Sunflower Dehulling - OFI Events · Sunflower Preparation Process Yields Moisture content 8,00 %...

Transcript of Sunflower Dehulling - OFI Events · Sunflower Preparation Process Yields Moisture content 8,00 %...

Sunflower Dehulling

Bühler AG2014

2 | © Bühler | Schlayer| 2014

Oilseeds World Production 2013/2014.Focus: Sunflower and Rapeseed

EU-27 SF RSWorld No 3 1Prod. : 8.53 20.8Growth 2012: +21.8% +8.2%Growth 2011: +2.7% +8.9%

Argentina SB SFWorld No 3 4 Prod. mio.t : 54.5 2.7Growth 2012: +10.5% -13.0%Growth 2011: +35.9% -22%

Ukraine SFWorld No 1Prod. mio.t : 11.5Growth 2012: +27.7%Growth 2011: +9.5%

Russia SFWorld No 2 Prod. mio.t : 10Growth 2012: +25.6%Growth 2011: +4.1%

Canada RSWorld No 2Prod. mio.t : 18Growth 2012: +29%Growth 2011: +23%

India RS SBWorld No 4 5Prod. mio.t : 7.0 11.8Growth 2012: +2.9% +2.6%Growth 2011: +7.6% +7.2%

China SB RSWorld No 4 3Prod. mio.t : 12.2 14.2Growth 2012: -6.9% +1.3%Growth 2011: -15.8% +5.9%

USA SBWorld No 1 Prod. mio.t : 88.66Growth 2012: +7.3%Growth 2011: +5.2%

Brazil SBWorld No 2 Prod. mio.t : 88.0Growth 2012: +7.3%Growth 2011: +32.3%

World Wide Production

Soybeans:Rapeseed:Sunflower:Total oilseeds*:

*Includes: Soybeans, Rapeseed, Cottonseed, Sunflower, Peanut, Palm kernel, Copra

Source: USDA

mio t 284,94

69,9742,43

502,27

2012 + 6,2 %

+ 11,0 %+ 16,5 %+ 5,8 %

2011 + 19,3 %+ 13,6 %

+ 5,3 %+ 13,8 %

3 | © Bühler |

Sunflowerseed Production

Market Outlook

Growth of sunflowerseed production in Europe and Eastern Europe

Demand for high valuable products like animal feed and vegetable oil due to growth of world population and increase of living conditions

Especially important:o High yields of oil (low oil residues and low oil losses)

o High content of protein in meal

o Digestibility of meal due to less fiber content

4 | © Bühler |

Hull ControlSeparation

Dehulling

Dehullingo beating by impactors

ORo crushing by corrugated roller mills

Separationo separation of hulls & kernels

by oscillating sieveso aspiration of hulls by air

Hull Controlo sifting of hulls and kernels

Flakingo flaking of kernels to open oil cells

Sunflower Preparation Processes

Sunflower Seed

Kernels + Hulls

Hulls

Kernels (fine)

Flaking

Flaked Seed

Hulls + Kernels (fine)

5 | © Bühler |

Vertical Impact Dehuller Horizontal Impact Dehuller

CapacitiesSunflower up to 150 - 180 t/24h

* All capacities and performances values are depending on raw material specifications & conditions.

DehullingKey Preparation Technology

CapacitiesSunflower up to 150 - 180 t/24h

CapacitiesSunflower up to 260 - 320 t/24h

Corrugated Roller Mill

6 | © Bühler |

For high capacity multi-seed crushing

- Suitable for multi-seed processes- High capacity - Limited dehulling efficiency

The roller miller assures flexible processing of multiseeds.

DehullingCorrugated Roller Mill

7 | © Bühler |

DehullingWorking Principles of Corrugated Roller Mill

OLCB | Cracking Mill OLCB | 2012

level controlled feeding device

feeder allows consistent distribution over entire roll width

permanent magnet removes ferrous particles in feed

individual roll gap adjustment

scraper knives cleans rolls from seed residues

7

1

2

35

6

4

1. Inlet bin with product level sensor2. Pneumatic metering slide gate3. Roll feeder with variable speed4. Permanent Magnet5. Product guide plate and roll end sealing6. Cracking rolls with pneumatic driven roll gap7. Scraper knife

sharp to sharp

Differential Speed

8 | © Bühler |

For efficient multi-seed impact dehulling.

- Suitable for multi-seed dehulling- Smooth dehulling for low fines content- Quiet, clean and safe operation

The versatile dehuller adapts to your requirements.

DehullingVertical Impact Dehuller

9 | © Bühler |

DehullingWorking Principle of Horizontal Impact Dehuller.

1. Product feed2. Rotor3. Impact cone4. Outlet5. Dehulling tuner

5

Feeder screw for even feed

Level indicator (top/bottom) avoids choking

Permanent Magnet

Grooved rotor for controlled, fines avoiding product impact

Dehulling degree adjustment through adjustable impact cone (spacers)

10 | © Bühler |

DehullingEspecially Suited for Multi-Seed Oil Mills.

Main advantages:Applicable for dehulling of various oilseeds incl. sunflower, cotton seed, and soybeans

High process safety due to screw feeder, magnet and level probes

Continuously adjustable screw and rotor speed allow perfectly controlled process

Alternative impact cone surface characteristic (smooth, fluted) for optimized dehulling

Efficient especially with higher moisture content

1. Rotor2. Wear plates3. Impact paddles

Impact cone characteristicsSmooth: SunflowerFluted: Soy, cotton seed

11 | © Bühler |

For state-of-the-art sunflower dehulling.

- Smooth dehulling for low fines- Long machine lifetime- Easy maintenance of key parts

Applied in the sunflower seed processing industry exclusively.

DehullingHorizontal Impact Dehuller

12 | © Bühler |

DehullingWorking Principle of Horizontal Impact Dehuller.

1. Product feed2. Rotor3. Impact chest4. Outlet5. Dehulling tuner

1

4

32

5

5

Feeder roll with integrated frequency converter

Magnet

Wear resistant and adjustable impact chest

Only applicable for sunflower seeds

13 | © Bühler |

DehullingSimple Way of Dehulling.

Main advantages:Simple and fast adjustment of impact chest and thus excellent dehulling quality

No aspiration required

Simple and easy accessible and exchangeable wear parts

Efficient especially with lower moisture content

Permanent magnets Impact chest adjustment

Impact rotor Impact chest

14 | © Bühler |

DehullingSystem Comparison.

Corrugated Roller Mill

Vertical Dehuller

Horizontal Dehuller

Dehulling Efficiency + ++ ++

Sunflower Suitability + ++ ++

Other oilseeds ++ + N/A

End Product Quality + ++ ++

Integrated Safety Features + ++ +

Aspiration Yes Yes No

Throughput (t/h) ++ + +

Efficiency (kWh/t) ++ 0 +

Space requirement 0 ++ +

Serviceability ++ + ++

* ++ … very good; + … good; 0 … acceptable; N/A … not applicable

15 | © Bühler |

DehullingTechnical Datas - Overview.

Impact Dehuller Corrugated Roller Mill Vertical Dehuller Horizontal

Dehuller

Dimensions (mm)LengthWidthHeight

2.9201.9001.130

2.110550

1.820

2.9232.0031.925

Rotor / Roll diameter (mm)Rotor / Roll length (mm)

3001.600

600-

8002.150

Aspiration needed (m3/min) 20 15 0

Motor power (kW)Feeder driveMain drive

0,7518,5

0.37 (FC optional)15-22 (FC optional)

0.3318

Weight (kg, net) 3.690 825 2’640

Beaters / Throw paddles / Rolls 2 8 16

Throughput (t/24h)SunflowerSoybeanCotton seed (max. 4% lint)

260 – 320500 - 800230 – 260

150 - 180120 - 150120 - 150

150 - 180--

16 | © Bühler |

SeparationHull Separator

Efficient sifter for hull separation.

- Optimal separation of oilseed kernels from hulls- High throughput capacities- Easy operation and maintenance- Designed especially for oilseed separation

Applied in the oilseed processing industry for the dehulling of sunflower seeds and soya.

17 | © Bühler |

Separation Key Preparation Technology

Hull Separator SMA 203-3 OL

1. Proven main hull aspiration systemEasy adjustable, powerful suction nozzles

2. Proven post hull aspiration systemMulti-tunable aspiration channelLarge control window for optimal setting

2

1

18 | © Bühler |

fine hullsImpact Dehuller

Cleaning

hulls to sifter

fine seed to flaker

backflow of undehulled seed

dehulled seed to 2nd stage or to flaker

Separation Working Principle and Technical Data

coarse hulls

19 | © Bühler |

Impact Dehuller

fine seed to flaker back

flow

of u

ndeh

ulle

dse

ed

dehulled seed to 2nd stage or to flaker

hulls to hull control

Separation Working Principle and Technical Data

20 | © Bühler |

Sunflower Preparation Processes

Differentiation through the rest of hull content and amount of kernel loss by efficient hull controls

* additional 2,5-3 % botanical oil content in hulls

Objective • reduction of fiber content in meal by hull removal

• increase of final protein content

• highest oil yield

Different Dehulling Processes

2- stage Dehulling

1- stage Dehulling

Hull Removal from 26% to 10%

Hull Removal from 26% to 14 – 12 %

21 | © Bühler |

Sunflower Preparation Processes2- stage Dehulling with Total Hull Control

1. Dehuller2. Separator3. Filter/Cyclone4. Hull Sifter5. Hull Drum Sieve6. Hull Separator

1

2

3

4 6

5

2

* additional 2,5-3 % botanical oil content in hulls

10% rest hull

1,0-1,2% oil loss with hulls*

Separation Hull Control

22 | © Bühler |

Sunflower Preparation Process.1- stage Dehulling with Total Hull Control

12% rest hull

0,9-1,1% oil loss with hulls*

1. Dehuller2. Separator3. Filter/Cyclone4. Hull Sifter5. Hull Drum Sieve6. Hull Separator

* additional 2,5-3 % botanical oil content in hulls

1

2

3

46

5

Separation Hull Control

dehulling results

low kernel/ oil losses

high investment

23 | © Bühler |

Sunflower Preparation Process.1-stage Dehulling with Partial Hull Control

14% rest hull

1,0-1,2% oil loss with hulls*

1. Dehuller2. Separator3. Filter/Cyclone4. Hull Sifter

* additional 2,5-3 % botanical oil content in hulls

1

2

3

4

Separation Hull Control

24 | © Bühler |

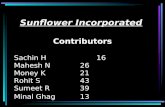

Sunflower Preparation ProcessYields

Moisture content 8,00 %Oil content 43,00 % NSCrude fiber content 17,50 % NS

Protein content 18,00 % NSHull content 26,00 % NSImpurities < 1,00 % NS

YIELDS AFTER DEHULLING

SUNFLOWER INPUT SPECIFICATION

* based on seed input; all figures determined with Bühler Oil Balance calculation

DEHULLING

Rest hull content in dehulled fraction

Capacity prior to dehullingCapacity prior to expeller pressing

YIELD

Total hulls removedAdditional oil loss*

Extraction mealProtein contentCrude fiber contentOil content

Expeller crude oilExtraction crude oil

2 stage

10 %

100 t/24h80 t/24h

18 t/24h0,21 %

37 t/24h44,5 %19 %

1,0 %34 t/24h

7 t/24h

1 stage

partial

14 %

100 t/24h84 t/24h

14 t/24h0,16 %

41 t/24h41 %23 %

1,0 %33 t/24h

8 t/24h

no dehulling

26 %

100 t/24h100 t/24h

0.0 t/24h0.0 %

56.2 t/24h31.4 %29.3 %

1,0 %30 t/24h11 t/24h

1 stage

total

12 %

100 t/24h82 t/24h

16 t/24h0,17 %39 t/24h42,5 %22 %1,0 %

33 t/24h8 t/24h

25 | © Bühler |

Sunflower Preparation Process.Performance Figures

Dehulling Stages

Rest Hull Content

Protein Content

Loss of Oilbased on Hulls

Loss of Oilbased on seed input

1-stage - partial

14 %

41%

1,2 – 1,0 %

0,15 – 0,2 %

2-stages

10 %

44,5 %

1,2 – 1,0 %

0,2 - 0,3 %

1-stage - total

12 %

42,5 %

0,9 – 1,1 %

0,17 – 0,2 %

Moisture content 8,00 %Oil content 43,00 % NSCrude fiber content 17,50 % NS

Protein content 18,00 % NSHull content 26,00 % NSImpurities < 1,00 % NS

SUNFLOWER INPUT SPECIFICATION

26 | © Bühler |

State of the art features

Flake thickness adjustment during operations

Easy access for regular maintenance

Correct roll type and surface

Optimal Sunflower throughput

(at 0.4mm flake thickness, cold, 8% H2O)

capacities of approx. 400 t/24h

Flaking is Key in Achieving Low Rest Oil in Meal.

27 | © Bühler |

www.buhlergroup.com

Bühler’s High Performance Flaking Mill OLFB.

Bühler’s state-of-the-art flaking mill.

- High performance flaking mill- Flake thickness adjustment during operations- Compact and efficient- Easy maintenance, safe operation