Summit Anchor Compan y, Inc.summitanchor.com/images/roofwall/sa_anchor_03.07.08.1.pdfSummit Anchor...

Transcript of Summit Anchor Compan y, Inc.summitanchor.com/images/roofwall/sa_anchor_03.07.08.1.pdfSummit Anchor...

Summit Anchor Company, Inc.®Safety From The Top Down

Suspended Access Systems andFall Protection

Roof and Wall Safety/Tie-Back Anchors

• 800.372.1098 • 301.620.8820 Safety and Tie-Back Anchors

Summit Anchor Company can provide anchorage that will facilitate whatever exterior maintenancemight be required on your building. Some common examples of this type of maintenance are:• Window cleaning

• Construction of the building

• Waterproofing and caulking

• Façade pressure washing

• Any interior or exterior maintenance where suspended work must be performed.

OverviewNational SafetyStandardsOSHA regulationsspecifically requireindependent anchorages(suspension anchor and fallarrest anchor) “capable ofsupporting 5,000 pounds”when suspendedmaintenance work isperformed.

ANSI/IWCA I-14.1 (3.9Anchorages) clearly states“Building owners andwindow cleaningcontractors shall not allowsuspended work to beperformed unless it hasbeen determined that thebuilding has providedidentified and certifiedanchorage”.

Although roofand wall anchors alonemay not satisfy all of thesafety requirements of yourstructure, when properlydesigned and installed theycan play a vital role inachieving compliance withboth OSHA requirementsand ANSI I-14 standards.

2

Anchors may be used to tie back boatswain chairs or portable outrigger beams for swing stageoperations.

Regardless of what mechanical suspension device may be used by your exterior maintenancecontractor, there must be two independent means of support for each suspended worker. This is inaccord with ANSI/IWCA I-14.1 (5.8.22 C) which states: “Anchorage of the lifeline should be independentof any portable support device”.

Summit Anchor Company can assist you to design a system to comply with OSHA and ANSI I-14requirements. By utilizing our expertly engineered anchors along with a well designed anchor locationroof plan, we provide the highest level of safety for suspended workers.

Why Specify Summit Anchor Company?

Our anchor eyes are drop forged, resulting in a stronger anchor than the common U-bar type anchors.According to the Forging Industry Association: “Forgings have grain oriented to shape for greaterstrength. Machined bar and plate may be susceptible to fatigue and stress corrosion becausemachining cuts material grain pattern. In most cases, forging yields a grain structure oriented to thepart, resulting in optimum strength, ductility, and resistance to impact and fatigue.”

Here are some other reasons...

• Corrosion resistance Our anchors are completely hot-dipped galvanized with stainless bolts. HollowStructural Sections (HSS) are filled with molded urethane insulation to prevent condensation. Suchcondensation protection is absolutely essential in order to prevent corrosion when exposed to theelements found on the roof. Other manufacturers seldom fill their HSS or pipes with moldedurethane insulation.

OSHA regulations and ANSI Safety Standards require two independent anchors for each suspended worker. One anchor suspends theworkers’ equipment (i.e. boatswain chair) the other anchor is used to tie off fall arrest equipment or safety line.

• 800.372.1098 • 301.620.8820 Safety and Tie-Back Anchors

3

• OSHA/ANSI compliance Our anchorshave been engineered and tested tocomply with current OSHA regulationsand ANSI I.14.1 safety standard for fallarrest and suspended maintenance.

• Custom design Our roof and wallanchors are designed for a variety ofpermanent attachments to reinforcedconcrete or structural steel. Summitroof and wall anchors can also bemodified to fit virtually any structure.

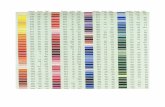

• Roof flashings Available in stainlesssteel, copper, or spun aluminum (Figure1) with Ethylene Propylene DieneMonomer (E.P.D.M.) top and bottomgrommets that do not require messycaulking around anchor (Figure 2).

• Free consultations for architects andengineers throughout the completedesign cycle on anchor layout andcompliance issues.

• Anchors fabricated in the U.S.A.

Summit Anchor Co. roof and wall anchor eyes are dropforged resulting in the strongest and most durableanchors on the market.

No apparent permanent deflection is observed whentesting our standard 10” tube anchors to 5,000 lb. CLICK HERE to view test report.

Figure 1

• 800.372.1098 • 301.620.8820 Safety and Tie-Back Anchors

4

Figure 2

• 800.372.1098 • 301.620.8820 Safety and Tie-Back Anchors

5

Anchor Forgings being manufactured in a2,500 lb Double Acting Erie Forge Hammer

Anchor Forgings being Trimmed &Pierced in 150 Ton Minster Trim Press

Trimmed & Pierced Anchor Forgingdropping into material handling container

Close-up View of Trimmed & PiercedAnchor Forging

Forging Process for Anchor Eyes

Weld to Beam Roof Anchor (SM-4) Cast in Place Balcony Anchor (SM-5-RB) Cast in Place Wall Anchor (SM-82) Cast in Place Roof Anchor (SM-5)

Bolt Through Roof AnchorSummit Model #SM-1-4B

Epoxy Mounted Roof AnchorSummit Model #SM-2-8-PL

Wrap Around Beam Roof AnchorSummit Model #SM-3-J

Wrap Around Beam and Slab Roof AnchorSummit Model #SM-3-S

• 800.372.1098 • 301.620.8820 Safety and Tie-Back Anchors

6

NOTE: Summit anchors are capable of supporting 5,000 lb. ultimate load and 1,250 lb. allowable load. Anchors may fail due to improper installation or inadequate supporting structure.Serious injury or death may result from anchor failure. Installation of anchors must be performed under the supervision of a professional engineer with experience in suspended accessequipment. Additionally, anchors shall be tested under the supervision of a P.E. and certified before being placed into service.

Wrap Around Beam Roof AnchorSummit Model #SM-3

Weld to Beam Roof Anchor at Beam IntersectionSummit Model #SM-4-I

Weld to Beam Roof AnchorSummit Model #SM-4

Cast-In-Place Roof AnchorSummit Model #SM-5

• 800.372.1098 • 301.620.8820 Safety and Tie-Back Anchors

7

• 800.372.1098 • 301.620.8820 Safety and Tie-Back Anchors

8

Bolt Through Wall AnchorSummit Model #SM-81-10-PL

Cast-In-Place Wall Anchor with SpacerSummit Model #SM-82-10-PL-HSS

Cast-In-Place Wall AnchorSummit Model #SM-82-10-PL

Epoxy Mounted Wall AnchorSummit Model #SM-83-8-PL

• 800.372.1098 • 301.620.8820 Safety and Tie-Back Anchors

Standard Epoxy Mounted Wall AnchorSummit Model #SM-83-10-PL

Bolt Through CMU Wall AnchorSummit Model #SM-85

Epoxy Mounted Recessed Balcony AnchorSummit Model #SM-RB-2

Cast-In-Place Recessed Balcony AnchorSummit Model #SM-RB-5

9

Design and LayoutCompliance with OSHA regulations and ANSI standards requires more than the best anchors on themarket. Careful planning is required before installation of any roof or wall anchors. Factors to beconsidered include structural building elements and layout requirements before proceeding with ananchor location plan.

Minimum RequirementsCurrent OSHA/ANSI standards require compliant fallprotection and suspended maintenance equipmenton all buildings.

1) OSHA/ANSI standards require 2 independentanchors for each worker (one for rigging ofsuspension equipment and one for personal fallarrest) whenever suspended work is performed.

2) OSHA/ANSI standards state anchors must becapable of supporting 5000 lbs. load.

3) OSHA/ANSI state that anchors should not beplaced within 6 ft. of the roof edge unless a 42in. parapet exists or fall protection is provided toaccess those anchors safely.

4) ANSI I14.1 Window Cleaning Safety Standard requires that anchor spacing should not exceed 12 ft.

Preliminary Anchor Layout ProceduresBefore placing the first anchor on your building,pertinent rigging and structural factors need to betaken into consideration. A careful examination of thearchitectural/structural plans is required to determinewhat type of anchorage should be used and where itmust be placed. This exam should include thefollowing:1) Identification of all areas needing access by suspended

workers. These areas are, but not limited to:a) Window locations that may require access by

suspended workers (any window above 20 ft.).b) Building façade requiring periodic maintenance

(i.e. re-caulking and waterproofing) will generallyrequire suspended work to be performed on thebuilding.

c) Any other part of the building requiring access byworkers above 6 ft. from grade.

Wall anchors may be mounted on structurally adequatecurbs and parapets

Buildings over 300 ft. are well suited fora permanently installed powered platform, because“Rope descents shall not exceed 300 feet”

(ANSI/IWCA I.14.1, Para 5.7.12).

• 800.372.1098 • 301.620.8820 Safety and Tie-Back Anchors

10

d) Additional building features that may requirespecial access equipment. Such features mayinclude buildings over 300 ft., overhangs, atria, andsloped roofs.

2) Identification of location where workers will accessanchors. Verify that safe access is provided to theseareas by doors, roof hatch etc. Examples of theselocations where anchors may be located are asfollows:a) Main roofsb) Lower roofsc) Balconies

3) Determine if rope descent systems or swing stageequipment or both will be used to access thebuildings’ façade.

4) Verify that the parapet wall is of sufficient strength tosupport the loads imposed (when rope decentsystems are used) although OSHA or ANSI guidelinesdo not specify 1,800 lbs. is considered acceptable.

Some buildings may require the addition of adavit or portable outrigger arm to eliminatethe load to a non load-bearing parapet wall.

Parapets must be capable of supporting theload imposed by workers. A non load-bearingparapet may incorporate davits or outriggerarms to avoid overloading to the parapet.

5) Examine structural drawings for areassuitable for attaching roof or wall anchors.Note that OSHA and ANSI requirementsstate anchors must be capable ofsupporting 5,000 lbs. without failure (see Specifications for more detail).

Examples as follows:a) Roof slabsb) Concrete beamsc) Concrete curbs

6) Lay out anchors in accordance with anchor layout guidelines. Anchors need to be situated in a wayso as to provide workers’ ropes or cables unobstructed access when rigging.

Parapet must be capable of supporting the loadimposed by workers.

Portable Outrigger

• 800.372.1098 • 301.620.8820 Safety and Tie-Back Anchors

11

d) Steel beamse) Mechanical roof supports

Anchor Layout Procedure1) Place anchors in line with work areas requiring service (see diagram below).

2) Provide two independent anchors for each descent.

3) Anchors may be offset no more than 15 degrees from perpendicular, provided displacement of therope under load may be eliminated (see anchor spacing chart). Note: ANSI I.14.1 bases anchorlayout on tie backs placed no more than 15 degrees from a perpendicular line with the suspensionpoint. It has been interpreted that a lanyard can increase the anchor spacing, but, this will increasethe fall arrest distance, so the presumed offset of a workers lanyard should be kept to a minimum.This is in harmony with OSHA regulations which state that fall arrest distances should be no morethan 6 ft.

4) Do not place anchors behind obstructions such as HVAC units. Anchor location and spacing mayneed to be adjusted to avoid such obstructions.

5) Do not place anchors within 6 ft. of parapet wall unless a 42 in. parapet or guardrail is provided.

Suggested Anchor SpacingDistance Between Anchors and Point of Suspension (Drop)

• 800.372.1098 • 301.620.8820 Safety and Tie-Back Anchors

12

Design AssistanceWe provide a single source contact, from meticulous planning of a roof anchor layout to expertinstallation of the system. Summit Anchor takes great care to ensure that the highest level of safety ismet every step of the way. Our roof anchors and wall anchors are OSHA compliant and cost effective.

Summit Anchor Company is happy to assist architects, engineers, building owners and managers withthe design of OSHA/ANSI compliant fall protection systems. We can provide a preliminary anchorlayout plan. This initial consultation and preliminary design service is offered free of charge.

Contact Summit Anchor Co., for assistance with your anchor layout.

To provide you with the best system for your project, werequest that you provide us with the following information:1) architectural and structural roof plans2) building elevation plans3) section drawings showing parapet and mechanical room

walls4) additional drawings showing details relevant to

suspended maintenance on building façade

Summit Anchor Company is dedicated to the highest quality product and expertinstallation of our equipment. To ensure maximum safety and optimal use of ourequipment call us to today for your free initial consultation.

1.800.372.1098

• 800.372.1098 • 301.620.8820 Safety and Tie-Back Anchors

13