeled tractor with the enhanced traction and flo-tation of rubber tracks,” says Dan Valen, Cash Crop Marketing Segment Lead-er. “The rubber tracks are matched to large diameter front wheels to deliver ex-cellent maneuverability and to overcome some of the issues that may arise with conventional twin tracked vehicles. A key feature of SmartTrax is the ability to turn tightly and cleanly at the headland. This improves versatility as the tractor is also suit-able for top work, such as spraying and top dressing.”Optimized flotation and traction with minimized soil disturbance

Designed by New Hol-land specifically for high power applications, Smart-Trax is offered on the top three models in the T8 Tier 4B Series. A GEN-ESIS T8 SmartTrax has a larger contact patch with the soil, enhancing trac-tion and reducing ground pressure and compaction. The contact patch of the 24-inch SmartTrax system is up to 65% greater than a 710/75R42 single rear tire set. The 18-inch SmartTrax system is 35% larger than a set of 480/95R50 rear du-als. The reduced ground pressure allows earlier ac-cess to drying land and can provide extended working late in the season with a re-duced risk of damage to the structure of the soil.

GENESIS T8 Smart-Trax tractors benefit from wheeled tractor agility. Top-soil disturbance in a tight headland turn is minimized, with the rear tracks follow-ing the path of the front tires without forming a “berm” ridge. The combination of wheeled front axle and rear tracks enables a New Hol-land GENESIS T8 Smart-Trax tractor to operate at full power in turns around wet field areas or on the headlands. This full power capability is a key advantage over twin tracks, which shut down power in one track to make the turn, when full power can get you through the tough working condi-tions. Purpose-developed high clearance, high torque front and rear axles

Purpose-developed ax-les have the high strength build required to transfer high power and torque to the ground as well as carry heavy loads. The front axle is designed to transfer full power to large diameter wheels while still allowing a 55º turn angle. This en-sures a GENESIS T8 Smart-Trax can turn tightly for optimum productivity.Up to seven different working widths

By offering a choice of undercarriage, New Hol-land GENESIS T8 Smart-Trax tractors can be speci-fied to offer a choice of working widths, with track spacing choices of between

76- and 152-inches (1930- to 3960mm). The actual track width can also be matched to suit specific needs: “conventional” nar-row undercarriage models have a choice of 16-, 18- or 24-inch (400-, 460- or 610mm) tracks. For use in more extreme conditions, to include steep terrain or extremely wet conditions, wide undercarriage models are offered with a choice of 24- or 30-inch (610- or 760mm) tracks.Choice of Auto Command CVT or Power Command full powershift transmission

The proven New Hol-land Auto Command con-tinuously variable trans-mission is standard on the T8.435 and an option on the T8.410 with full pow-ershift Power Command as standard. A key advantage of SmartTrax is that the GENESIS T8 models are based upon well-proven platforms that will be fa-miliar to New Holland op-erators.Revised fuel tank and cab steps for easy cab access

SmartTrax increase the overall height of the trac-tor. To ensure that ease of access is not compromised, New Holland fit purpose-designed access steps to make getting in out of the cab safe and easier. To ac-commodate the revised steps, the fuel tank is re-profiled but fuel capacity is the same. b

2 SIDE GRIP VIBRATORS AVAILABLE FOR EXCAVATORS IN THE 20 TONS AND LARGER WEIGHT CLASS

PICKING UP, POSITIONING AND DRIVING PILES IN EXCESS OF 35 FEET LONG IN A SINGLE OPERATION.

OTHER EXCAVATOR AND CRANE MOUNTED VIBRATORS AVAILABLE.

S I D E G R I PV I B R A T O R S

MAGNUM ATTACHMENTS WILL GIVE

THE WORKING END OF YOUR MACHINERY

SUPERIOR PERFORMANCE AND DURABILITY.

71 STEINWAY BLVD, TORONTO, ON M9W 6H6

416.679.8752 | 1.877.640.2862 | FAX 416.679.8753

New Holland GENESIS T8 SmartTrax: Rubber Track Traction, Wheeled Tractor Versatility

The New Holland GENESIS T8 includes purpose-developed high torque axles that match large-diameter front wheels with the rear tracks.

New Holland T8 Series Cab

October 2014 Supply Post Central/Eastern Canada Edition · Our Readers Are Your Buyers Page 11

Measurable growth and streamlined

business practices during the past five years post-recession has been the trend in the Canadian non-residential construction industry, according to the most recent data available from Statistics Canada. In fact, Statscan reports a $12.92-billion investment in non-residential build-ing construction in the first quarter of 2014, a value that represents $1.79-bil-lion in growth compared to the first quarter of 2009.

“Ask most Albertan contractors about the 2008-2009 recession and they will pause to try and remember those days. For-tunately, activity is so ro-bust today as to put it far out of their memory,” says Michael Mangum, Senior Consultant, FMI Centre for Strategic Leadership. “Conditions in the East have struggled to shake the effects of what some are calling the Great Reces-sion. Metropolitan Toronto is fully back as numerous cranes dot the sky, yet that

options and attachments allow the user to customize the machine to their needs.

To learn more about the Mustang R Series skid steer loaders please visit www.mustangmfg.com.Applications

Mustang R Series skid steer loaders are avail-able in Canada and North

is not broadly shared in the balance of Ontario or in the Maritimes.”

But that does not mean all Eastern Canadian com-panies struggled.

“We actually grew through the recession,” says Cory Bell, President of Dartmouth, NS-based Lindsay Construction. “It created opportunity for us because there was less work prior to stimulus, and we have a solid reputa-tion with trade contractors which allowed us to be-come more competitive.”

Bell says his company is currently active in New-foundland with the con-struction of a $13-million light industrial commercial building for a developer who will be servicing the off-shore market. The com-pany is also in the design phase for a $20-million multipurpose eight-storey building in downtown Halifax, and is in the earli-est stages of an undisclosed $45-million project.

“I do believe that the construction industry is much more sophisticated

America. These new mid-frame skid steer loaders are popular among agri-culturalists, contractors, landscapers, and excava-tion companies due to their excellent ground engaging capabilities and manoeu-vrability. Rental businesses will also benefit from the versatile nature of the new R Series skid steer loaders.

today than it was back pre-recession. There would have been a lot of hand-shake deals and verbal-ized communication versus written communication,” Bell says. “One of the big-gest differences really is document control, and con-trol of the information by all the key stakeholders.”

Other non-residential construction companies in Canada share a similar re-siliency.

“During the recession, clients were reluctant to commit, and funding be-came more difficult for cli-ents to source,” says Chris Collison, Vice President, Construction, at Edmon-ton, Alberta-based Seko Construction. “We were lucky in that we had a rea-sonable amount of backlog which kept the business busy during this difficult time.”

Collison says his com-pany is currently putting the finishing touches on a new $15-million head of-fice, warehouse, and shop for a major electrical com-pany in South Edmonton.

Interview“The design of the

new Mustang R Series Skid Steer Loaders is a result of almost 50 years of skid steer market ex-perience and extensive feedback from loyal Mus-tang equipment owners,” says Brian Rabe, Mus-tang Manager of Product Development. b

“We offer a service that is geared to walking an owner through the whole construction process from concept design, permitting, budgeting, final design and onsite construction.”

And if resilient growth

during the economic downturn is any indica-tion, the beginning of the next five-year cycle contin-

ues to show signs of prom-ise for the non-residential construction sector across the country. b

Front Page Story

Growing StrongerOne might think the construction industry took a deep hit in recent years after the 2008-2009 economic meltdown, but a closer look at the numbers tells a different story. By Mark Wolfe

“We actually grew through the recession.” — Cory Bell, Lindsay Construction.

courtesy lindsay construction“We were lucky in that we had a reasonable amount of backlog which kept the business busy during this difficult time.” — Chris Collison, Seko Construction.

courtesy seko construction

Total Canada Construction SpendingSum of Latest 10 Years (to 2014)

Category Billionseducational services $63.8Health care and social $55.4servicesretail trade $44.0accommodation and $21.4Food services

Grand total 10-year construction spending on the four categories [of] retail, accommo-dation and food, schools, and hospitals, has been $185 billion.

*Source: Statistics Canada and Reed Construction Data

Continued from page 9

Page 12 Supply Post Central/Eastern Canada Edition · supplypost.com October 2014

The latest additions to the CI500 Prisec Horizontal Shaft Impactor (HSI) range of crushers, the Prisec 3 primary CI531, and the sec-ondary CI532, have been developed to deliver excep-tional rates of productivity and efficiency. As with the rest of the Prisec range, these new HSI crushers possess the ability to be configured into either a pri-mary or secondary crusher operating mode and with this unique, exclusive to Sandvik, patented design, providing customers with unparalleled adaptability. Additionally single stage crushing is also a possi-bility with the ability to recirculate material to the primary versions of the crushers.Exceptional reduction ratios

Sandvik’s revolutionary all new design of crush-ing chamber ensures even greater reduction ratios

than have been previously obtainable. Furthermore the Prisec TM 3 crushers are able to easily produce impressive reduction ra-tios through the use of two uniquely designed cur-tains, which have tradition-ally required a three cur-tain configuration crusher. As well as enhanced pro-ductivity, this means fewer wear parts and reduced maintenance.Energy efficient overload protection

The CI531 and CI532 Prisec 3 are equipped with an infinite hydrau-lic curtain adjustment combined with a brake positioning system which relieves pressure, and set-ting, when un-crushable objects enter the crusher. No hydraulic power is required during normal operation, thus saving on operating power and reducing total power con-sumption. Both first and

second curtains are infi-nitely adjustable via the Sandvik’s patented ad-justment / braking system which is located on the cross beams of the crush-er. This system gives hy-draulic adjustment of both curtains, via the standard supply electric hydraulic power pack.Dealing with crusher blockages

Crusher blockages have always historically been a problem, espe-cially when operating in a primary mode. Removal of the blockage, with the combined downtime and health and safety risks en-countered, are now elimi-nated with the new genera-tion Prisec 3 crusher. Due to the exceptional features of the crushers no stopping of the crusher is necessary, with no operator interven-tion inside the crusher, no heavy lifting gear required, all resulting in maximum

uptime and reduced health and safety problems.Rotor and hammer design

The rotor and hammers can be considered as the heart of the crusher; this is why those used on the Pri-sec 3 range are both robust and efficient. Rotors have superior weight and design, essential for delivering the high inertia required for optimum crusher perfor-mance, thus ensuring sta-bility and smooth operation during production. The unique “banana” shaped self-sharpening hammer design helps to keep the contact heads sharper dur-ing operation, resulting in more effective shearing of the incoming material, and hence improved produc-tion. Easy and safe

maintenanceA unique key safety in-

terlock system ensures safe maintenance of the crusher and prevents accidental opening of the crusher and inspection doors even in multiple installations. It also allows the ability to raise curtains during opera-tion without stopping the crusher to clear blockages, and re-set automatically to operating setting. This maximizes uptime and re-duces the need for heavy lifting gear and operator / maintenance intervention, thereby reducing further Health & Safety risks.Maximum uptime, Maximum breakage

Through the modular-ized nature of the Prisec 3 range, wear parts can be turned for maximum life/usage with the same

size being used across the whole range of crushers. In addition, Sandvik’s world leading technology in the hammer and liner mate-rial composition provides options far surpassing old industry standard of man-ganese, resulting in even lower operating cost per ton and the ability to oper-ate efficiently in a variety of materials, especially re-cycling applications.Customer focused development

The two new rugged, high quality HSI crushers offer customers world lead-ing benefits and advantag-es. Low operating cost per ton, which combined with granted patented technol-ogy, places Sandvik Con-struction at the forefront of HSI design and develop-ment. b

Quote Your NextBuilding Project 1-800-668-5111ext

2024

Serving Canada’s Mining and Energy Industries for Over 30 Years

FUTUREBUILDINGS

Arch Style or Straight Wall

Two Companies Joined Forces to Provide the Industrywith Rugged Pre-engineered Steel Building Solutions

BUILDINGS FOR MINING

Sandvik’s New Prisec TM 3 CI531 & CI532 HSI Crushers

The latest additions to the CI500 Prisec Horizontal Shaft Impactor (HSI) range of crushers, the Prisec 3 primary CI531, and the secondary CI532, have been developed to deliver exceptional rates of productivity and efficiency.

Ontario is now home to North America’s larg-est power plant fuelled completely by biomass. The Atikokan Generat-ing Station conversion is complete and the station is now generating electric-ity and helping meet local power needs in north-western Ontario.

Atikokan Generating Station, which employs 70 full-time workers, burned

its last coal two years ago, on Sept. 11, 2012. Conver-sion of the station began in mid-2012 and included construction of two silos and boiler modifications to accommodate the biomass. The project employed over 200 highly skilled trades people and technical work-ers.

A coal-free energy mix will lead to a significant reduction in harmful emis-

sions, cleaner air and a healthier environment.

The biomass used to fuel Atikokan Generating Station is being harvested and processed in Ontario. Domestic suppliers have leveraged this opportunity to secure contracts to pro-vide pellets to international buyers.

Providing clean, reli-able and affordable power is part of the government’s plan to invest in people, build modern infrastruc-ture and support a dynam-ic and innovative business climate across Ontario. b

A New Era Of Cleaner Air In Ontario

Hyundai Construc-tion Equipment Americas, Inc., a leading earthmov-ing and material handling equipment manufacturer, is pleased to announce the appointment of Hydro-mec, Inc. to their rapidly growing dealer network. Hydromec, Inc. will pro-vide sales and service of Hyundai equipment from their dealership locations in Dolbeau-Mistassini and Chicoutimi, Quebec.

“Hydromec, Inc. is a standout dealership who’s made it their mission to provide the best equip-

ment, parts and service in their region. Like Hyun-dai, their customers are the central focus of their busi-ness,” states Kirk Gillette, Vice President of CE Sales at Hyundai Construction Equipment. “We’re de-lighted to have a dealer of this nature join our grow-ing dealer network.”

Hydromec, Inc. will now carry Hyundai’s full line of quality construction equipment, which includes wheel loaders, crawler and wheeled excavators, mini-excavators and skid-steers. The full stock of Hyundai

equipment will be readily available for sale or rent.

“Hyundai equipment is innovative and offers eco-nomical operation along with superior performance and comfort,” states Jean Trottier, President of Hy-dromec, Inc. “Hyundai is a true world class brand and we’re thrilled to offer our customers equipment of this quality. We look for-ward to a strong, success-ful partnership with the company.”

Hydromec, Inc. sales staff has been fully trained in the application, sales, parts and service of Hyun-dai Construction Equip-ment products and offers prompt and professional parts and service support to its customers. b

Hyundai Appoints Hydromec, Inc. As Authorized Dealer In Quebec

to place an ad, call 1-800-663-4802 or visit supplypost.com october2014·page13classifieds

ATTACHMENTS

(2) TTS Trenchers, rebuilt discs. $55,000. Quesnel, BC.pHoNE: (250) 992-7959

1997 TTS Delta Trencher. Bought new in ‘97. C/w 5 rebound pads, 2 springs, spare cylinder, numerous hoses and some parts. $33,500. Creston, BC.pHoNE: (250) 428-2535

TRK ATTACHMENTS Case 580 Extendahoe Thumbs in stock. Made in Canada. Hyd. $2,350; Man. $1,975; Del. $188 Can-Wide, non-rural.www.trkattach.capHoNE: (905) 641-9981

Advertise your machine in the classifieds! Call Tanya today for deadlines & rates.TANYA: 1-800-663-4802

Shaw Bros. Attachments for excavators, loaders, skidsteers, crusher buck-ets, screening buckets, thumbs, breakers, grap-ples, snow equipment & much more at best prices.www.shawbros.capHoNE: (877) 625-9677

Advertise your machine in the classifieds! Call Tanya today for deadlines & rates.TANYA: 1-800-663-4802

buSiNESSESKurt Leroy Trucking Ltd. has 2 separate Bill-13 Hauling Contracts for sale. Total volume 192,000m3, sell separately or as package. Campbell River, BC [email protected]: (250) 287-9812

Multiple machines with contracts in place! 1975 Caterp i l lar D9H, a lso D355A Komatsu, 325BL hoe, Terratech mounder on 648D JD, 2000 660C Timberjack, (2) F-250 pickups. Start your own business in reforestation site prep. Currently have machines working. Just step in and start generat-ing revenue! $250,000 min. investment. Open to offers. Slake Lake, AB.pHoNE: (780) 849-0449

CAMpS

Luxury 52 man Camp! C/w desalination system, A/C, incineration, heli-pad, inter-net throughout and TVs in all rooms. For sale or lease with full service catering available. Located on the West coast of B.C.pHoNE: (604) 269-2002

CoNCRETE

New/Used Preem por-table batch plant, 30 TNE powder silo, (2) 12 yd3 agg bins, digital water & weight controls. Optional fully automated controls available. 75 yd3/hr. POR, Sales/Rental. Medicine Hat, AB.pHoNE: (403) 866-4220

fEllER buNCHERS2004 Madill 2200B feller buncher, exc. cond., 360° Tigercat saw head. 16,000 hrs. Williams Lake, BC.pHoNE: (250) 267-1772

loAdERS (Wheel)

1972 Cat 966B, complete rebuilt motor, c/w bucket & log grapple. Exc. cond, well maintained. $25,000. Castlegar, BC.pHoNE: (250) 365-2261

MillS

Mills - Blades - Sharpeners. Mills starting at $135/mth.www.portablebandsaw mills.capHoNE: (877) 537-5099

Advertise your machine in the classifieds! Call Tanya today for deadlines & rates.TANYA: 1-800-663-4802

pRoCESSoRS

2006 Volvo 210B, 19,500 hrs, forestry cab with riser, colour monitor, aux. fuel tank, new hyd. pump, clean fix reversing fan. $89,000. Quesnel, BC.pHoNE: (250) 255-8037

SAWMillS

Rig-Mat / Pallet manufac-turing plant - production line for manufacture of rig-mat blocks and pal-lets used in the Oil & Gas industry. Rock Creek, BC.pHoNE: (250) 446-2450

SliNgERS

2003 Slinger body for sale, serial #04MO3272 M-17 Bay lynx, fully operational, low hrs, $21,000 OBO. Call Steve or Ray.pHoNE: (250) 474-5145

TRAilERS

(2) 2010 Arnes 110 tonne dual lane lowbeds. 10'6"W x 24'L, pin joint deck, axles expand to 19'W. Surplus equipment, project f in-ished. New $240,000 each, sell for $165,000 each. Surrey, BC.pHoNE: (604) 580-9877

Advertise your machine in the classifieds! Call Tanya today for deadlines & rates.TANYA: 1-800-663-4802

(1) 4 axle wagon; (3) 2 axle

pups; (1) 3 axle wagon.

1992 -2003 . Nahann i .

Castlegar, BC.

pHoNE: (250) 365-2261

WANTEd

W a n t t o b u y C l a r k

Planetary Axles, also Axle

Tech. Call Steve or Jake.

pHoNE: (360) 794-2021

DEERE CONSTRUCTIONParts & Components

BRANDT VALUE PARTS1-877-685-4886

One of the largest inventories of used, rebuilt, and new

surplus Deere parts and components in North America.

We also stock parts for Hitachi, Timberjack, Caterpillar, Ditch

Witch and can locate those hard to find parts that we may not

have in stock.

Talon Energy Services Inc. has established a large industrial fabrica-tion facility in Port aux Basques thanks in part to a repayable invest-ment of $500,000 from the Government of Can-ada. The announcement was recently made by the Honourable Kellie Leitch, Minister of Labour and Minister of Status of Women, on behalf of the Honourable Rob Moore, Regional Minister for Newfoundland and Labra-dor and Minister of State (Atlantic Canada Oppor-tunities Agency).

Talon Energy Services Inc. specializes in a range of energy services and so-

lutions for the oil and gas, resource and industrial sectors. Government of Canada funding assisted with the acquisition of fab-rication equipment specific to supplying large subsea and other industrial com-ponents in support of the region’s offshore oil pro-duction fields.

The company has an extensive track record both in North America and internationally and has worked as far afield as South East Asia, South America, West Africa and the Middle East. In 2014, Talon Energy Services was ranked among PROF-IT 500 Canada’s Fastest-Growing Companies. b

Feds support oil & Gas industry in newfoundland and labrador

EAGLE EQUIPMENT• 2001 Tamrock 700 Scout Rock Drill, 8,800 hrs, Asking .......................$89,900

• Rebuilt Hydraulic Hammers (all sizes)

• Used Trucks, Floats And Trailers

www.eagleequipment.ca

Percy Jackson, Sales Manager: TF: 1-800-461-8625 | C: 705-626-3362

AXIS FORESTRY INC.• AftermarketPartsSourceToFitYourWaratahProcessor

• RebuiltWaratahProcessorsAvailable

• TradeInOrRebuildYourWaratah

• RepairingWaratahComputers• RepairingIQANSkidder/BuncherJoysticks

• CanShipAnywhere

www.axisforestry.com1-888-678-2947

Page 14 Supply Post Central/Eastern Canada Edition · supplypost.com October 2014

Used equipment auc-tions provide buyers and sellers an opportunity to acquire and dispose of a wide range of heavy equip-ment. Leading up to the big day, buyers and sellers should make sure they are prepared to ensure an effi-cient and successful trans-action.Tips for Equipment Buyers• Learn the rules of the

auctionRules can vary from

auction to auction so every buyer should be aware of how the auction is operat-ed to avoid confusion. For instance, buyers will likely need to register for the auction ahead of time and there may be minimum bid requirements. Look for an auction company that of-fers customer support to help with any issues that arise before, during and af-ter the auction.• Determine what equip-

ment to purchaseBuyers should review

their fleets so that they can go into an auction with a

list of current inventory. This reduces the chance of purchasing a machine that isn’t needed or missing out on an opportunity to buy a great piece of equip-ment. Think about upcom-ing projects to determine if additional pieces of core equipment will be needed or if specialty equipment is essential.• Research the value of the

desired equipment Buyers are better pre-

pared when they under-stand the current value of the machines they’re interested in. Take note of the selling price for ma-chines with similar year, make, model and hours. If the bidding goes well over these selling prices, con-sider waiting for another piece of equipment. It’s im-portant for buyers to set a budget and keep it in mind during the auction.Tips for Equipment Sellers• Understand market

trendsBefore disposing of a

machine, a seller should

take a look at how the mar-ket is performing. Although there is steady demand for used heavy equipment, there can be peaks for cer-tain types of equipment depending on the time of year. Many organizations look to acquire equipment at the beginning of the year to prepare for spring and summer projects. A seller should consider the ben-efit of selling now versus waiting and be aware of the current value of their equipment.• Pick the best selling plat-

form for the business’ needsToday, businesses have

more options than ever for selling their equipment. Many are turning to on-line auctions because they are convenient and don’t require equipment to be moved until it is sold. Sell-ers can also reach a wider audience because they can tap into buyers located around the world. Online auctions are also held more frequently than traditional auctions. A seller should

weigh the pros and cons of every marketplace, and choose the option that works best for his or her unique needs.• Clean equipment

It’s important to present a good looking machine at auction to attract interest. Cleaning the interior and exterior of the equipment is critical so that you don’t put off potential buyers and negatively impact the price.• Make repairs and adjust-

ments if necessarySellers may want to

make minor repairs in or-der to increase the resale value of a piece of equip-ment. This includes fixing broken glass, replacing lights and making steer-ing and wheel alignments. Any abnormal wear or malfunctions that will re-quire a large investment should be weighed. Some-times the resale value will not provide enough net profit for a seller, but oth-

er times investing in these repairs is more than offset by the increased selling price.

Buyers and sellers must both prepare for a used heavy equipment auction before bidding day. By do-ing so, fleet managers can ensure that they acquire and dispose of equipment in a way that suits their business needs. bBy Sue McGregor, Manag-ing Director of Canada, IronPlanet

Preparing for an Equipment Auction: Tips for Buyers and Seller

Ontario is improving the health and well-being of workers in the province’s underground mines by act-ing on its advisory group’s early work.

Led by the province’s Chief Prevention Officer, the advisory group’s com-prehensive mining safety review has prepared a progress report including a number of key initiatives.

In response to the pre-liminary work of the advi-sory group, Ontario will:• Improve the visibility

of workers through in-creased promotion of high visibility apparel

• Develop a mining health database that will serve as a valuable tool to track incidents of illness, exposure to a number of carcinogenic substances, helping to prevent min-ers from being exposed to unsafe levels and as-sist in the development of improved health and safety rules

• Create a sharper focus on hazards to improve health and well-being in the new training stan-dards for joint health and safety committees, which are made up of workers and manage-

ment•Fund a study to be

completed by Lauren-tian University that will look for ways to reduce loss of feeling in the feet triggered by con-tinuous use of vibrating machinery, which puts workers at greater risk for slips and falls inju-ries, especially on high work platformsThe mining safety re-

view final report will be provided to the province early next year.

Protecting the health and safety of miners and all of the province’s workers is part of the government’s plan to build Ontario up by investing in people, build-ing modern infrastructure and supporting a dynamic and innovative business climate. b

Ontario Taking Steps To Improve Mining Safety

Rising a symbolic 1,776 feet above the skyline of Manhattan and standing as the tallest skyscraper in the Western Hemisphere, One World Trade Center is setting new standards in building a more resilient, safe and sustainable ur-ban landscape. Monumen-tal in scale, this landmark 104-story tower features 3,500,000 square feet of space that will accommo-date activities vital to the nation’s economy.

Taking advantage of in-novative construction ma-terials, One World Trade Center is designed to be the safest and most environ-mentally friendly commer-cial building in the world. The structure includes a massive cast-in-place, rein-forced concrete inner core that runs the full height of the tower — an extra-strong backbone that provides support for gravitational loads as well as resistance

to wind and seismic forces. The concrete core walls measure three feet thick or more above ground and up to twice that below grade. Higher up, the concrete core walls slim down to two feet thick.

The 200,000 cubic yards of concrete used in the tow-er’s superstructure-with a strength that has never been used on such a scale in building construction-was custom-designed to ensure high levels of dura-bility, constructability and sustainability. Support-ing columns on the first 40 floors were made from 12,000- to 14,000-psi self-consolidating concrete and the upper floors with 8,600- to 10,000-psi mix designs. To meet the compressive strength requirements, the design and engineering team relied on a highly spe-cialized concrete mix that included Lafarge Portland Type I/II and NewCem slag

cements, as well as other supplementary cementi-tious materials. Engineered for high strength and long-term durability, NewCem slag cement helps achieve greater strength potential and helps control shrink-age, creep and cracking in mass concrete structures.

High-strength concrete was the ideal material for meeting the high-priority safety requirements for One World Trade Center because key supporting members-such as eleva-tor and stair enclosures-often relied upon to resist wind, seismic and other impact forces, are designed with an extra measure of durability and resilience. The concrete also made a strong contribution to the sustainable design of the building, which is expected to receive LEED Gold cer-tification when it opens later this year. In addition, the tower was constructed with mostly post-industrial recycled materials, includ-ing the NewCem slag ce-ment, which is a by-prod-uct of the steel-making process. b

Durable And Sustainable Construction Reaches New Heights

EDMONTON1-877-450-4327

CALGARY1-888-252-3880

www.GEARCENTRE-OFFHWY.comSURREY

1-877-882-1529MISSISSAUGA1-888-246-5077

Transmissions • Torque ConvertersPlanetary Axles • Differentials • Transfer Cases

Pump Drives • Wheel Drives • Mixer DrivesFULL SERVICE FACILITIES

October 2014 Supply Post Central/Eastern Canada Edition · Our Readers Are Your Buyers Page 15

Sky rocketing property prices for years on end have not detracted from the popularity of Munich’s old town. New living and work areas are in demand like never before. A new office building is currently being built in an exclusive setting on the heritage-list-ed Maximiliansplatz. The building was fully leased even before construction began in 2013. The gen-eral contractor, Riedel Bau GmbH & Co. KG from Low-er Franconia, rented one of WOLFFKRAN’s most mod-ern cranes for the construc-tion of the building shell: the WOLFF 166 B with hy-draulic luffing gear.

The luffing crane im-presses on this city con-struction site mainly because of its compact-ness. “The site is very cramped on all sides,” ex-plains Ulrich Langenbein, Deputy Sales Director at WOLFFKRAN Germany, regarding the biggest chal-lenge of the project. “With construction work un-derway on adjacent sites, there are cranes all over the place that we have to

watch out for,” continues Mr. Langenbein. In addi-tion to its flat-top design that does away with the traditional rope luffing gear and its compact steel coun-terweights, the biggest ad-vantage of the 166 B is its jib, which can be raised to an almost vertical position. “Because of its design, the WOLFF can slew in the minimum of space with-out projecting beyond the site, meaning that we can work without any danger of collision. There is also no danger when the crane is not in use owing to the very steep out-of-service position of the jib,” says Norbert Zährl, Site Man-ager for Riedel Bau. The construction company from Schweinfurt has five WOLFF cranes in its fleet and has been a convinced customer of the Heilbronn premium manufacturer for many years. Space saving, full performance

Despite its compact-ness, the WOLFF delivers a remarkable performance when it comes to lifting of concrete and structural

components at the Munich site: It has a maximum lift-ing capacity of 12 tons in the 2-fall operation, a tip load capacity of 3.4 tons with a 45 meter jib and a maximum lifting speed of 87 m/min. The load-sensing control of the luff-ing gear regulates the luff-ing speed according to the load. So the 166 B only needs a comparably small 22 kW motor to reach a luffing time of 90 seconds.

The 166 B scores further points on the city-center building site when it comes to the assembly. The hoist rope winch is designed so that the complete jib can be easily pre-assembled on the ground. The luff-ing crane could also be erected on a lower tower height than would have been the case with a saddle jib crane, which saved ad-ditional time. Earlier this year, the construction site team erected the WOLFF 166 B in just one day – yet another plus given the tight schedule of the construc-tion project, which is due for completion at the begin-ning of 2015. b

WOLFF 166 B In Use At The Maximiliansplatz, Munich

The hoist rope winch is designed so that the complete jib can be easily pre-assembled on the ground.

Brandt Equipment Solu-tions Ltd. is now in full pro-duction of our new Com-pact Excavator Hydraulic Quick Coupler. This inno-vative new coupler is sold exclusively for the Deere 27D, 35D, 35G, 50D, 50G, 60D and 60G Compact Ex-cavators.

Unveiled at the 2014 ConExpo event in Las Ve-gas, all of the coupler’s fea-tures were showcased at the largest show in the in-dustry. The response from Deere dealers and contrac-tors is extremely positive as this exciting new product fills a long standing need within the Deere Compact Excavator lineup.

Productivity is every-thing in today’s construc-tion industry, and Brandt’s new coupler is designed to be safe, quick, and conve-

nient to make your opera-tion more efficient.• Operators never have to

leave the cab in order to change attachments.

• Installation is a breeze with the control kit de-signed specifically for each machine.

• Plug and play; the elec-trical harness supplied comes cut to length with quick connectors already installed.

• Cab controls are easily in-tegrated into the Deere in-terior not only to maintain a factory looking appear-ance, they are conveniently located at your fingertips.

• Designed to pick up Brandt lugged attach-ments as well as the fac-tory Deere attachments.Safety is essential on ev-

ery job site, and Brandt’s new Hydraulic Quick Cou-

pler offers an abundance of safety features all designed to keep your work site as safe as possible.• Wedge is engaged with

mechanical pressure in order to prevent dropping attachments in the event of a hydraulic failure.

• Patented automatic safety locking system provides an extra level of protection does not require the operator to leave the cab.

• Pressure sensing audible alarm in the cab.

• Visual LED warning light in the cab.

• Fail-resistant control valve design.Brandt Equipment So-

lutions Ltd. designs and manufactures the most in-novative attachment and guarding solutions for John Deere Construction and Forestry equipment. A highly talented and experi-enced design team works closely with customers to achieve productive solu-tions for all their heavy equipment needs. b

Brandt’s New Hydraulic Quick Coupler For Compact Excavators

Page 16 Supply Post Central/Eastern Canada Edition · supplypost.com October 2014

Equipment featured are a representation of items available at IronPlanet. Items are sold and added to inventory weekly. California Auction Company Bond #70259785. Preliminary list to date. Equipment subject to change. © 1999-2014 IronPlanet, Inc. All Rights Reserved. IronPlanet®, IronClad Assurance® and Auctions you can trust® are registered service marks of IronPlanet, Inc. All other marks and brands are the property of their respective owners.

888-433-5426

WEEKLY ONLINE AUCTIONS

2012 Kleemann MC110Z Mobile Jaw Crusher

2011 AltaStream APPD 180N 180 kW Generator

2001 Liebherr LTM 1080/1 All Terrain Crane

Morbark Wolverine Wheel Feller Buncher

2012 JCB 300ECO Skid-Steer Loader

2007 Caterpillar 385CL Track Excavator

2001 Caterpillar 725 Articulated Dump Truck

Olympic Knuckle Boom on 1989 Western Star 4964F Tri/A Truck

Pioneer Portable Roll Crusher

2011 Case Quadtrac 550 Rubber Track Tractor

2006 Caterpillar 322C Forest Machine

1996 Volvo WG Bin Hauler Truck

Buy. Sell. Fast. Easy.www.ironplanet.com