Supplementary Materials for€¦ · a sample chamber connected to ahome- built vacuum-pumping...

Transcript of Supplementary Materials for€¦ · a sample chamber connected to ahome- built vacuum-pumping...

www.sciencemag.org/cgi/content/full/science.aaf8060/DC1

Supplementary Materials for

A vacuum flash–assisted solution process for high-efficiency large-area

perovskite solar cells

Xiong Li, Dongqin Bi, Chenyi Yi, Jean-David Décoppet, Jingshan Luo, Shaik Mohammed Zakeeruddin, Anders Hagfeldt, Michael Grätzel*

*Corresponding author. E-mail: [email protected]

Published 9 June 2016 on Science First Release DOI: 10.1126/science.aaf8060

This PDF file includes: Materials and Methods

Supplementary Text

Figs. S1 to S8

Tables S1 to S6

1

Materials and Methods

Synthesis of inorganic/organic halide materials

MABr was synthesized by stirring a mixture of methylamine (5 mL, 40% in methanol) and HBr

(6 mL, 48% in water) at room temperature for 2 h. The solvent was evaporated in a rotavap and

the remaining solid was poured into 50 mL ether and filtrated. The precipitate was washed three

times with ether and dried under vacuum to get a white crystalline MABr product. FAI was

synthesized according to a reported procedure (16). All the other materials were purchased from

commercial sources and used as received.

Solar cell preparation

A 30 nm TiO2 blocking layer was deposited on the pre-cleaned FTO (NSG) by spray pyrolysis

using O2 as the carrying gas at 450°C from a precursor solution of 0.6 ml titanium

diisopropoxide and 0.4 ml bis(acetylacetonate) in 7 ml anhydrous isopropanol. A 150 nm

mesoporous TiO2 was coated on the substrate by spin-coating with a speed of 5000 rpm for 10 s

with a ramp rate of 2000 rpm s-1, from a diluted 30 nm TiO2 particle paste (Dyesol 30 NR-D) in

ethanol with the weight ratio of TiO2 paste/ethanol = 6:1, and then the substrates was sintered at

500°C for 20 min. The perovskite film was deposited by spin-coating onto the TiO2 substrate.

The FA0.81MA0.15PbI2.51Br0.45 precursor solution was prepared in a glovebox from a 1.35M PbX2

(X = I, Br) in the mixed solvent of DMF, GBL and DMSO, with the molar ratios of GBL/DMF =

1.1:1 and PbX2/DMSO = 1:1. The spin coating procedure was done in ambient air by a

consecutive two-step spin-coating process at first 1000 rpm for 28 s with a ramp of 200 rpm s-1

and second 4000 rpm for 18 s with a ramp of 2000 rpm s-1. For the deposition of the pervoskite

2

using the vacuum-flash assisted solution processing (VASP) treatment, the substrate was put into

a sample chamber connected to a home-built vacuum-pumping instrumentation, as illustrated in

Figure 1. By opening the valve connecting the specimen chamber to the pump system the

perovskite film was immediately exposed to low pressure maintained at 20 Pa for 10 s, followed

by full repressurisation by admitting ambient air into the specimen chamber. Subsequently the

substrate was covered under a petri dish on a hotplate and annealed at 100°C for 30 mins in

ambient air at 20 % relative humidity. After cooling down to room temperature, the hole-

transporting material of spiro-OMeTAD was deposited on top by spin-coating. The spin coating

procedure was done in glovebox flushed with dry air , first 1500 rpm for 10 s with a ramp of 200

rpm s-1, second 4500 rpm for 30 s with a ramp of 2000 rpm s-1. The spiro-OMeTAD solutions

were prepared dissolving the spiro-OMeTAD in chlorobenzene at a concentration of 65 mM,

with the addition of 30 mM bis(trifluoromethanesulfonyl)imide from a stock solution in

acetonitrile), 200 mM of tert-butylpyridine. Finally, 80 nm of gold was deposited by thermal

evaporation using a shadow mask to pattern the electrodes.

Device characterization

Current–voltage characteristics were recorded by applying an external potential bias to the cell

while recording the generated photocurrent with a digital source meter (Keithley Model 2400).

The light source was a 450-W xenon lamp (Oriel) equipped with a SchottK113 Tempax sunlight

filter (Praezisions Glas & OptikGmbH) to match the emission spectrum of the lamp to the

AM1.5G standard. Before each measurement, the exact light intensity was determined using a

calibrated Si reference diode equipped with an infrared cut-off filter (KG-3, Schott). IPCE

spectra were recorded under a constant white light bias of approximately 5 mW cm-2 supplied by

3

an array of white light emitting diodes. The excitation beam coming from a 300-W xenon lamp

(ILC Technology) was focused through a Gemini-180 double monochromator (Jobin Yvon Ltd)

and chopped at approximately 2 Hz. The signal was recorded using a Model SR830 DSP Lock-In

Amplifier (Stanford Research Systems). All measurements were conducted using a non-

reflective metal mask with an aperture area of 1.00 cm2 or 0.16 cm2 to covering part of the active

area of the device and avoiding light scattering through the sides.

Material characterization

X-ray diffraction (XRD) spectra were recorded on an X’Pert MPD PRO (PANanalytical)

equipped with a ceramic tube providing Ni-filtered (CuK = 1.54060 Å) radiation and a RTMS

X’Celerator (PANalytical). The measurements were done in BRAGG-BRENTANO geometry

from 2 θ = 8 to 88 degree. The samples were mounted without further modification and the

automatic divergence slit (10 mm) and beam mask (10 mm) were adjusted to the dimension of

the films. A step size of 0.008 degree was chosen for an acquisition time of 270.57 s degree-1. A

baseline correction was applied to all X-Ray powder diffractograms to compensate for the broad

feature arising from the FTO glass and anatase substrate. Scanning electron microscope (SEM)

images were recorded using a high-resolution scanning electron microscope (FESEM, Merlin).

An electron beam accelerated to 3 kV was used with an in-lens detector. The spectra were

measured with the perovskite infiltrated mesoscopic TiO2 films supported by FTO glass using a

PerkinElmer Lambda 950 spectrophotometer. Atomic force microscope (AFM) was performed

using Bruker multimode 8 in “tapping” mode. Ultraviole-visible (UV-vis)Absorption spectra

were measured on a PerkinElmer UV-Vis spectrophotometer. The absorptance of the sample was

determined from a transmittance/diffuse reflectance measurement using an integrating sphere.

4

We used the “PerkinElmer Lambda 950 nm” set-up employing the integrating sphere system “60

nm InGaAs integrating sphere” obtained from the same company. The light source was a

deuterium or tungsten halogen lamps and the signal is detected by a gridless photomultiplier with

Peltier-controlled PbS detector. The UV WinLab software allows to process the data.

Photoluminescence (PL) spectra were recorded by exciting the perovskite films deposited onto

mesoporous TiO2 at 425 nm with a frequency-doubled picosecond Ti-Sapphire laser (pulse width

~ 2 ps, pump fluence ~ 0.1 µJ/cm2, spot diameter ~ 0.1 mm). The lase pulse impinged on the

perovskite capping layer. The emission was recorded with a spectrometer (Horiba Jobin Yvon

iHr320 and a CCD Sy). Time-resolved photoluminescence (TRPL) experiments were performed

on the same samples using the same laser, and the signal was recorded using a Hamamatsu

Streak Camera. The samples were excited from the perovskite side under ambient conditions.

5

Fig. S1. Comparison of the morphology of perovskite films deposited on the mp-TiO2/FTO

substrates using VASP method applying a vacuum of. (A) 5 Pa, (B) 20 Pa, (C) 200 Pa and 2000

Pa presuure. The scanning electron microscopy (SEM) pictures presented for two magnifications

reveal stark differences in film morphology. At p = 2000 Pa, the perovskite film shows

polydisperse micrometer-sized perovskite islands, which are loosely distributed over the mp-

6

TiO2 layer with poor surface coverage. At a pressure of 200 Pa the perovskite grains show denser

packing and the coverage of perovskite film is improved even though some FTO remains

uncovered. Applying a vacuum of 20 or 5 Pa resulted in the formation of pinhole-free compact

perovskite capping layers. We employed 20 Pa in our investigations.

7

Fig. S2. Attenuated total reflection Fourier-transform infrared spectroscopy (ATR-FTIR) for the

perovskite devices of the composition FA0.81MA0.15PbI2.51Br0.45 perovskite intermediates treated

by vacuum-flash and the resulting perovskite polycrystalline film after air-annealing in ambient

air. The presence of the DMSO in the perovskite precursor is confirmed by the appearance of the

S=O stretching bands at 1019 cm-1. Considering that DMSO forms a stable 1 :1 Lewis acid-base

adduct with the PbX2 (X = I, Br) component, and based on the nominal composition of the

starting solution, the likely composition of the adduct is DMSO-PbI1.7Br0.3-(FAI)0.85(MABr)0.15

(14, 17–19).

8

Fig. S3. Top view SEM images showing the surface of a FA0.81MA0.15PbI2.51Br0.45 perovskite

precursor film freshly deposited on the mp-TiO2/FTO substrates after VASP treatment before

thermal annealing.

9

Fig. S4. Stabilized electric power output and the photocurrent density at maximum power point

as a function of time for the best performing PSC whose J-V curve is shown in Figure 4d and

recorded with a square aperture area of 1.00 cm2 under simulated one-sun illumination.

10

Fig. S5. Typical J-V curves and extracted PV parameters measured with square apertures of

different area (0.16 and 1.00 cm2 ) under simulated standard Am 1.5 illumination for a

FA0.81MA0.15PbI2.51Br0.45 PSC with an total area of 1.2×1.2 cm2 fabricated by VASP method.

11

12

Fig. S6. Independent certificate by Newport Corporation, an accredited PV laboratory

confirming a power conversion efficiency of 19.6% for a photovoltaic device fabricated by the

VASP method with an aperture area of 1.0×1.0 cm2. The certificate includes values for all PV

metrics as well the J-V curve and the normalized IPCE(EQE) spectrum of the cell.

13

Fig. S7. Large-area PSC device stability in ambient air. Evolution of device performance

parameters recorded with a square aperture area of 1.00 cm2 during aging in the dark at ambient

temperature. The laminated device was kept in ambient air for 39 days. PV performance metrics

were measured at regular intervals of 3 days employing simulated full solar AM 1.5 light at room

temperature.

14

Fig. S8. Temporal evolution of photovoltaic performance metrics of encapsulated perovskite

solar cells fabricated by VASP (red) and CP (black) methods aged under Indoor long term light

soaking test. During the this aging test, the encapsulated devices were continuously subjected to

15

a 10 mW cm-2 UV-filtered simulated sun light at 45 oC in ambient air and maintained at the open

circuit condition. They were removed at an interval of 18 hours from stability test and cooled

over 30 mins to equilibrate at ambient temperature before recording the photovoltaic device

performance metrics. Current-voltage measurement employed simulated AM 1.5 solar light at

100 mW cm−2 intensity. The devices prepared by VASP retain 90% of the initial performance

after 100 hours, whereas the control devices retain only 70% of the initial performance under the

same aging conditions. These results show that VSAP have obviously advantage to make high-

quality perovskite film without pinholes, and indicate that the devices made by the VASP

method resist better to photodegration than the reference sample.

16

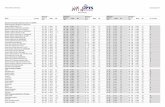

Table S1. Photovoltaic parameters recorded at a scanning rate of 50 mV s-1 in reverse direction

for a batch of twenty FA0.81MA0.15PbI2.51Br0.45-based perovskite devices fabricated by

conventional process (CP) measured with an aperture area of 1.0×1.0 cm2 under standard AM

1.5G (air mass 1.5 global) illumination.

Cell No. VOC

(mV) JSC

(mA cm-2)

FF Light Intensity

(mW cm-2)

PCE (%)

1 950 17.29 0.66 98.0 9.96

2 927 17.12 0.570 97.0 9.32

3 959 17.67 0.593 98.3 10.23

4 940 16.91 0.622 96.5 10.17

5 957 17.42 0.612 96.4 10.59

6 912 17.01 0.533 96.6 8.43

7 934 16.86 0.601 96.1 9.85

8 945 16.31 0.606 96.0 9.56

9 968 16.47 0.572 95.9 8.36

10 946 17.92 0.564 97.3 9.82

11 932 17.31 0.505 95.9 8.39

12 936 17.73 0.566 96.8 9.57

13 921 17.75 0.588 95.7 9.87

14 929 17.22 0.555 97.0 9.04

15 908 17.76 0.600 96.8 9.77

16 949 18.13 0.611 97.1 10.79

17

17 932 17.21 0.580 97.5 9.54

18 946 17.01 0.610 97.0 10.12

19 936 17.21 0.560 96.5 9.35

20 939 16.61 0.600 96.0 9.75

Average 938±15 17.25±0.49 0.588±0.03 96.7±0.7 9.62±0.67

18

Table S2. Photovoltaic parameters recorded at a scanning rate of 50 mV s-1 in reverse direction

for a batch of twenty FA0.81MA0.15PbI2.51Br0.45-based perovskite devices fabricated by vacuum-

flash assisted solution processing (VASP) measured with an aperture area of 1.0×1.0 cm2 under

standard AM 1.5G (air mass 1.5 global) illumination.

Cell No. VOC

(mV)

JSC

(mA cm-2)

FF Light Intensity

(mW cm-2)

PCE (%)

1 1132 23.78 0.755 99.4 20.28

2 1129 23.53 0.723 97.7 19.66

3 1135 22.97 0.755 98.8 19.71

4 1135 22.83 0.740 99.0 19.37

5 1137 22.54 0.743 98.7 19.29

6 1122 23.21 0.730 97.9 19.42

7 1130 23.03 0.744 98.8 19.36

8 1123 23.13 0.735 98.1 19.46

9 1126 22.98 0.744 98.1 19.44

10 1116 22.88 0.733 97.9 18.99

11 1121 23.36 0.722 98.0 19.15

12 1132 22.76 0.744 97.8 19.44

13 1131 23.31 0.721 98.0 19.39

14 1141 23.19 0.766 98.3 20.38

15 1140 23.45 0.743 98.2 20.23

16 1126 23.15 0.731 98.4 19.37

19

17 1114 23.02 0.744 97.2 19.50

18 1138 23.03 0.755 98.4 19.95

19 1132 23.24 0.744 98.6 19.64

20 1133 23.04 0.744 98.0 19.58

Average 1130±8 23.12±0.28 0.744±0.010 98.3±0.5 19.58±0.37

20

Table S3. Photovoltaic parameters recorded at a scanning rate of 50 mV s-1 in reverse direction

for a representative FA0.81MA0.15PbI2.51Br0.45-based perovskite device fabricated by vacuum

assisted solution process (VASP) measured at five different spots with a square aperture area of

0.16 cm2 sampled from a total active device area of 1.2×1.2 cm2 under standard AM 1.5G (air

mass 1.5 global) illumination.

Square VOC

(mV)

JSC

(mA/cm2)

FF PCE(%)

1 1072 24.09 0.79 20.40

2 1070 24.00 0.80 20.54

3 1070 24.31 0.79 20.55

4 1069 23.84 0.79 20.13

5 1065 23.96 0.78 19.90

Average 1069±3 24.04±0.18 0.79±0.01 20.31±0.28

21

Table S4. Stability of perovskite solar cells of the composition FA0.81MA0.15PbI2.51Br0.45

prepared by the VASP method. PCE was measured with a square aperture area of 1.00 cm2 under

100 mW cm-2 simulated standard AM1.5G sunlight.a

Time

(days)

VOC

(mV)

JSC

(mA cm-2)

FF PCE (%)

0 1133 23.09 0.744 19.26

3 1129 23.33 0.733 19.19

6 1123 23.27 0.744 19.31

9 1129 23.40 0.744 19.41

12 1130 23.41 0.731 19.34

15 1138 23.17 0.743 19.59

18 1126 23.15 0.744 19.19

21 1123 23.48 0.733 19.24

24 1142 23.36 0.744 19.63

27 1138 23.33 0.742 19.70

30 1135 23.47 0.744 19.82

33 1134 23.39 0.734 19.47

36 1140 23.48 0.755 19.96

39 1141 23.16 0.751 19.85

a the solar cells were sealed with epoxy glue and stored in the dark in a desiccator.

22

Table S5. Photovoltaic parameters recorded at a scanning rate of 50 mV s-1 in reverse direction

for a batch of ten FA0.81MA0.15PbI2.51Br0.45-based perovskite devices fabricated by anti-

solventvacuum-flash assisted solution processing (VASP) measured with an aperture area of

1.0×1.0 cm2 under standard AM 1.5G (air mass 1.5 global) illumination.

Cell No. VOC (V) JSC

(mA cm-2)

FF Light Intensity

(mW cm-2)

PCE (%)

1 1.13 22.00 0.722 99.7 18.00

2 1.12 22.10 0.714 99.9 17.69

3 1.11 20.29 0.701 95.7 16.50

4 1.09 20.10 0.691 96.4 15.70

5 1.10 20.90 0.700 96.3 16.71

6 1.11 20.67 0.710 95.3 17.09

7 1.12 21.30 0.710 97.9 17.30

8 1.13 21.51 0.719 100.1 17.46

9 1.07 21.26 0.687 96.5 16.19

10 1.10 21.06 0.712 95.8 17.22

Average 1.11±0.02 21.12±0.66 0.707±0.012 97.4±1.9 16.99±0.71

23

Table S6. Photovoltaic parameters recorded at a scanning rate of 50 mV s-1 in reverse direction

for a batch of ten perovskite devices of the composition FA0.8Cs0.2Pb1.03I2.90Br0.16 with an active

area of 0.6×0.6 cm2 fabricated by vacuum assisted solution process (VASP) measured with an

aperture area of 0.4×0.4 cm2 under standard AM 1.5G (air mass 1.5 global) illumination.

Cell No. VOC (V) JSC

(mA cm-2)

FF Light Intensity

(mW cm-2)

PCE (%)

1 1.13 21.28 0.707 97.4 17.24

2 1.12 19.19 0.755 96.6 16.63

3 1.11 20.51 0.688 97.1 15.96

4 1.12 20.58 0.711 96.9 16.92

5 1.14 21.22 0.724 96.6 18.08

6 1.12 20.84 0.714 96.6 17.33

7 1.12 20.77 0.712 97.7 17.01

8 1.13 20.96 0.733 97.1 17.66

9 1.13 21.07 0.707 96.8 17.07

10 1.12 20.40 0.673 97.0 15.79

Average 1.12±0.01 20.68±0.60 0.71±0.02 97.0±0.4 16.97±0.70