Sud-Chemie – Catalysts & Applications...

Transcript of Sud-Chemie – Catalysts & Applications...

Sud-Chemie – Catalysts & Applications Overview

Page Page Page Page ---- 1111 ----Long Beach Seminar, April 11-13Catalysts

Note: All information contained herein is Strictly CONFIDENTIAL.

September 2009

A Portrait of the SÜD-CHEMIE Group

SÜD-CHEMIE GROUP PRODUCTS DIVISIONS

� ADSORBENTS

� CATALYSTS

SÜD-CHEMIE GROUPComprises SÜD-CHEMIE AG the parent company and over 60

subsidiaries and joint ventures, in 25 countries.

Page Page Page Page ---- 2222 ----Sept. 2009 CONFIDENTIAL

Creating Performance Technology

subsidiaries and joint ventures, in 25 countries.� Annual Sales: 1.2 Billion EURO in 2008� Employees: Approx. 5,000

SÜD-CHEMIE AG: Shareholder company, founded 1857

Headquarters Munich, Germany

Süd-Chemie Group – StructureGroup Structure 2008

ADSORBENTSSales: EUR 700 MM

CATALYSTSSales: EUR 500 MM

SÜD-CHEMIE GROUP

Page Page Page Page ---- 3333 ----Sept. 2009 CONFIDENTIAL

Adsorbents andAdditives

PerformancePackaging

Foundry Productsand Specialty Resins

Catalytic Technology Energy andEnvironment

Water Treatment

Sales: EUR 700 MM Sales: EUR 500 MM

Süd-Chemie Group Catalysts Division

Refinery Air Purification

Catalytic Technology Energy and Environment

Page Page Page Page ---- 4444 ----Sept. 2009 CONFIDENTIAL

Chemicals

Petrochemicals

Olefin Polymerization

Fuel-Cell Technology

Energy Storage

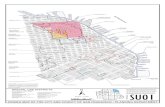

Sud-Chemie Global Presence

Region 2Americas

Region 1EMEA (+China)

Region 3Asia Pacific

Little Ferry Heufeld

Novara

Moosburg

Bitterfeld

PanjinToyama

Severodonesk

Novomoskovsk

Louisville (SP & WP) Nanjing (2009)

Page Page Page Page ---- 5555 ----Sept. 2009 CONFIDENTIAL

R&D Center (9)

Sales Office (22)

Sales & Tech. Center (5)

Production Site (17+3)

Region 4India

Novara

Al-Masseid

Sasolburg

Richardsbay

Baroda

Cochin

Jinshan

Kujang

Shimonoseki

Region 3-1SEA

Louisville/USA

Needham/USA

Heufeld/Germany

Novara/Italy

Moosburg/Germany

Toyama/Japan

Little Ferry/USA

Pohang/Korea

Panjin/China

Jinhai/China

Süd-Chemie GroupWorldwide Presence: Research and Development

Page Page Page Page ---- 6666 ----Sept. 2009 CONFIDENTIAL

Novara/Italy

Puebla/Mexico

Belen/USA

Nandesari/India

Cileungsi/Indonesia

• Catalysts • Adsorbents

Jinhai/ChinaChoisy-le-Roi/

France

Why Catalysts?What do they do?

� In general terms, a catalyst is described as a substance that INCREASES the rate of a reaction

Page Page Page Page ---- 8888 ----Sept. 2009 CONFIDENTIAL

substance that INCREASES the rate of a reaction without being CONSUMED by the reaction.

� Most commercially important reactions are just not FAST enough to be viable without the use of a CATALYST.

Süd-Chemie – BCT Catalysts Portfolio

SÜD-CHEMIE CATALYSTS

Chemicals• Ammonia• Methanol• EDC

PETROCHEMICALS• Houdry - CATOFIN• Olefins Purification• Ethylene Oxide• Aromatics• StyreneRefining

• Hydrogen• Oligimerization• S & Cl Traps• Isomerization

Page Page Page Page ---- 9999 ----Sept. 2009 CONFIDENTIAL

SÜD-CHEMIE CATALYSTS • EDC• Hydrogenation• Custom• Oxidation Ph.Anhy• Oxidation H2SO4

Energy & Environment• Hydrogen• VOC Removal• CO Removal• NOx Removal

• Isomerization• Dewaxing• GTL • Biodiesel

Olefin Polymerization• Ziegler-Natta for PP• Ziegler-Natta for HDPE

Catalysts for Petrochemical Applications

Olefins Conversion/Purification: • Selective Hydrogenation

– OleMax ® G83/G58 Series

• Poison Guards– Actisorb ®

– Monomer Purification

– PolyMax ®

• Iso-octene Hydrogenation– (KBR/Neste/FORTUM) – SF-800

Aromatics Processing

Page Page Page Page ---- 11111111 ----Sept. 2009 CONFIDENTIAL

Aromatics Processing• Alkylation to EB

– EBUF/EBEMAX

• EB to Stryene– Styromax ®

• Toluene Disproportionation– TDP1

• Xylene Isomerization– Isoxyl

Olefin Production:• Alkane Dehydrogenation Houdry® Process

– Catofin® & Catadiene® catalyst

• Other custom catalysts

C2 Front end HydrogenationC2 Front end Hydrogenation

C2-Tail end HydrogenationC2-Tail end Hydrogenation

C3-MAPD HydrogenationC3-MAPD Hydrogenation

Olefins Purification – OleMax ®

Page Page Page Page ---- 12121212 ----Sept. 2009 CONFIDENTIAL

PYGAS HydrogenationPYGAS Hydrogenation

C3-MAPD HydrogenationC3-MAPD Hydrogenation

C4-Stream HydrogenationC4-Stream Hydrogenation

(various process options)

Styrene Production – StyroMax ®

Styrene is produced by the dehydrogenation of ethylbenzene

C6H5-CH2CH3 ←→ C6H5-CHCH2 + H2 ∆H = ~29 kcal/mol

Page Page Page Page ---- 13131313 ----Sept. 2009 CONFIDENTIAL

Houdry – Olefins Production

C3H8 C3H6 + H2

Propane Dehydrogenation

Page Page Page Page ---- 14141414 ----Sept. 2009 CONFIDENTIAL

i-C4H10 i-C4H8 + H2

Isobutane Dehydrogenation

Manufacture Proprietary Cr2O3/Al2O3 Catalysts

Own Commercial Processes– Dehydrogenation for production of olefins

• CATADIENE® for 1,3-Butadiene

Houdry Overview

Page Page Page Page ---- 15151515 ----Sept. 2009 CONFIDENTIAL

• CATADIENE for 1,3-Butadiene

• CATOFIN® for i-Butylene and Propylene

– Hydrodealkylation to produce high purity benzene

• PYROTOL® - pyrolysis gasoline

• LITOL® - coke oven light oil

• DETOL® - alkylaromatics

Engineering and Licensing partner – CBI/Lummus

Typical Flowsheet for NH3 Plant

HC Feed

Steam Air

Process Objective:High purity H2 and N2

stream at ~3:1 ratio

Chemicals - Ammonia

Page Page Page Page ---- 17171717 ----Sept. 2009 CONFIDENTIAL

Purification Pre Reformer Secondary ReformerPrimary Reformer

HT CO Shift

HTS

LT CO Shift CO2 Removal

Ammonia

CO2

Methanation NH3 Synthesis Loop

Reforming

stream at ~3:1 ratio

Secondary Reformer toallow addition of N2

required for the reaction

Synthesis Loop:3H2 + N2 ↔↔↔↔ 2NH3

Evolution of Reforming

Catalysts

less pressu

re dro

p

Tubular Steam Reforming Applications

Page Page Page Page ---- 18181818 ----Sept. 2009 CONFIDENTIAL

less pressu

re dro

p

more activity

COALPurge gasRecycle

MegaMethanol Process / Coal based - MegaMax

Chemicals - Methanol

Page Page Page Page ---- 19191919 ----Sept. 2009 CONFIDENTIAL

CoalGasification

MethanolSynthesis

MethanolDistillation

PureMethanol

AirSeparation Air

Oxygen

SourGas Shift

Syngas Purification

Formaldehyde (FA) from Methanol FAMAX®

Ethylene Dichloride (EDC) by oxychlorination OXYMAX®

®

Chemicals - Oxidation Catalysts

Page Page Page Page ---- 20202020 ----Sept. 2009 CONFIDENTIAL

Maleic Anhydride (MA) from Butane (Scientific Design) SYNDANE®

Ethylene Oxide (EO) (Scientific Design) SYNDOX®

Phthalic Anhydride (PA) from o-Xylene PHTHALIMAX®

Sulfuric Acid SULFOMAX®

Products & Applications

SC maintains a position of leadership or co-leadership in the supply of catalysts for

oxychlorination, formaldehyde and terephthalic acid.

� OXYMAX : for synthesis of 1,2-dichloroethane by oxychlorination.

7 catalyst types available for standard processes

Chemicals

Page Page Page Page ---- 21212121 ----Sept. 2009 CONFIDENTIAL

� FAMAX : for oxidative dehydrogenation of

methanol to yield formaldehyde.

6 catalyst types are currently available

� H2MAX5/HAR : for selective hydrogenation of ethylanthraquinone

to ethylanthrahydroquinone to produce hydrogen peroxide.

4 catalyst types available

� H2MAX50/HD : for the purification of terephthalic acid by hydrogenation.

2 types of catalysts have been developed

Catalysts & Adsorbents for Refineries

Page Page Page Page ---- 22222222 ----Sept. 2009 CONFIDENTIAL

for Refineries

HT CO ShiftShiftMax 120 (C12-4)ShiftMax 100

DMW

CH3OH = VOC

Refinery – H2 Production

Page Page Page Page ---- 23232323 ----Sept. 2009 CONFIDENTIAL

Primary ReformerReforMax 250 (C11-NK)ReforMax 210 (G91)ReforMax 330 (G90)

LT CO ShiftShiftMax 240 ShiftMax 210 (C18-7)ShiftMax 200

MethanationMETH 134 (C13-4)

PurificationHDMax 200 (C49)HDMax 310 (20-7)

Actisorb S2 (G-72D)Actisorb S3 (G-72E)

Refinery – Naphtha Upgrading

n-pentane

HYSOPAR® - Zeolite CatalystHYSOPAR® - Zeolite Catalyst

iso-pentane

Page Page Page Page ---- 24242424 ----Sept. 2009 CONFIDENTIAL

Operating Conditions:

- Temperature: 250 °°°°C- Pressure: 25 barg- LHSV 1.5 h-1

- H2/HC-Ratio 1.0

Operating Conditions:

- Temperature: 250 °°°°C- Pressure: 25 barg- LHSV 1.5 h-1

- H2/HC-Ratio 1.0

HYSOPAR® - Zeolite CatalystHYSOPAR® - Zeolite Catalyst

Medium Operating TemperatureHigh Catalyst ActivityLow Investment & Operating CostNo Corrosion RisksTolerates Water & SulphurFeed Pretreatment optionalCatalyst is regenerable

LPG Recycle

Quench

Feed Pretreatment

SpentPropane

Refinery - Polygasoline

Page Page Page Page ---- 25252525 ----Sept. 2009 CONFIDENTIAL

Feed Surge Drum

C3=/C4= Fresh Feed

Reactor

Polygasoline

Stabilizer DepropanizerLPG

Quench

H2ODrain

SpentButane

What is Solid Phosphoric Acid Catalyst?

� 25% free acid supported on a solid phase of primarily silicon phosphate(s)

� At least two forms of crystalline silicon phosphates can exist in the catalyst

Refinery - Polygasoline

Page Page Page Page ---- 26262626 ----Sept. 2009 CONFIDENTIAL

can exist in the catalyst

• silicon orthophosphate - “Si4(PO4)6”

• silicon pyrophosphate - SiP2O7

� the free acid is the active catalyst

Refinery - Gas To Liquids

SÜD-CHEMIE Perfectly Covers the Whole Portfolio of Catalysts Involved

in GTL (= Gas To Liquids) Synfuels Technology

Market Leader in Syngas Catalysts

Long-term Experience with Fischer-Tropsch Catalysts

Page Page Page Page ---- 27272727 ----Sept. 2009 CONFIDENTIAL

Long-term Experience with Fischer-Tropsch Catalysts

Leading Supplier of advanced Zeolite Catalysts for

Upgrading of light Hydrocarbons

Downstream Processing to High Value Special Products

SÜD-CHEMIE is the Partner for GTL Catalyst Technology

Refinery – Contaminant Removal

ActiSorb ® Series of Adsorbents for various applications– Sulfur Guards based on Ni, Cu-Zn, ZnO, Zn-Mn

– Desulfurization upstream of semi-regenerative reformer to remove organic Sulfur and H2S

– Arsine and Sulfur Removal from Refinery Propylene (related to FCC

units)

Page Page Page Page ---- 28282828 ----Sept. 2009 CONFIDENTIAL

units)

– Gas and Liquid phase Chloride Treaters in CCR Units as alternate to

Aluminas

– Sulfur Impregnated carbon for Natural Gas purification – Hg Removal

– Silver on Alumina adsorbent for gas phase Hg removal

Refinery – Aromatics Clay Treatment

Raffinate

NAPHTHA

Reformer

Naphtha Hydrotreater

H2

C6, C7

BT Extraction

Benzene

PX - Extraction C8 Isomeris.

Tonsil CO 616 Gp-Xylene

Toluene Hydro- dealkylation

Trans- alkylation

Light Ends

S

BC

TC

D

Page Page Page Page ---- 29292929 ----Sept. 2009 CONFIDENTIAL

C8+Extraction

C8

C9+C9 / C10

Heavy Aromatics

C10+

o-XyleneS SplitterBC Benzene ColumnTC Toluene ColumnXS Xylene SplitteroX o-Xylene RerunA9C A9 ColumnD Deheptanizer

XS

oXA9C

D

Tonsil CO 610 G

Tonsil CO 630 GTonsil CO 616 GS

Catalyst Type:

� Highly-optimized 4th Generation-MgCl2-based Ziegler-Natta catalyst system

Product Range:

� Homopolymers

C-MAX® PP Catalyst PortfolioOverview

Page Page Page Page ---- 31313131 ----Sept. 2009 CONFIDENTIAL

� Homopolymers� Impact Copolymers� Random Copolymers

Process Platforms served by C-MAX

catalysts:

� Bulk loop process platform� Stirred bulk processes� Stirred-bed gas phase processes� Fluidized-bed gas phase processes

Energy and EnvironmentAir Purification

Page Page Page Page ---- 32323232 ----Sept. 2009 CONFIDENTIAL

Air Purification

1. Semiconductor Industry

2. System Integrator (VOC, DeNOx, DeN2O, etc.)� Chemical Industry

� Coating and Printing Industry� Appliances, Airplanes

3. Power generation� Stationary Gas-/Diesel Engines, Turbines

BEE Air Purification: Market Segments

Page Page Page Page ---- 33333333 ----Sept. 2009 CONFIDENTIAL

� Stationary Gas-/Diesel Engines, Turbines� Nuclear Industry

4. Mobile Engines� Motorcycles� Off-road

� Retrofit

5. Zeolites� Cold start (DOC, TWC)� SCR, DeNOx

�� Commercial Printing Commercial Printing

�� Flexible Packaging Flexible Packaging

�� Wood ProductsWood Products

�� Pulp & PaperPulp & Paper

�� Pharmaceuticals Pharmaceuticals

Markets & Applications Markets & Applications

Page Page Page Page ---- 34343434 ----Sept. 2009 CONFIDENTIAL

�� Pharmaceuticals Pharmaceuticals

�� Metal DecoratingMetal Decorating

�� Converting Converting

�� CoatingCoating

�� Painting/FinishingPainting/Finishing

�� Baking/Food ProcessesBaking/Food Processes

�� Chemical ProcessingChemical Processing

Acrylic Acid (AA)Polyethylene Terephthalate (PET)Phthalic Anhydride (PA)Purified Terephthalic Acid (PTA)Acrylonitrile (AN)

Chemical off-gas Treatment

Page Page Page Page ---- 35353535 ----Sept. 2009 CONFIDENTIAL

Acrylonitrile (AN)PhenolMaleic Anhrdride (MA)Nitric Acid (DeN2O)Methyl Methacrylate (MMA)Formaldehyde (FA)Urea Production (H2 removal in CO2)

RECUPERATIVE CATALYTIC OXIDIZERS

� Skid-Mounted Designs� Handle air flows up to 85,000

Nm3/hr� Cost-efficient way to Control

� VOC’s� Air Toxics� Odor Emissions

� Low CO & NOx compared to

Page Page Page Page ---- 36363636 ----Sept. 2009 CONFIDENTIAL

� Low CO & NOx compared to Thermal Systems

� Meets destruction removal

efficiency (DRE) of up to 99+%� Heat “Recuperated” up to 70% via

Heat Exchanger

Catalyst Modules: Ceramic and Metallic Supports

Page Page Page Page ---- 39393939 ----Sept. 2009 CONFIDENTIAL